Patents

Literature

107results about How to "Improve waterproof quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

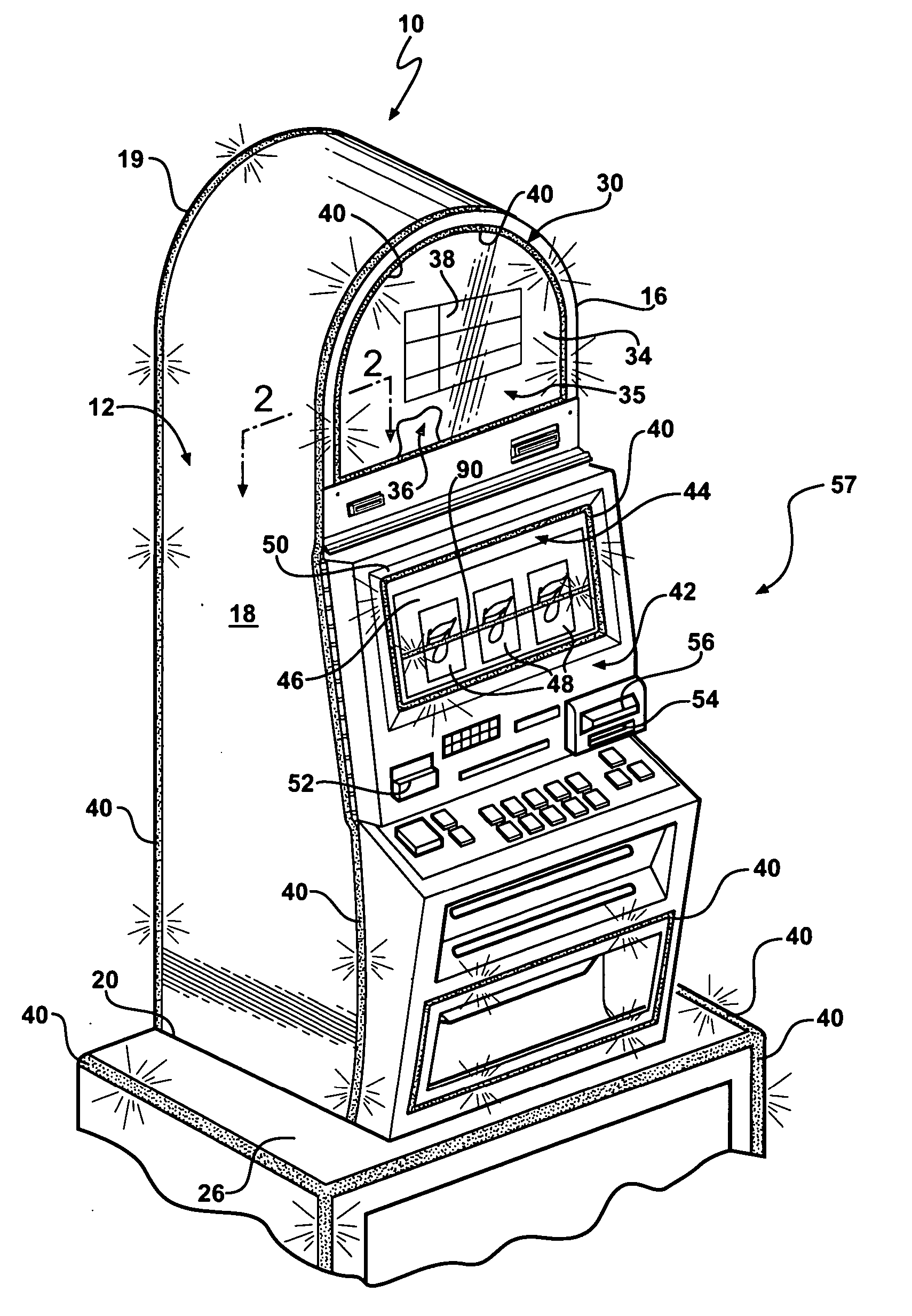

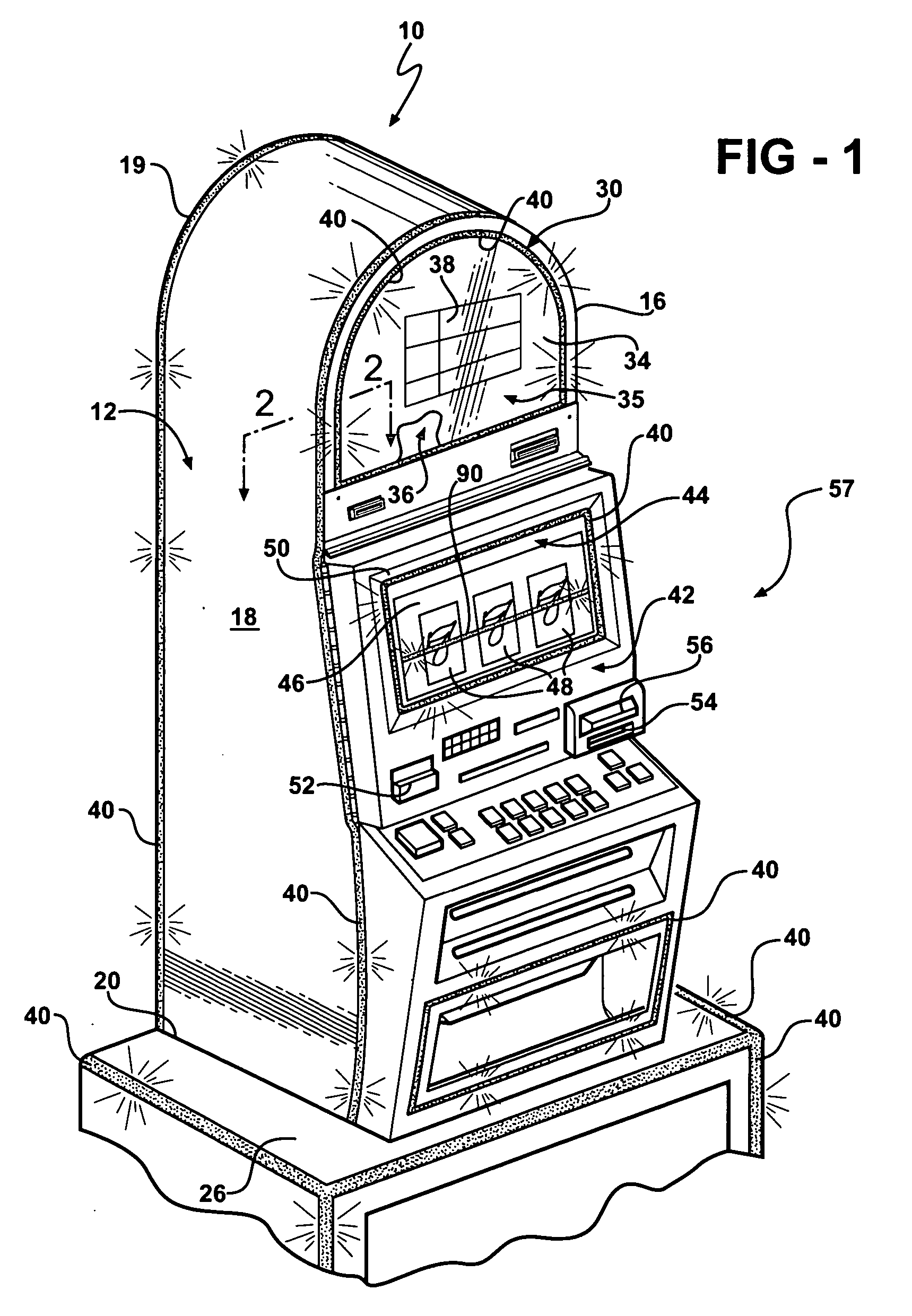

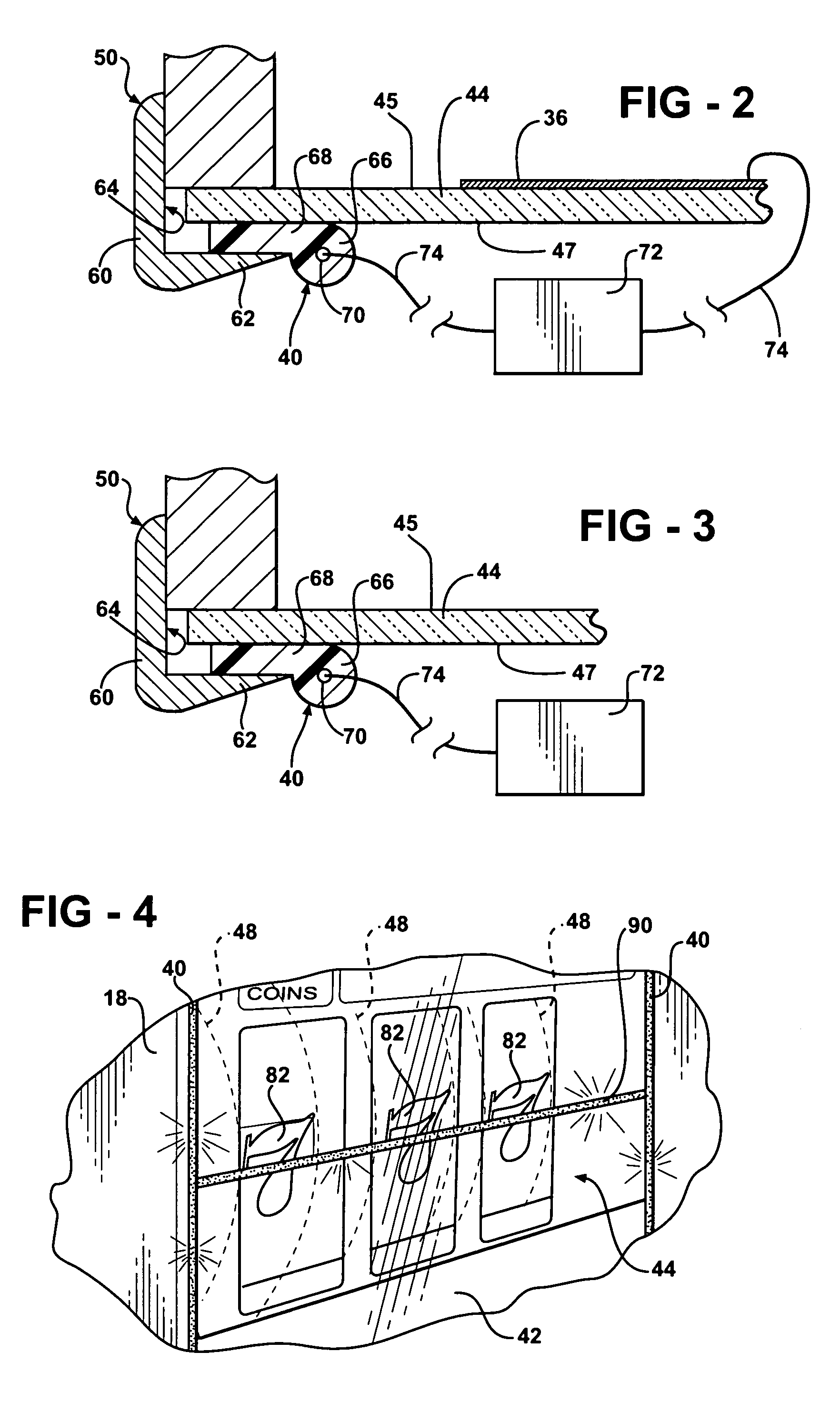

Gaming machine and a method of lighting the same

ActiveUS20060094511A1Improved energy-saving alternativeFunction increaseApparatus for meter-controlled dispensingVideo gamesInteraction deviceLight emitting device

A gaming machine includes a cabinet having a glass panel, a player interaction device disposed in the cabinet for determining a winning outcome of the game, and a light emitting device, such as, EL wire, sheet, and the like, extends about the periphery of the glass panel and / or behind the glass panel. A plurality of reels are disposed inside the cabinet and are rotatable about an axis with each reel having an outer surface and a reel strip mounted thereto and a plurality of symbols defined on the reel strip and exposed to the glass panel. At least one pay line is spaced from each of the reels. The pay line is illuminated independent from and in alternating mode with the symbols in response to the winning outcome of the game.

