Carbon fiber and method for producing same

A manufacturing method and carbon fiber technology, applied in the direction of chemical characteristics of fibers, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve the problems of short fiber length, low molding processability, low productivity, etc., and improve productivity. and mechanical properties, excellent tensile elastic modulus, the effect of reducing the required amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

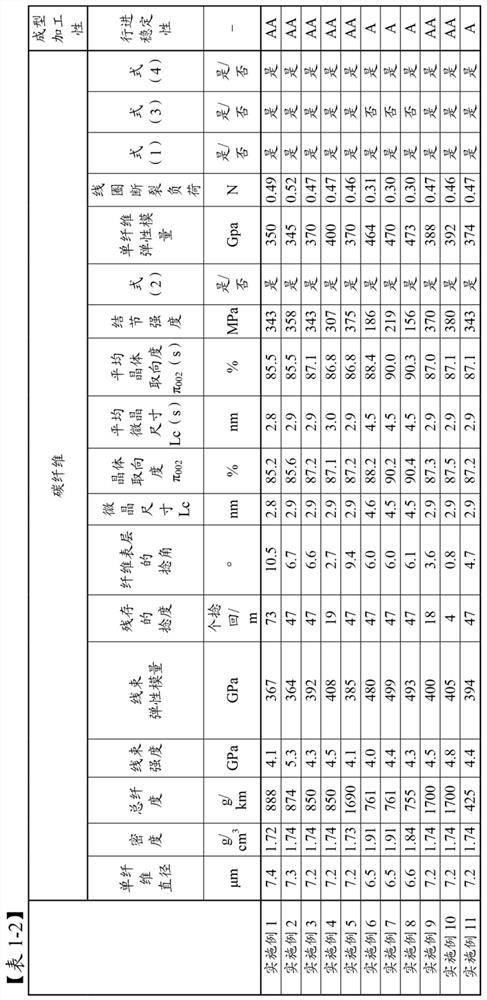

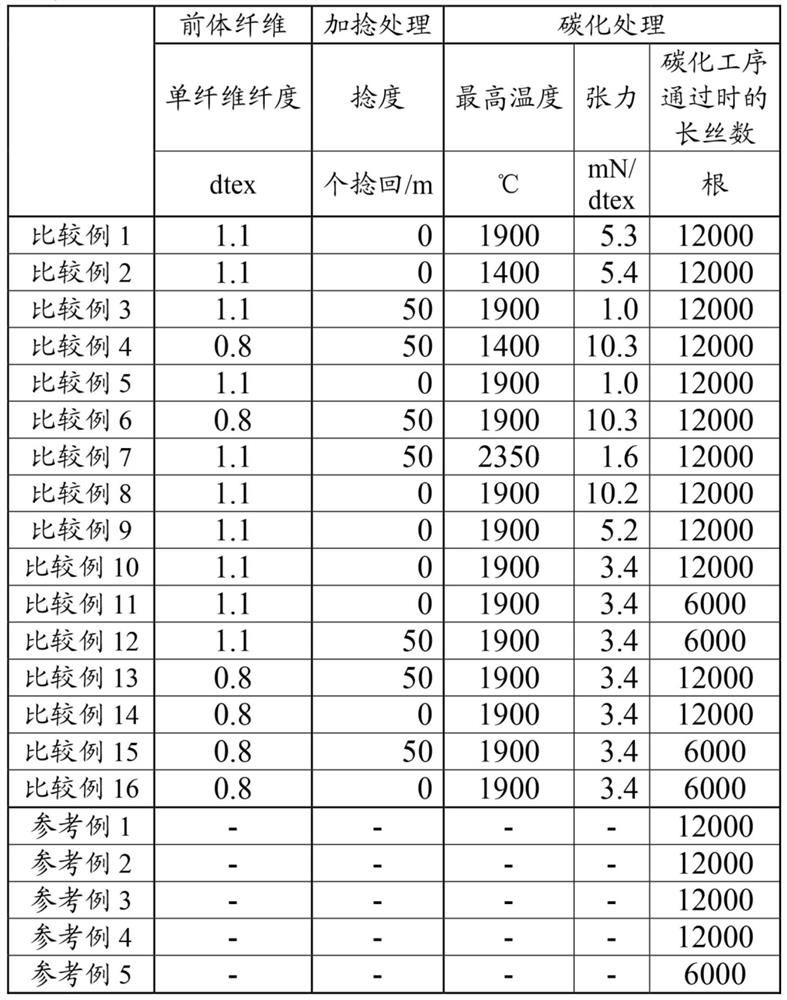

Embodiment 1

[0180] After the flame-resistant fiber bundle is obtained by the method described in the general examples, the obtained flame-resistant fiber bundle is twisted to give 75 twists / m twist, and in a nitrogen atmosphere at a temperature of 300 to 800°C, Pre-carbonization treatment was performed at a draw ratio of 0.97 to obtain a pre-carbonized fiber bundle. Then, under the conditions shown in Table 1, the pre-carbonized fiber bundles are subjected to carbonization treatment, and then, using sulfuric acid aqueous solution as electrolyte, carry out electrolytic surface treatment with an electric quantity of 30 coulombs per 1 g of carbon fiber, to obtain surface oxygen concentration ( O / C) is a carbon fiber bundle of 0.09. The passability of the carbonization step was good, and the quality of the obtained carbon fiber bundle was also good. The moldability was rated AA, which was at a very high level. Table 1 shows the evaluation results of the obtained carbon fibers.

Embodiment 2

[0182] A carbon fiber bundle was obtained in the same manner as in Example except that the twist was 50 twists / m and the tension during the carbonization treatment was 5.2 mN / dtex. The passability of the carbonization step was good, and the quality of the obtained carbon fiber bundle was also good. The moldability was rated AA, which was at a very high level. Table 1 shows the evaluation results of the obtained carbon fibers.

Embodiment 3

[0184] A carbon fiber bundle was obtained in the same manner as in Example 2, except that the tension during the carbonization treatment was 10.2 mN / dtex. The passability of the carbonization step was good, and the quality of the obtained carbon fiber bundle was also good. The moldability was rated AA, which was at a very high level. Table 1 shows the evaluation results of the obtained carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com