Patents

Literature

48results about How to "Reduce the amount needed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing sewage from industrial cycle water

InactiveCN101172724AIncrease the concentration factorImprove running qualityScale removal and water softeningMultistage water/sewage treatmentFilter systemEnvironmental engineering

The invention relates to a method for treating industrial circulating water and sewage through the technology of a nano filter film. The invention is characterized in that one part of the sewage is used as the supplementing water of a circulating water system, while the other part is reused after being processed through a nano filter system after the sewage of the industrial circulating cooling water system is flocculated and precipitated and filtered; one part and the other part are added into the circulating water system after being mixed with a certain proportion so as to achieve the reuse of the industrial circulating water, thereby increasing the condensation times of the whole system, decreasing the water implementing quantity and the sewage discharge quantity of the system, and increasing the economic effect of the whole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

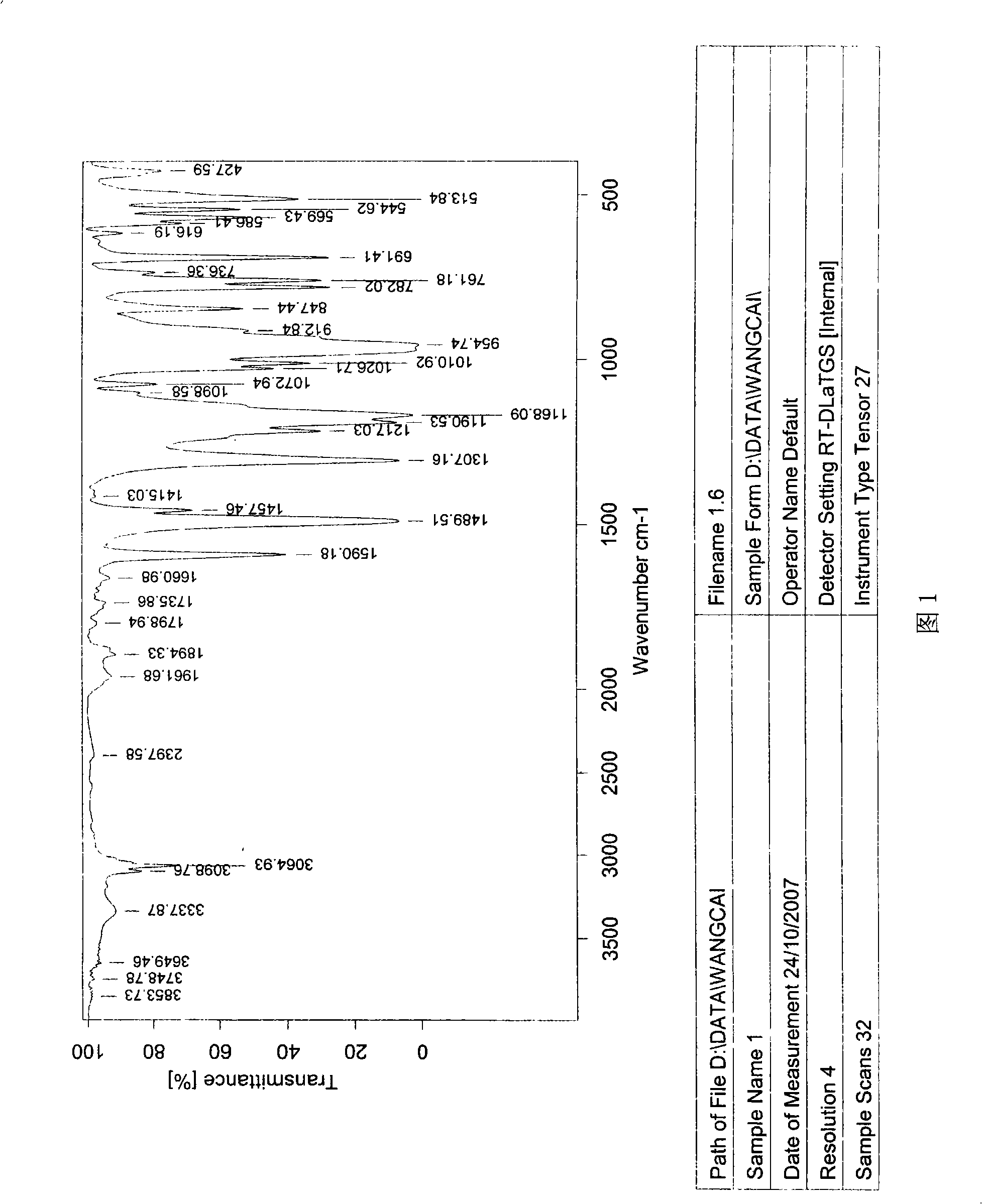

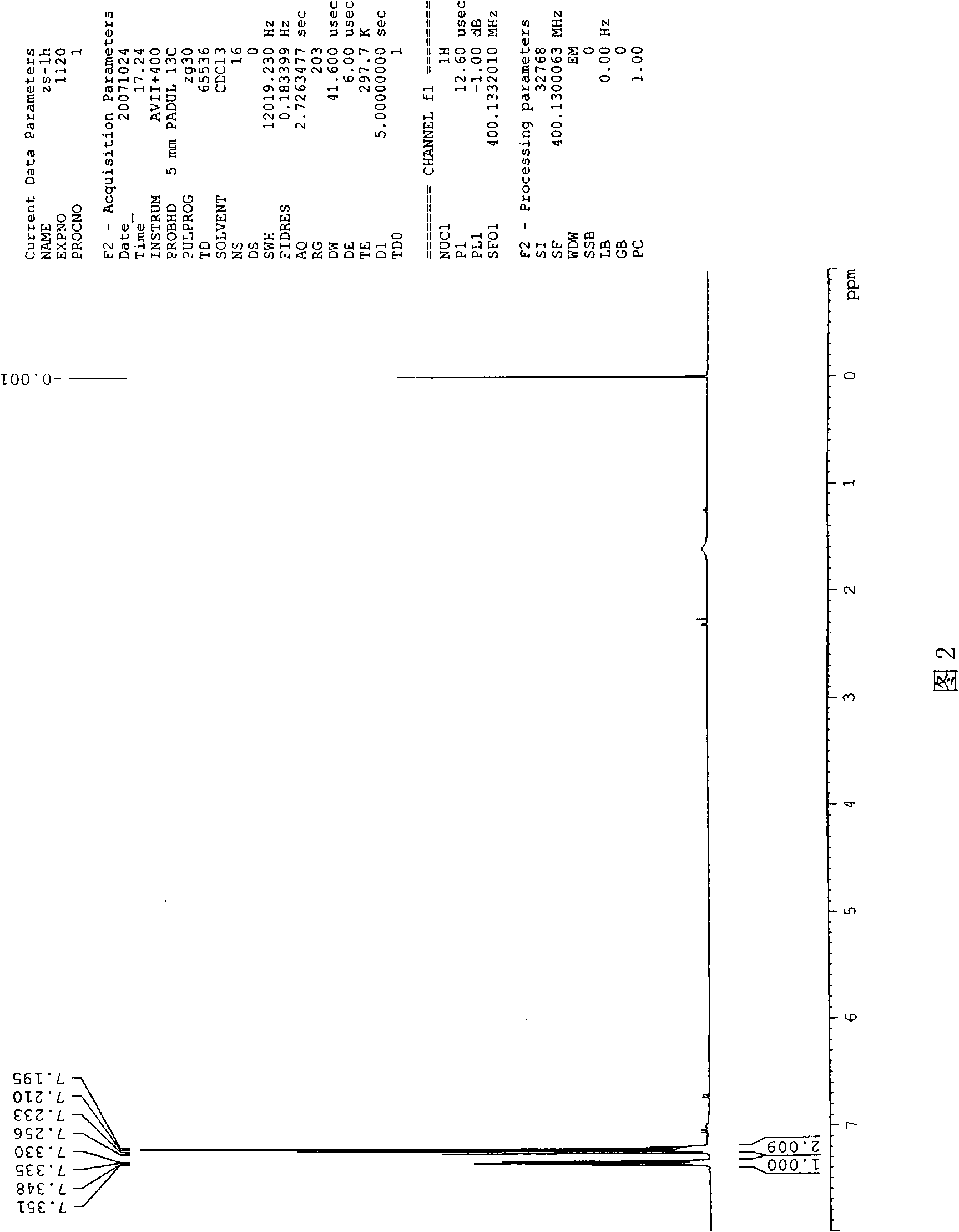

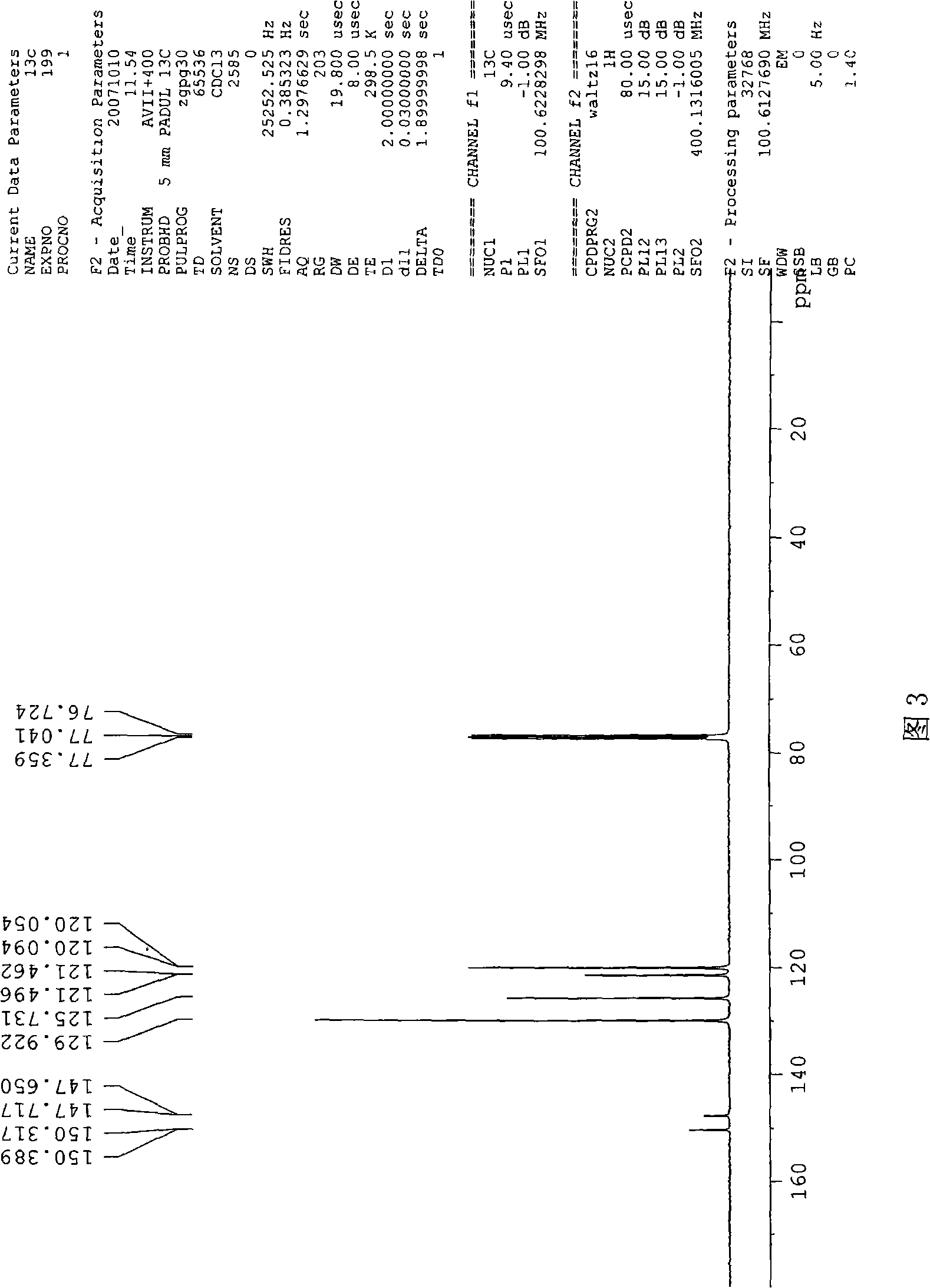

Non-halogen phosphoric acid ester combustion inhibitor for engineering plastic and method of preparing the same

ActiveCN101319057ASufficient supplyReduce investmentFireproof paintsPhosphoric Acid EstersManufacturing cost reduction

The invention relates to a halogen-free phosphate fire retardant used for engineering plastics and a method for producing the same, belonging to the engineering plastic fire retardant and the method for synthesizing the engineering plastic fire retardant technical field. The chemical name of the fire retardant is hydroquinone double phenyl bisphosphate oligomer, and the chemical structural formula is shown on the bottom right. The method comprises the following processing steps: firstly, the method adopts hydroquinone and phosphorus oxychloride as raw materials and a lewis acid as a catalyst for heating reaction; and secondly, the reaction mixture is heated up and dripped with phenol for reaction by taking the lewis acid as the catalyst. The production method has sufficient supply of the raw materials and simple reaction conditions, can reduce the manufacturing cost, and makes products have obvious price advantage; and simultaneously the material has the characteristics of zero halogen, low smoke, low toxity, low corrosiveness, high heat distortion temperature, good fire resistance, good processability, capability of being recycled, etc., and can be widely used as the fire retardant of various engineering plastics.

