Inhaul cable sheath and preparation method thereof

A sheath and element technology, applied in the field of cable sheath and its preparation, can solve the problems of abnormal noise, contact friction between steel wire ropes and metal parts, wear and tear, etc., achieve good heat resistance and water resistance, and improve anti-oxidation. Reasonable effect of performance and raw material ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

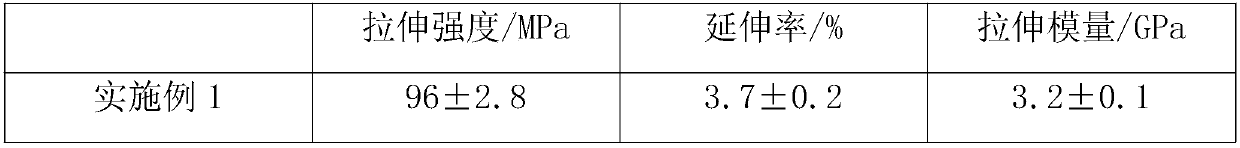

Embodiment 1

[0023] A cable sheath, which is composed of several sheath elements. The sheath element is a half-pipe body with a tenon pin and a tenon groove respectively at two joints. The sheath element is made of the following raw materials in parts by mass: 10 parts of modified rubber, 6 parts of cyclodextrin, 5 parts of antioxidant, 3.6 parts of anti-ultraviolet agent, 1.2 parts of magnesium borate whiskers, 1.2 parts of nano-carbon fiber, 6 parts of Vaseline, 2.4 parts of tourmaline particles, 1.6 parts of silicon carbide, 0.8 parts of diethylene glycol dibenzoate, 1.2 parts of nano-titanium dioxide, 0.8 parts of calcium-zinc composite stabilizer, 1.2 parts of rare earth, 2.4 parts of scale-like additives; the rare earth in the present embodiment is preferably the silicate of yttrium group heavy rare earth .

[0024] Among them, the modified rubber is EPDM rubber modified with maleic anhydride.

[0025] Wherein, the flake additive is selected from flake graphite powder.

[0026] Amo...

Embodiment 2

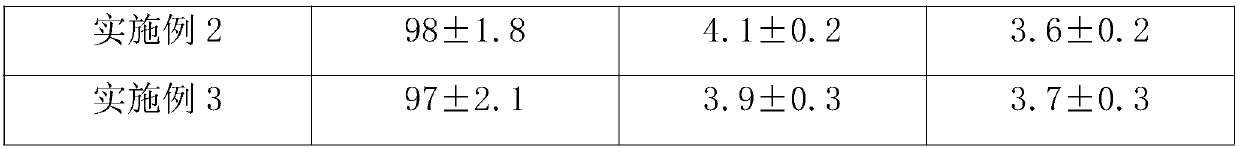

[0032] A cable sheath, which is composed of several sheath elements. The sheath element is a half-pipe body with a tenon pin and a tenon groove respectively at two joints. The sheath element is made of the following raw materials in parts by mass: 15 parts of modified rubber, 9 parts of cyclodextrin, 6 parts of antioxidant, 5 parts of anti-ultraviolet agent, 2.4 parts of magnesium borate whiskers, 2.4 parts of nano-carbon fiber, 10 parts of Vaseline, 3.6 parts of tourmaline particles, 2.4 parts of silicon carbide, 1.6 parts of diethylene glycol dibenzoate, 2 parts of nano-titanium dioxide, 1.2 parts of calcium-zinc composite stabilizer, 3 parts of rare earth, 4 parts of scale-like additives; the rare earth in the present embodiment is preferably the silicate of yttrium group heavy rare earth

[0033] Among them, the modified rubber is EPDM rubber modified with maleic anhydride.

[0034] Wherein, the scaly additive is a mixture of flake graphite powder and flake aluminum powder...

Embodiment 3

[0041] A cable sheath, which is composed of several sheath elements. The sheath element is a half-pipe body with a tenon pin and a tenon groove respectively at two joints. The sheath element is made of the following raw materials in parts by mass: 20 parts of modified rubber, 12 parts of cyclodextrin, 8 parts of antioxidant, 6.4 parts of anti-ultraviolet agent, 3.6 parts of magnesium borate whiskers, 3.6 parts of nano-carbon fiber, 12 parts of petrolatum, 4.8 parts of tourmaline particles, 3.2 parts of silicon carbide, 2.4 parts of diethylene glycol dibenzoate, 3 parts of nano-titanium dioxide, 1.6 parts of calcium-zinc composite stabilizer, 5 parts of rare earth, and 6 parts of scale-like additives.

[0042] Among them, the modified rubber is EPDM rubber modified with maleic anhydride.

[0043] Wherein, the scaly additive is a mixture of flake graphite powder and flake aluminum powder, the mass ratio of which is 1:1.8.

[0044]Among them, the antioxidant is selected from thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com