Owner:VIDEO GAMING TECH

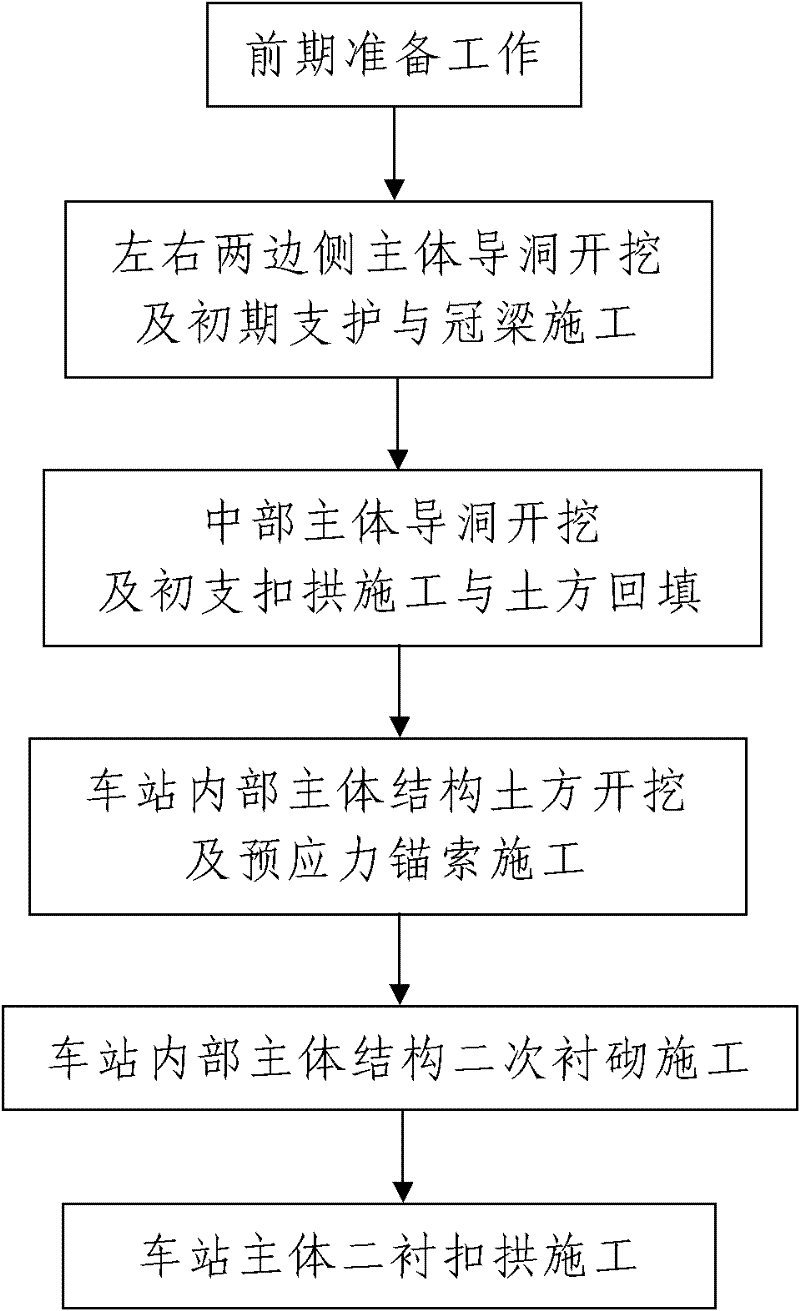

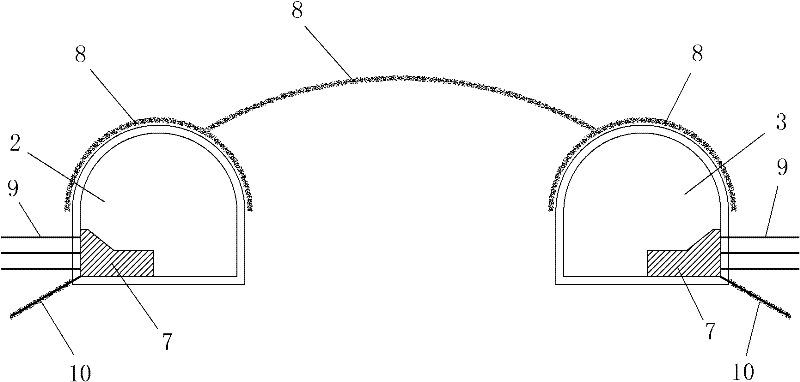

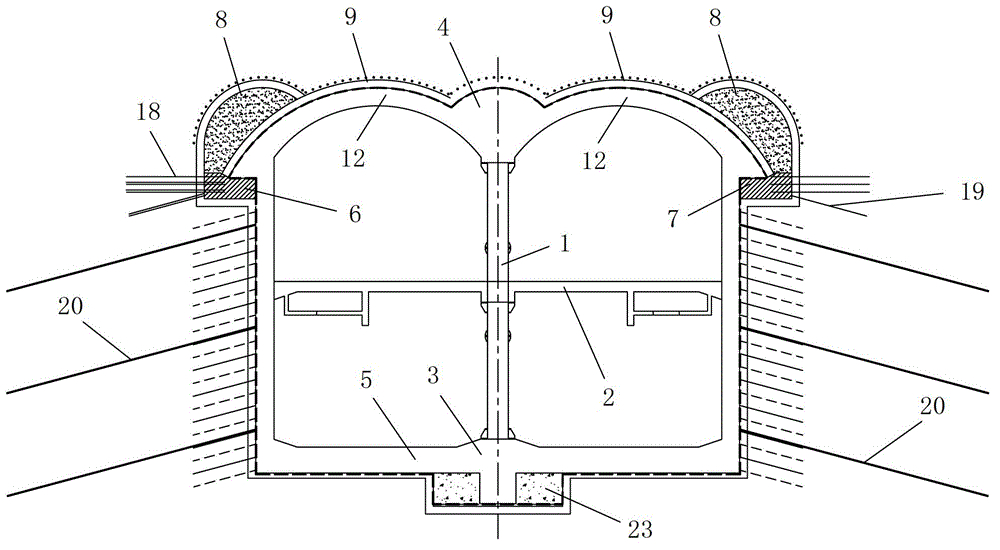

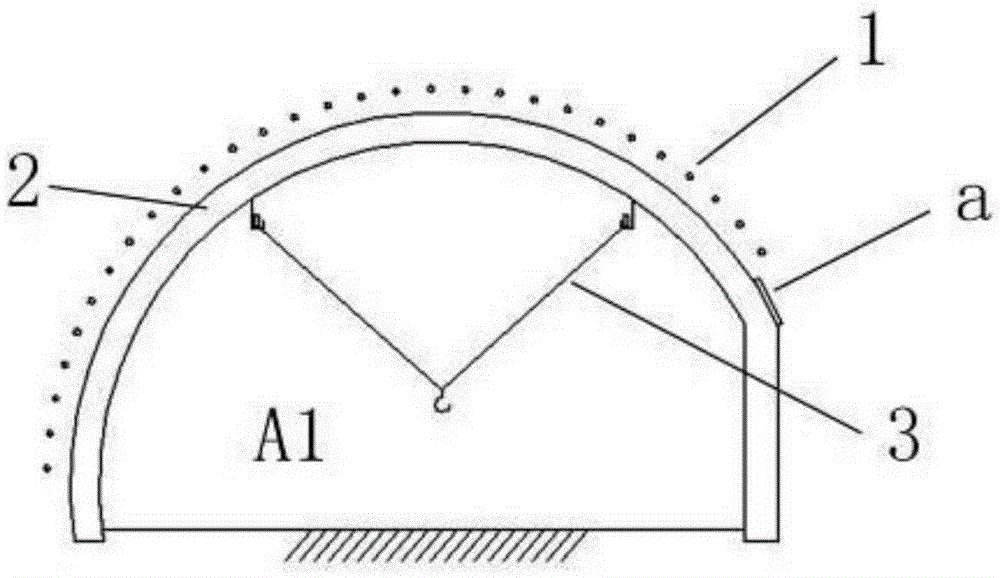

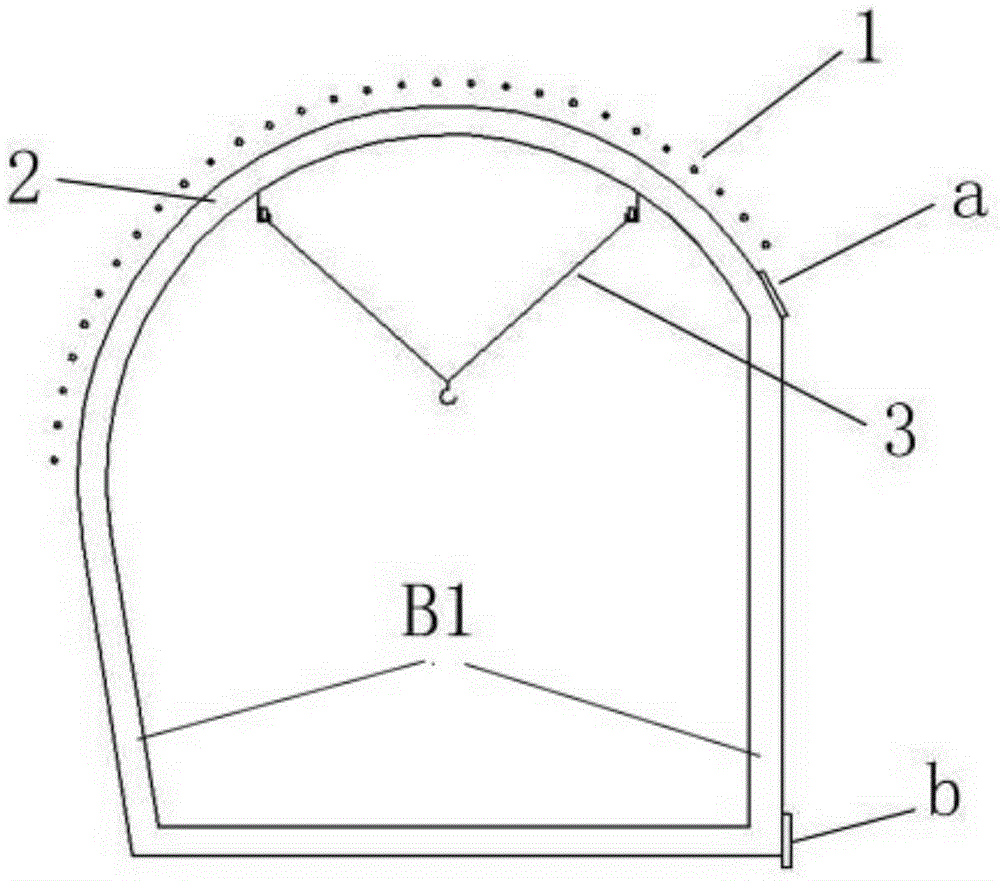

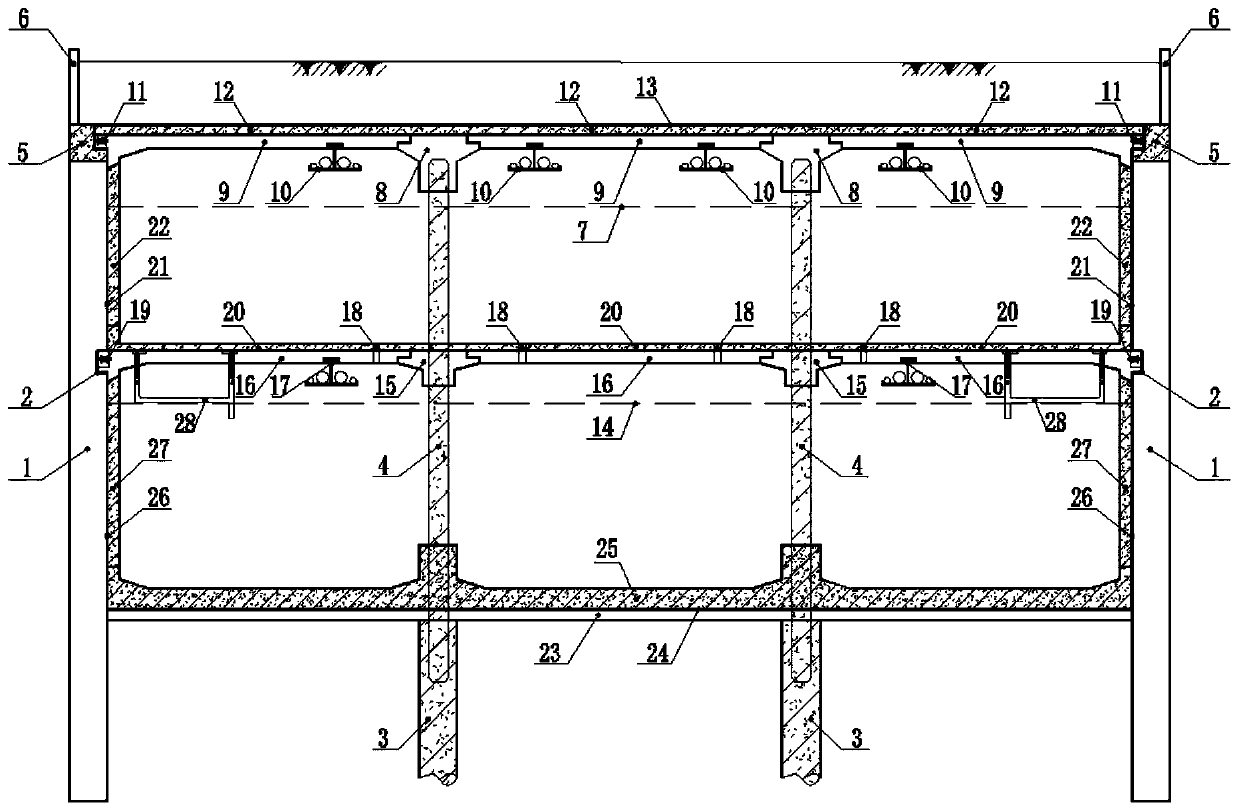

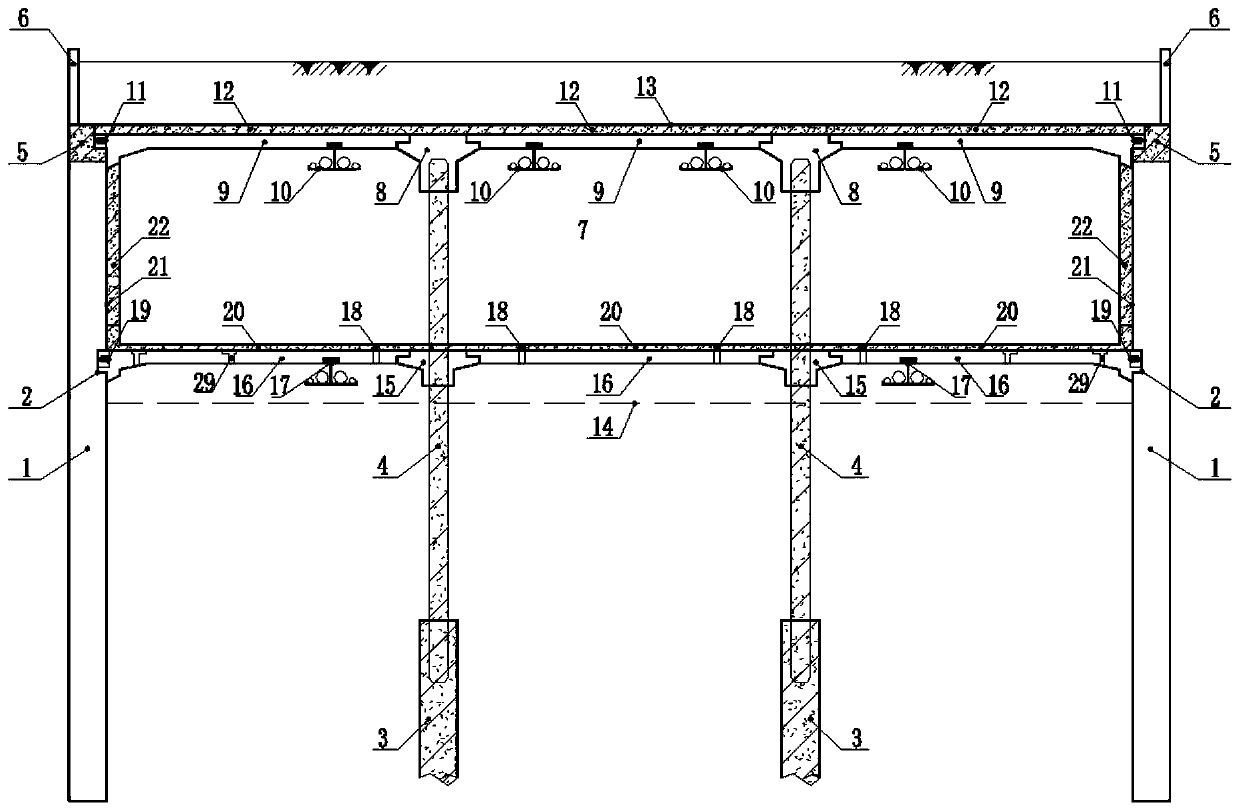

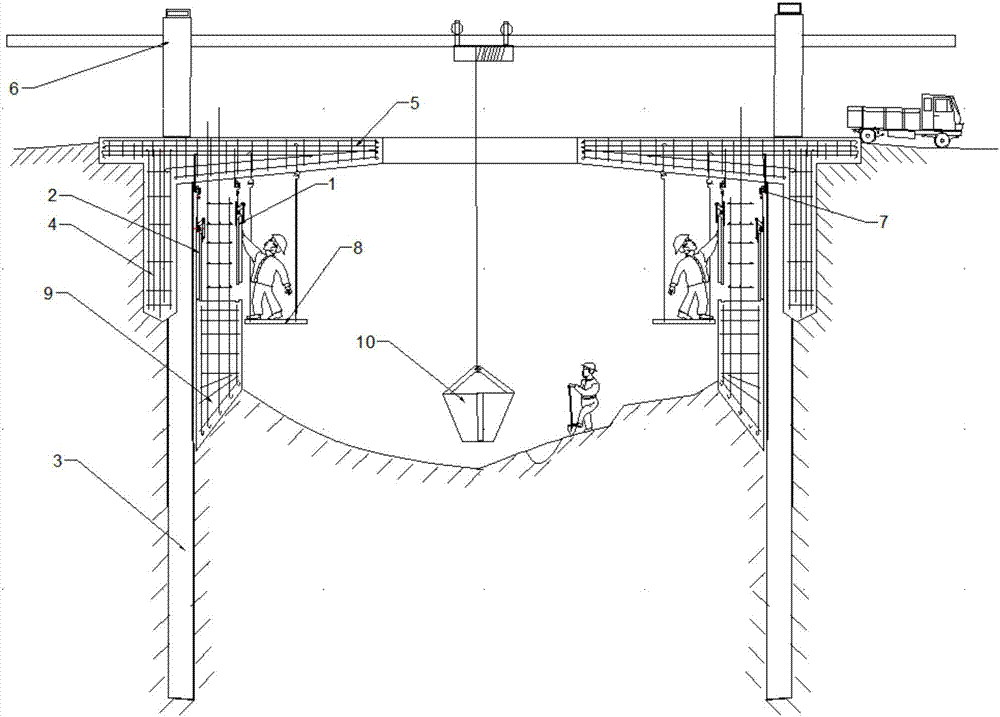

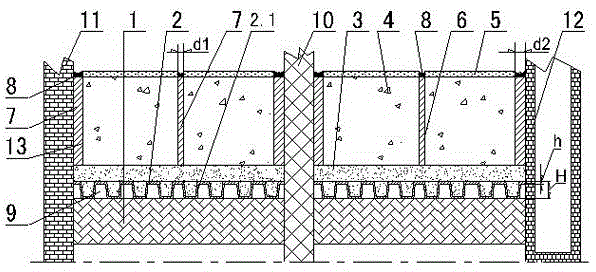

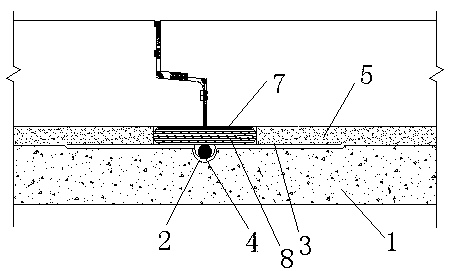

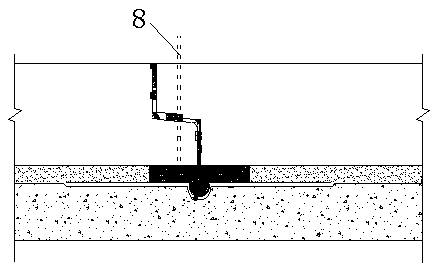

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

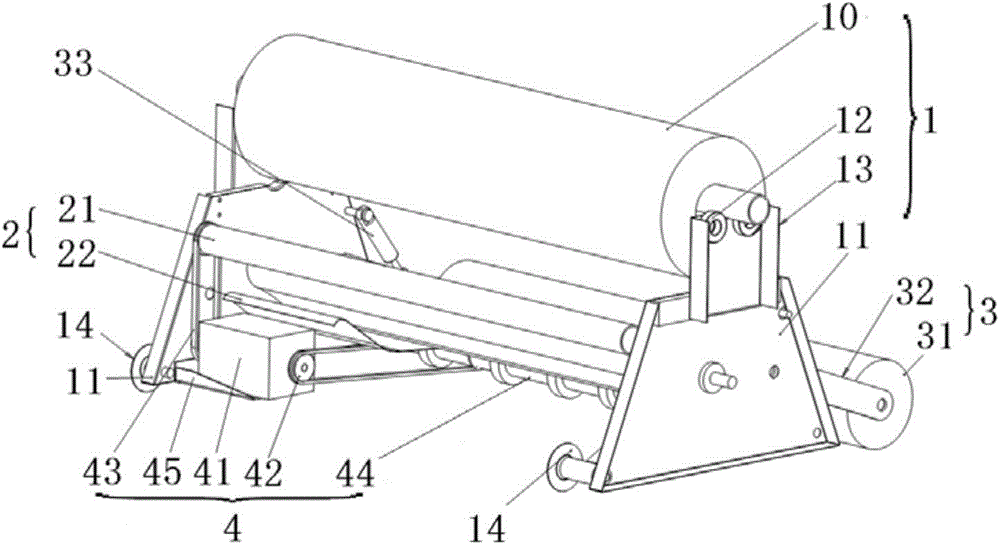

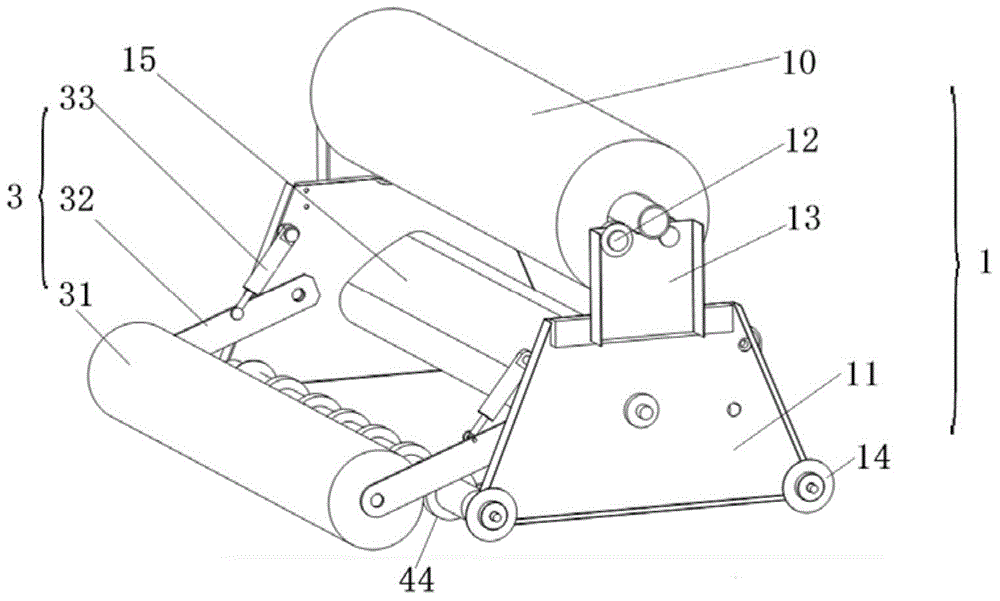