Owner:ZHEJIANG WANSHENG

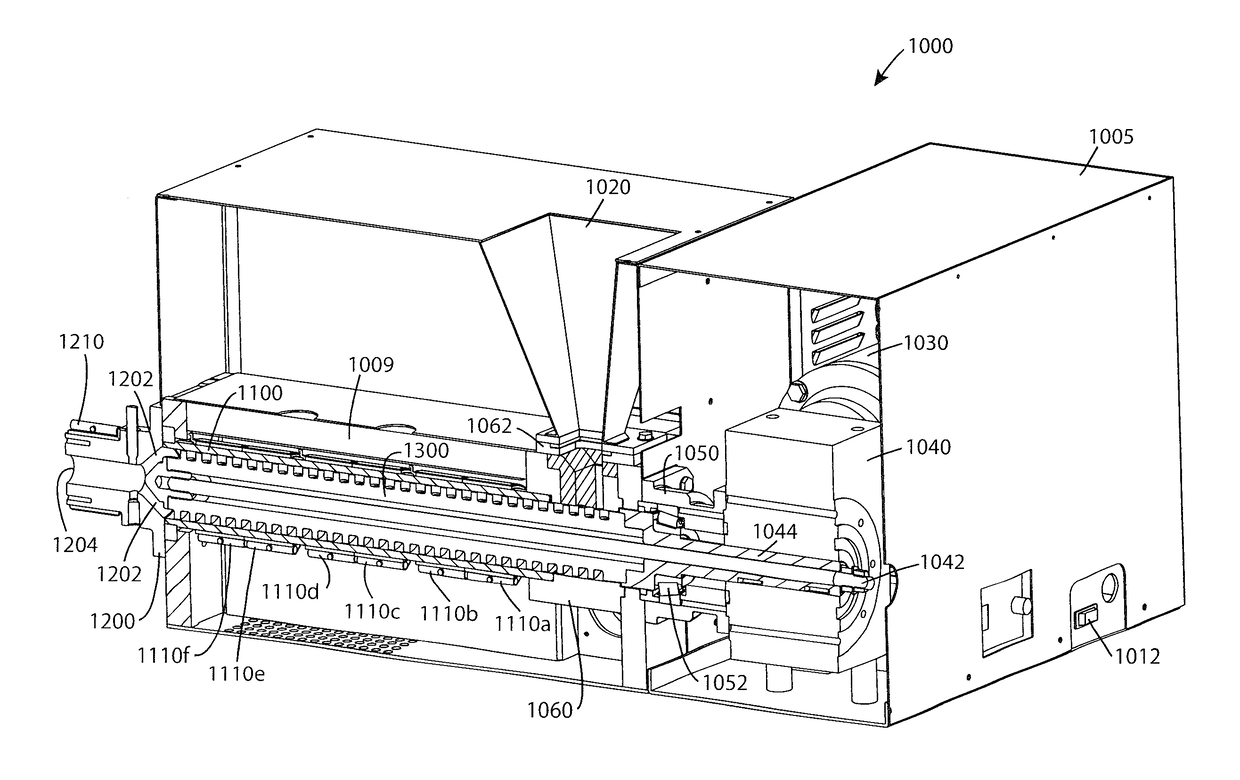

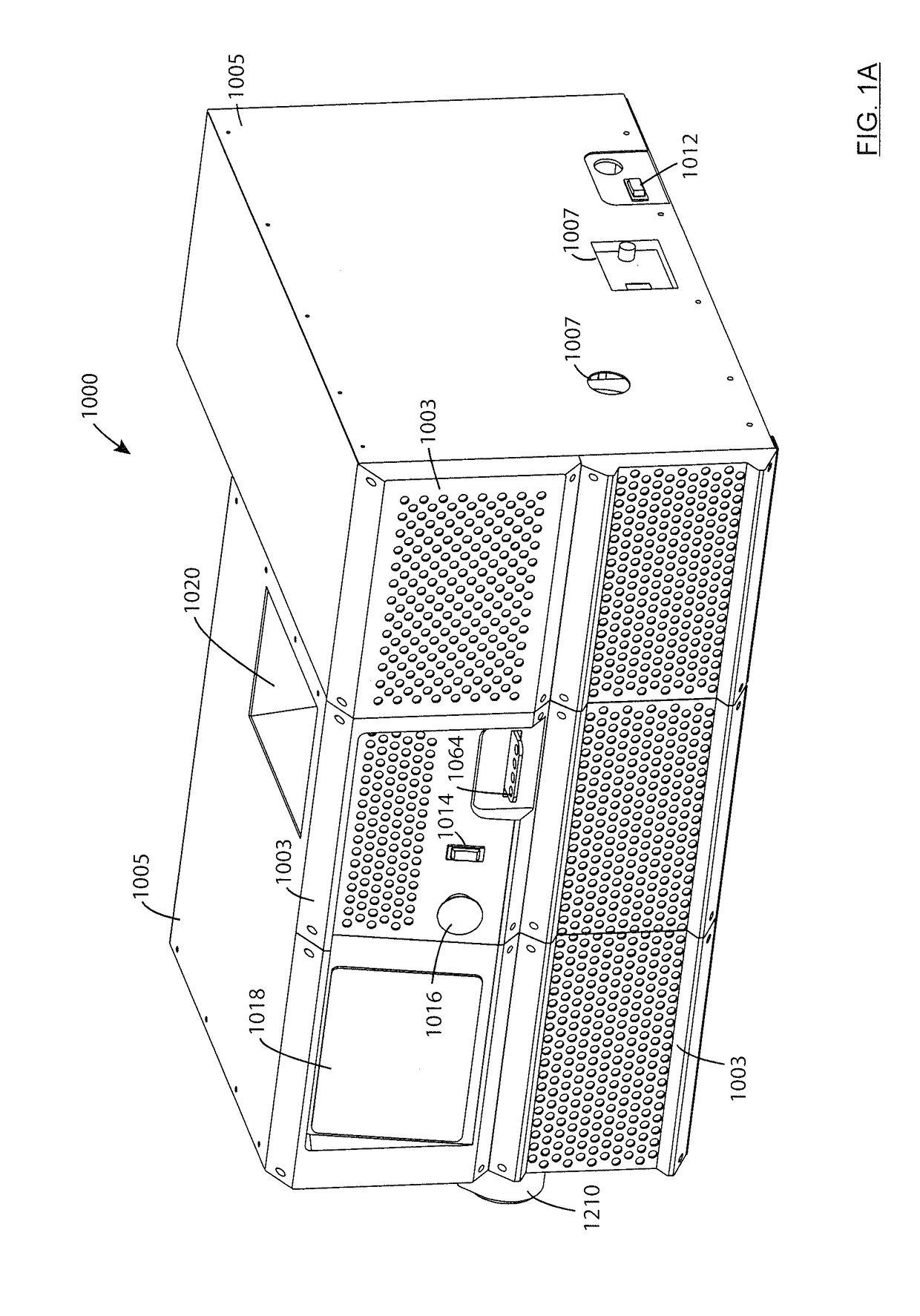

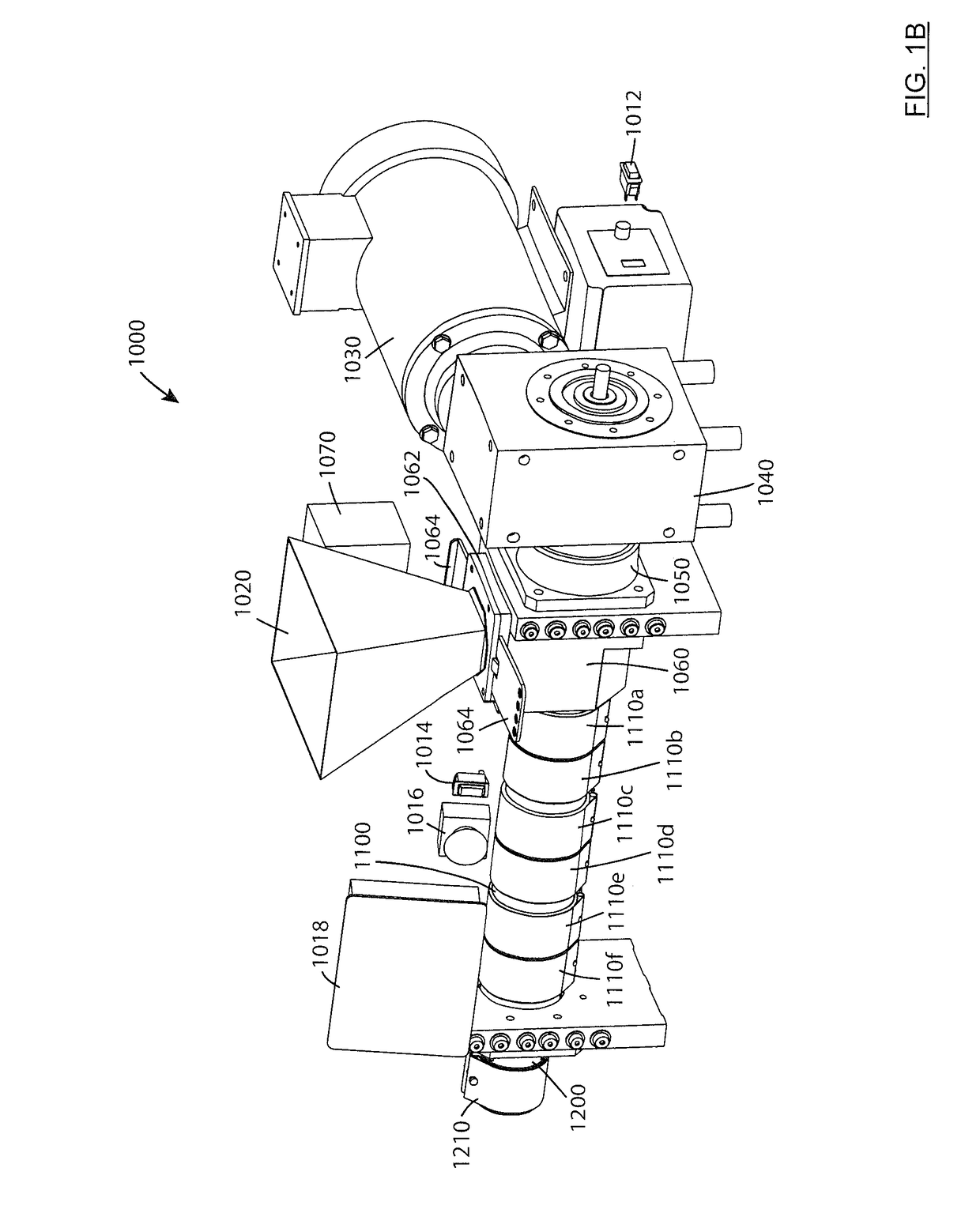

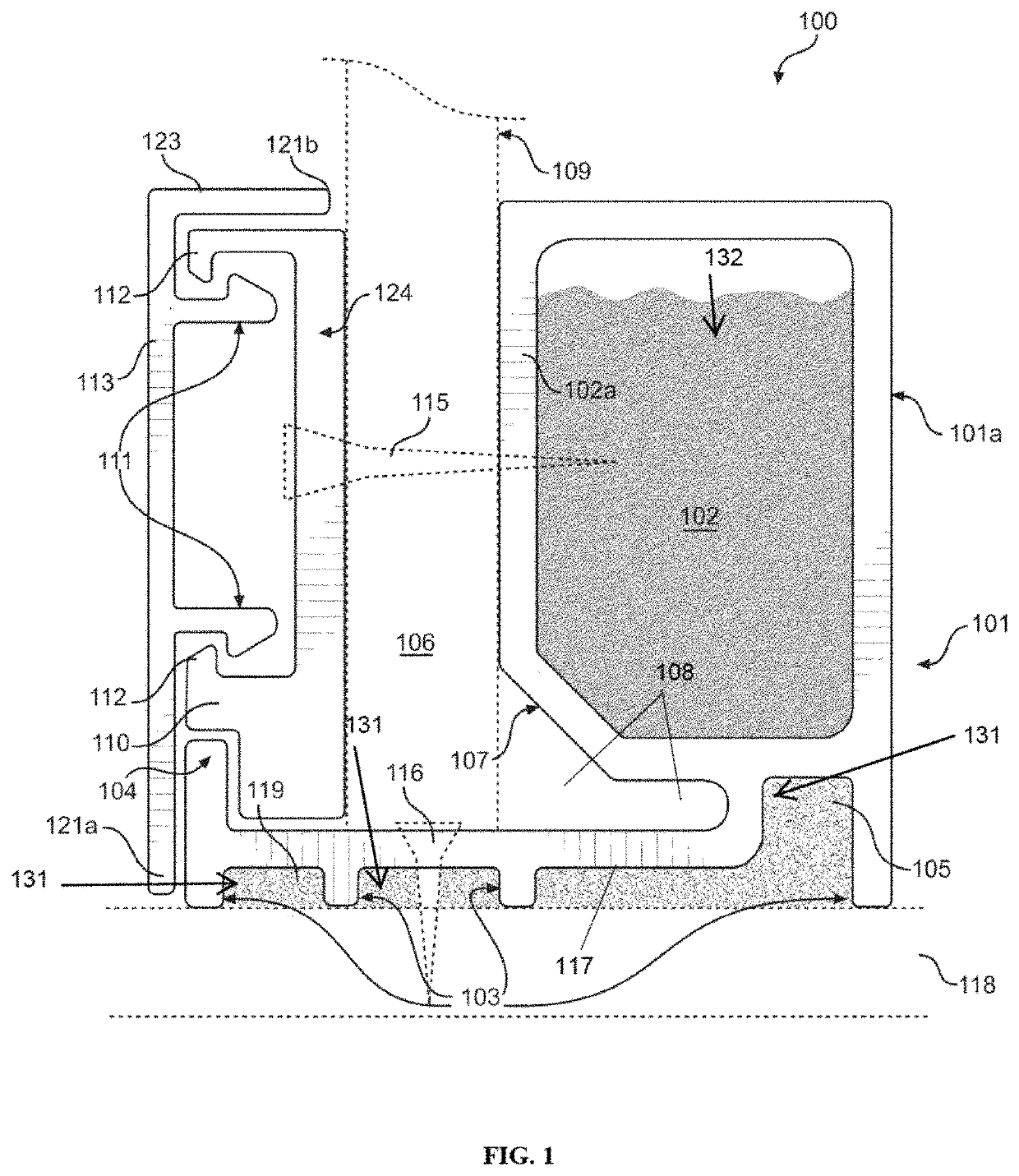

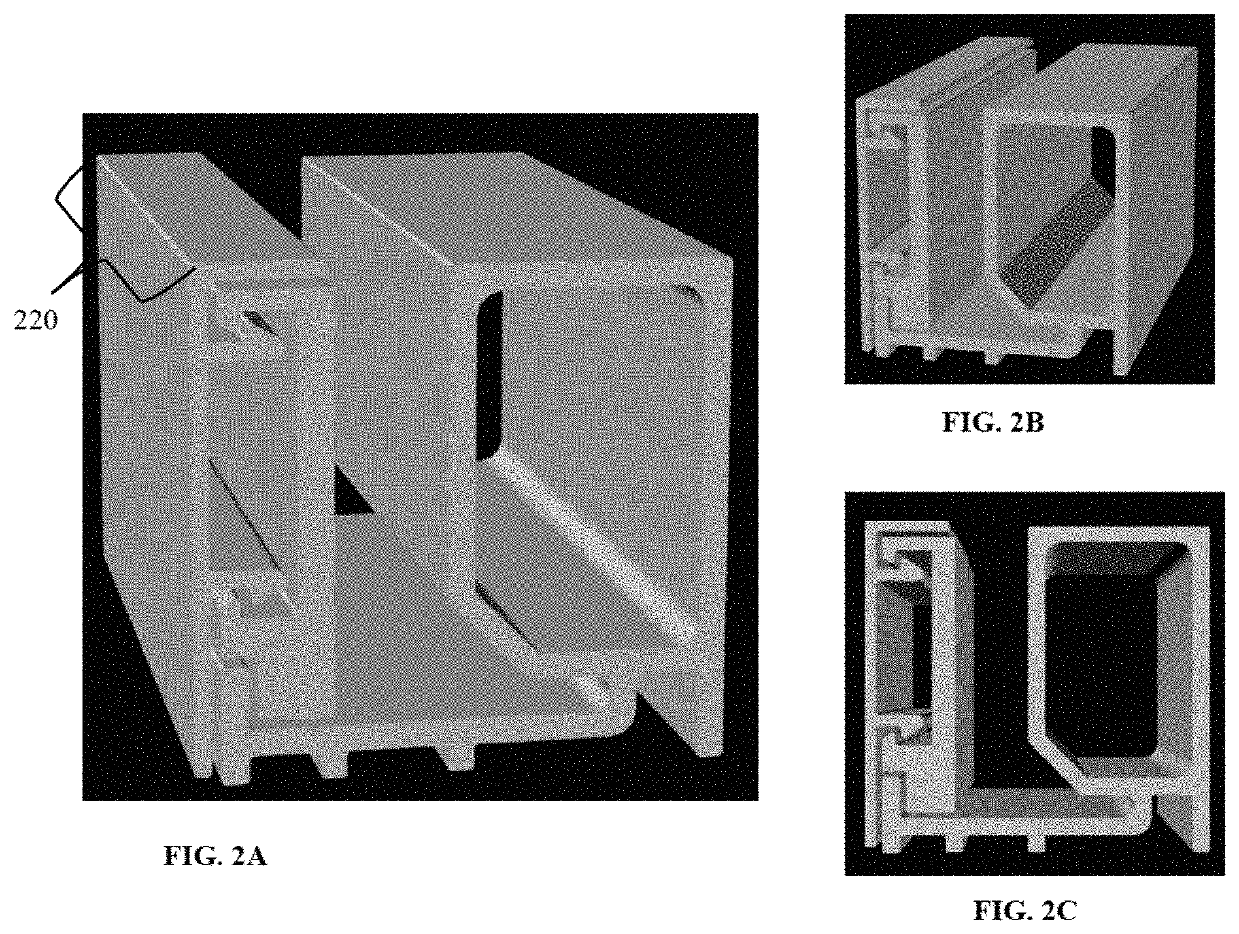

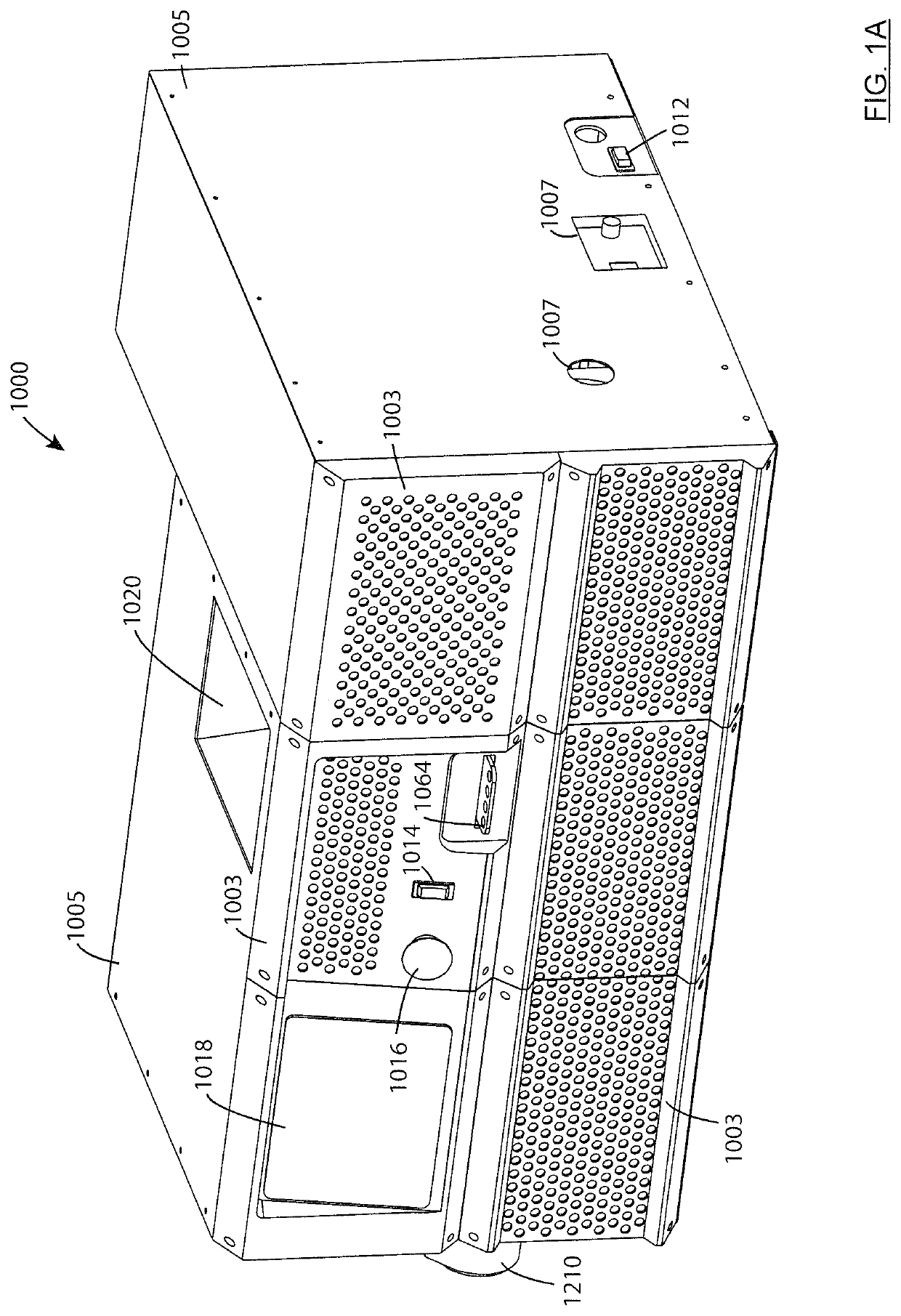

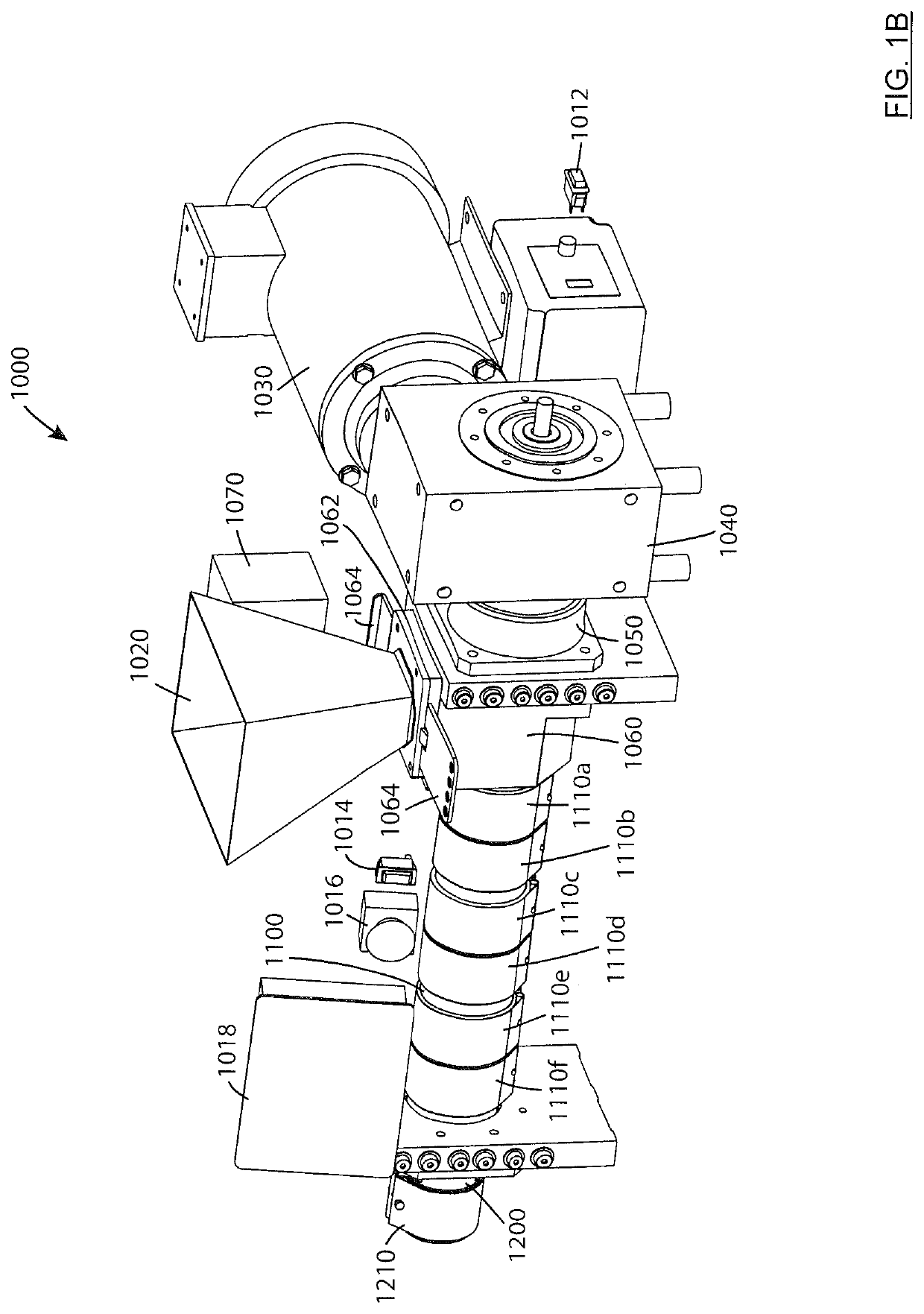

Extruder

ActiveUS20180236705A1Reduced strain orientationReduce and minimize amount of heatTubular articlesScrew positionEngineering

An extruder has a barrel extending from a feed inlet end to an extruder outlet end. The barrel has an inner surface, an outer surface, and a wall thickness between the inner and outer surfaces. The extruder also has at least one heating member positioned provided on the barrel; a screw drive motor drivingly connected to a rotatably mounted screw positioned within the barrel, whereby the screw is rotatable at various revolutions per minute (RPM); and a controller is operably connected to the screw drive motor to adjust the RPM of the screw based upon a temperature of material passing through and / or being extruded from the barrel. Methods for operating an extruder filling a mold are also provided.

Owner:OMACHRON INTPROP

Process for preparing sodium percarbonate

InactiveCN1463913AReduce heat loadReduce the amount neededOrganic compound preparationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh sodiumReaction rate

The present invention belongs to the field of oxygen-containing bleaching agent preparing technology. Sodium carbonate solution is emulsified and hydrated to prepare hydrated sodium carbonate suspension, and hydrated sodium carbonate suspension is reacted with 25-70 % concentration hydrogen peroxide solution to obtain crystal while adding sodium chloride or sodium sulfate as sallification agent,sodium silicate, organic phosphonic acid, EDTA or its sodium salt as crystallization assistant. The said preparation process has fast reaction rate and lowered sodium carbonate content in mother liquid, high sodium percarbonate yield and low material consumption, and the sodium percarbonate product has high active oxygen content, large grain size, high humid and heat stability.

Owner:ZHEJIANG JINKE CHEM

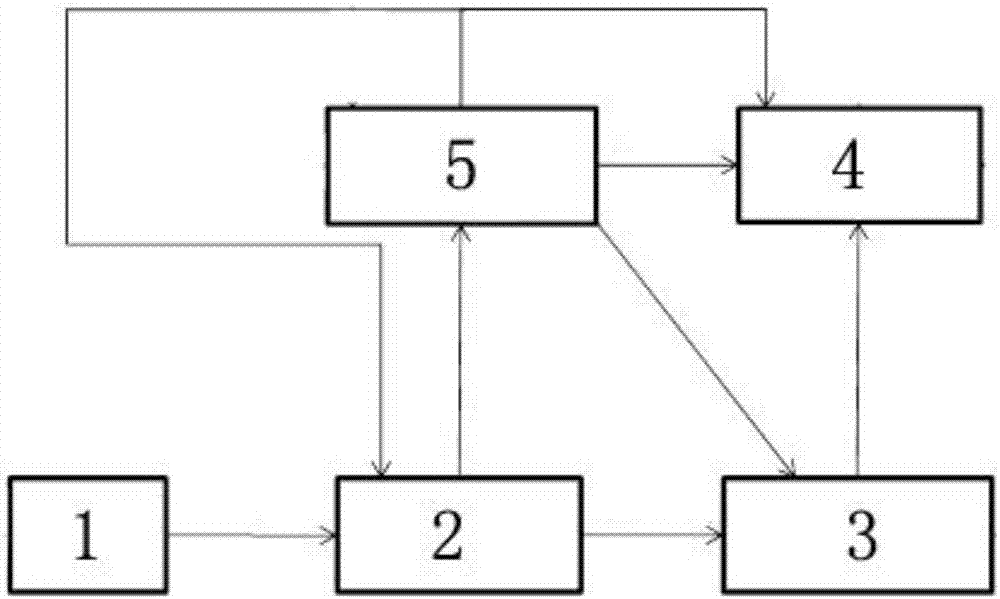

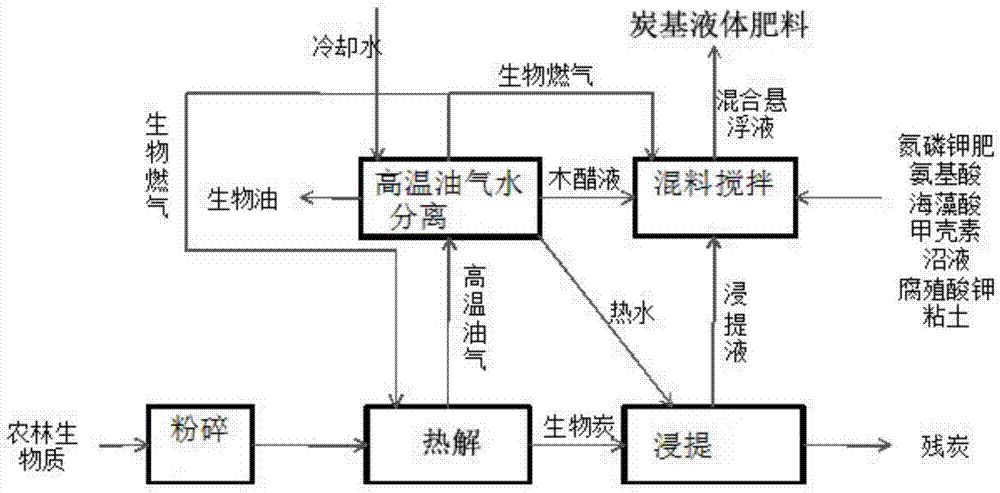

Carbon-based liquid fertilizer, and system and method for production of the same

InactiveCN108002895AIncrease productionReduce the amount neededGaseous fuelsWaste based fuelChitin formationSlurry

The invention relates to a carbon-based liquid fertilizer. The carbon-based liquid fertilizer is prepared from the following components in parts by weight: 1 to 3 parts of wood vinegar, 2 to 6 parts of a biomass charcoal extract, 1 to 2 parts of biogas slurry, 0.5 to 3 parts of a suspending concentrate, 3 to 8 parts of a nitrogen-phosphorus-potassium fertilizer, 1 to 3 parts of potassium humate, 0.5 to 2 parts of alginic acid, 0.5 to 2 parts of chitin and 0.5 to 2 parts of amino acid. The invention also relates to a system and a method for production of the carbon-based liquid fertilizer. Through application of the carbon-based liquid fertilizer, the yield of a crop is more obviously improved, and the usage amount of a chemical fertilizer can be effectively reduced.

Owner:北京源农炭肥技术有限公司

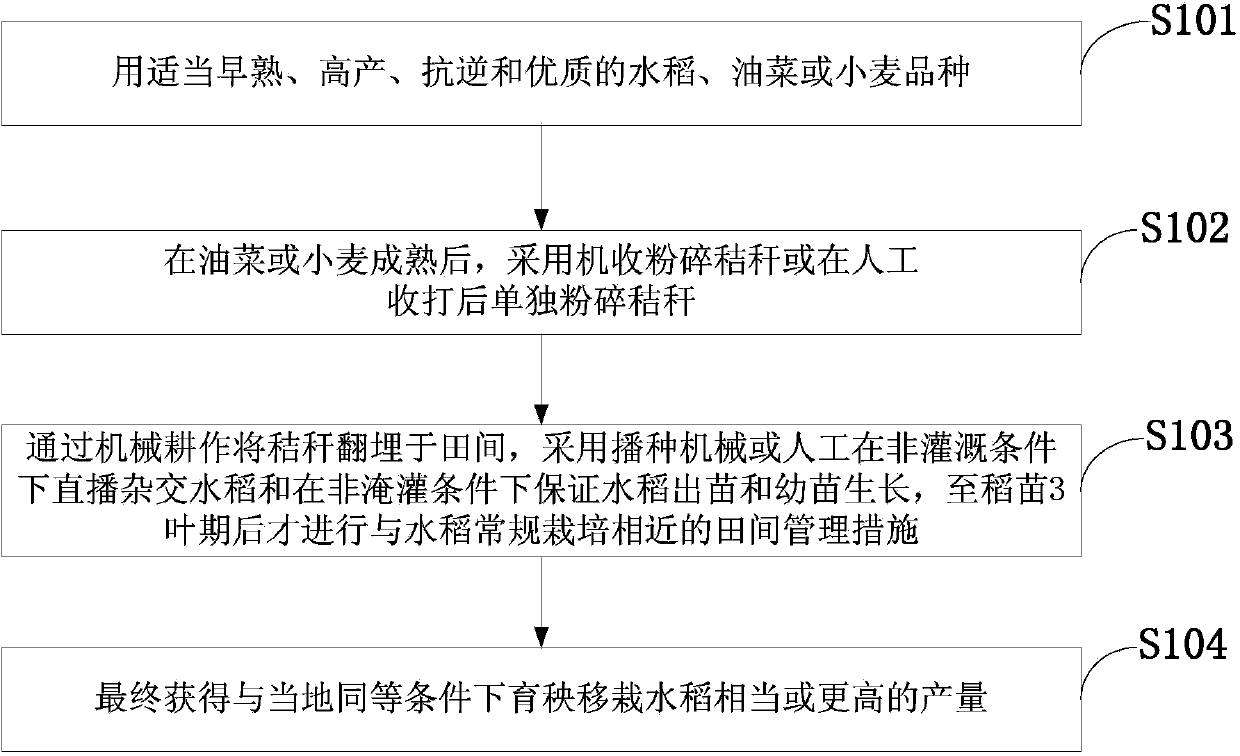

Hybrid rice water saving direct sowing cultivation method based on smashing, burying and retuning to field of preceding crop straw

The invention discloses an oilseed rape and wheat stubble hybrid rice water saving direct sowing cultivation method based on smashing, burying and retuning to field of preceding crop straw, wherein the cultivation method combines agricultural machinery with the agricultural technology closely. Appropriately-precocious, high-yield, stress-resistant and high-quality rice and oilseed rape or wheat varieties are selected, after the oilseed rape or wheat is mature, straw smashing during machine harvesting or separate straw smashing after harvesting is adopted, the smashed straw is buried in the field through mechanical farming, direct sowing of hybrid rice is carried out through sowing machines or workers under non-irrigation conditions, emergence and growth of rice seedlings are guaranteed under non-basin irrigation conditions, field management measures similar to normal rice cultivation are not taken until the three-leaf stage of the rice seedlings, and the yield equal to or higher than that of local seedling raising and transplanting rice under equal conditions is obtained finally. The hybrid rice water saving direct sowing cultivation method based on smashing, burying and retuning to field of the preceding crop straw realizes light and simple returning to field and effective utilization of oilseed rape and wheat straw, can substantially save water for rice irrigation and avoid seasonal water consumption peaks and water competition contradictions in rice production in arid regions, and realizes cost-reducing efficient ecological rice cultivation.

