Synthesis method and application of biodegradable high-molecular-weight polyester

A high molecular weight, biodegradable technology, applied in the field of biodegradable high molecular weight polyester preparation, can solve the problems of large capillary phenomenon, inability to process films, dark polyester color, etc., achieve excellent mechanical and thermal properties, improve biodegradation The effect of improving performance and thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

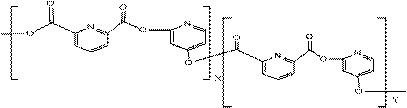

Image

Examples

Embodiment 1

[0024] Example 1: 1.000 g (6.0 mmol) of 2,6-dipicolinic acid, 0.667 g (6.0 mmol) of 2,4-dihydroxypyridine and 0.002 g of ethyl titanate were sequentially added to a 50 mL single-necked flask, and the reaction The used mixture was reacted for 4.0 h at 165° C. under the protection of nitrogen. Then raise the temperature to 210° C., and react for 3.0 h under a pressure environment of 15 KPa to obtain a crude polymer product. After cooling the crude polymer product, add a certain amount of chloroform, shake to promote dissolution, and add isopropanol to the filtrate after filtration until the precipitate produced no longer increases. The filter residue obtained after filtration was washed with ethanol, and then vacuum-dried at 60°C for 3.0h to obtain polyester P 1 , its weight-average molecular weight is 279,330Da, the molecular weight distribution is 4.9, and the yield is 90.05%.

[0025] Polyester P 1 High molecular weight, transparent, used as the main component of surgical ...

Embodiment 2

[0030] Example 2: Add 1.000g (6.0 mmol) of 2,6-dipicolinic acid, 0.678g (6.1mmol) of 2,5-dihydroxypyridine and 0.002g of ethyl titanate to a 50mL single-necked flask in sequence. The mixture was reacted at 165°C for 4.0 h under nitrogen protection. Then raise the temperature to 210° C., and react for 3.0 h under a pressure environment of 15 KPa to obtain a crude polymer product. After cooling the crude polymer product, add a certain amount of chloroform, shake to promote dissolution, and add isopropanol to the filtrate after filtration until the precipitate produced no longer increases. The filter residue obtained after filtration was washed with ethanol, and then vacuum-dried at 60°C for 3.0h to obtain polyester P 2 , its weight average molecular weight is 263,3227Da, the molecular weight distribution is 3.6, and the yield is 90.09%.

[0031] Polyester P 2 High molecular weight, transparent, used as the main component of surgical suture processing, the method is as follows...

Embodiment 3

[0033] Example 3: 1.000 g (6.0 mmol) of 2,6-dipicolinic acid, 0.678 g (6.1 mmol) of 2,3-dihydroxypyridine and 0.002 g of bis(triethanolamine) titanic acid were sequentially added to a 50 mL single-necked flask Diisopropyl ester, the reaction mixture was reacted at 165°C for 4.0h under the protection of nitrogen. Then raise the temperature to 210° C., and react for 3.0 h under a pressure environment of 15 KPa to obtain a crude polymer product. After cooling the crude polymer product, add a certain amount of chloroform, shake to promote dissolution, and add isopropanol to the filtrate after filtration until the precipitate produced no longer increases. The filter residue obtained after filtration was washed with ethanol, and then vacuum-dried at 60°C for 3.0h to obtain polyester P 3 , its weight average molecular weight is 230,338Da, the molecular weight distribution is 3.0, and the yield is 91.05%.

[0034] Polyester P 3 High molecular weight, transparent, used as the main c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com