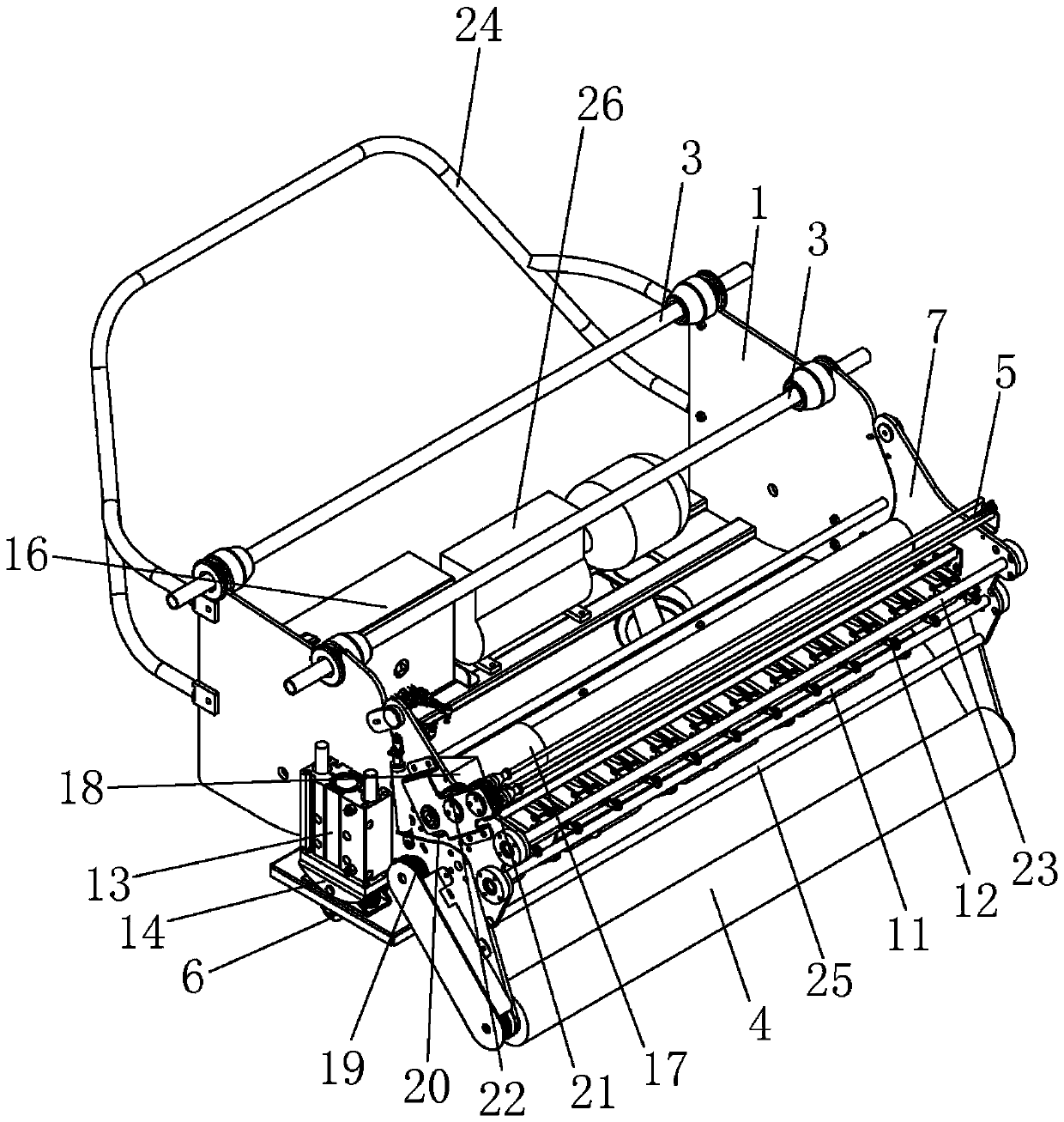

Waterproof roll paver and paving method

The invention provides a waterproof roll paver and a paving method, belongs to the technical field of waterproof rolls, and can solve the problems of easy pollution and easy fall of overlap edges of traditional wet paved rolls. The waterproof roll paver comprises a support device for supporting and sending out the waterproof rolls, a guide device for tensioning the waterproof rolls sent out from the support device, a driving device for towing the waterproof rolls guided out from the guide device to pave on a basal surface and driving the paver to move, and a pressing device for compacting the paved waterproof rolls. The waterproof roll paver can enable the overlap widths of the overlap edges of the waterproof rolls to be consistent, is free of leaking points, fall and pollution on the overlap edges, can realize continuous paving, can save the labor, improves the working efficiency, and greatly enhances the waterproof quality. The waterproof roll paver is suitable for paving various waterproof rolls, and specifically for wetly paving asphalt rolls.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