Owner:SOUTHWEAT UNIV OF SCI & TECH

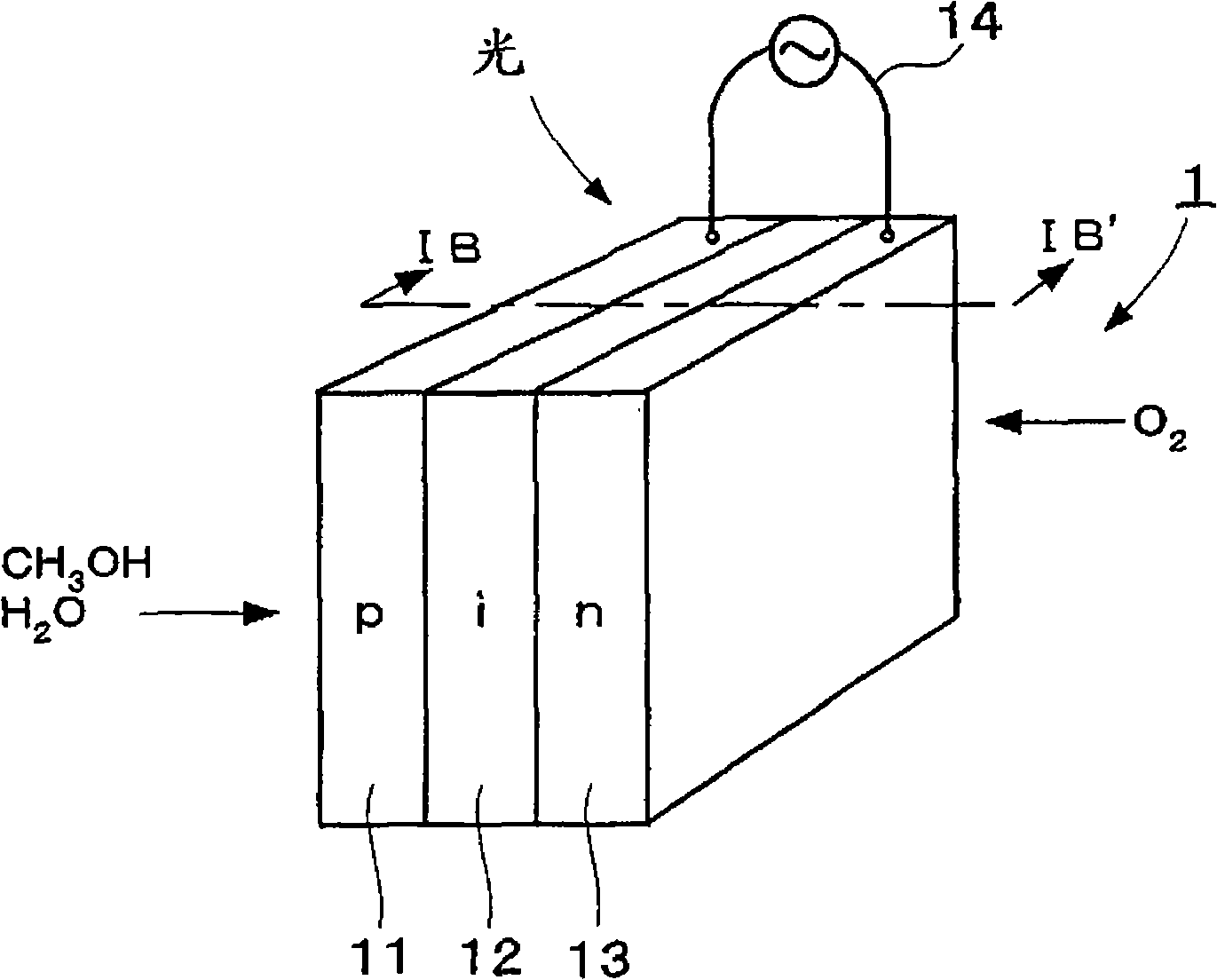

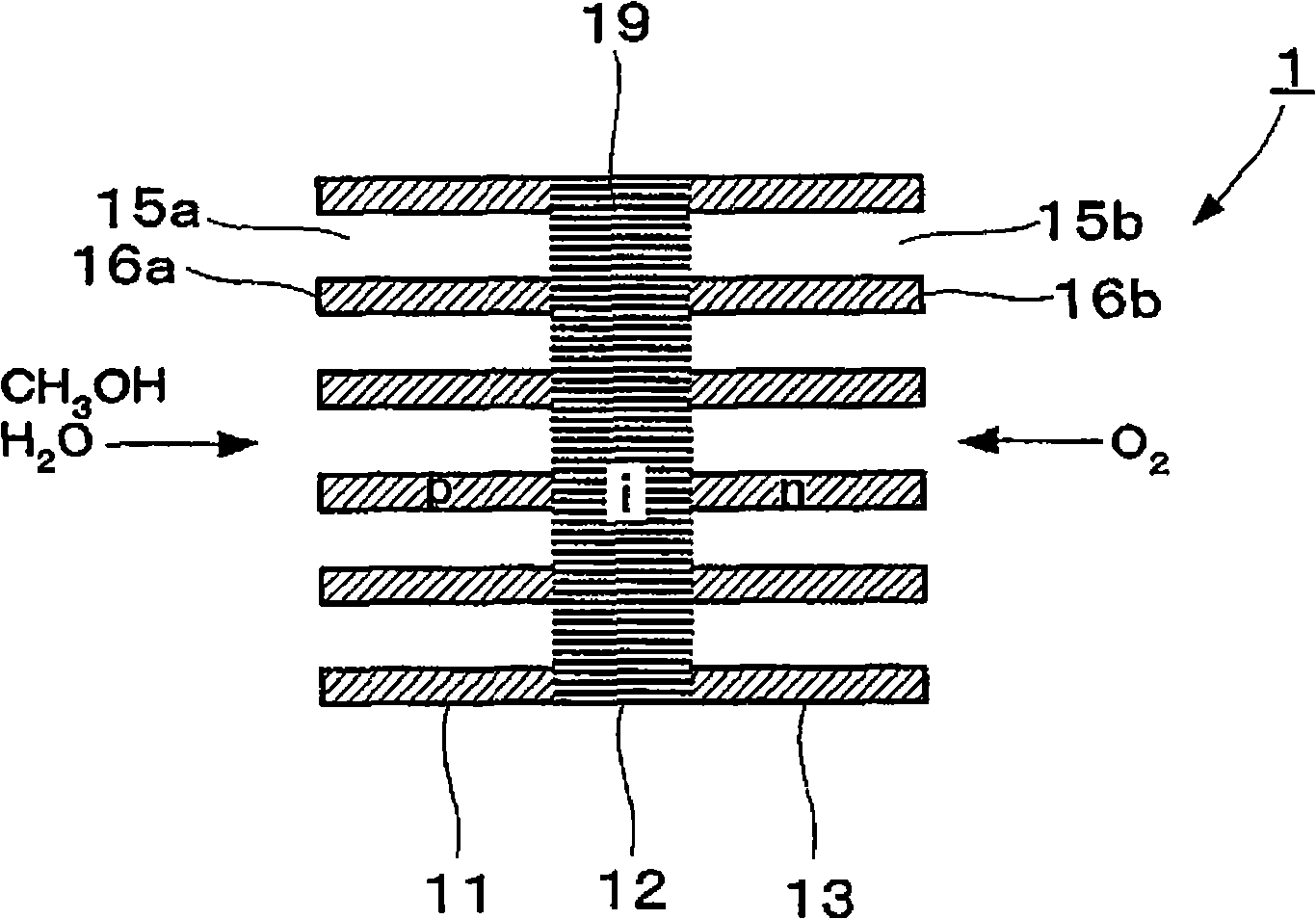

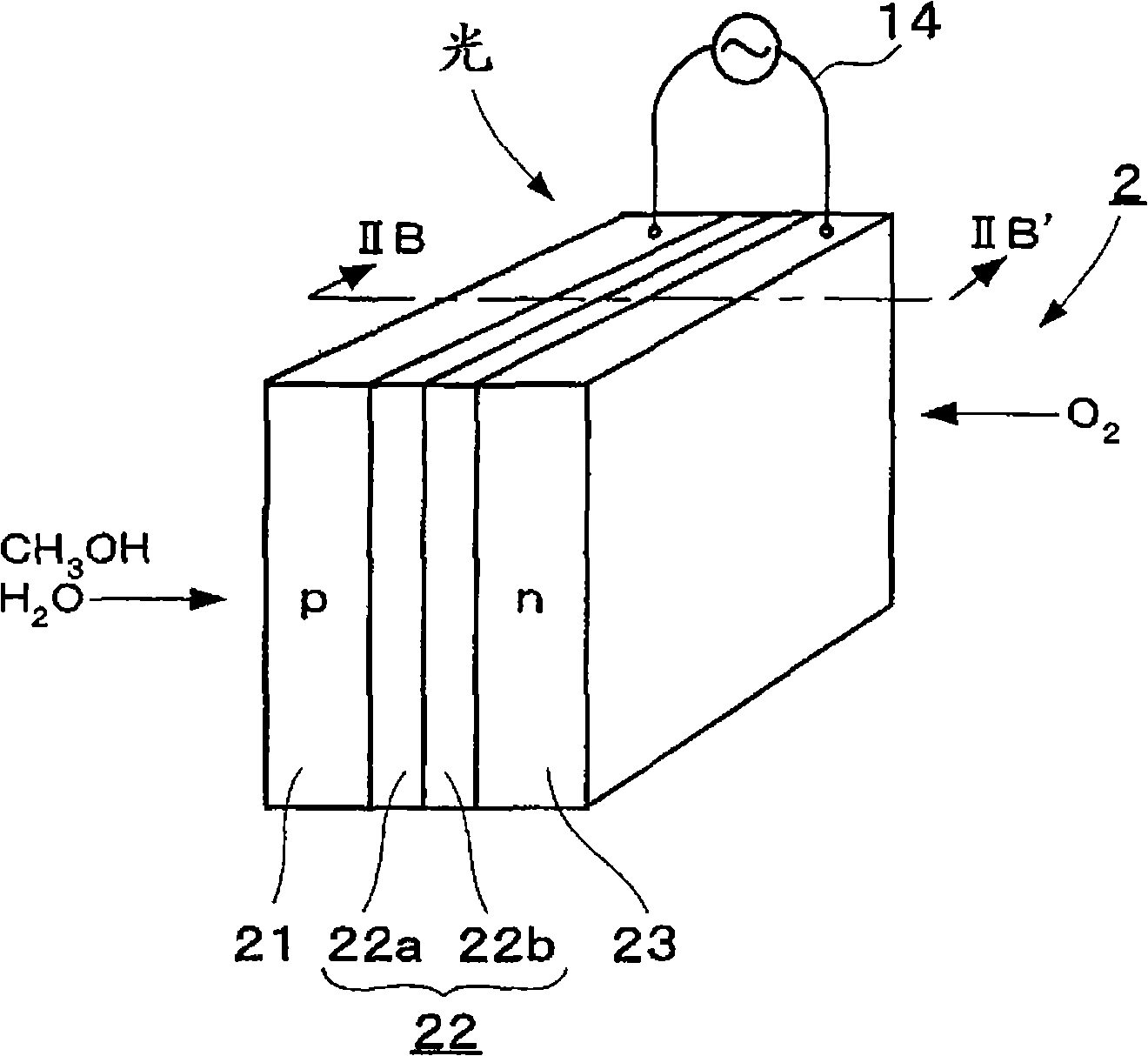

Fuel battery unit cell, fuel battery unit cell array, fuel battery module, and fuel battery system

InactiveCN101278428ACatalytic activationIncrease the speed of oxidation reactionElectrolyte holding meansFuel cells groupingPtru catalystFuel cells

This invention provides a fuel battery unit cell, which can realize a size reduction and a cost reduction, a fuel battery unit cell array, a fuel battery module, and a fuel battery system. The fuel battery unit cell has a pin structure comprising a fuel electrode (11) formed of a p-type semiconductor, an oxygen electrode (13) formed of an n-type semiconductor, and an intermediate layer (12) interposed between the fuel electrode (11) and the oxygen electrode (13) and formed of an authentic semiconductor. The fuel electrode (11) and the oxygen electrode (13) are porous and permeable to a fluid. A metal-base catalyst layer is provided on the inner surface of pores in the porous part. The intermediate layer (12) is porous and permeable to a hydrogen ion produced in the fuel electrode (11) and is impermeable to electrons. A hydrogen-containing fuel is supplied on the surface of the fuel electrode (11), and an oxygen-containing oxidizing fluid is supplied on the surface of the oxygen electrode (13). Connecting terminals electrically connected respectively to the fuel electrode (11) and the oxygen electrode (13) are provided.

Owner:MICRO SILITRON INC

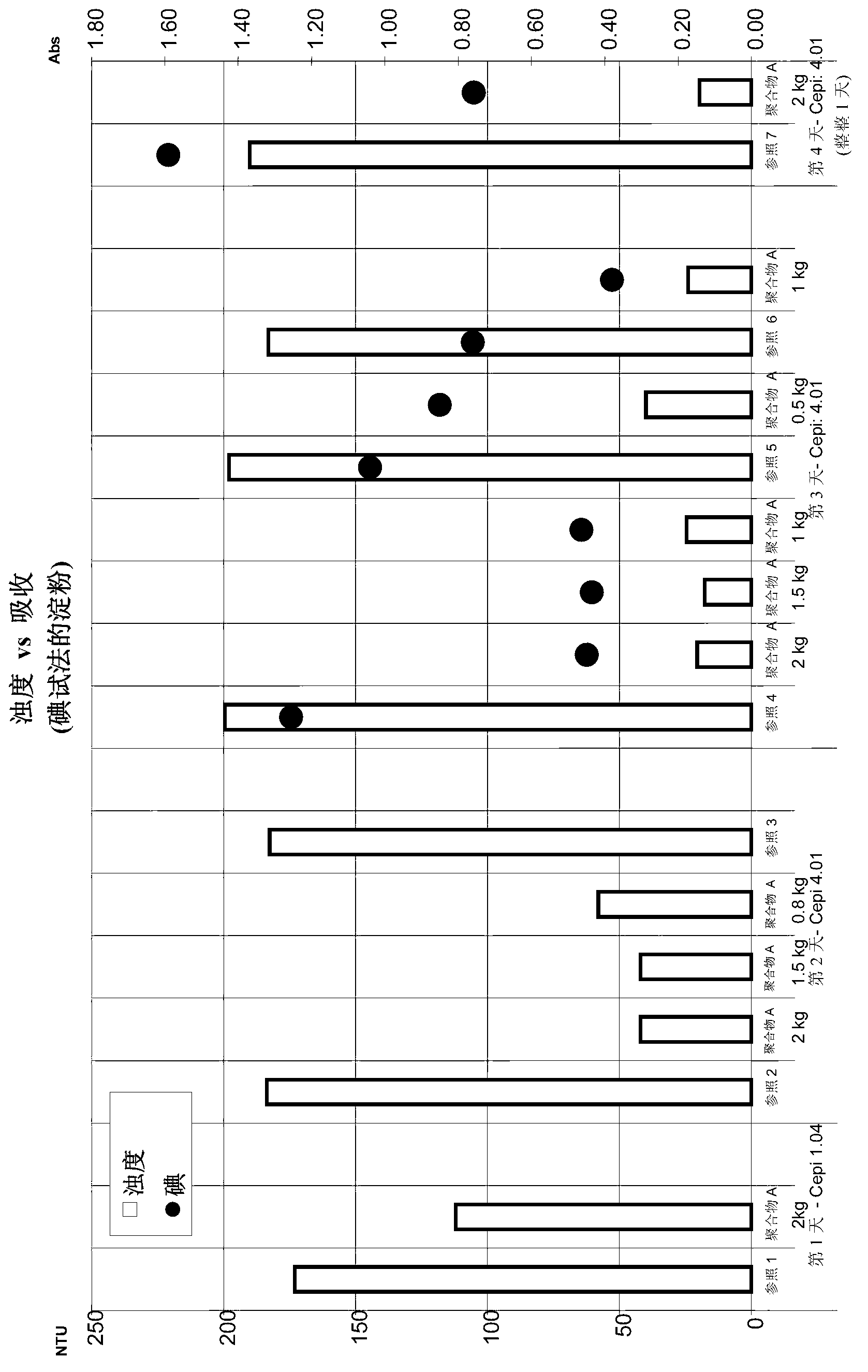

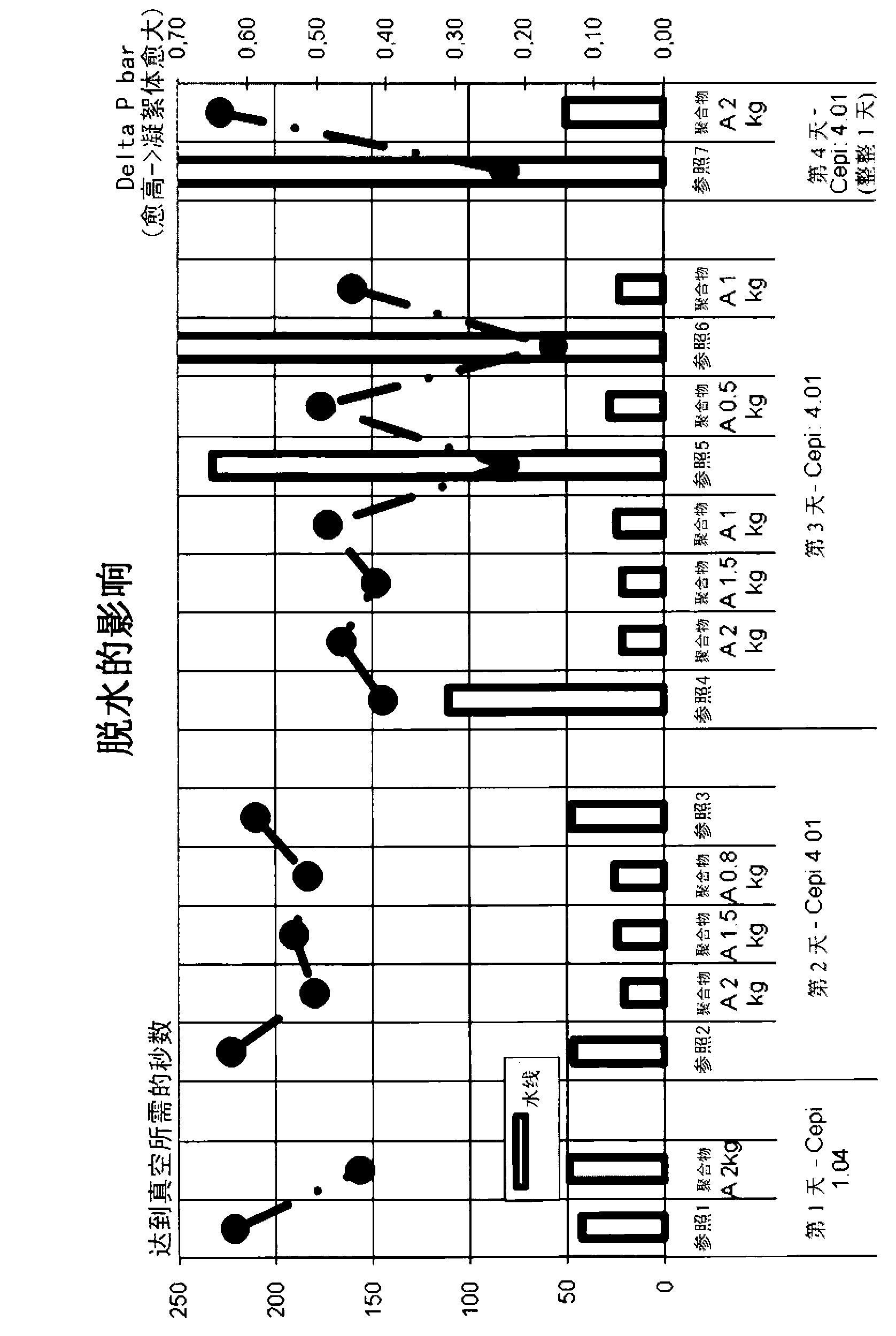

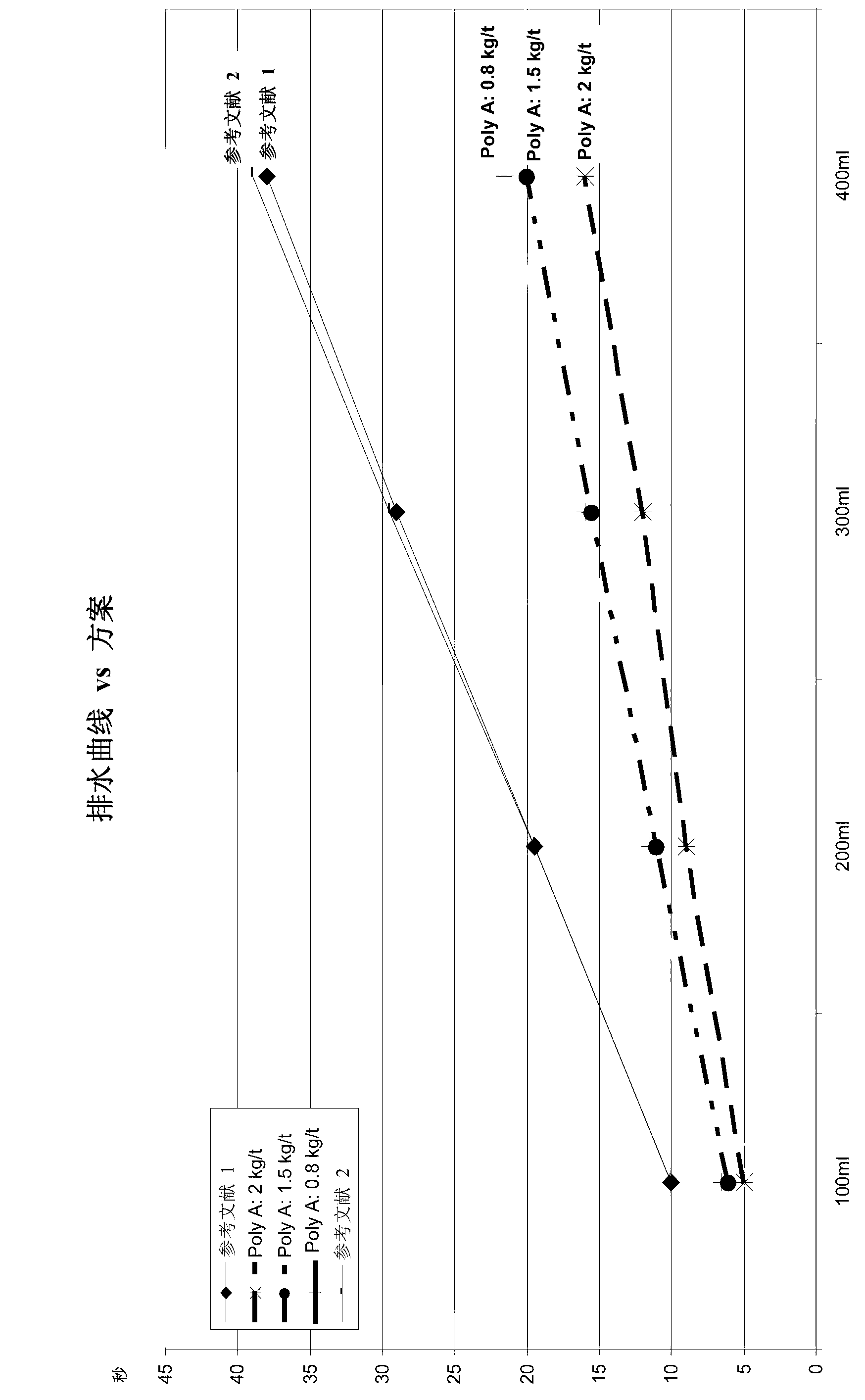

Method for increasing the advantages of starch in pulped cellulosic material in the production of paper and paperboard

ActiveCN103180510AReduce the amount neededAvoid degradationReinforcing agents additionPaper/cardboardCellulosePaperboard

The invention relates to a method for increasing the benefit from starch in pulped, preferably repulped cellulosic material at paper or paperboard manufacturing comprising the steps of (a) pulping a cellulosic material containing a starch; (b) treating the cellulosic material containing the starch with one or more biocides, preferably in the thick stock area; and (h) adding an ionic polymer and preferably, an auxiliary ionic polymer to the cellulosic material; wherein the ionic polymer and the optionally added auxiliary ionic polymer preferably have a different average molecular weight and preferably a different ionicity, wherein the tonicity Is the molar content of ionic monomer units relative to the total amount of monomer units.

Owner:SOLENIS TECH CAYMAN

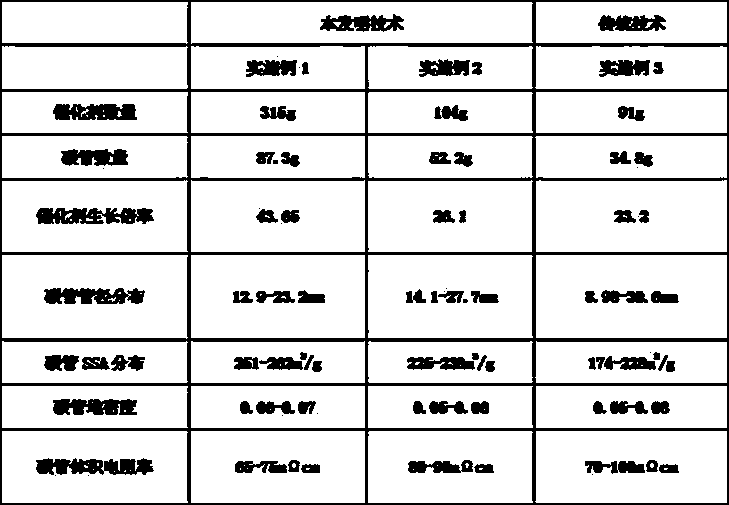

Method for continuously preparing multi-metal oxide pore structure catalyst for carbon nanotube

InactiveCN108079999AUniform areaImprove yield rateMaterial nanotechnologyCatalyst activation/preparationCarbon nanotubeSolvent

The invention relates to the technical field of synthesis of multi-metal oxide catalysts for carbon nanotubes, in particular to a method for continuously a preparing multi-metal oxide pore structure catalyst for a carbon nanotube. The method comprises the following steps: preparing a solution from different raw materials, and preparing the multi-metal oxide pore structure catalyst for a carbon nanotube by using a micro channel reactor, namely continuously pumping an active metal salt solution and an alkali solution of an inert metal salt into the micro channel reactor, under certain conditions, performing a precipitation reaction in the micro channel reactor to prepare a precursor, filtering a reactant, washing, drying, roasting, and screening, thereby obtaining a multi-metal oxide pore catalyst. Compared with a conventional process, the method has the advantages that the stability and the consistence of catalyst production are greatly improved, and the yield is increased; in the reaction process, the amount of a solvent is greatly reduced, and the environment is well protected; and nanotubes catalyzed by using the catalyst are concentrated in tube diameter distribution and good inindex parallelism, and the market competitiveness of products is improved.

Owner:SHANDONG DAZHAN NANO MATERIALS

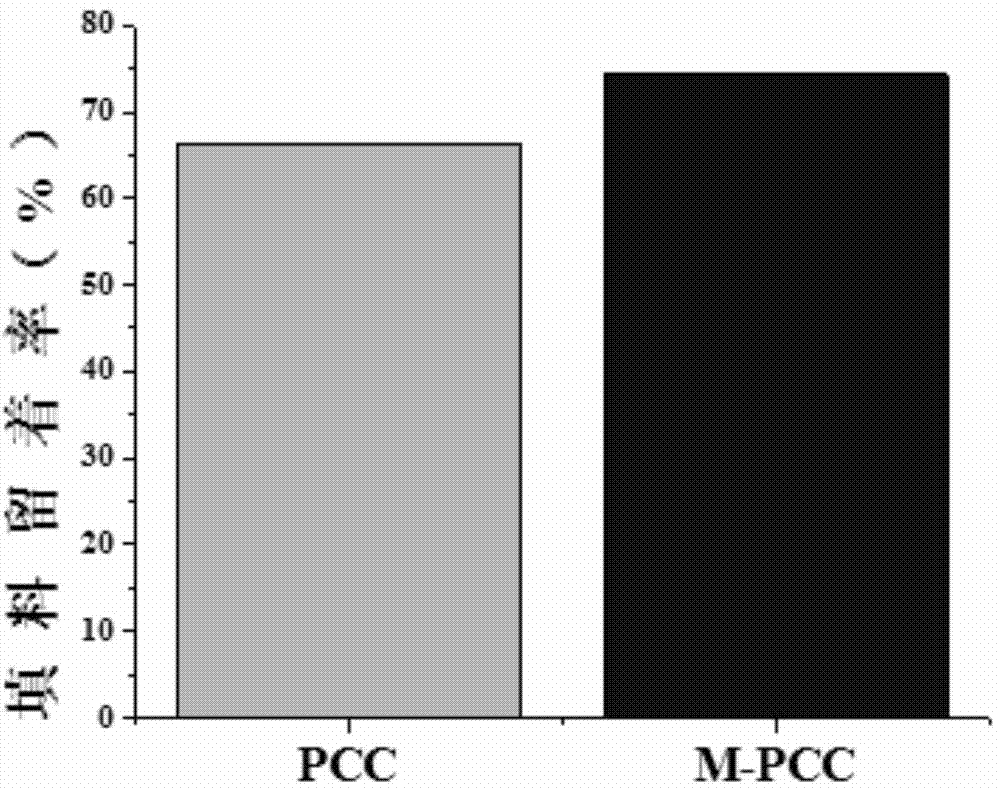

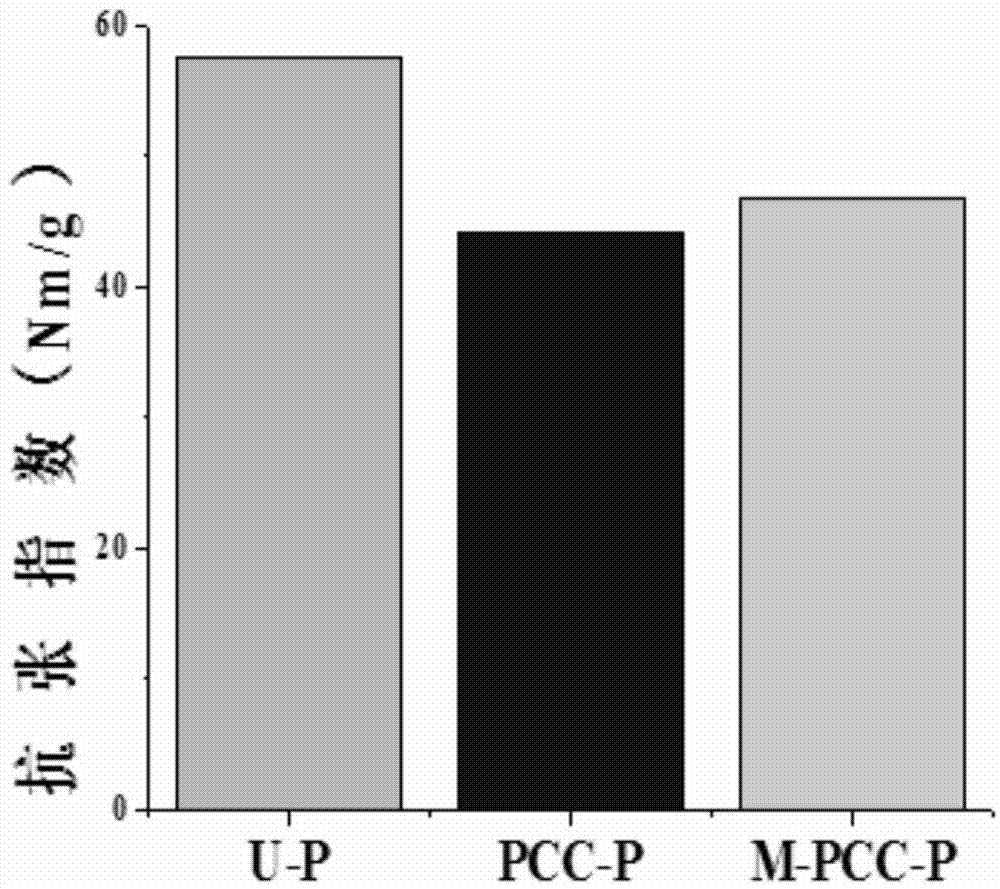

Preparation method of ultrasonic-assisted starch/rosin clathrate-based modified filler

ActiveCN104119700AImprove bindingReduce negative impactInorganic compound additionPigment treatment with macromolecular organic compoundsChemistryAlant starch

The invention discloses a preparation method of an ultrasonic-assisted starch / rosin clathrate-based modified filler, relates to the pulping and paper-making engineering field, in particular relates to the preparation method of the ultrasonic-assisted starch / rosin clathrate-based modified filler, and aims to solve the problem that: inorganic fillers in the prior art have negative effects on the strength properties of finished paper and the application efficiency of sizing agents. The method is as follows: 1, gelatinized starch preparation; 2, rosin saponification liquid preparation; 3, starch / rosin clathrate water-containing system preparation; and 4, starch / rosin clathrate-based modified filler preparation. The preparation method significantly improves the binding force of the inorganic fillers and pulp fiber, and reduces the filling-caused negative effects on the strength properties of the finished paper; the hydrophobic properties of the finished paper can be significantly improved by clathration of hydrophobic rosin in the cavity structure of starch, and the papermaking sizing agent dosage can be reduced.

