Construction method for following up and injecting thixotropic slurry outside box body in pipe roofing supporting and pushing construction

A technology of thixotropic mud and jacking construction, which is applied in the construction, road bottom and other directions, can solve the problems of many grouting pipe joints, complex construction process, long construction period, etc., to improve construction efficiency, improve grouting efficiency, environmental protection low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

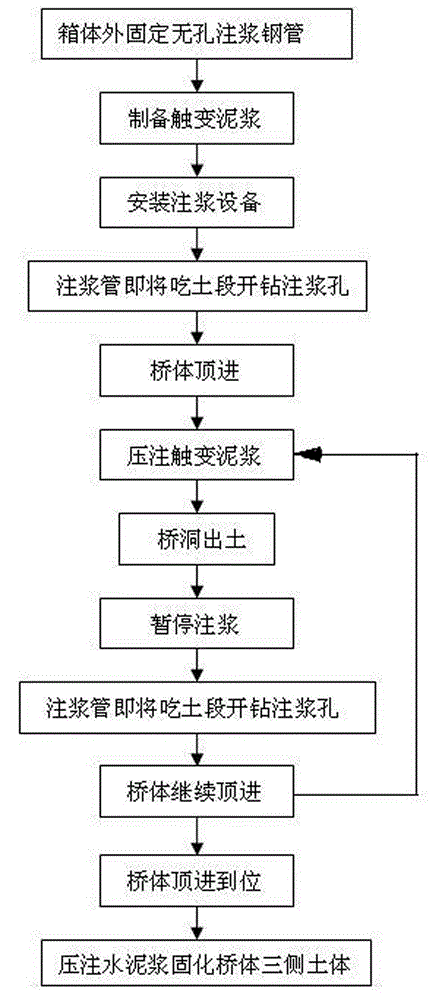

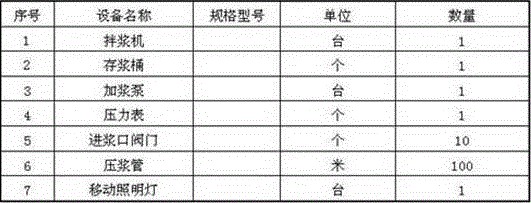

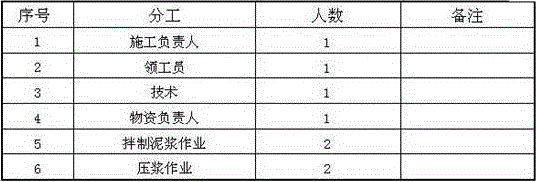

[0034] The technological principle of the present invention is: when using the pipe-curtain support and jacking construction technology to jack up the frame bridge at the key point of the existing line, the pipe-curtain steel pipe is used as the slideway under the bottom plate of the frame culvert box, and the steel pipe has been grouted and pre-fabricated. Attached grouting pipes are left, and when the steel edge is used to eat soil for jacking, the soil under the bottom plate will not be disturbed, and the resistance is small. During the jacking process, the bottom plate part does not need to take thixotropic grouting measures, but uses side walls and roofs The non-porous grouting steel pipe is fixed on the outside. During the jacking process of the bridge and culvert, the thixotropic mud is injected into the side wall and roof outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com