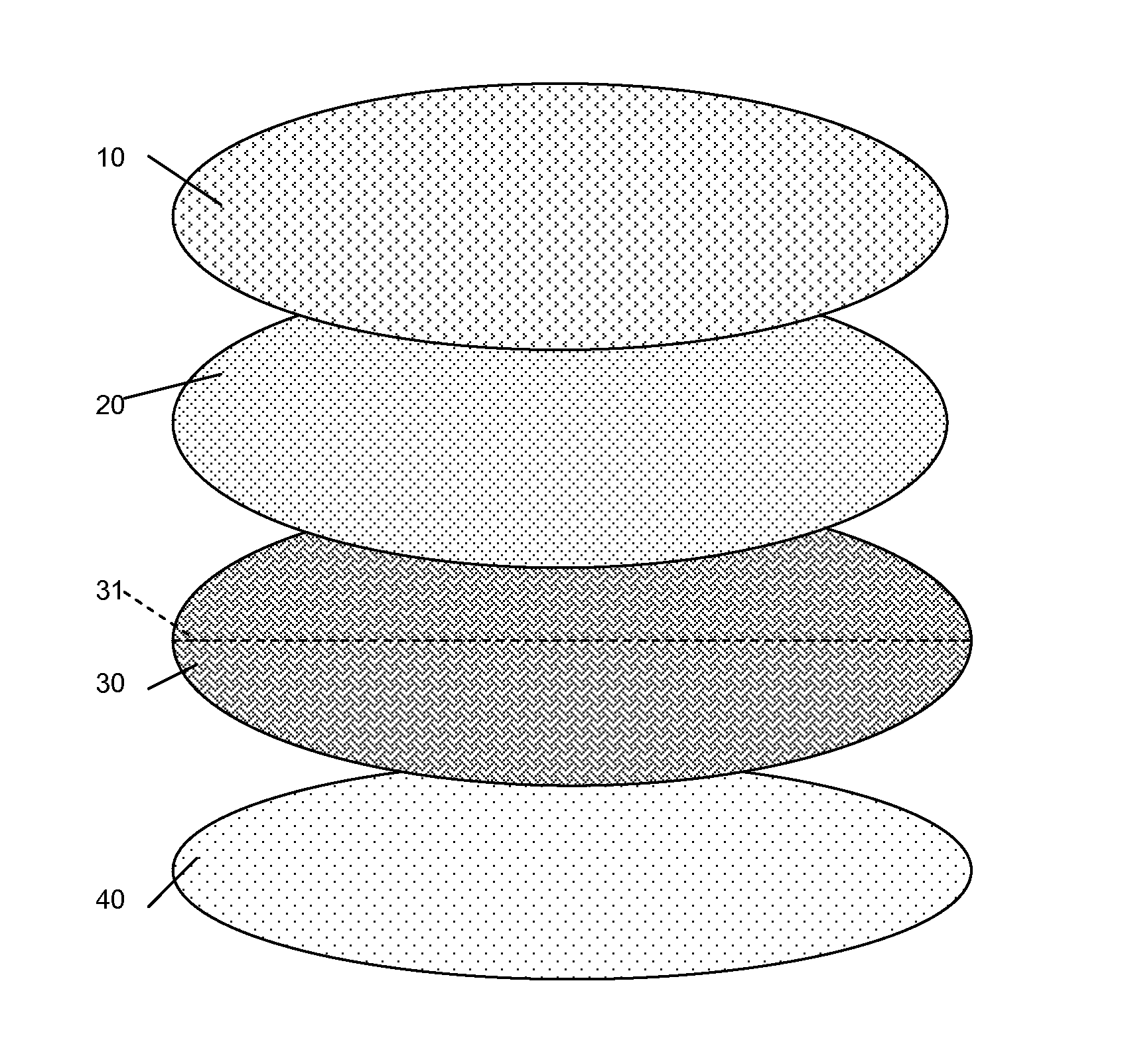

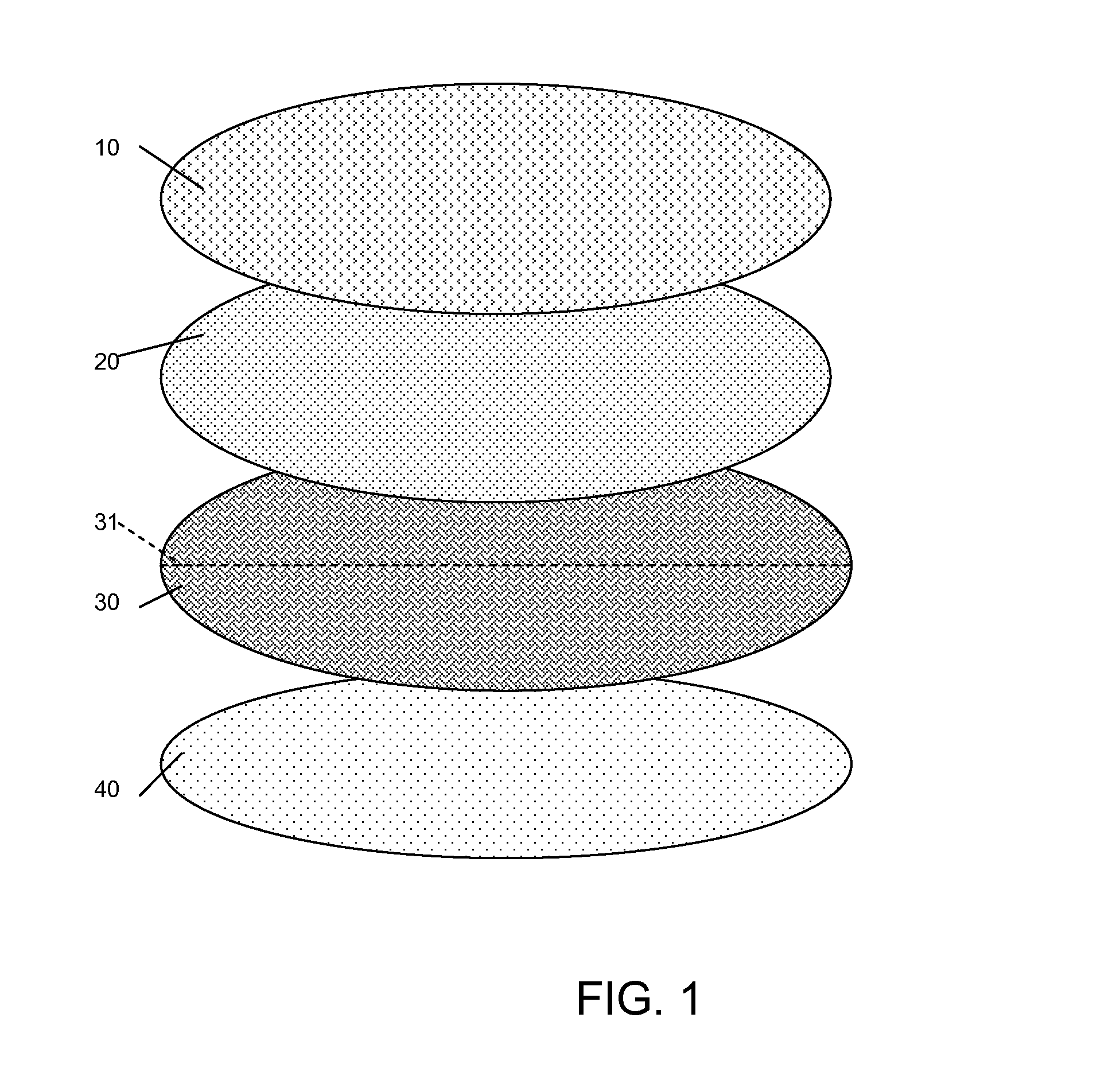

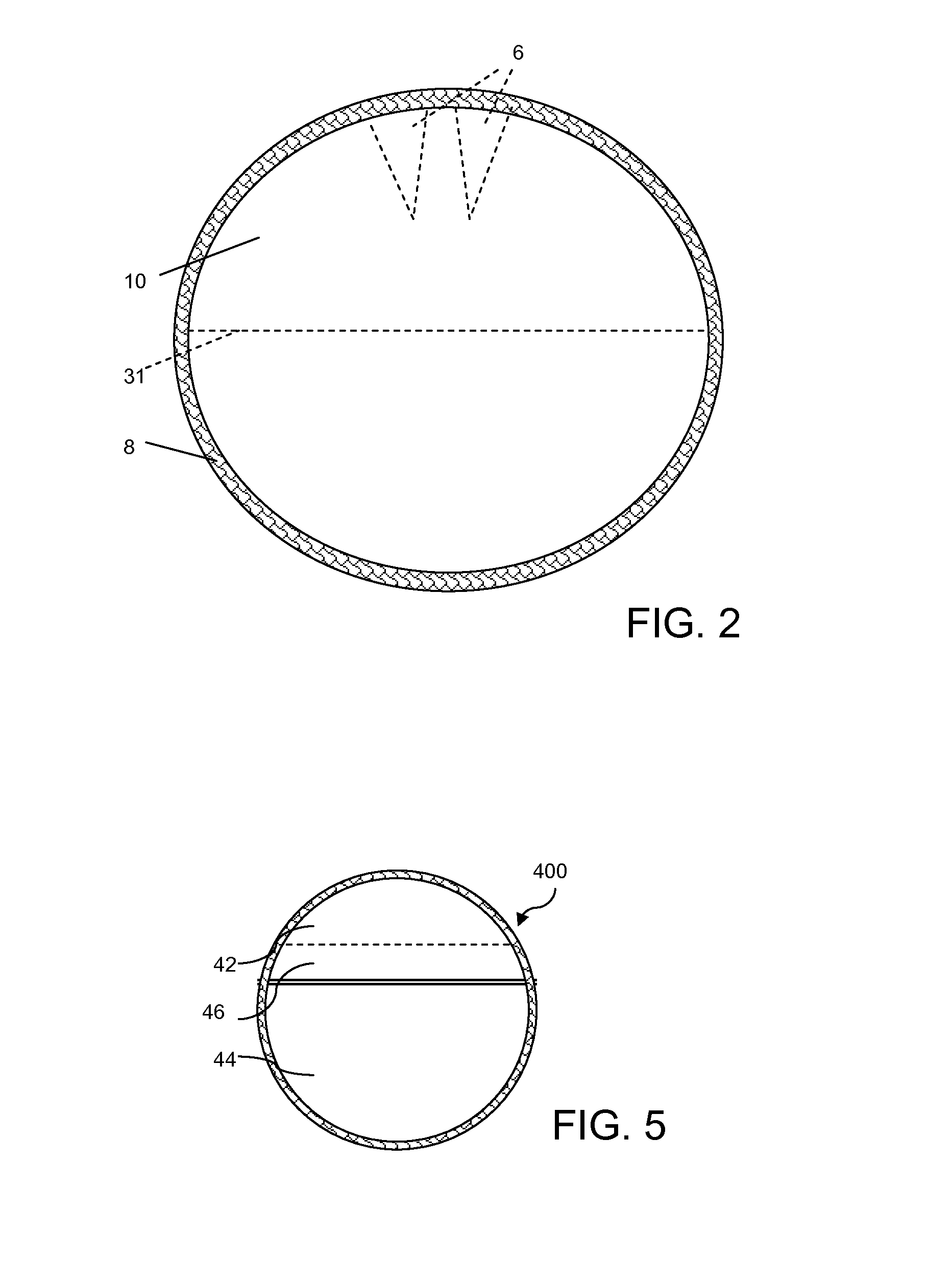

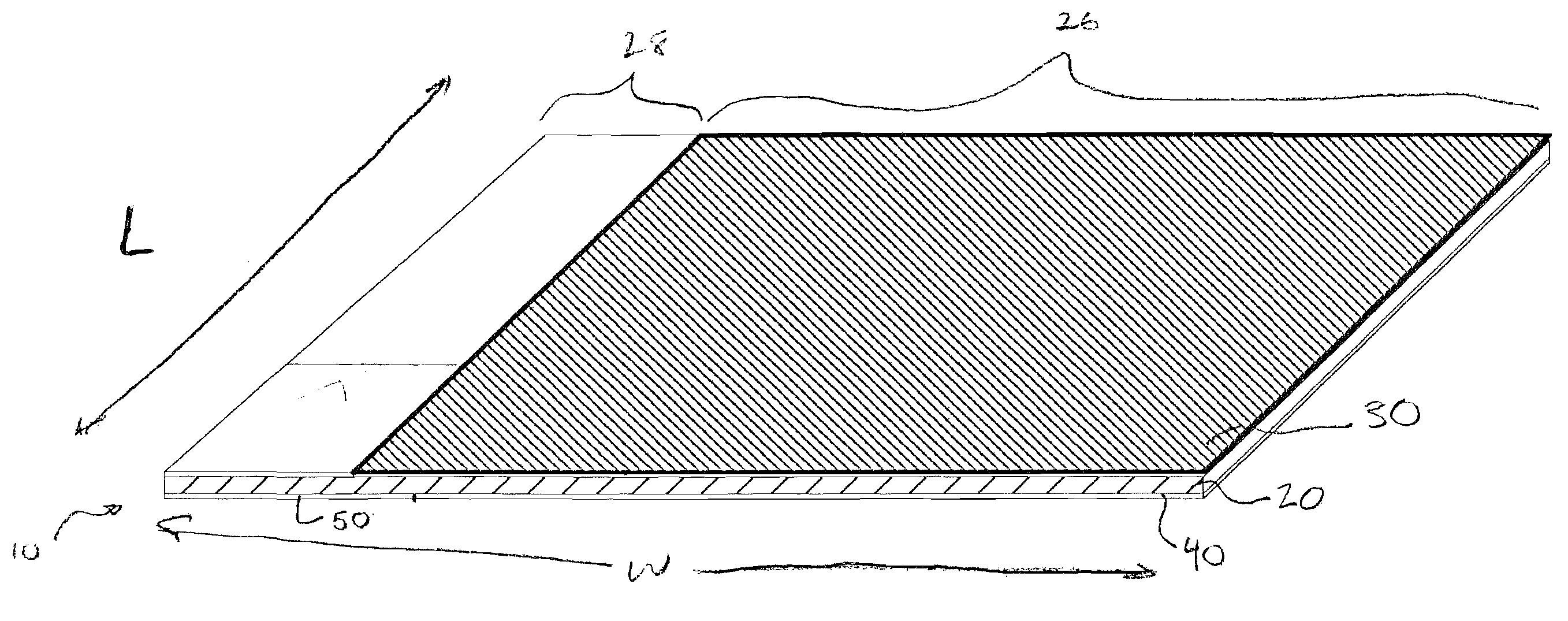

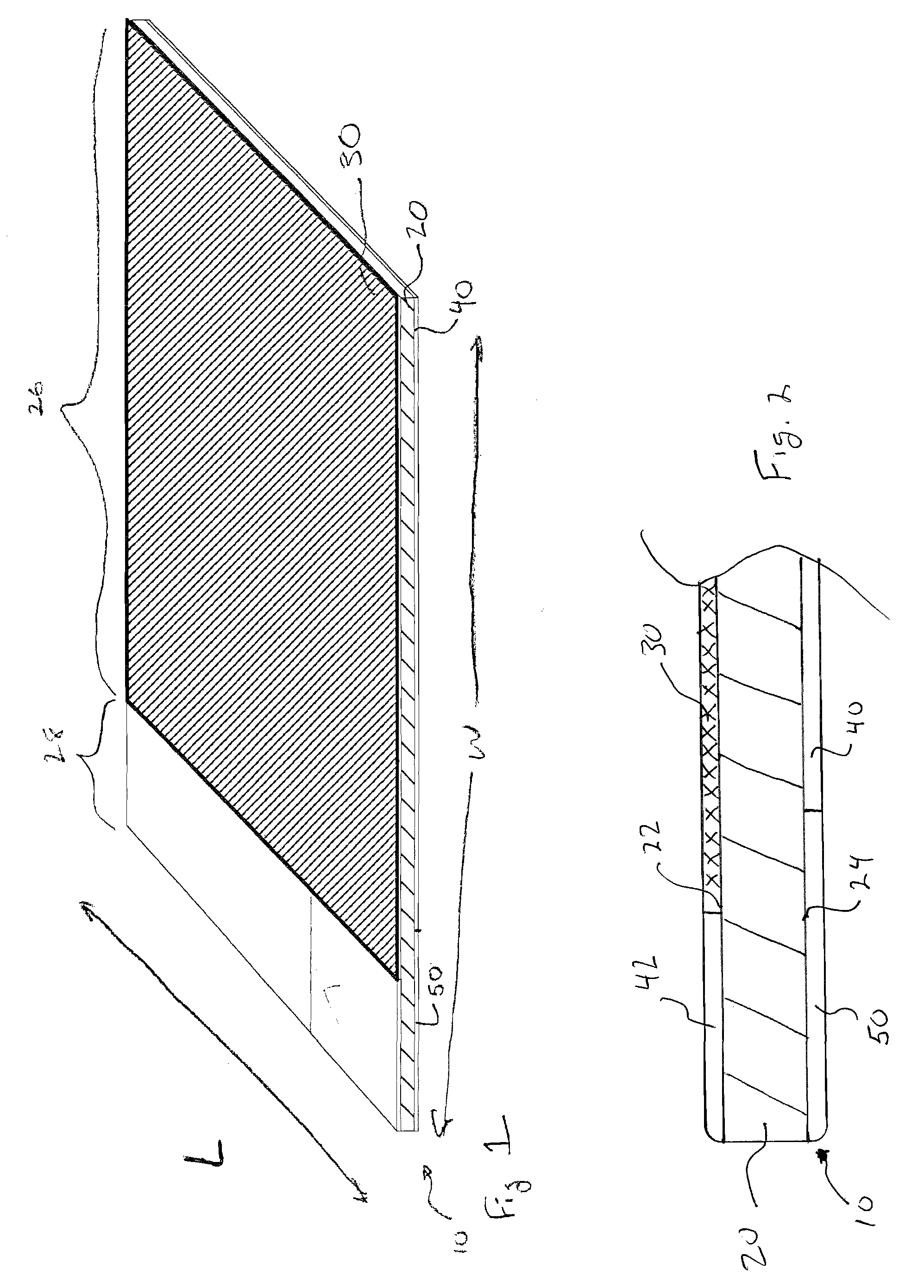

Nursing Bra Pad

InactiveUS20100121300A1Rapid anti-microbialFast dryingBreast bandagesBaby linensSkin contactMoisture

A nursing bra pad has a concave, cup-shape formed from a rounded section of multi-layer composite textile having a first, skin contact layer formed from a non-shearing, moisture vapor permeable woven fabric of synthetic filament yarns. A second layer and optional third layer are formed from moisture absorbing and retaining fabrics. The second layer is a breathable fabric that draws moisture from the inner to the outer surface of the fabric. The optional third microfiber layer provides moisture retention and may be positioned between the first layer and the second layer or between the second and fourth layers. The fourth layer, which may optionally be coated with polyurethane, is formed from a breathable, waterproof fabric woven from synthetic yarn to allow moisture vapor transfer away from the skin. The three or four layers are stitched together along their edges. The layers are stitched to generally conform to the shape of the breast.