Owner:NORTHEAST FORESTRY UNIVERSITY

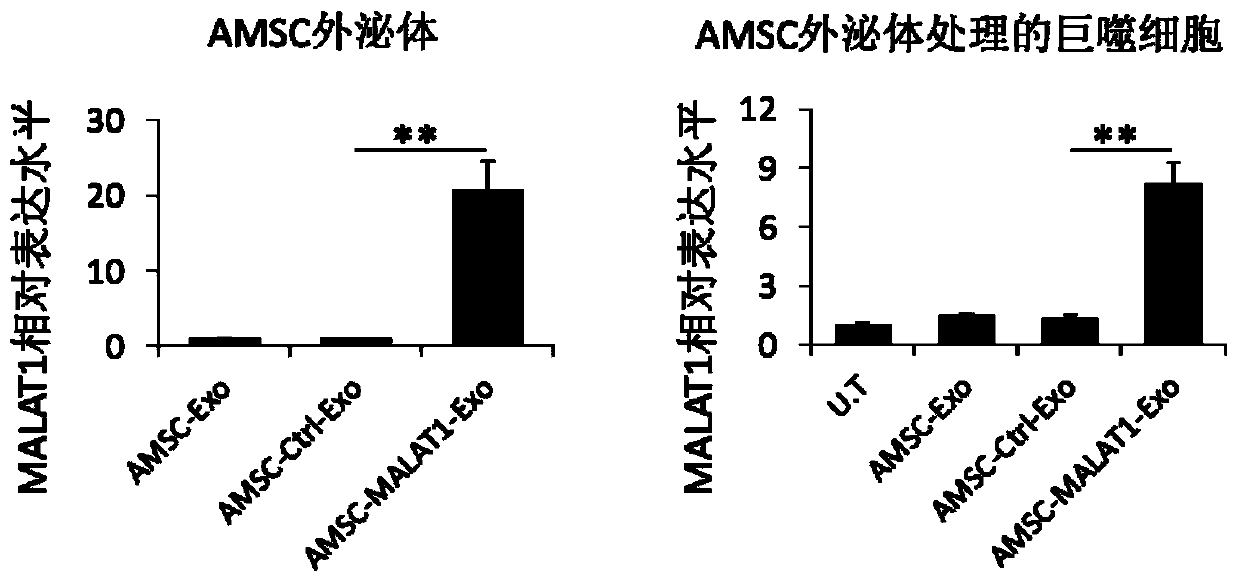

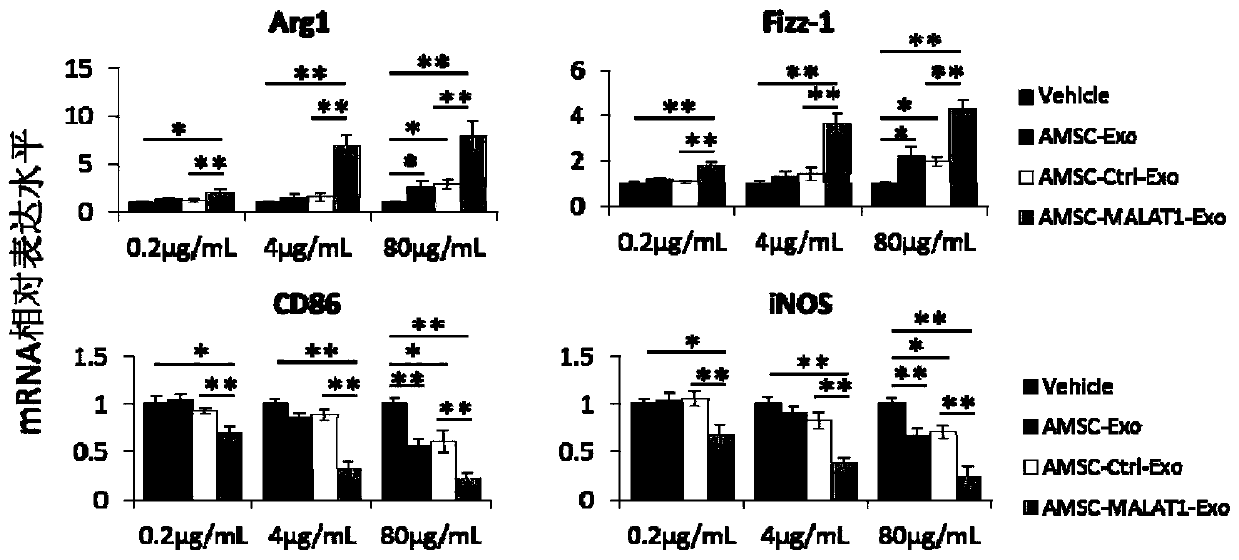

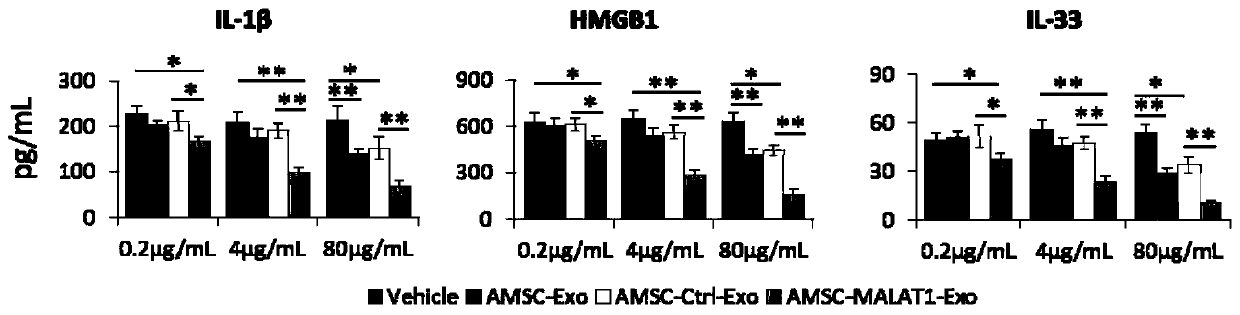

Application of AMSC-MALAT1-Exo to preparation of medicine for treating hepatic diseases and preparation method of AMSC-MALAT1-Exo

ActiveCN110075124AGood regulation of macrophage function phenotypeGood for liver diseaseGenetically modified cellsDigestive systemMALAT1Liver macrophage

The invention belongs to the technical field of biology, and relates to novel application of mesenchymal stem cell source exosomes, in particular to building of lncRNA MALAT1 modified fat source mesenchymal stem cells and preparation of the exosome of the mesenchymal stem cells, and application of the exosome to preparation of a hepatic disease treatment biological agent and a liver macrophage targeted biological agent. According to the thought, MALAT1 modified AMSCs are built, and the exosome is prepared; through experiments such as ELISA, WB and streaming in the cell level, the regulation and control advantages of the AMSC-MALAT1-Exo on the macrophage functional phenotype are defined; through in vivo experiments, the curative effect on hepatic diseases and the action advantages on the regulation and control of the liver macrophage functional phenotype of the MALAT1 modified AMSC source exosome are defined. The liver macrophage targeted biological agent or medicine with the improved curative effect is further prepared.

Owner:ZHEJIANG UNIV

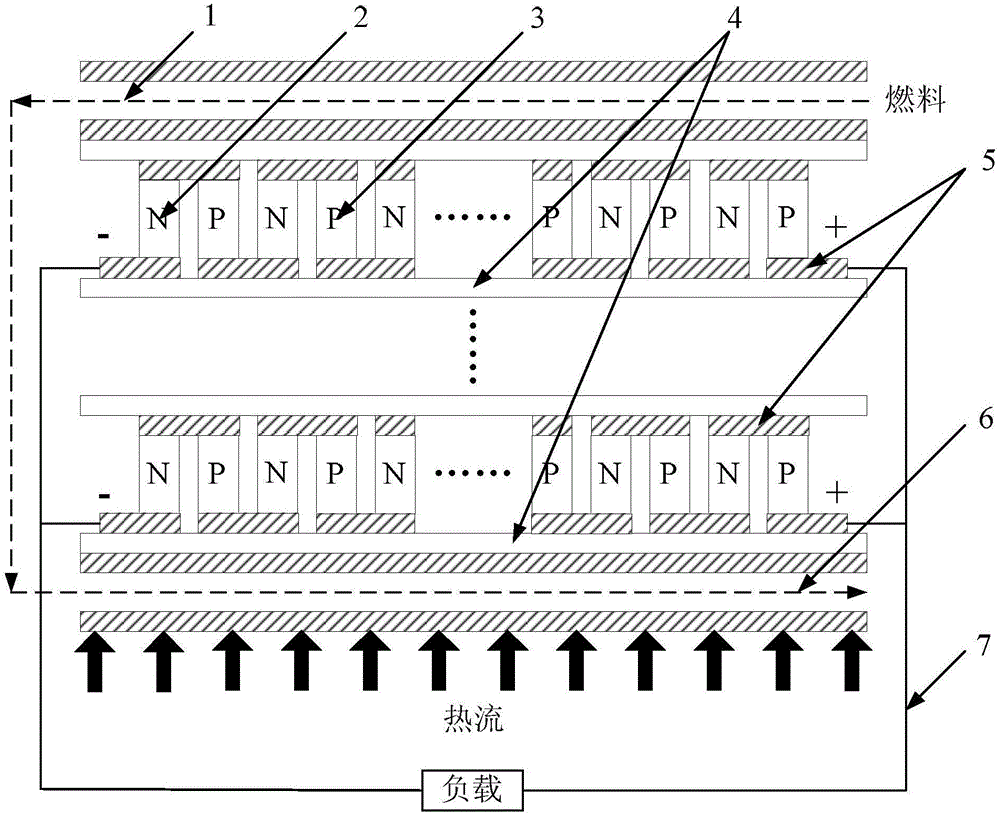

Multi-stage semiconductor thermoelectric power generation and cooling integrated system for hypersonic flight vehicle

InactiveCN106533263ALightweight structureReduce quality penaltyGenerators/motorsThermoelectric materialsHeat conducting

The invention discloses a multi-stage semiconductor thermoelectric power generation and cooling integrated system for a hypersonic flight vehicle, relates to a multi-stage semiconductor thermoelectric power generation and cooling integrated technology for the hypersonic flight vehicle, and aims to satisfy thermal protection and power supply requirement of long-endurance hypersonic flight. Each stage of semiconductor thermoelectric power generation apparatus comprises multiple N type semiconductor thermoelectric materials, multiple P type semiconductor thermoelectric materials and multiple flow-guiding sheets; the N type semiconductor thermoelectric materials and the P type semiconductor thermoelectric materials are arranged at intervals, and are connected in series in sequence through the flow-guiding sheets; the multiple stages of semiconductor thermoelectric power generation apparatuses are connected in parallel to form a multi-stage semiconductor thermoelectric power generation system; heat-conducting insulating layers, tightly attached to the flow-guiding sheets, are arranged on the two sides of each stage of semiconductor thermoelectric power generation apparatus; and a low-temperature channel and a high-temperature channel which are connected are formed in the two sides of the multi-stage semiconductor thermoelectric power generation system respectively. The multi-stage semiconductor thermoelectric power generation and cooling integrated system is applicable to the hypersonic flight vehicle.

Owner:HARBIN INST OF TECH

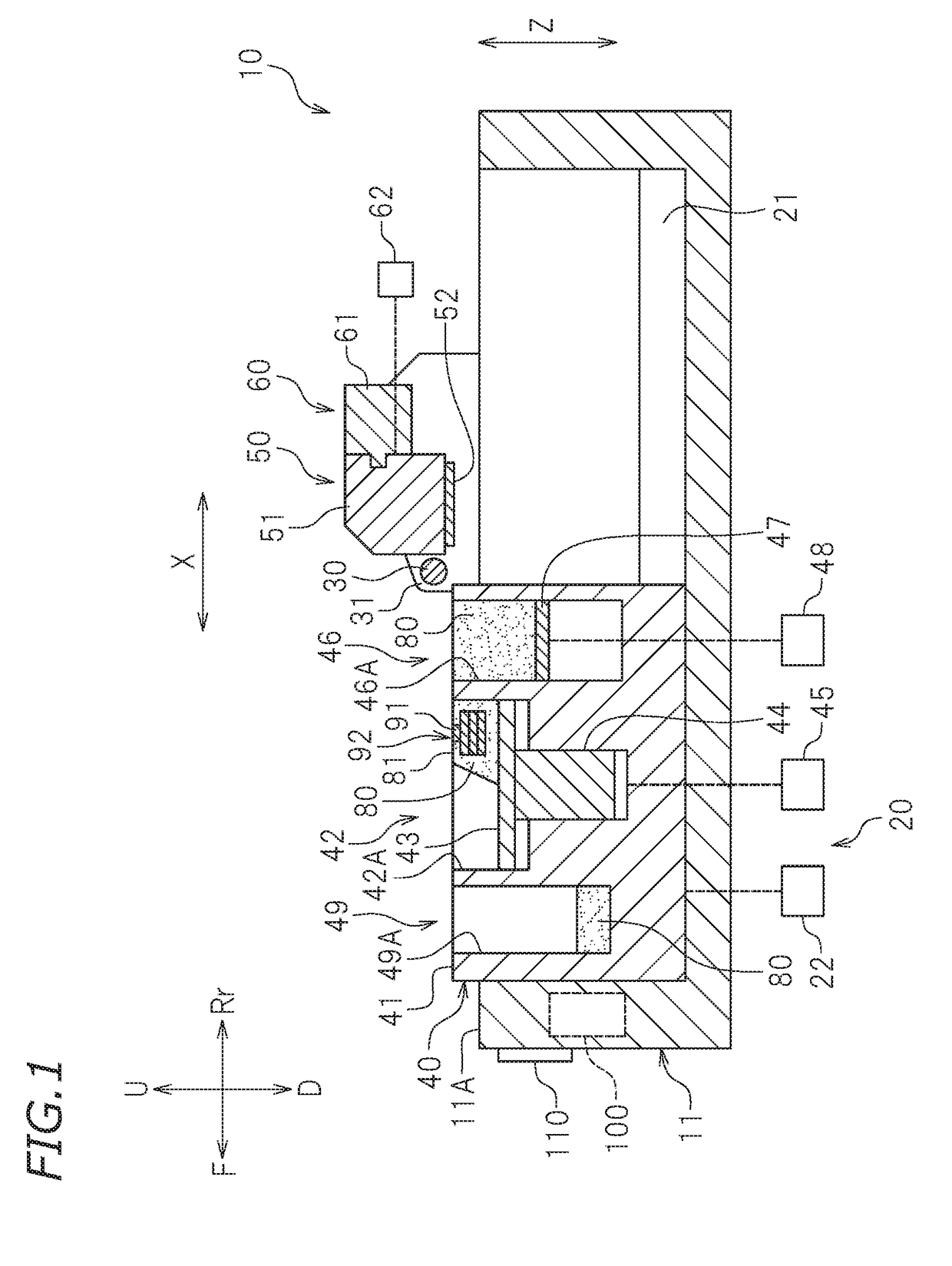

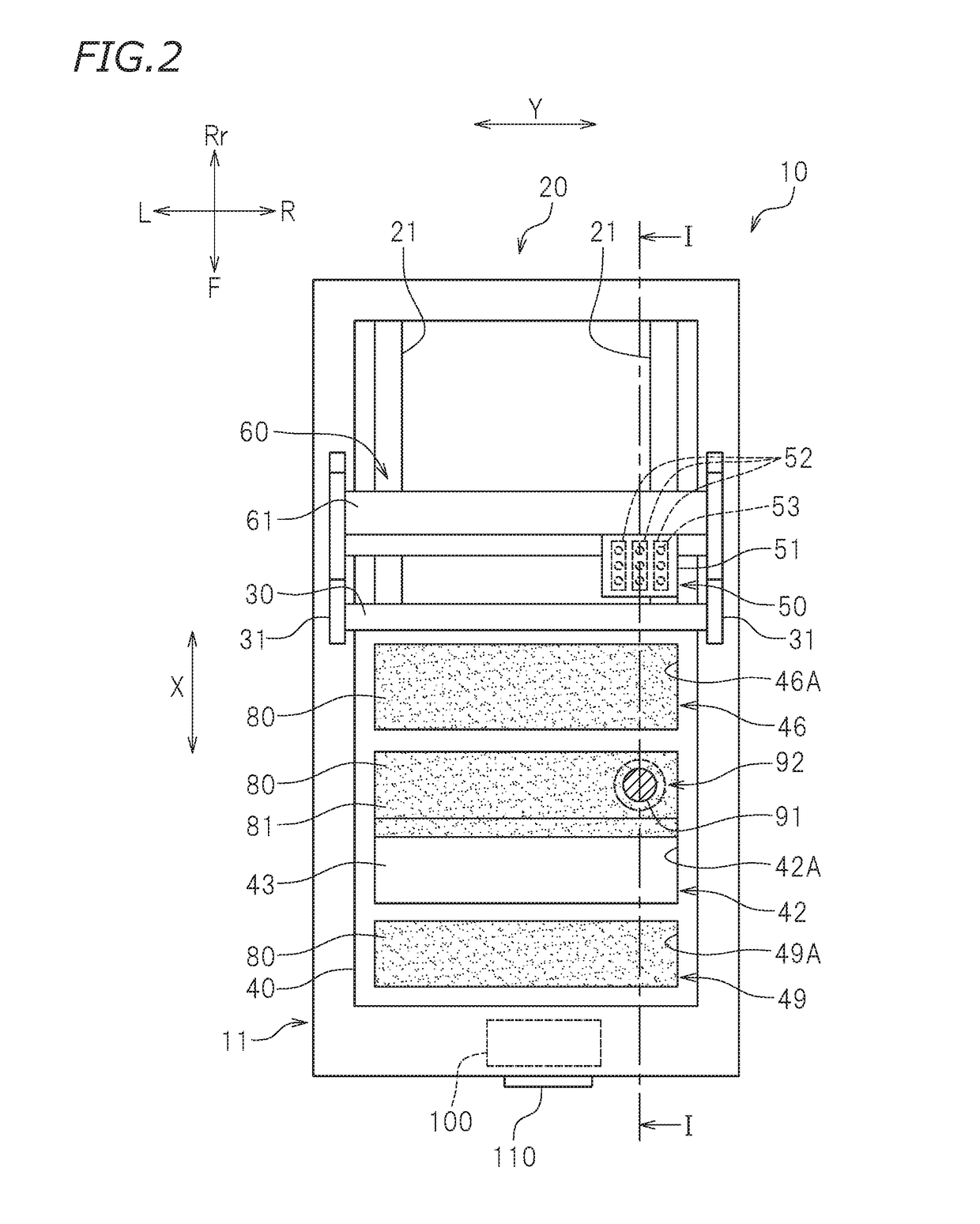

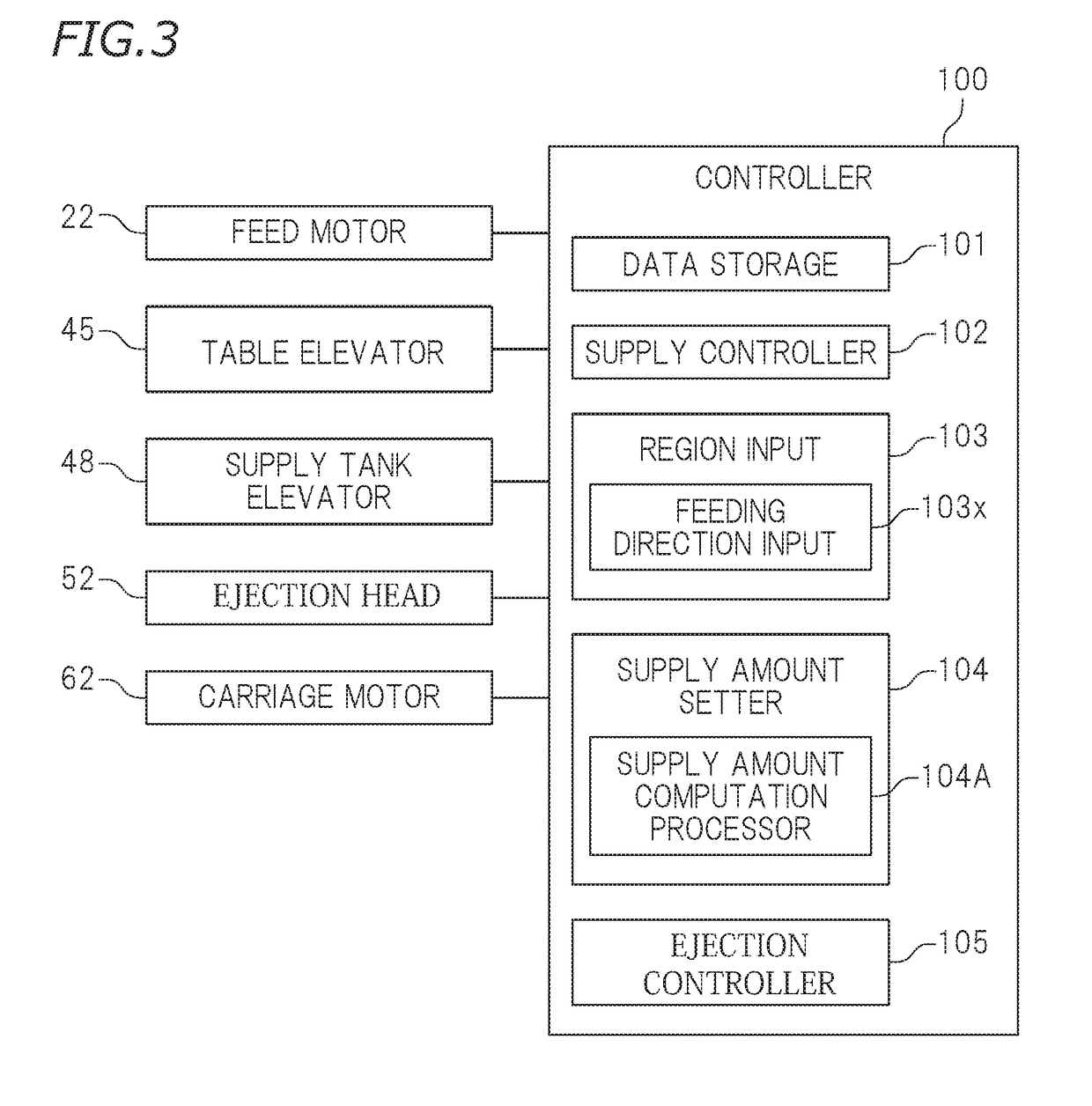

Three-dimensional printing device and method for printing three-dimensional object

InactiveUS20190030793A1Eliminates wasteful formationReduce the amount requiredManufacturing enclosuresManufacturing data aquisition/processing3 dimensional printingElectrical and Electronics engineering

A three-dimensional printing device includes a layer former that levels off a supplied powder material to form a powder layer including a flat portion having a predetermined height on a printing table, and a supply amount setter that sets an amount of the powder material to be supplied. The supply amount setter sets, as the amount of the powder material to be supplied, an amount smaller than a reference supply amount corresponding to a volume determined as a result of an area size of the printing table being multiplied by the predetermined height. If an amount smaller than the reference supply amount is set as the amount of the powder material to be supplied, the layer former forms the powder layer having the flat portion such that the flat portion has an area size smaller than the area size of the printing table.

Owner:ROLAND DG CORP

Audiovisual content delivery system

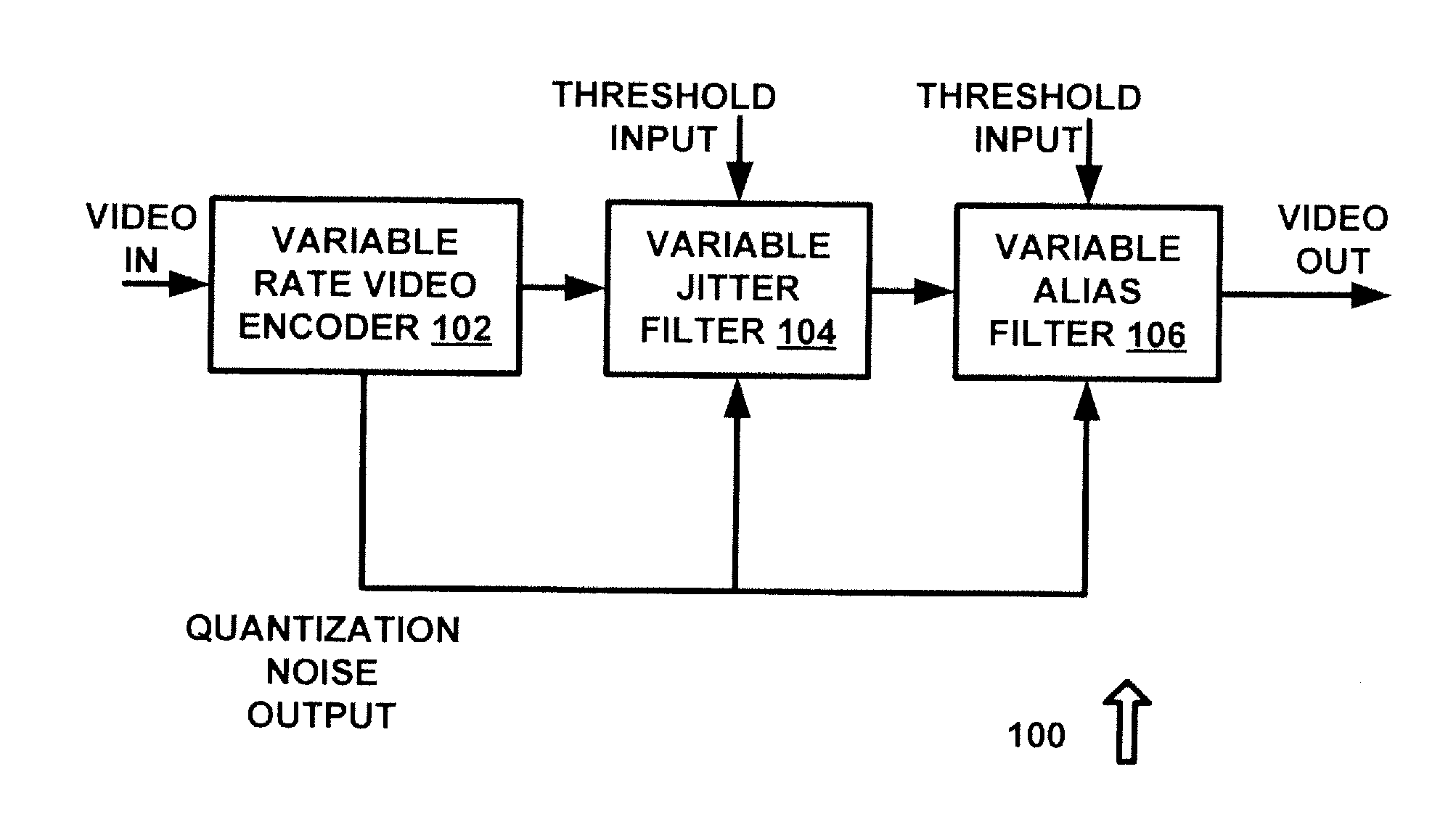

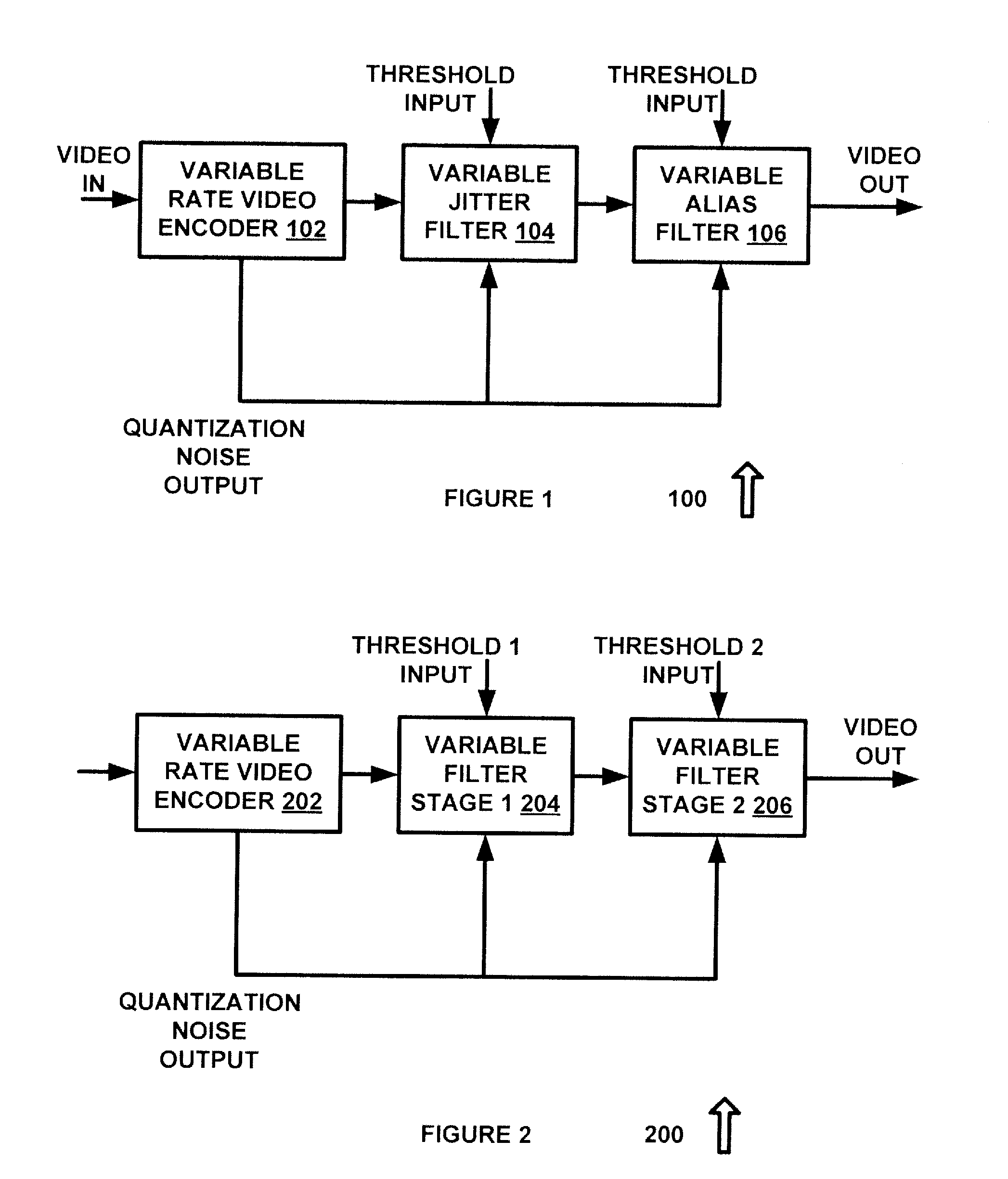

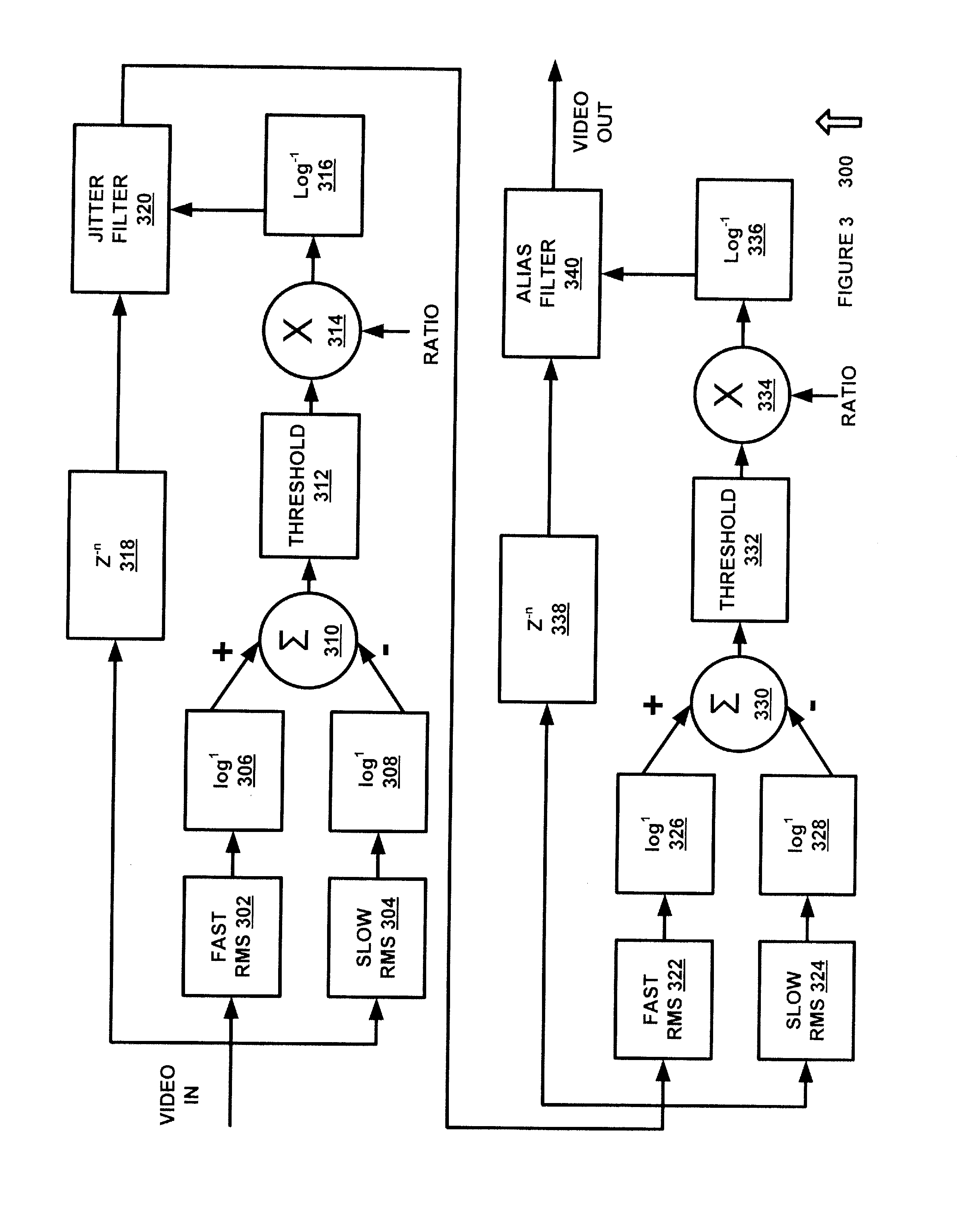

InactiveUS20110164827A1Reduce the amount neededQuality improvementCharacter and pattern recognitionDigital video signal modificationPattern recognitionImaging quality

A system for processing video data to improve image quality at low data rates comprising an encoder generating an entropy signal representing the relative entropy of the video data and a plurality of filters each receiving the entropy signal and a threshold setting and filtering the video data if the entropy signal is greater than the threshold setting.

Owner:VISIV TECH

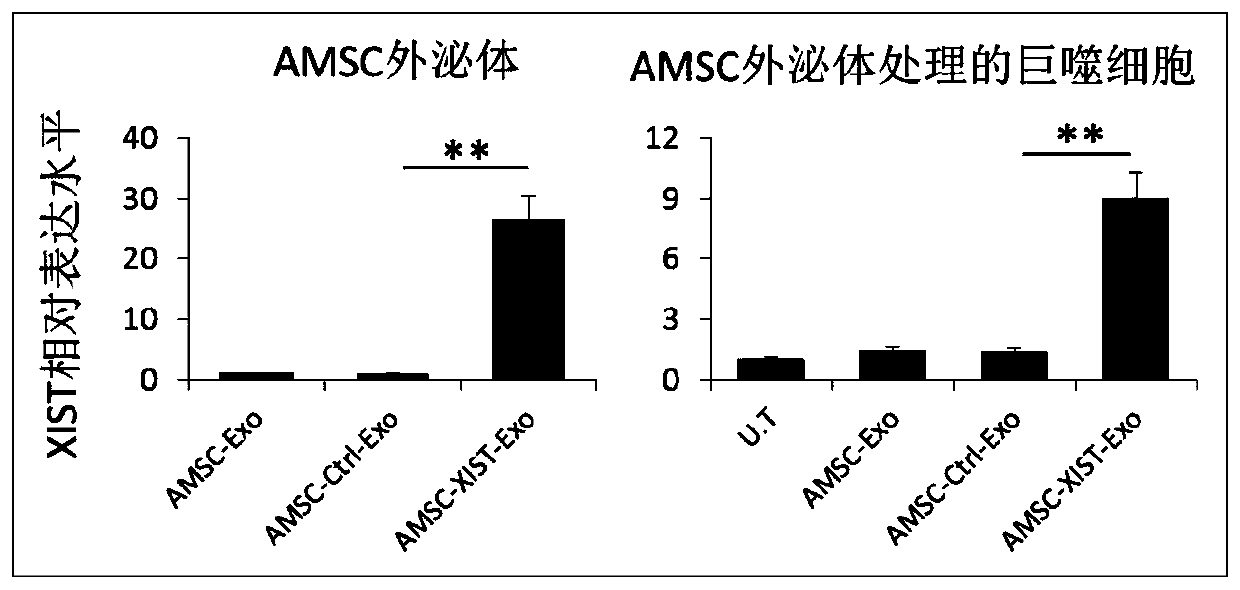

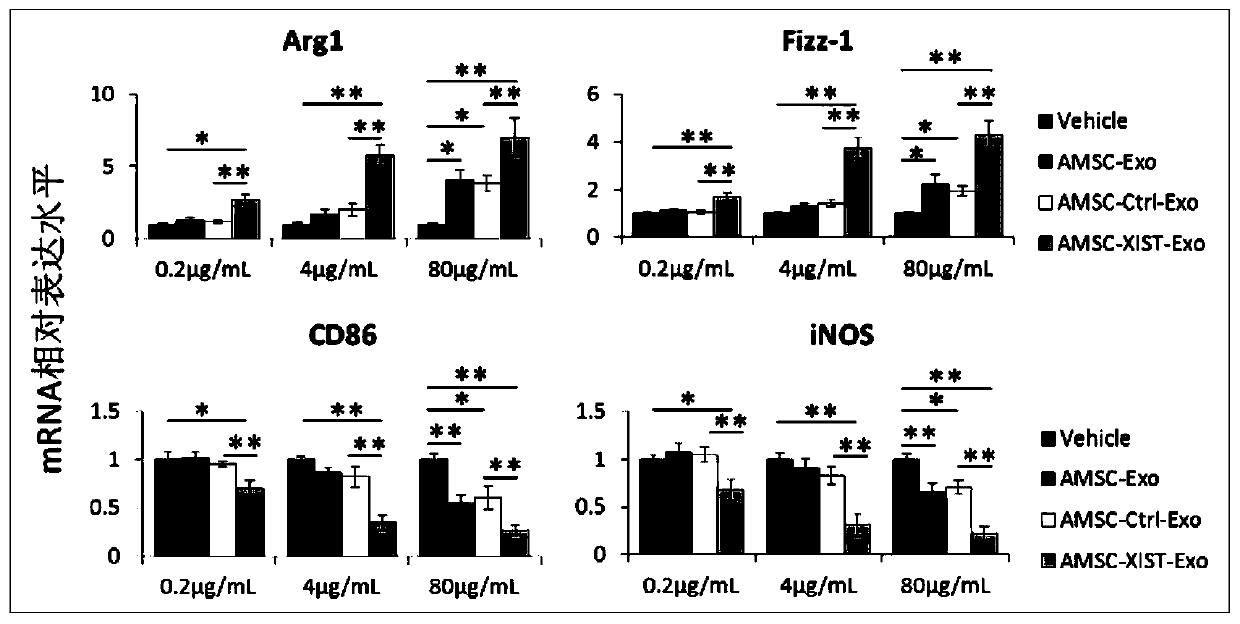

Preparation and application of XIST-modified adipose-derived mesenchymal stem cell exosomes

ActiveCN109735570AGreat application potentialSmall doseDigestive systemUnknown materialsDiseaseCurative effect

The invention provides preparation and application of XIST-modified adipose-derived mesenchymal stem cell exosomes. By constructing an XIST-modified AMSC, preparing the exudates thereof, and determining the regulation advantage of the AMSC-XIST-Exo on the functional phenotype of the macrophage at a cell level through experiments such as ELISA, WB, streaming and the like, through in vivo experiments, the curative effect of the XIST-modified AMSC-derived exosomes on liver diseases and the effect advantage of the XIST-modified AMSC-derived exosomes on regulating the functional phenotype of livermacrophages are determined. The effective dosage of AMSC-XIST-Exo can be as low as 1 mg / kg. The XIST-modified adipose-derived mesenchymal stem cell exosomes greatly reduces the dose (reduced by tensof times) required by exosol treatment, and improves the application potential of AMSC-Exo and even MSC-Exo in the clinical treatment of liver diseases.

Owner:ZHEJIANG UNIV

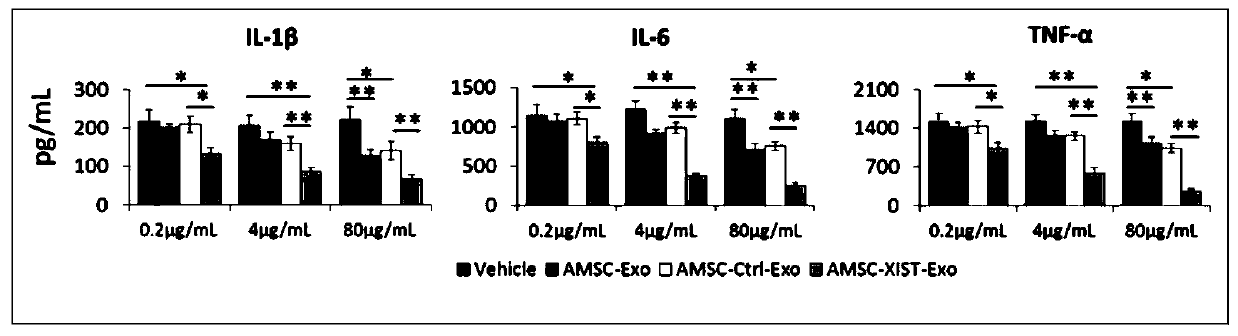

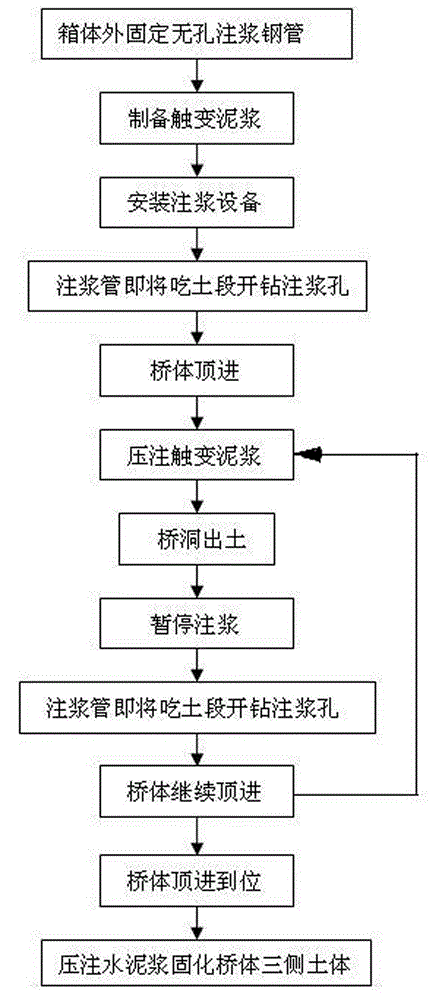

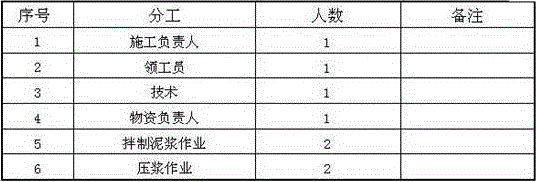

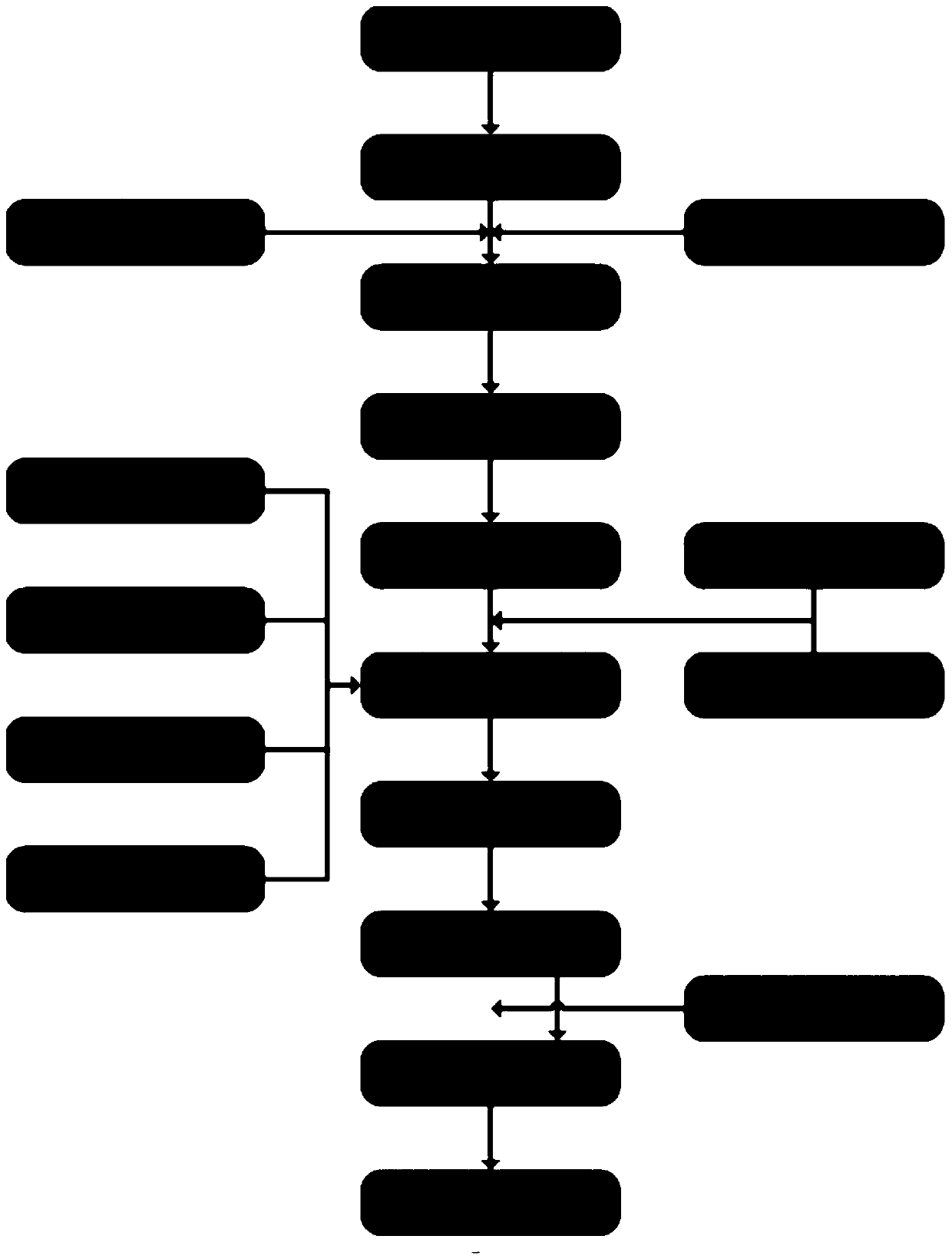

Construction method for following up and injecting thixotropic slurry outside box body in pipe roofing supporting and pushing construction

The invention discloses a construction method for following up and injecting thixotropic slurry outside a box body in pipe roofing supporting and pushing construction, and belongs to the technical field of bridge and culvert construction. The method comprises the following steps: fixing a slurry injection pipe without holes outside a box body; preparing thixotropic slurry; mounting slurry ejection equipment; drilling an slurry injection hole in a soil immersion section of the slurry ejection pipe; jacking the box body; performing pressure injection on the thixotropic slurry; discharging soil of a culvert; suspending slurry injection; drilling the slurry injection hole in the soil immersion section of the slurry ejection pipe, continuously jacking the box body, and circulating the subsequent processes till the box body is jacked to a proper position; performing pressure injection on cement past to solidify the soil bodies on three sides of the box body. The method solves the problems that in the prior art, the quantity of slurry injection pipe connectors is large, a large quantity of conveying pipes are required, the construction technology is relatively complex, the construction period is relatively prolonged, and the construction cost is high.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