Owner:PERSIMMON SCI

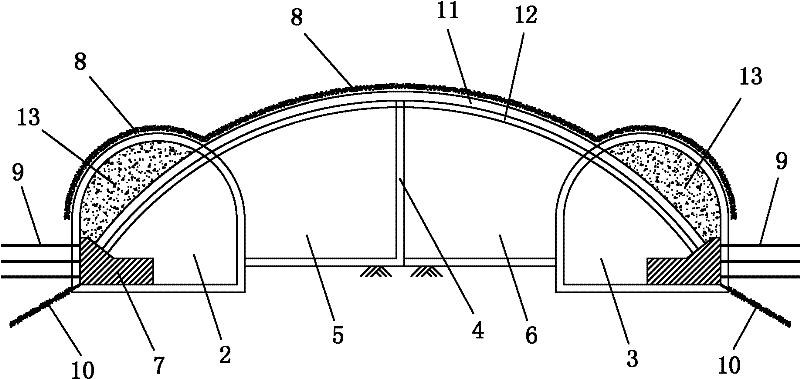

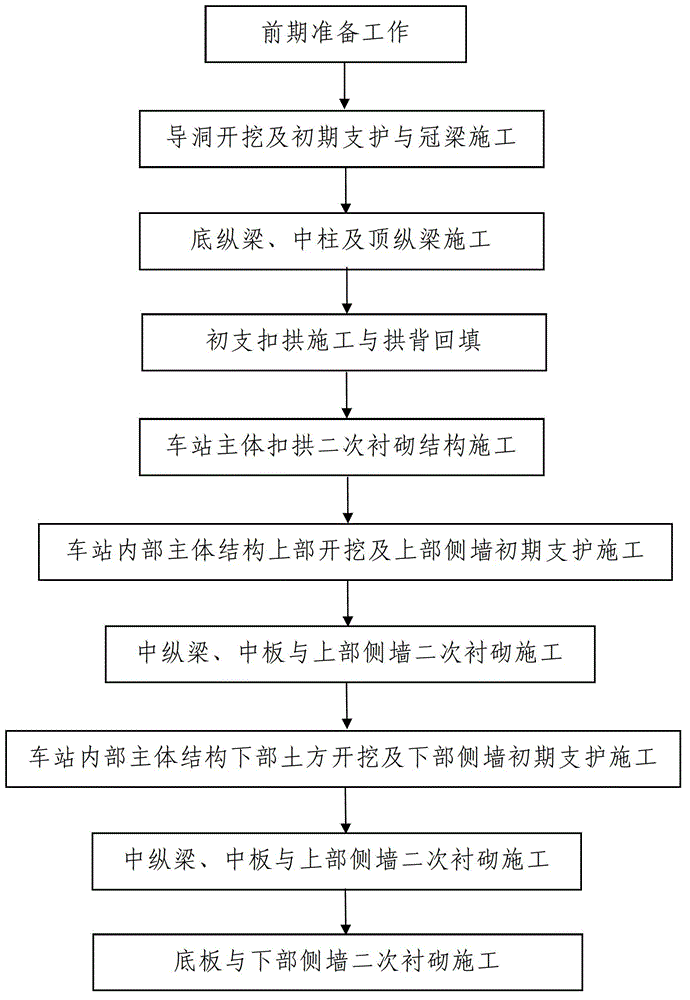

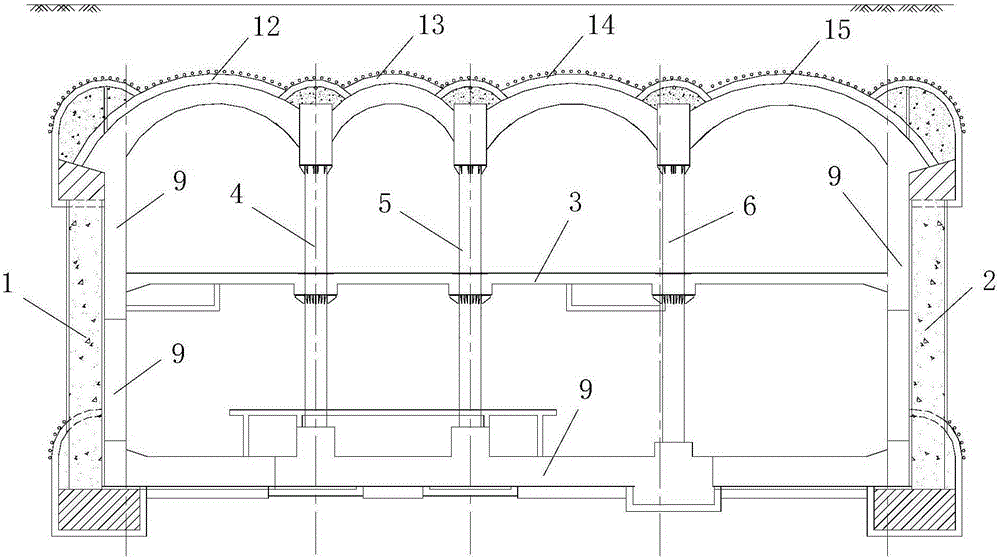

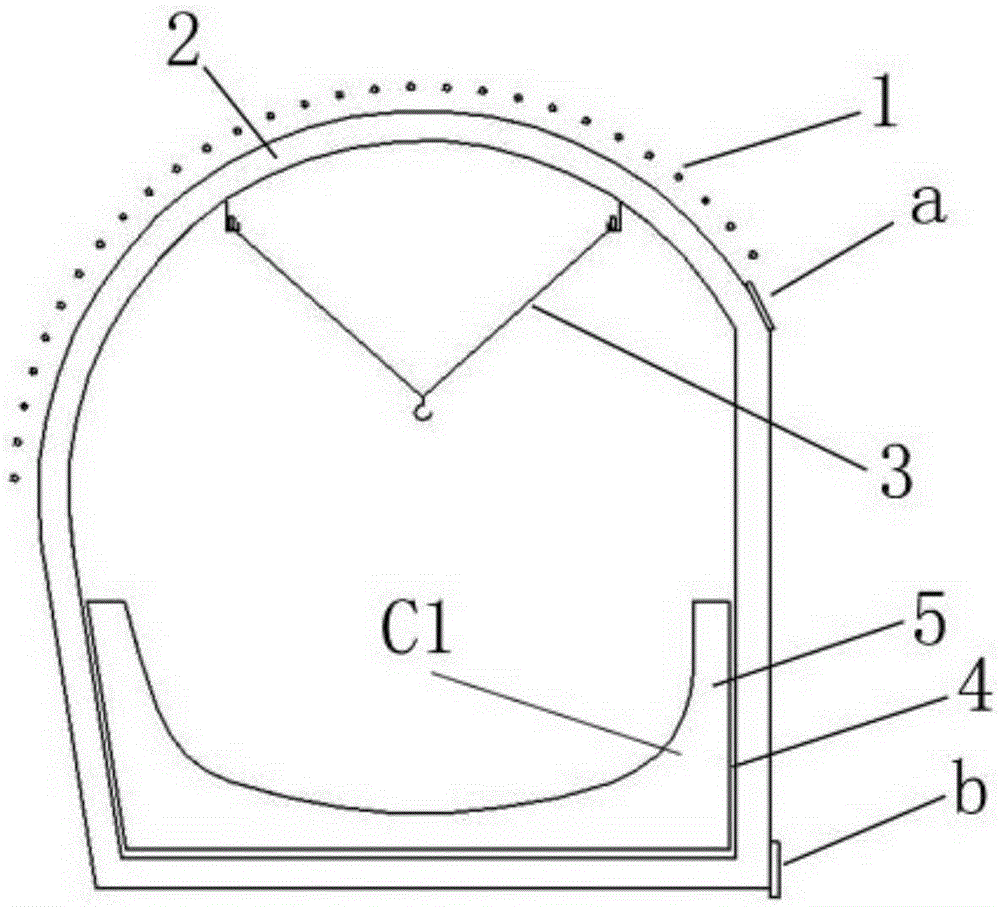

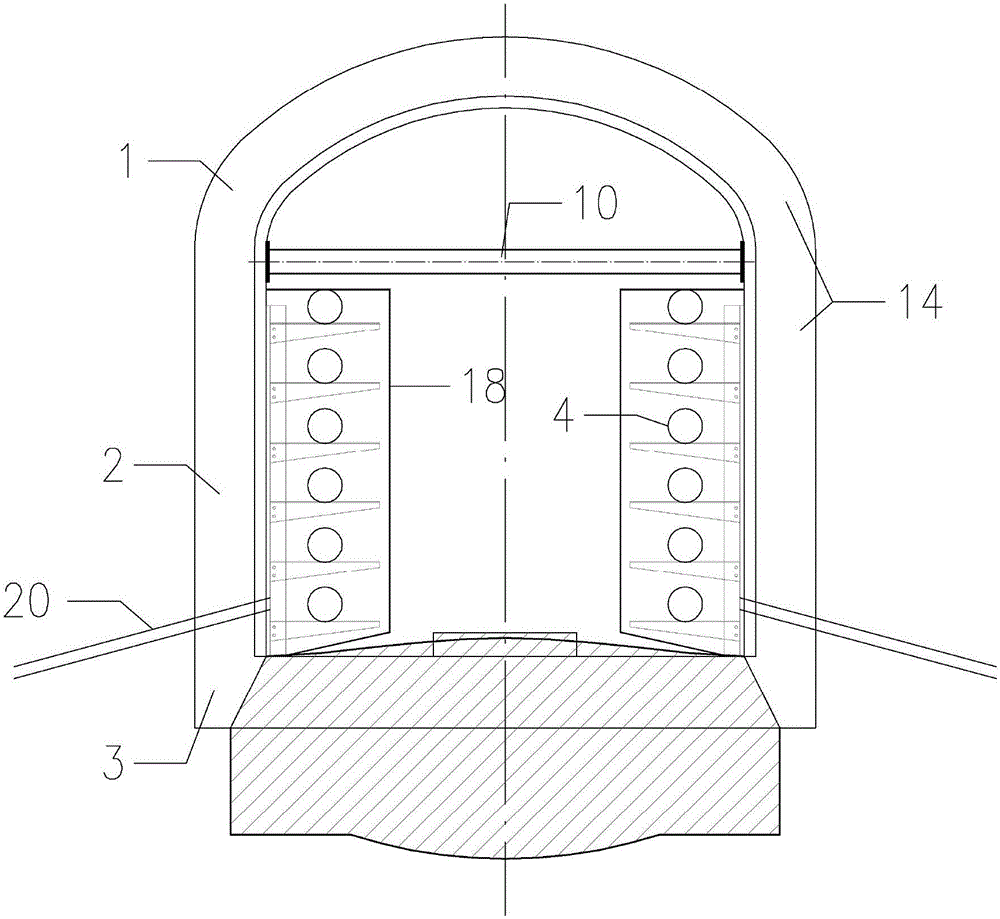

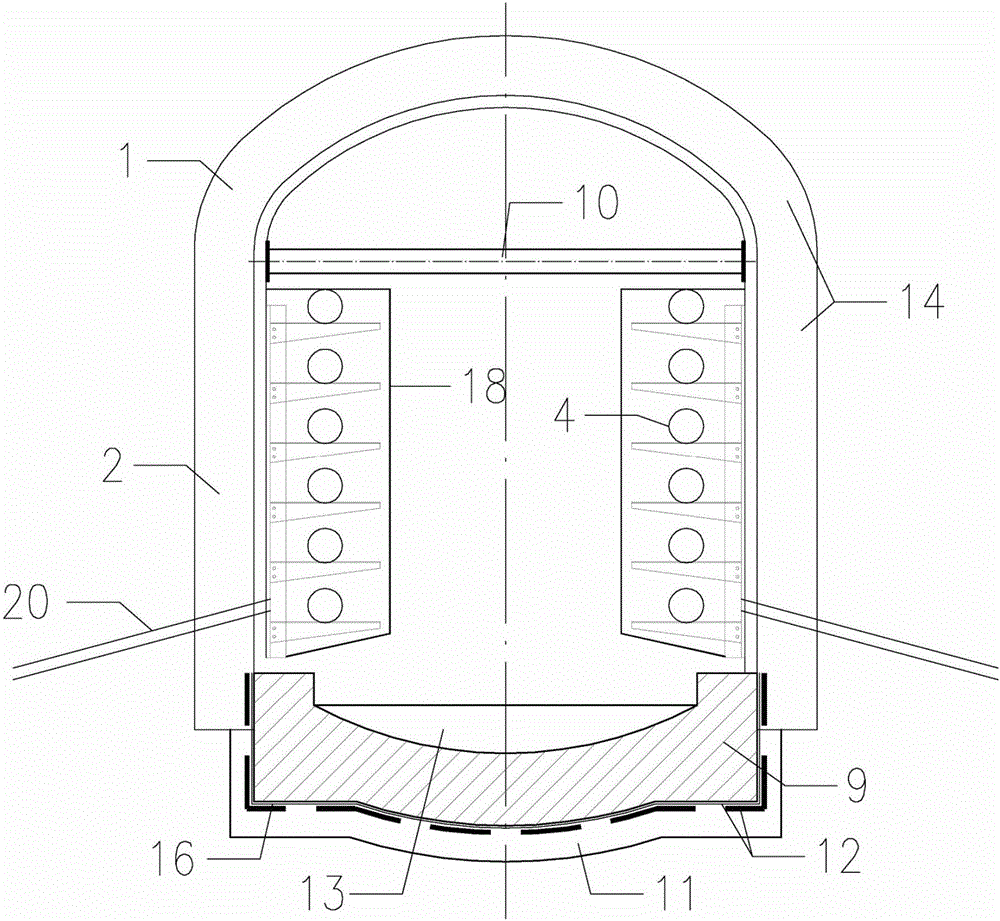

Main structure for metro long-span station and pillar arching construction method thereof

ActiveCN102748040AEasy constructionSimplify construction stepsUnderground chambersEngineeringLong span

The invention discloses a main structure for a metro long-span station and a pillar arching construction method thereof. The main structure comprises a station interior main structure, a plurality of middle pillars, a middle plate and a main arch part, wherein the station interior main structure is dug; the middle plate is located on the middle pillars; the main arch part is located right above the main structure; a bottom longitudinal beam is arranged at the bottom of the station interior main structure; a top longitudinal beam is arranged on the main arch part; and a middle longitudinal beam is arranged between adjacent middle pillars. The construction method comprises the following steps: 1) preparing in earlier stage; 2) digging a guiding hole and performing primary bracing and bridging construction; 3) constructing the bottom longitudinal beam, the middle pillars and the top longitudinal beam; 4) constructing a primary branch arch and refilling an arch back; 5) performing arch secondary lining construction; 6) digging the upper part of the main structure and constructing a primary branch of a side wall of the upper part; 7) performing secondary lining construction of the middle longitudinal beam, the middle plate and the side wall of the upper part; 8) digging the lower part of the main structure and constructing the primary branch of the side wall of the lower part; and 9) performing secondary lining construction for a base plate and the side wall of the lower part. The construction method provided by the invention has the advantages of reasonable design, simple construction step, convenience in realizing, small construction difficulty and high construction speed.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