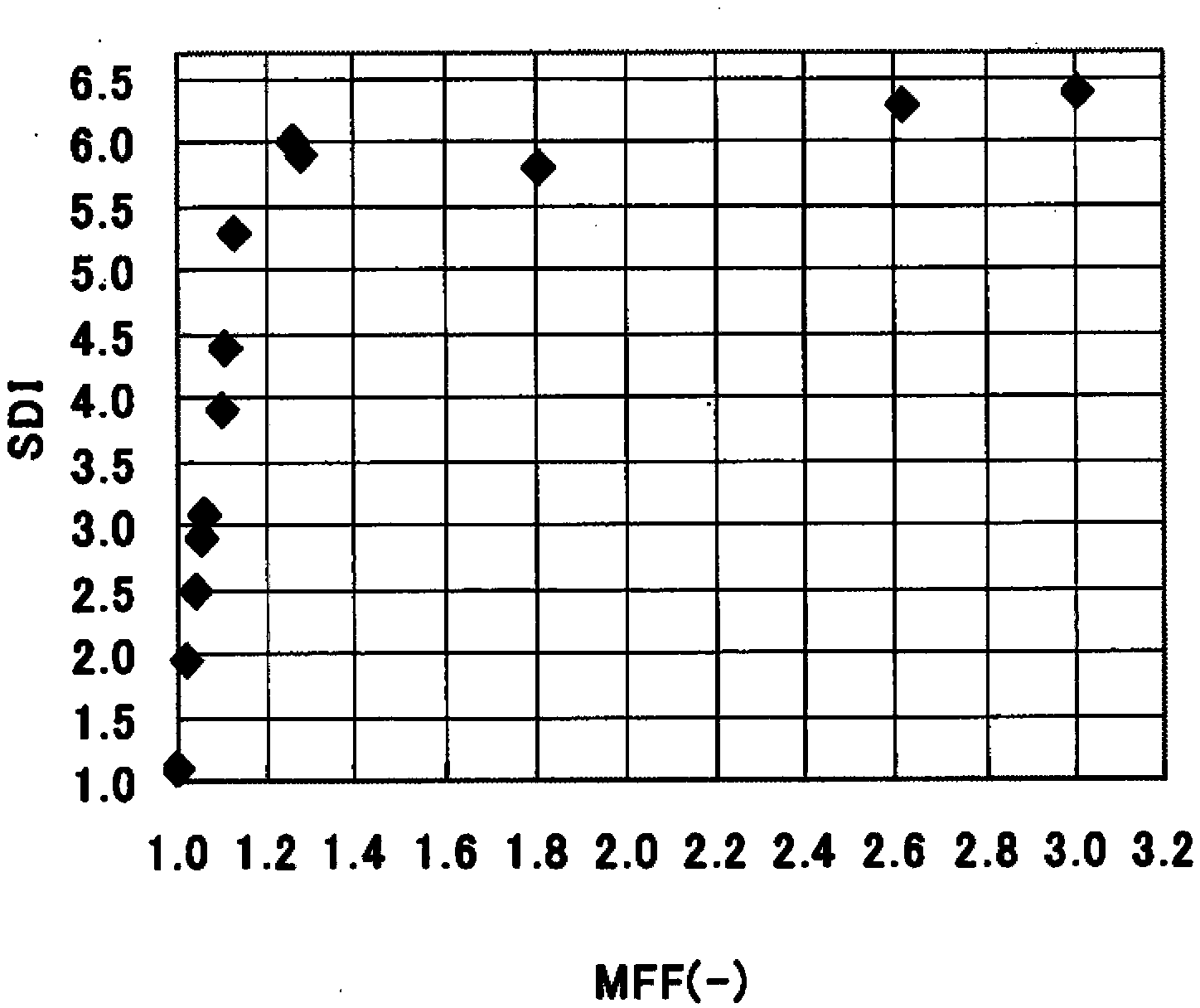

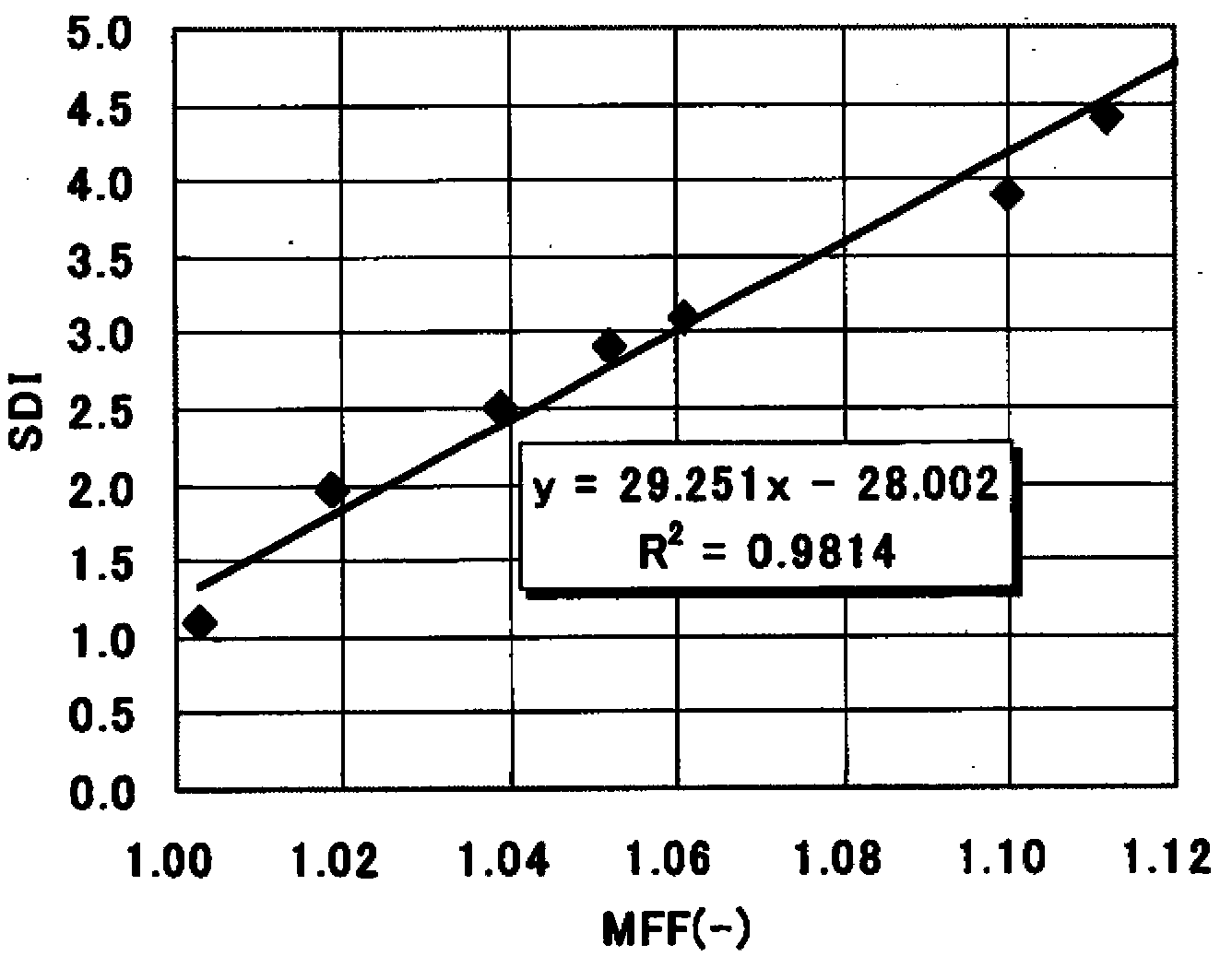

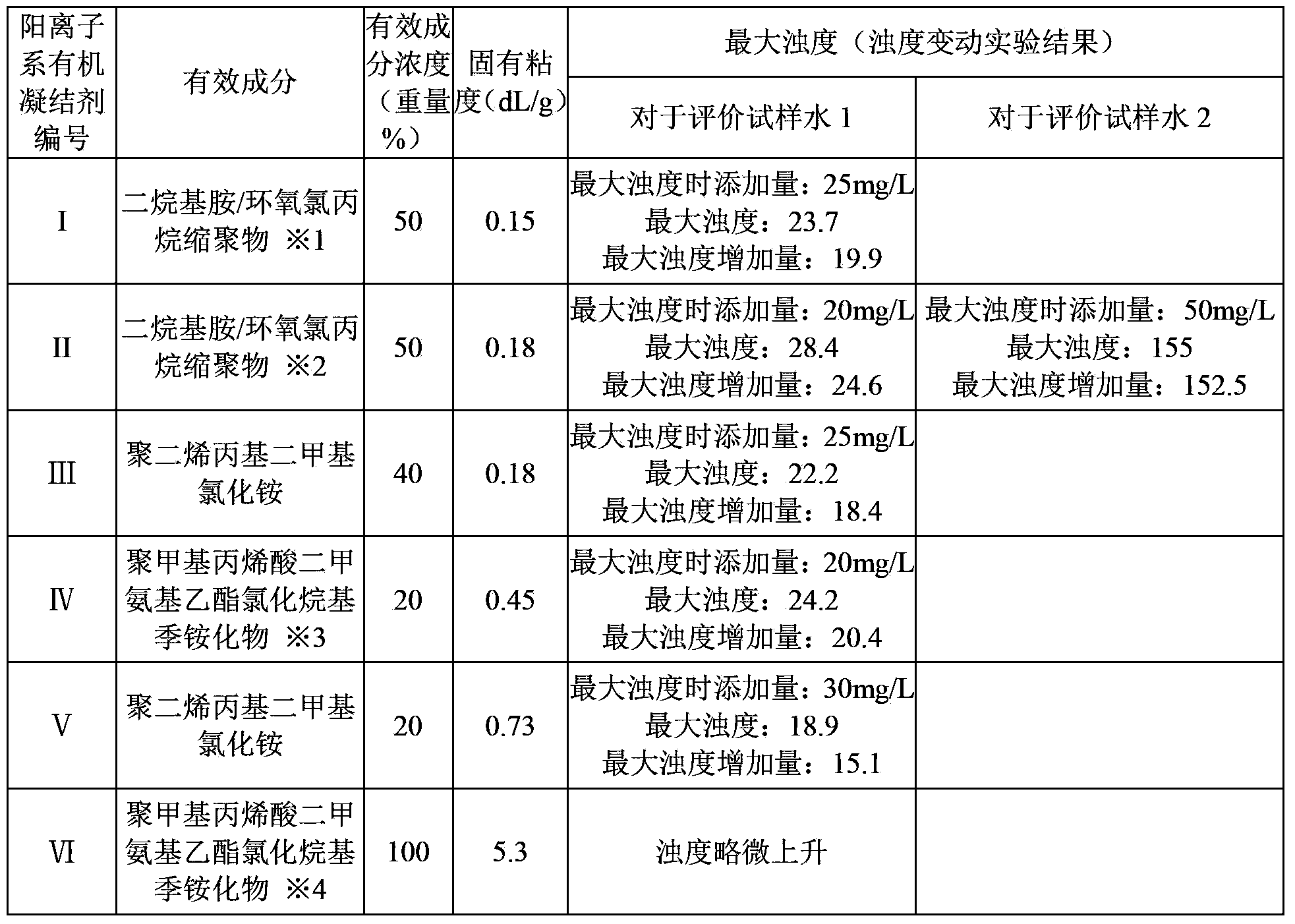

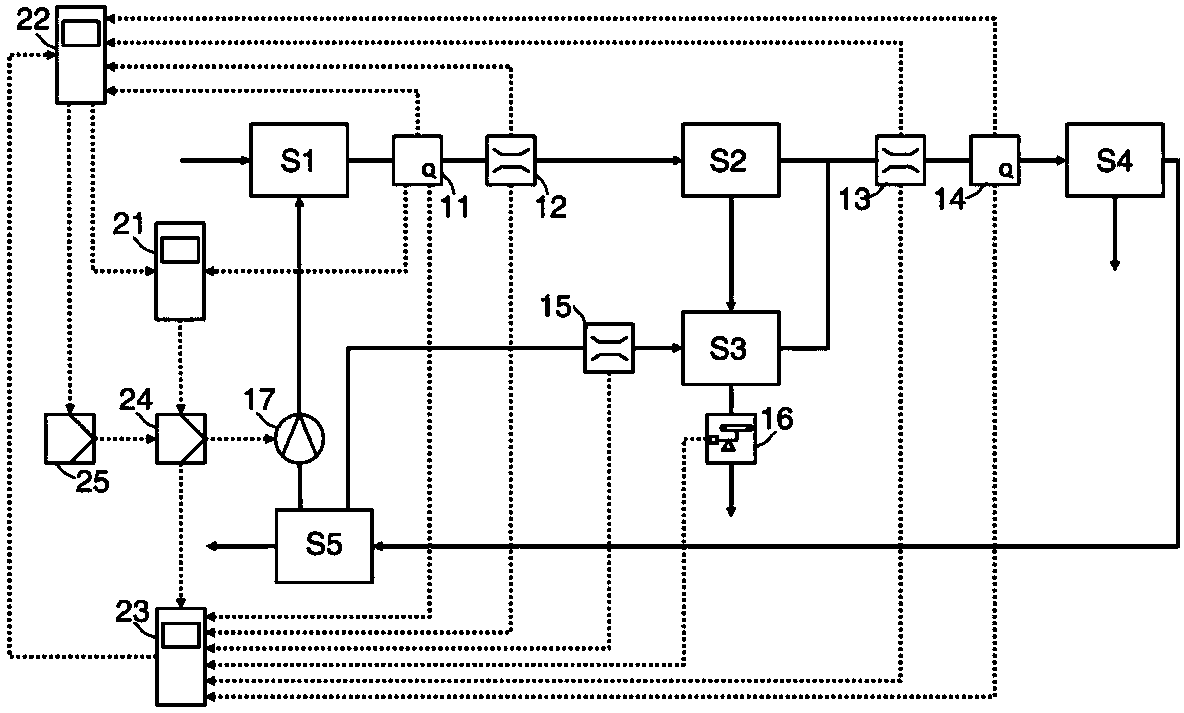

Treatment method and treatment device of discharge water of cooling water

ActiveCN103508532AReduce the amount neededWill not increase the occurrenceWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by flocculation/precipitationFiltrationCombined use

When agglutination treatment and filtration treatment are adopted as a pretreatment system of reverse osmosis membrane separation treatment to recycle water, excellent reverse osmosis water supply is obtained through reduction of demand of inorganic agglutinants in the agglutination treatment, and treatment which is continuously stable and effective for a long time is performed. Positive ion series organic agglutinants and inorganic agglutinants whose intrinsic viscosity is lower than 0.5 dL / g are added in the discharge water of cooling water, so as to perform agglutination treatment. In the agglutination treatment of the discharge water of the cooling water, through combining use of the positive ion series organic agglutinants and inorganic agglutinants, excellent reverse osmosis water supply is obtained on the basis that the demand for the inorganic agglutinants is reduced.

Owner:KURITA WATER INDUSTRIES LTD

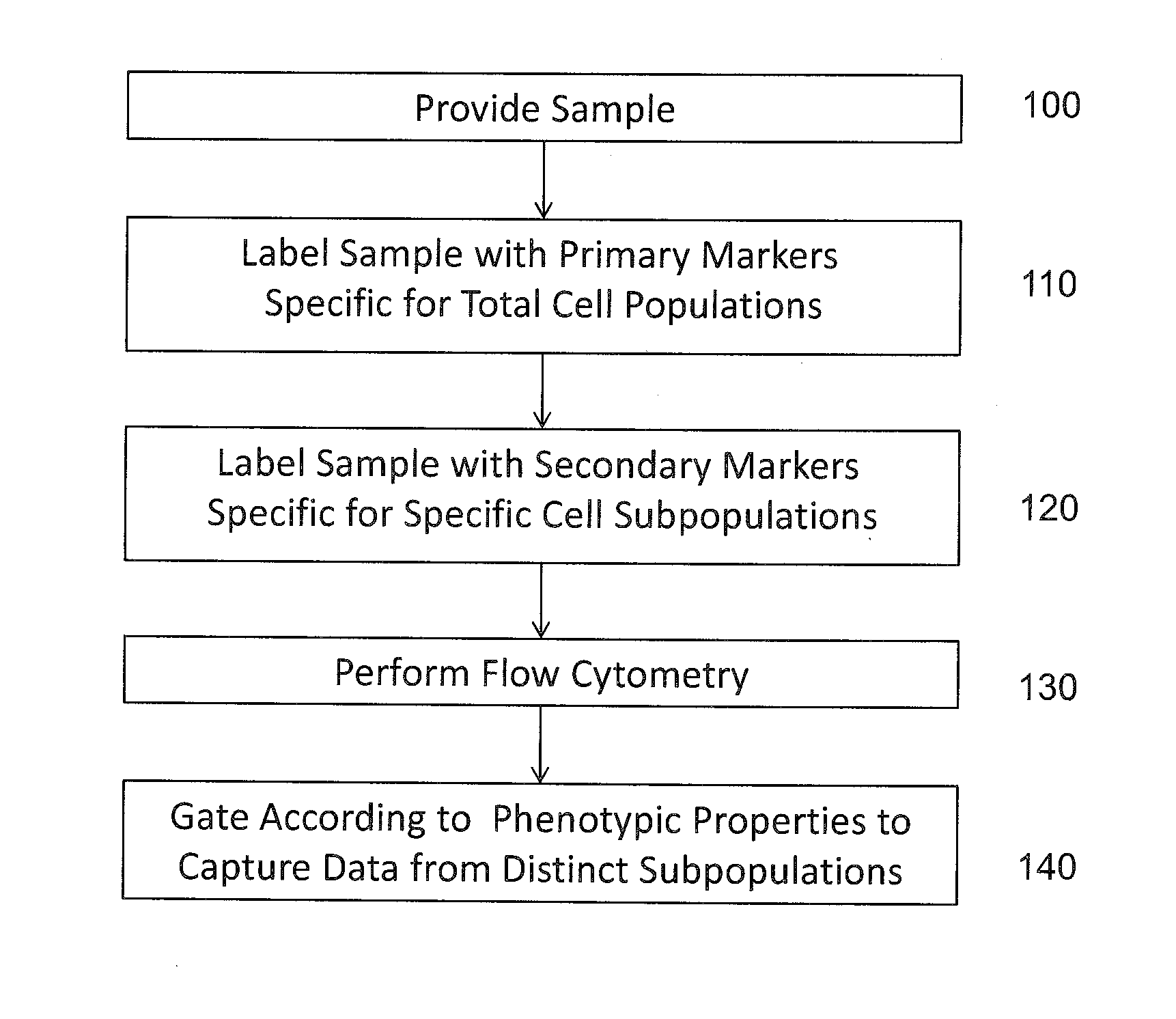

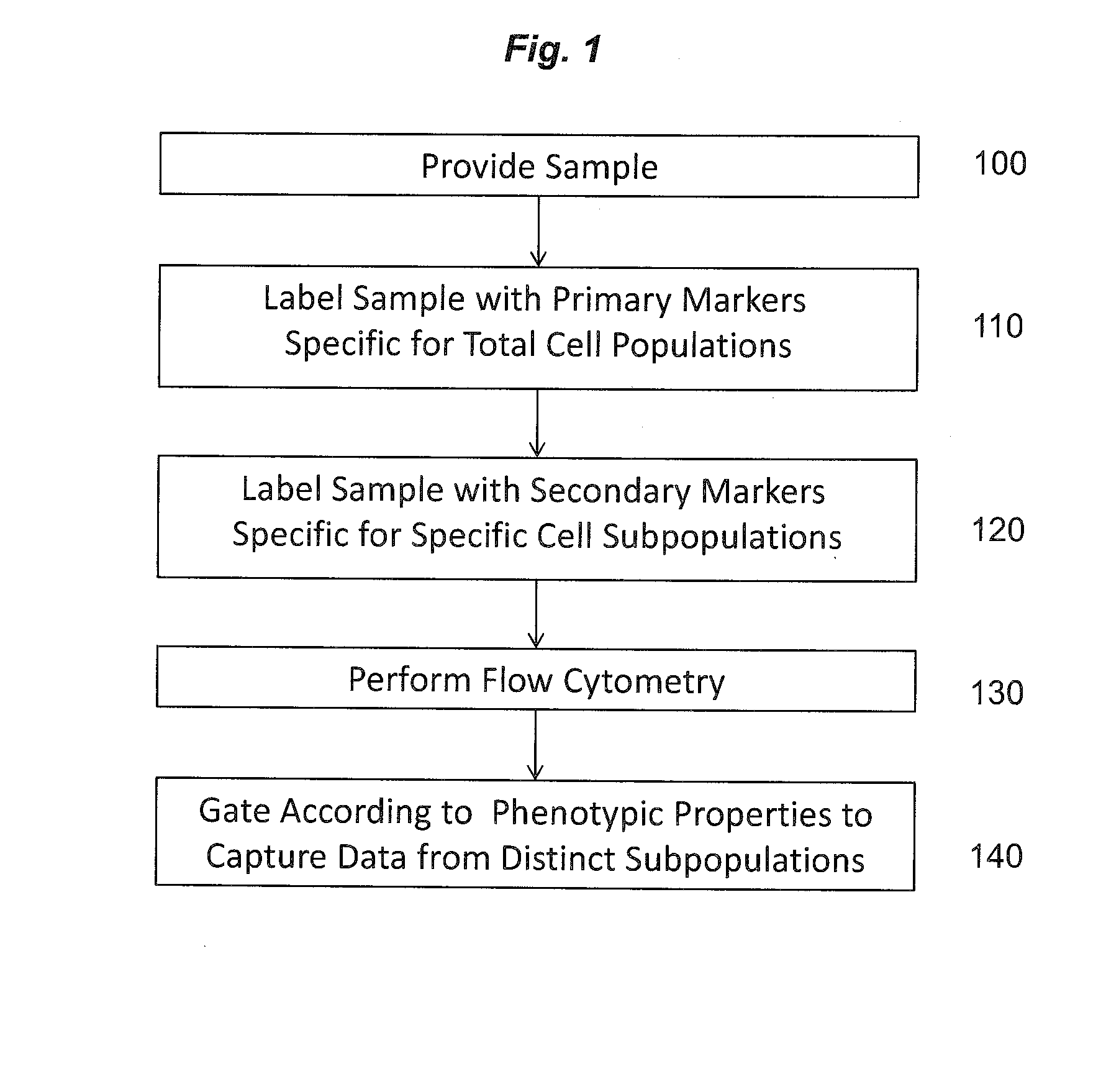

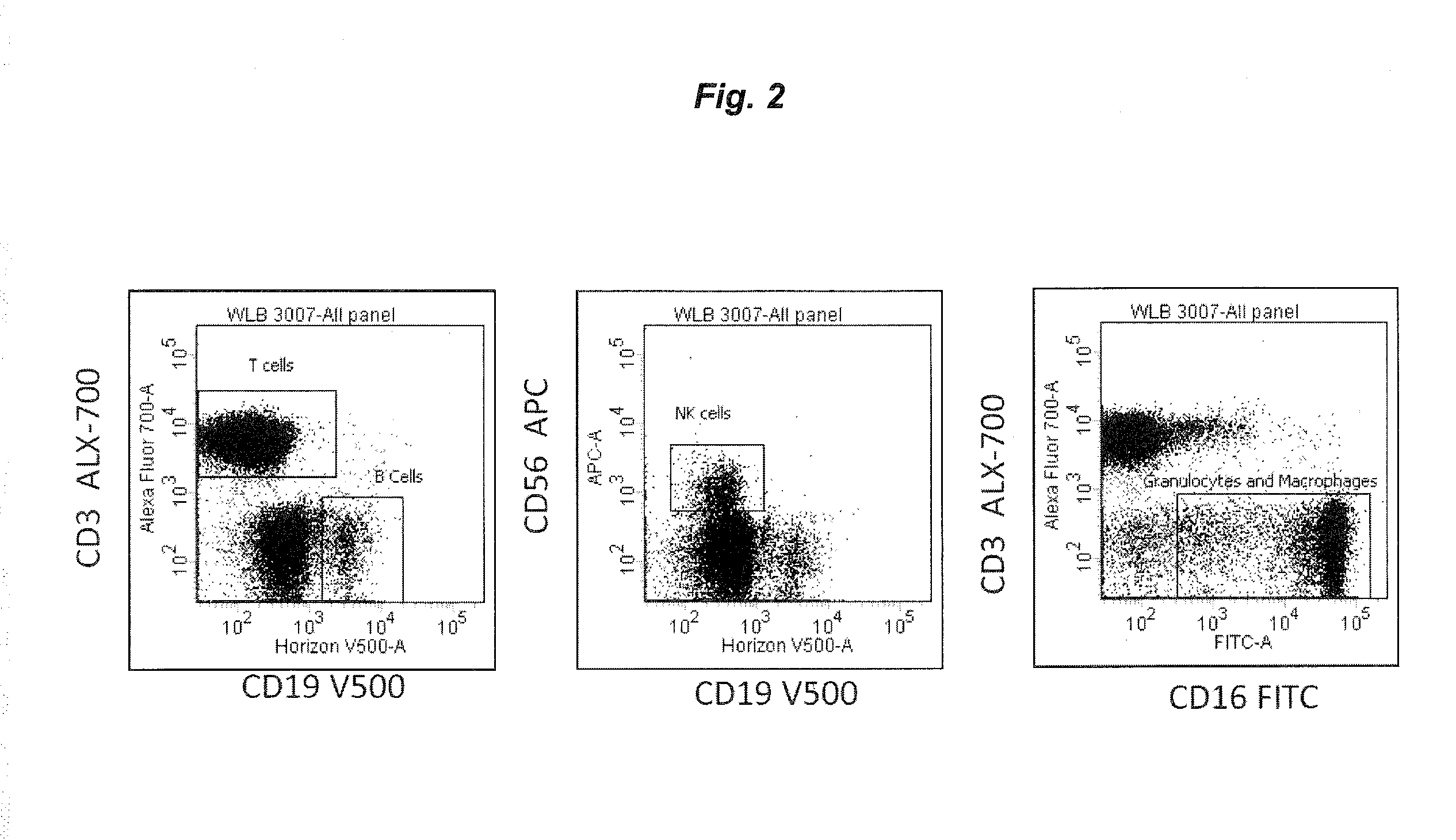

Data analysis methods utilizing phenotypic properties

InactiveUS20140349313A1Broaden their knowledgeReduce the amount neededBioreactor/fermenter combinationsBiological substance pretreatmentsSub populationsCell based

The present invention provides a method of identifying sub-populations of cells in a cellular sample. Aspects of the method include categorizing cells of the cellular sample into at least a first and second population based on a first phenotypic property. The method may further include sub-categorizing each of the first and second population into sub-populations of cells based on a second and third phenotypic property, e.g., by using X detectable labels providing Y distinct signals, wherein X>Y, to identify sub-populations of cells in the cellular sample.

Owner:BECTON DICKINSON & CO

Sunscreen composition comprising a thickening system, having improved water-resistance

InactiveUS20150216782A1Reduce the amount neededIncrease ratingsCosmetic preparationsToilet preparationsPolymer scienceSunscreen agents

One aspect of the invention relates to a sunscreen composition comprising at least one sunscreen agent, at least one film forming polymer, at least one solvent, and at least one thickening agent, wherein said thickening agent is present in an amount in the range of 0.01-0.2%(w / w). Another aspect of the present invention relates to the use of a thickening agent for increasing the sun protection factor of a sunscreen composition comprising at least one sunscreen agent, at least one film forming polymer, and at least one solvent. Yet another aspect of the present invention relates to a process for the manufacture of a sunscreen composition comprising the steps of i) providing at least one solvent, at least one thickening agent, at least one film forming polymer and at least one sunscreen agent, ii) admixing the components of step i) to provide a sunscreen composition. The sunscreen compositions of the invention have an improved water-resistance.

Owner:RIEMANN TRADING

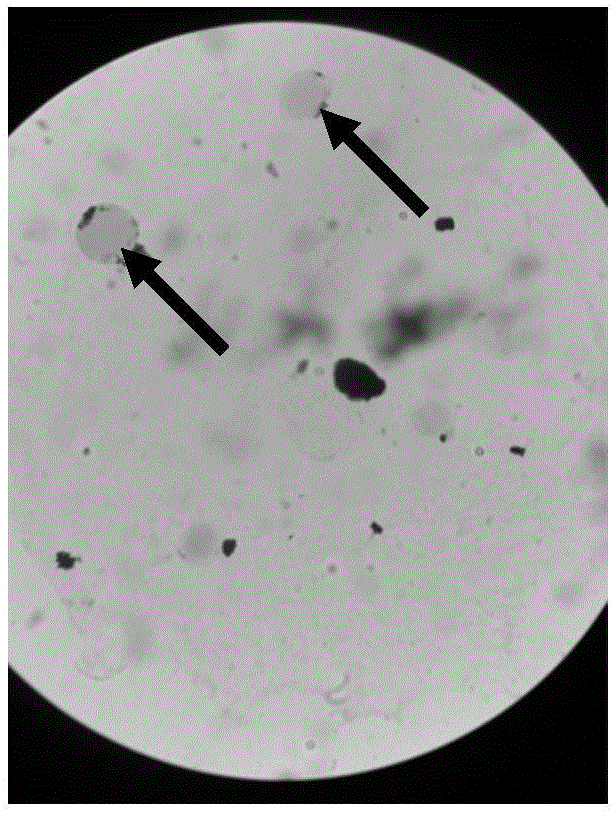

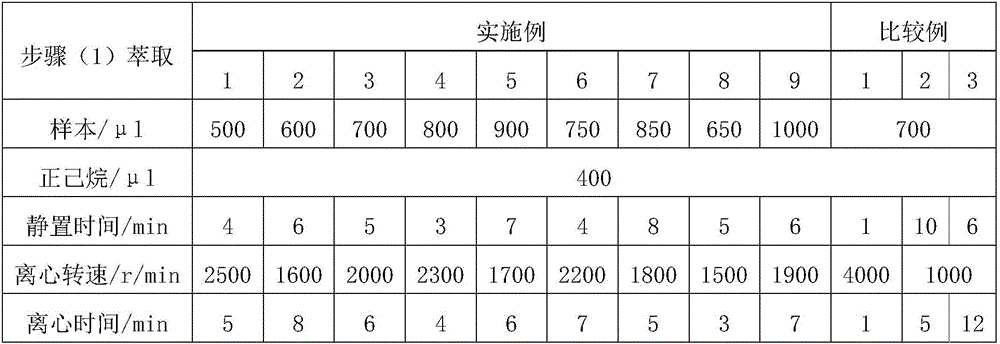

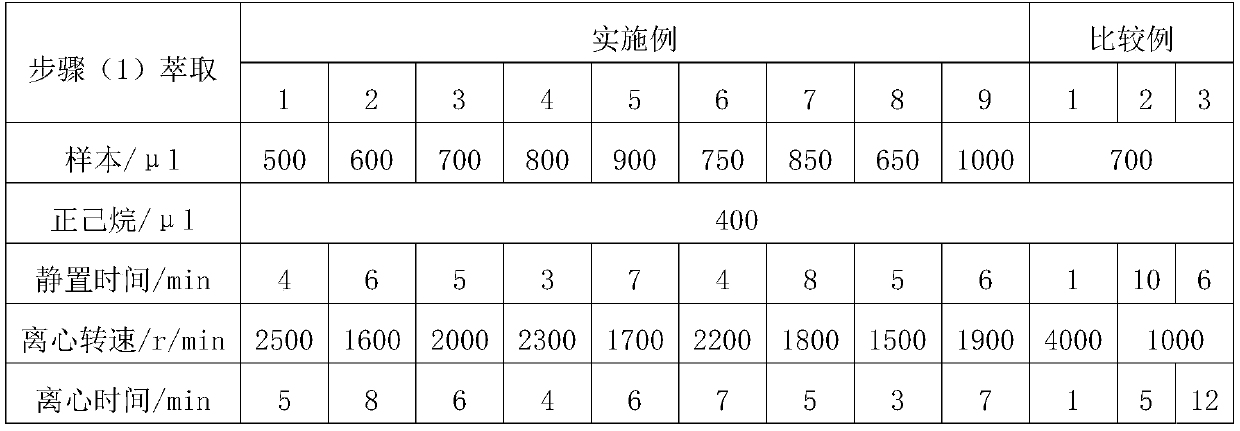

Method and kit for qualitatively detecting chyle

ActiveCN106442275AReduce the amount neededReduce usagePreparing sample for investigationIndividual particle analysisPresent methodChyle

The invention discloses a method and a kit for qualitatively detecting chyle. The kit comprises a reagent part, a consumable part and a specification, wherein normal hexane is taken as extract liquor of the reagent part. The method comprises the following steps: extracting a sample with normal hexane, dyeing and observing. According to the method and the kit provided by the invention, a common reagent for food inspection, namely, normal hexane is taken as the extract liquor, the required quantity ratio of the sample to the extract liquor is reduced by 5-10 times of the required quantity ratio according to a present method, and the pollution of the reagent to the laboratory environment is reduced. Through 153 real samples in two years, normal hexane taken as the extract liquor for extracting chyle according to the method disclosed by the invention is confirmed and the accuracy thereof is verified. The method disclosed by the invention has the characteristics of convenience, quickness, high safety, little pollution, and the like, and is worthy of popularization and application.

Owner:THE THIRD MEDICAL CENT OF THE CHINESE PEOPLES LIBERATION ARMY GENERAL HOSPITAL

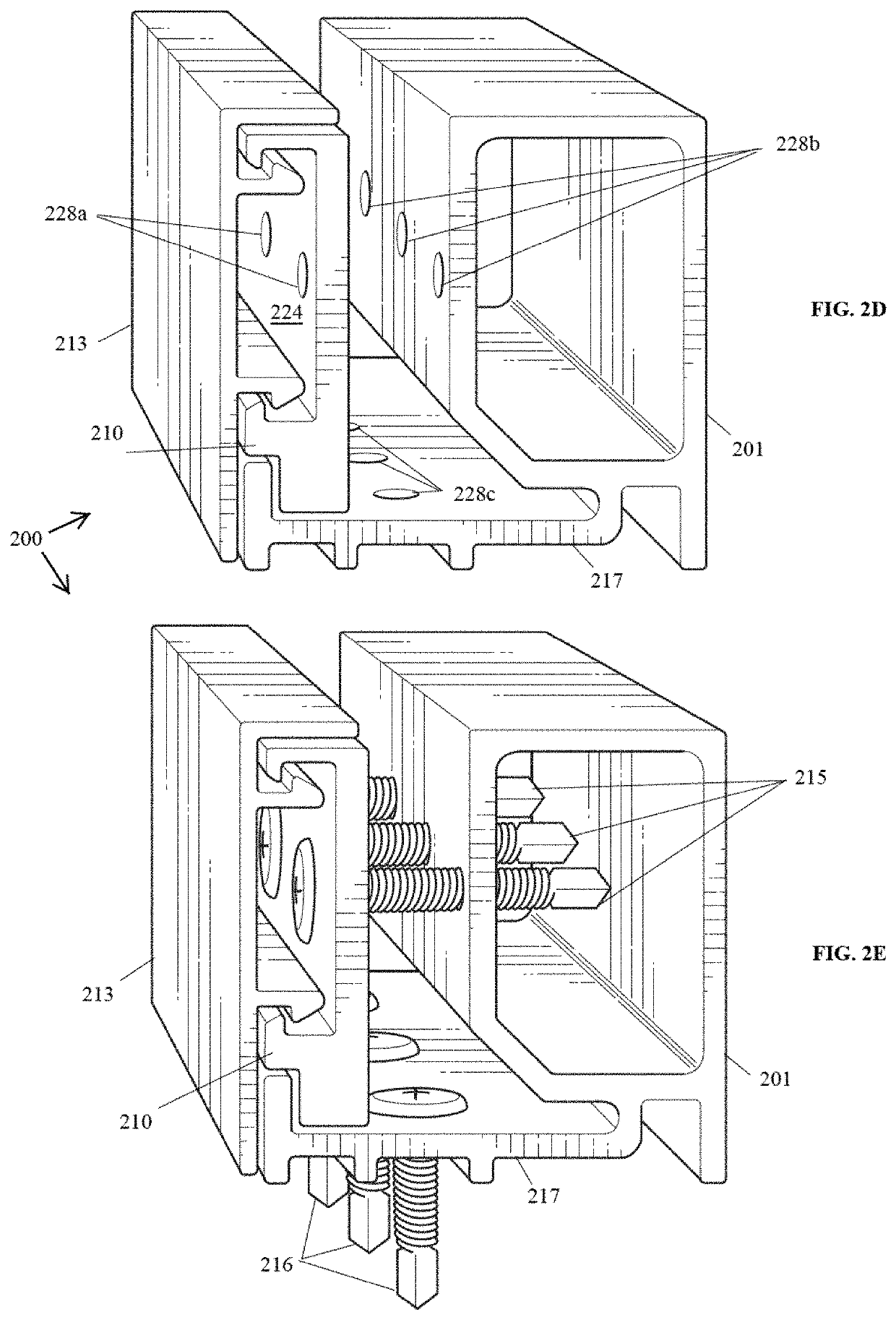

Security panel framing system and method

A security panel framing system adapted to be mounted onto a frame having a glass, the system having: a wedge having: an upper wedge lip; a wedge wall extending between a wedge top side and a wedge bottom side; a reinforced wedge end at the wedge bottom side; and a lower wedge lip; a cap adapted to be associated with the wedge, having: a first prong adapted to fit onto the upper wedge lip; a second prong adapted to fit between the lower wedge lip and the reinforced wedge end; and a return flange; wherein the system is assembled together when the cap is associated with the wedge front side; such that the return flange extends underneath the wedge bottom side; such that the wedge is adapted to be associated with a security panel mounted to the frame, such that the security panel protects the glass within the frame.

Owner:RIOT GLASS LLC

A method and kit for qualitative detection of chyle

ActiveCN106442275BReduce the amount neededReduce usagePreparing sample for investigationIndividual particle analysisPresent methodChyle

The invention discloses a method and a kit for qualitatively detecting chyle. The kit includes a reagent part, a consumable part and an instruction manual. The extraction liquid of the reagent part is n-hexane. The method includes extracting a sample with n-hexane, staining and observation. The method and kit of the present invention screen out a commonly used reagent for food inspection - n-hexane as the extraction liquid. The required amount of sample and extraction liquid is reduced by 5-10 times compared with the existing method, which reduces the impact of the reagent on the laboratory environment. pollute. The method of the present invention has been verified by 153 real samples in two years, and it is determined that n-hexane is used as the extraction agent to extract chyle, and its accuracy is verified; the method of the present invention has the characteristics of convenience, high safety, low pollution, etc., and has the value of promotion and application .

Owner:THE THIRD MEDICAL CENT OF THE CHINESE PEOPLES LIBERATION ARMY GENERAL HOSPITAL

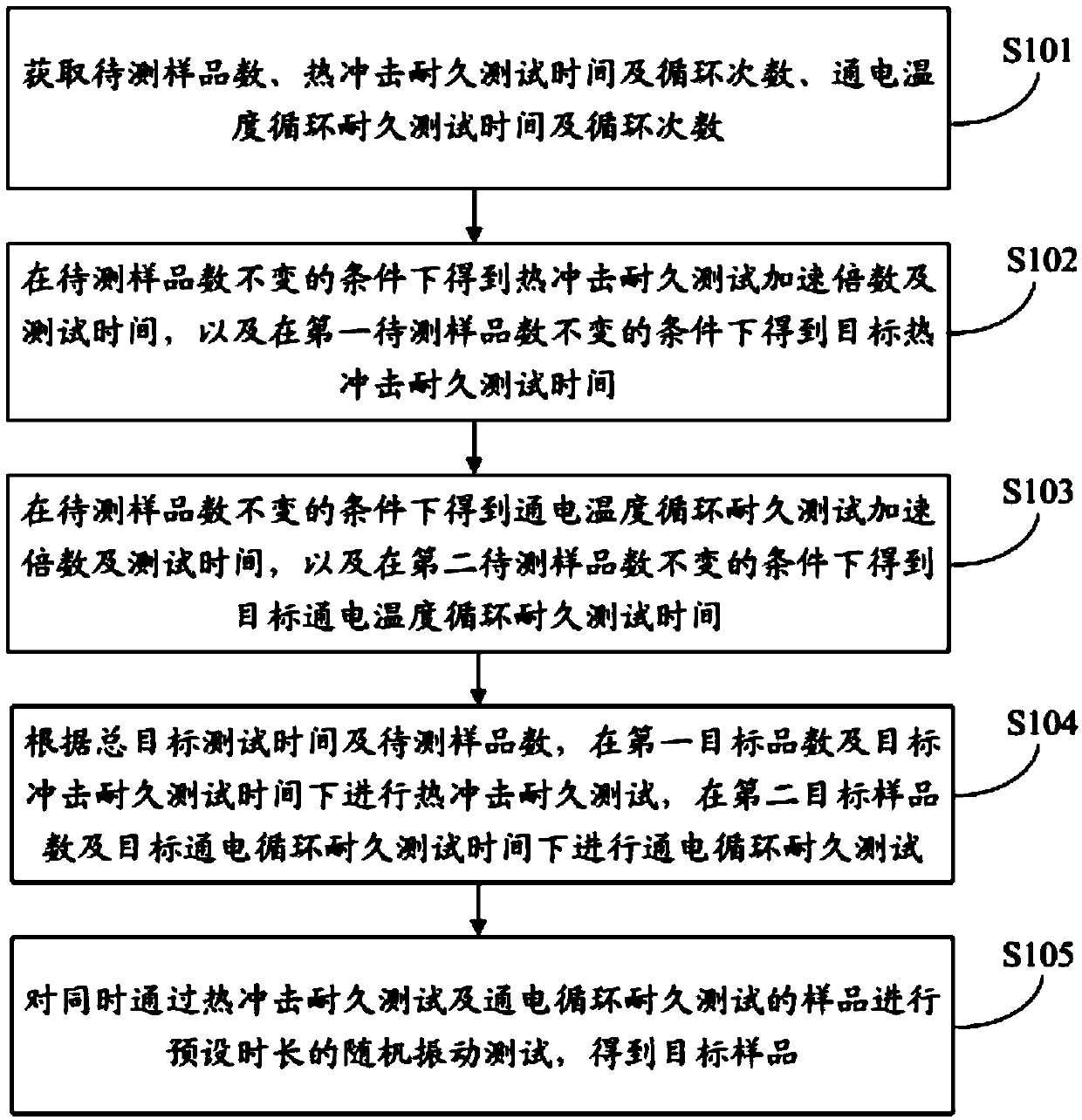

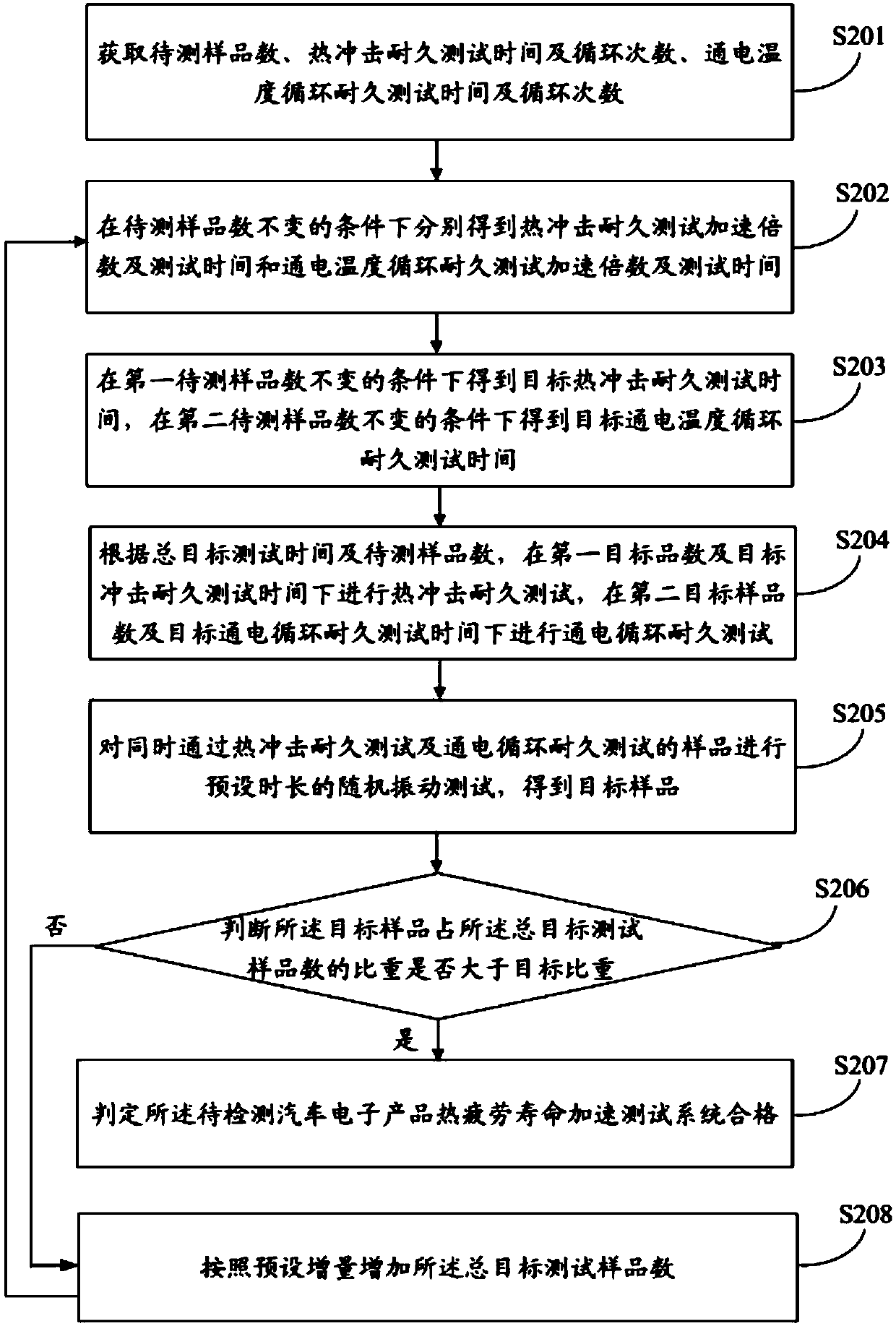

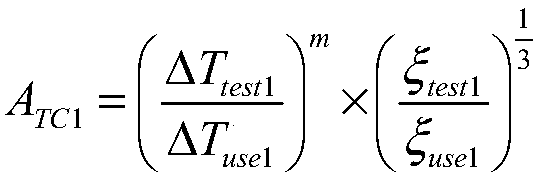

Automotive electronic product thermal fatigue service life accelerated testing method

ActiveCN109655683AReduce the number of cyclesShorten test timeEnvironmental/reliability testsVibration testingThermal impactThermal fatigue

The invention discloses an automotive electronic product thermal fatigue service life accelerated testing method which comprises the steps of respectively obtaining thermal impact durability testing acceleration times, testing time, energization temperature cycle durability testing acceleration times and testing time in a condition of no number change of to-be-tested samples; obtaining the targetthermal impact durability testing time in a condition of no number change of first to-be-tested samples, and obtaining target energization temperature cycle durability testing time on the condition ofno number change of second to-be-tested samples; performing thermal impact durability testing on the condition of the first target sample number and the target impact durability testing time, and performing energization cycle durability testing on the condition of the second target sample number and the target energization cycle durability testing time; and performing preset-time-length random vibration testing on the samples which pass the thermal impact durability testing and energization cycle durability testing, and obtaining the target sample. The method according to the invention can reduce the number of cycle times, testing time length and required amount of testing samples in existing automotive electronic product testing.

Owner:GUANGZHOU GRG METROLOGY & TEST CO LTD +1

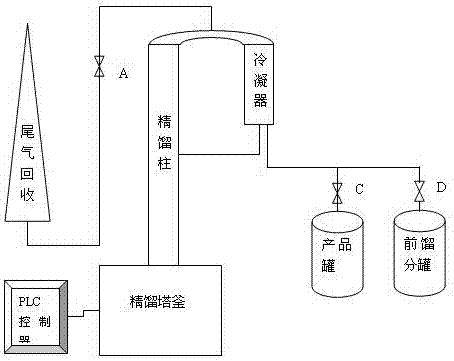

Distillation process of metal organic source

InactiveCN107118227AImprove separation efficiencyReduce the amount neededDistillation regulation/controlGroup 3/13 element organic compoundsRefluxSimple Organic Compounds

The invention provides a rectification process of metal-organic sources. Controlled by PLC, the rectification process of gradient temperature rise, intermittent heat-following total reflux, impurity removal, front fraction collection and product collection is completed. It has wide applicability and most metal-organic sources Compound purification, as long as the crude product contains impurity components with a lower boiling point than the product, it is applicable to this process condition; the invention effectively improves the separation efficiency of impurities in the rectification process, reduces the required amount of the fraction before containing impurities, and improves the efficiency of single rectification. The yield is 3-15%; the degree of automation is high, which greatly reduces the required workload, which is helpful to reduce the cost of the enterprise and control the process stability.

Owner:安徽亚格盛电子新材料有限公司

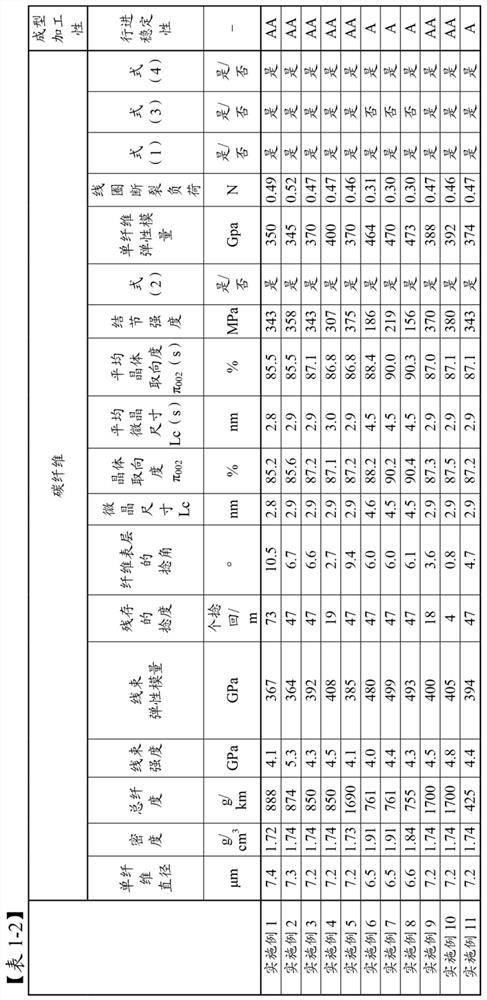

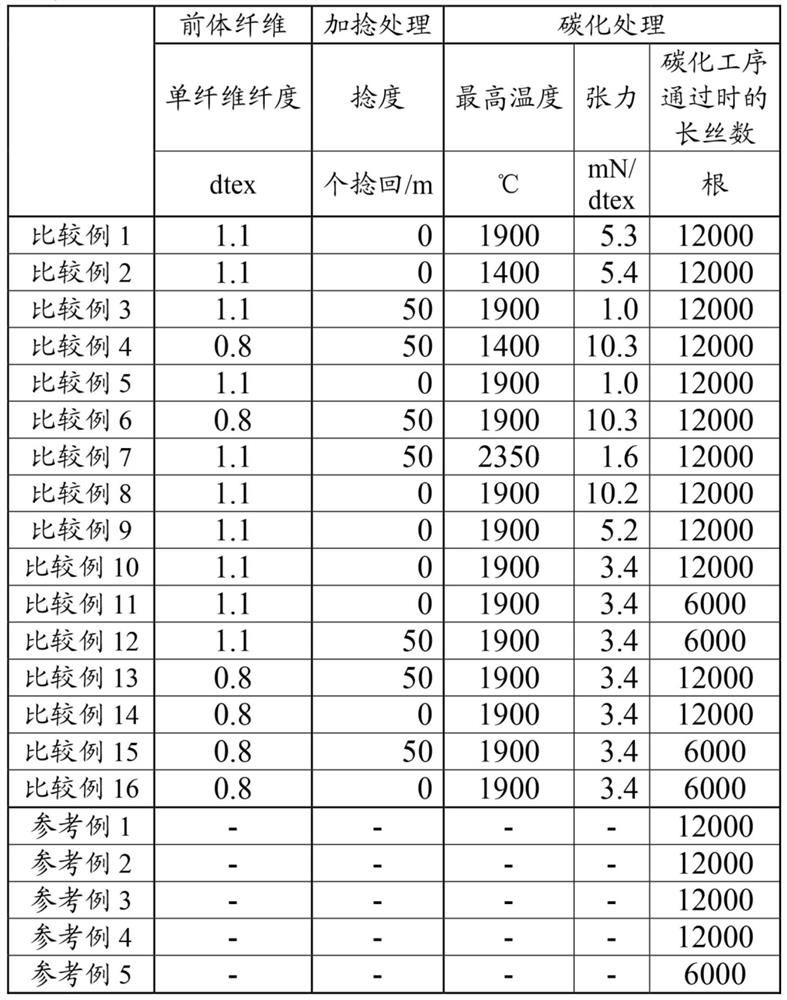

Carbon fiber and method for producing same

ActiveCN112368432AExcellent tensile modulusExcellent formabilityMonocomponent synthetic polymer artificial filamentPolymer scienceFiber bundle

The present invention addresses the problem of providing a carbon fiber for a carbon fiber reinforced composite material which is not easily damaged during a molding process and exhibits an excellentelastic modulus. The carbon fiber has a strand elastic modulus of at least 360 GPa, a strand strength of at least 3.5 GPa, and a single fiber diameter of at least 6.0 [mu]m, and satisfies one or moreof the requirements below. (A) When one end is a fixed end and the other end is a free end that can rotate about the axis of a fiber bundle, the remaining twist number is at least 2 turns / m. (B) The total fineness, which is the product of the single fiber fineness (g / km) as a carbon fiber and the number of filaments (counts), is at least 740 g / km. In addition, the single fiber elastic modulus Es (Gpa) and the loop breaking load A (N) of the carbon fiber satisfy the relationship of expression (1). (1): A>=-0.0017*Es+1.02. Furthermore, the single fiber diameter of the carbon fiber is at least 6.0 [mu]m, the relationship between the strand elastic modulus E (GPa) of the carbon fiber and the knot strength B (MPa) of the carbon fiber as evaluated at a heating loss rate of 0.15% or less at 450 DEG C satisfies expression (2), and the twist number of the carbon fiber is 20-80 turns / m. (2): B>= 6.7*109*E-2.85.

Owner:TORAY IND INC

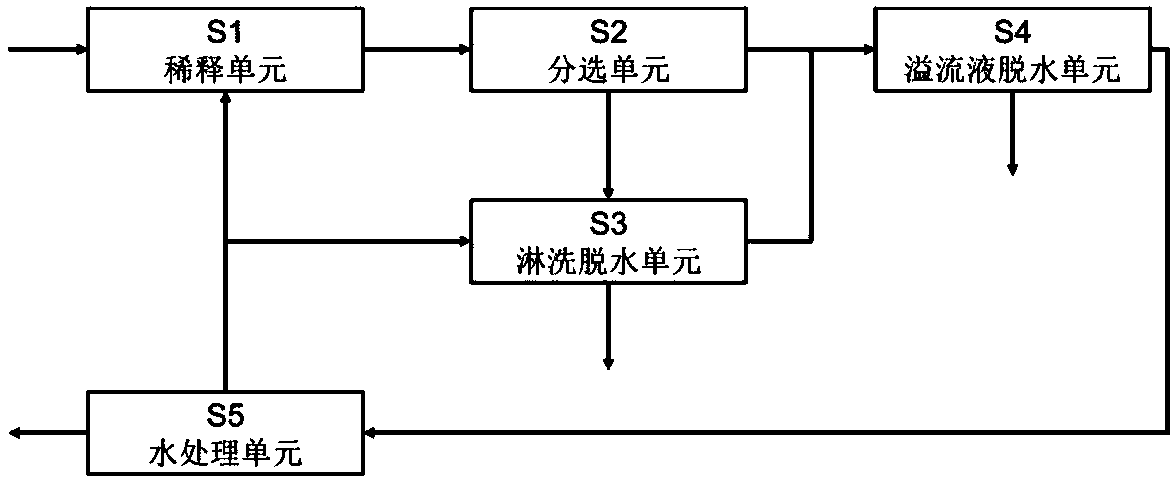

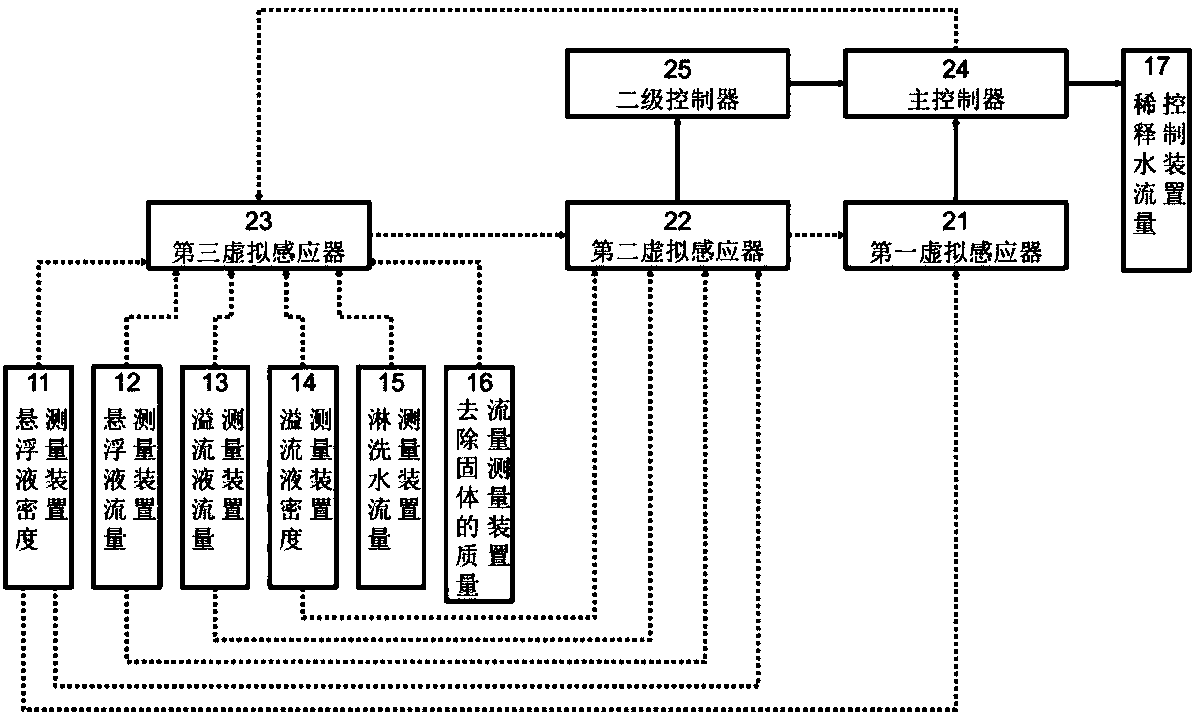

Treatment system and treatment method of solid-liquid mixture

ActiveCN108083362AImprove removal efficiencyImprove separation efficiencyWater treatment parameter controlWater contaminantsSolid massMedicine

The invention provides a treatment system and a treatment method of a solid-liquid mixture. The treatment method comprises the following steps: adding water in the solid-liquid mixture for diluting, thus obtaining a suspension solution; sorting the suspension solution, thus obtaining a sorted overflow solution and sorted granules; adding leaching water into the sorted granules for leaching, and dehydrating, thus obtaining a leached overflow solution and a removed solid body, wherein the removed solid body can be recycled after leaching and dehydrating; dehydrating the sorted overflow solutionand the leached overflow solution, thus obtaining filtrate and dehydrated residue, wherein the filtrate can be treated in a water treatment stage; controlling the flow of diluted water according to aset value of diluted solid mass fraction, total solid mass fraction, organic matter mass fraction and residual solid mass fraction after a sorting stage. By adopting the technical scheme of the invention, the water consumption for diluting is optimized, so that the stability and the effectiveness of the whole technology are increased, and the total demand for process water is reduced.

Owner:柏中环境科技(上海)股份有限公司 +2

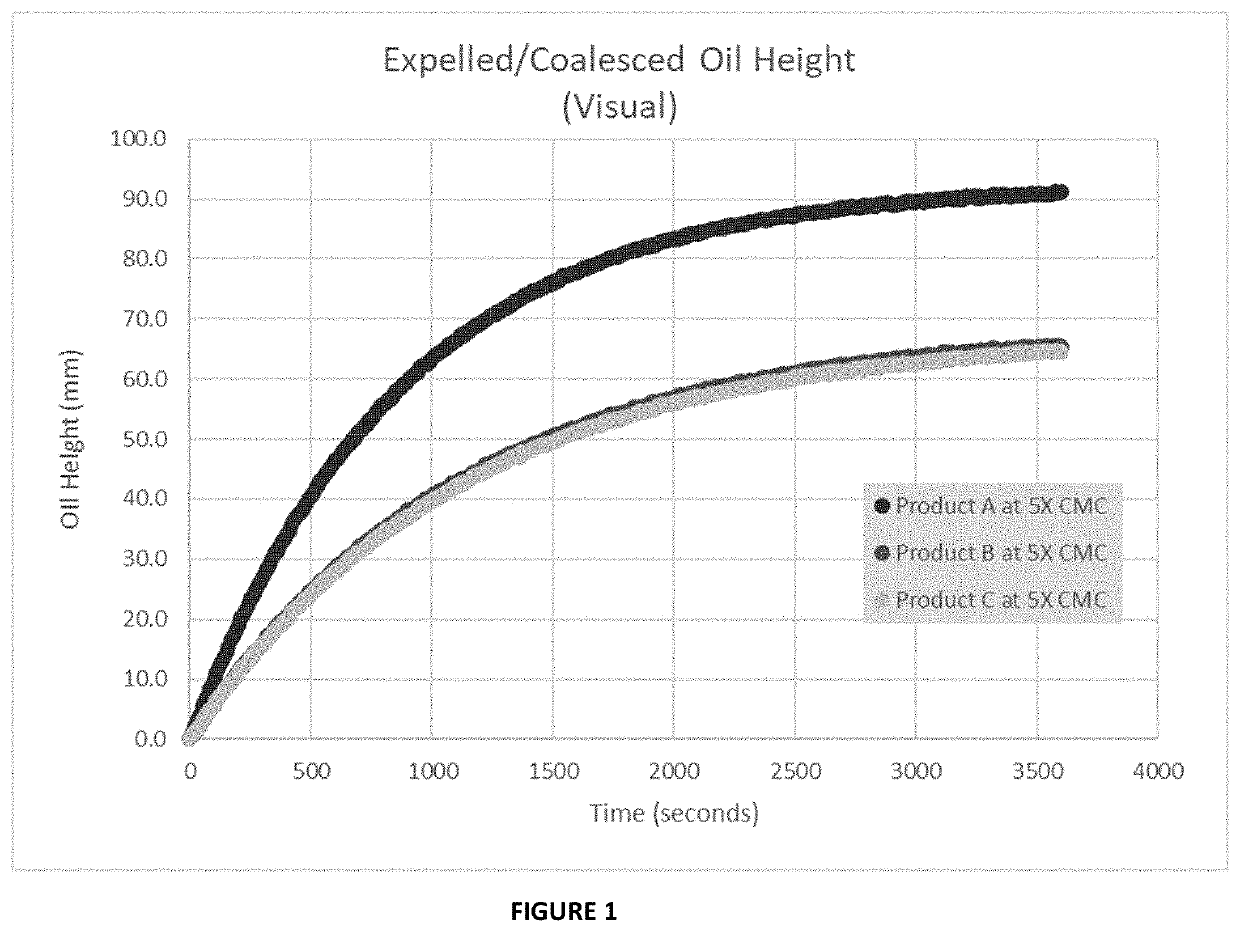

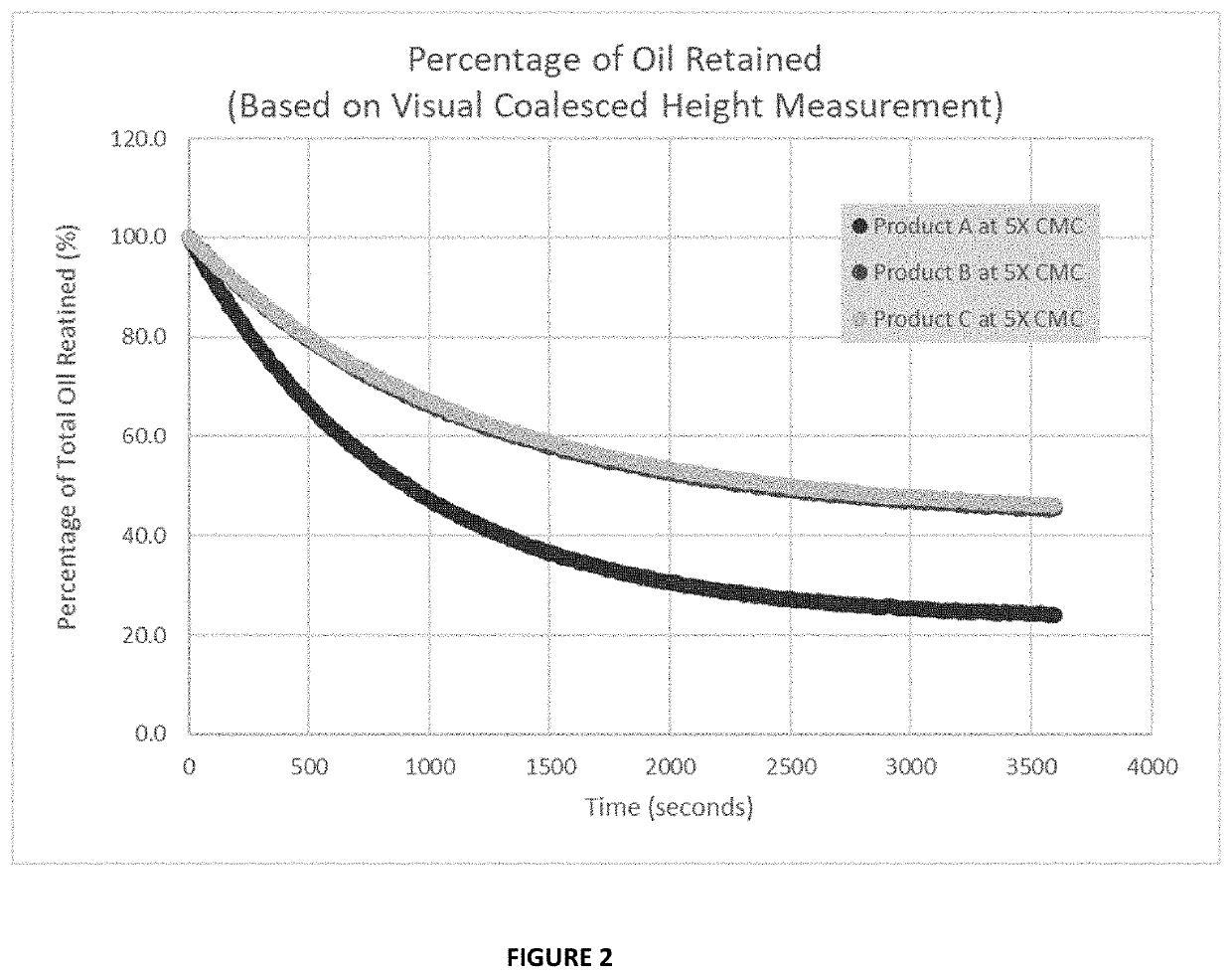

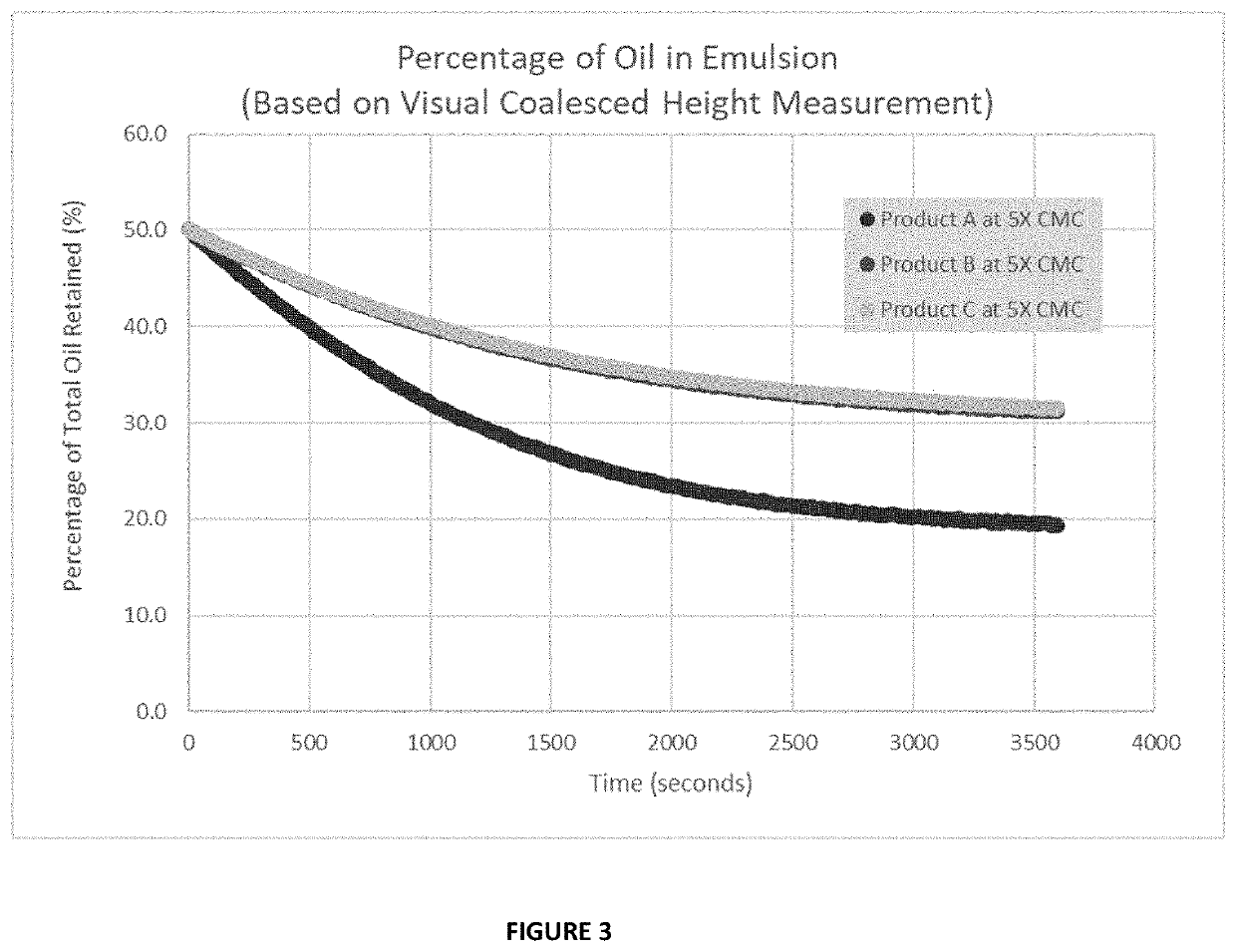

Compositions and methods for enhancing efficiencies of microbial-derived biosurfactants

ActiveUS11220699B1CMC valueLow surfactant concentrationHydrolasesFermentationBiotechnologyMicroorganism

Disclosed herein are compositions comprising a sophorolipid surfactant and a bio-synergist and the methods of using the same.

Owner:ADVANCED BIOCATALYTICS

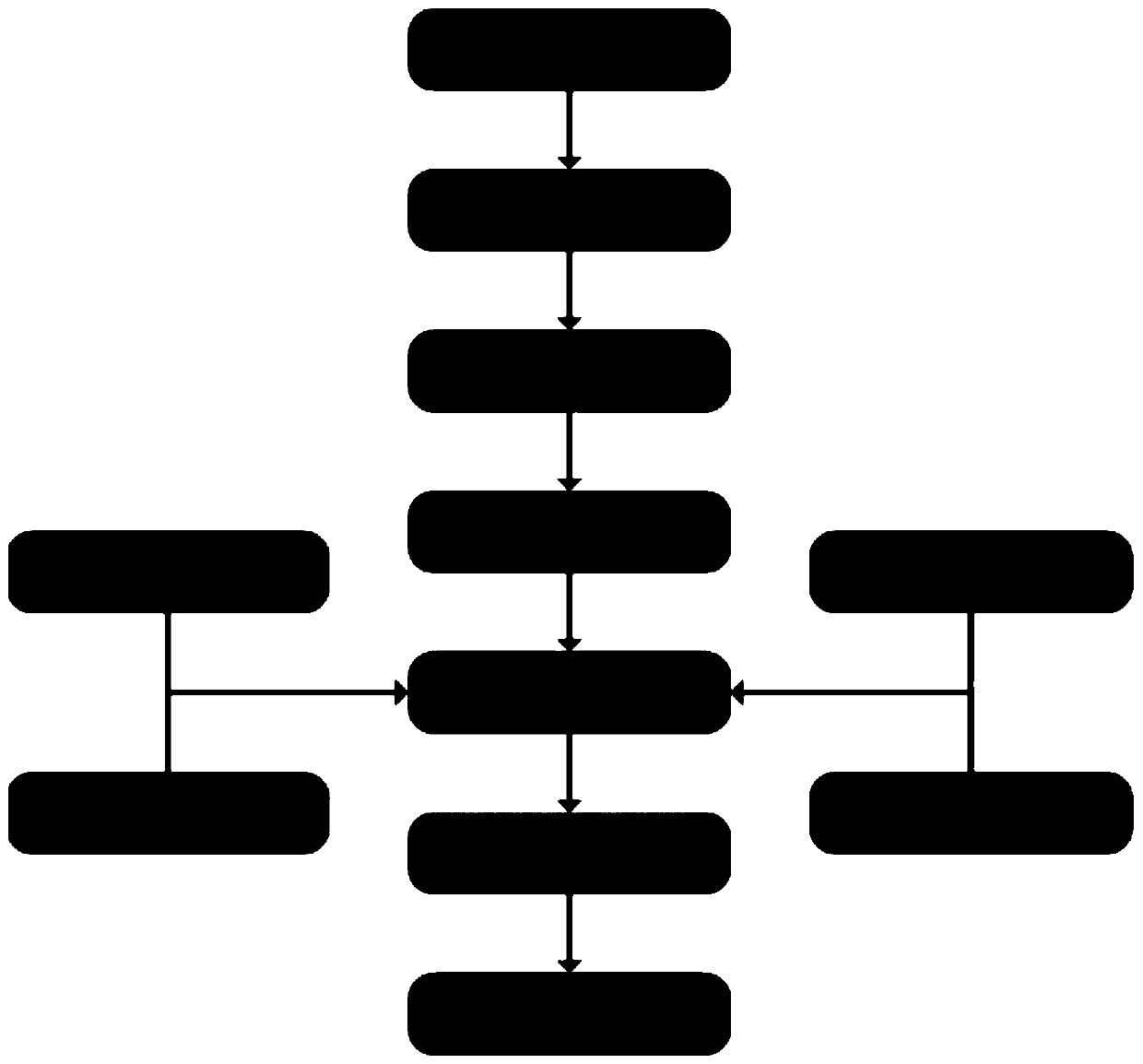

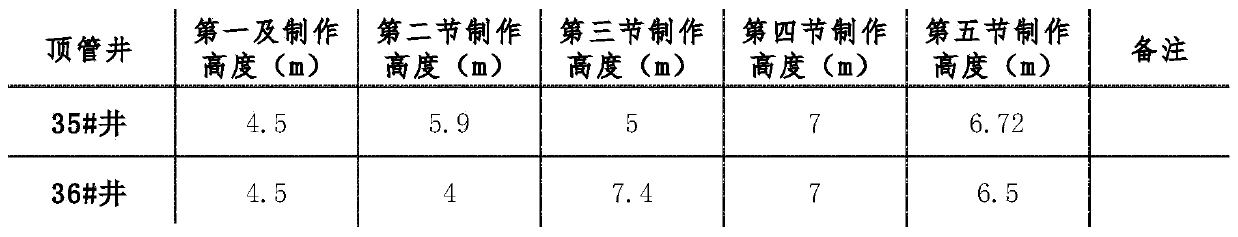

Manufacturing method of open caisson

InactiveCN111395377AImprove sinking accuracySpeed up the sinkingCaissonsButtressArchitectural engineering

The invention discloses a manufacturing method of an open caisson. The method comprises construction preparation work, foundation pit excavation and sand cushion layer and plain concrete cushion layermanufacturing, foundation pit excavation and sand cushion layer and plain concrete cushion layer manufacturing, open caisson first, second and third section manufacturing, open caisson first sinking,open caisson fourth and fifth section manufacturing, and open caisson second sinking. The open caisson adopts a non-drainage sinking process, the soil taking mode is air mud suction diver matching, and the sinking aiding mode is sinking by a pressing sinking method and sinking aiding by thixotropic mud resistance reduction; and the method further comprises underwater plain concrete bottom sealingof the open caisson, manufacturing of an open caisson bottom plate, and pipeline buttress, blowoff chamber and finishing construction. A five-section manufacturing method and a secondary sinking construction method are adopted; the pouring compactness is convenient to control, the pouring operation difficulty is low, the technical requirement threshold is low, the construction efficiency is high,the quality is easy to control, the construction safety factor is high, and the engineering cost is effectively reduced.

Owner:广东省建筑工程监理有限公司

Extruder

ActiveUS11198242B2Reduce and minimize amount of heatHigh heat transfer rateTubular articlesScrew positionElectric machinery

An extruder has a barrel extending from a feed inlet end to an extruder outlet end. The barrel has an inner surface, an outer surface, and a wall thickness between the inner and outer surfaces. The extruder also has at least one heating member positioned provided on the barrel; a screw drive motor drivingly connected to a rotatably mounted screw positioned within the barrel, whereby the screw is rotatable at various revolutions per minute (RPM); and a controller is operably connected to the screw drive motor to adjust the RPM of the screw based upon a temperature of material passing through and / or being extruded from the barrel. Methods for operating an extruder filling a mold are also provided.

Owner:OMACHRON INTPROP

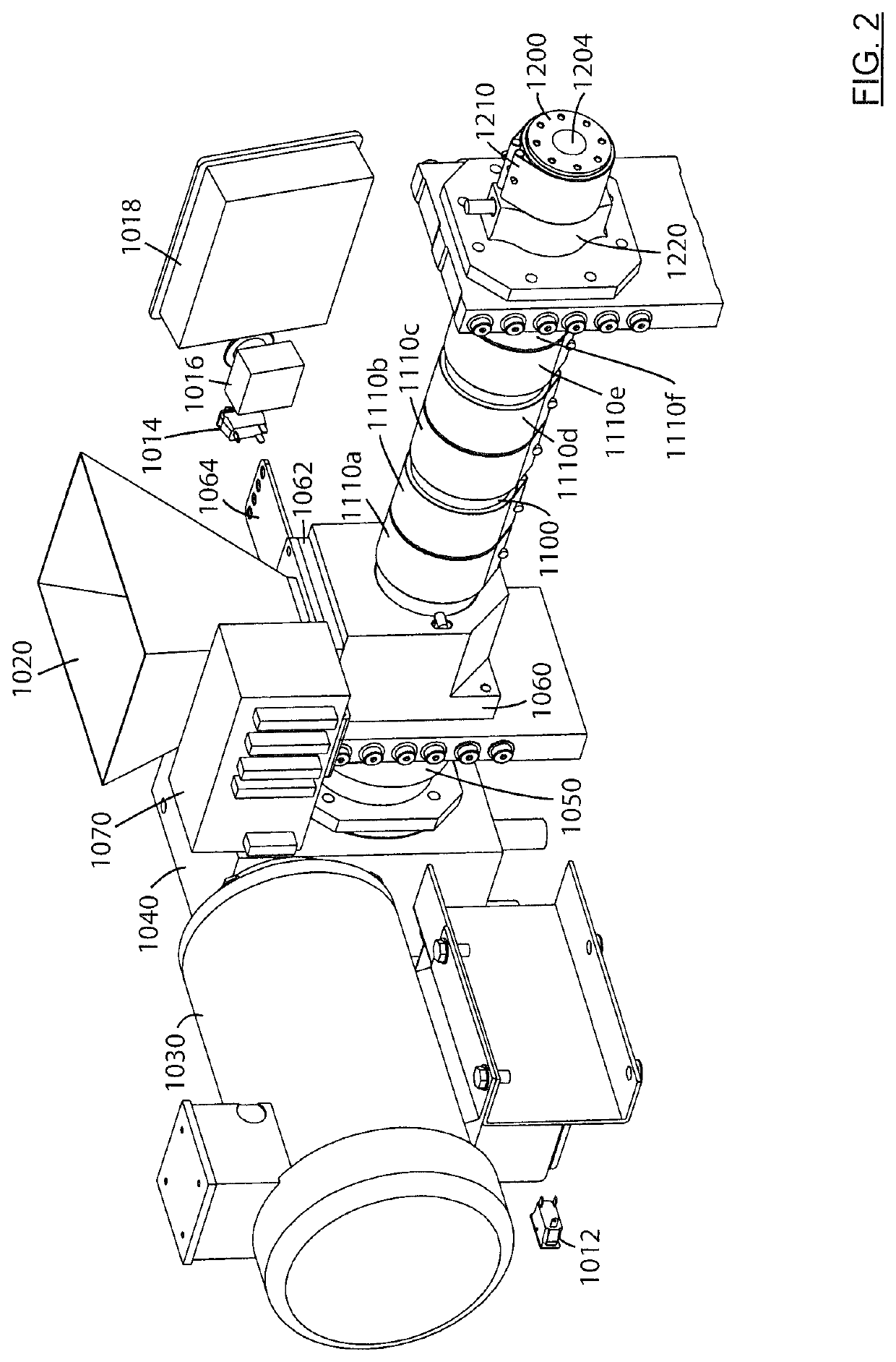

Method for constructing detecting system of hepatitis type B virus DNA

InactiveCN1219075CEnables ultra-sensitive detectionHigh specific selectivityMicrobiological testing/measurementThiolMagnetite Nanoparticles

A process for creating a detection system of HBV DNA includes such steps as designing oligonucleotide probe by using the 1873-1912 sites of HBV DNA as target sequence, dividing the probe into two parts (one including 20 nucleotides and another including 6 nucleotides), using the paraffin thiol to decorate the 5' or 3' terminal of oligonucleotide, using Au-S bone to link to probe to Au or Fe3O4 / Au nanoparticle, using manipulated capture probe, and adding linking chain and signal amplifying substances in the detection system. Its advantages are high sensitivity and specificity and low cost.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com