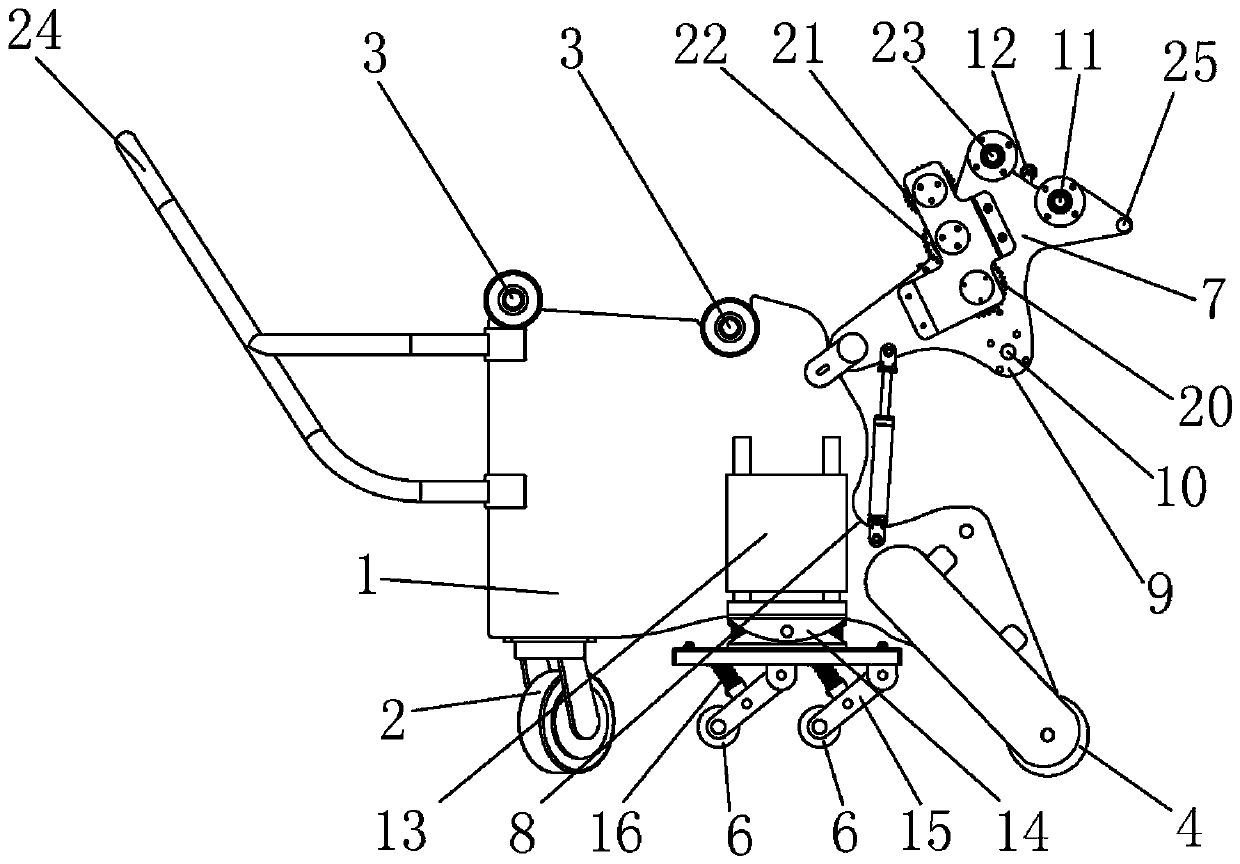

Coiled material level-laying forming machine and laying method of waterproof coiled material

The invention discloses a coiled material level-laying forming machine and a laying method of a coiled material. The coiled material level-laying forming machine comprises a rack and casters mounted at the bottom of the rack. Parallel waterproof coiled material supporting rolls, protective film wind-up rolls, waterproof film layer laying rolls and down-pressing rolling rolls are mounted on the rack in a hinged mode from top to bottom. The down-pressing rolling rolls are connected with a pressure adjusting device for adjusting the down-pressing pressure. A protective film detecting device whichis mounted on the rack is further arranged between the protective film wind-up rolls and the waterproof film layer laying rolls. The waterproof film layer laying rolls, the protective film wind-up rolls and the down-pressing rolling rolls synchronously rotate. In the laying process, the integrity of the waterproof coiled material can be continuously checked through the protective film detecting device, the pressure-adjustable down-pressing rolling rolls can adjust the rolling pressure according to different laying requirements, continuous laying can be achieved, labor can further be saved, the work efficiency is improved, the waterproof quality is greatly improved, and the coiled material level-laying forming machine is suitable for laying of various waterproof coiled materials, and especially suitable for wet laying of an asphalt coiled material.

Owner:ZHONGSHAN JINGCHENG MECHANICAL & ELECTRICAL EQUIP CO LTD

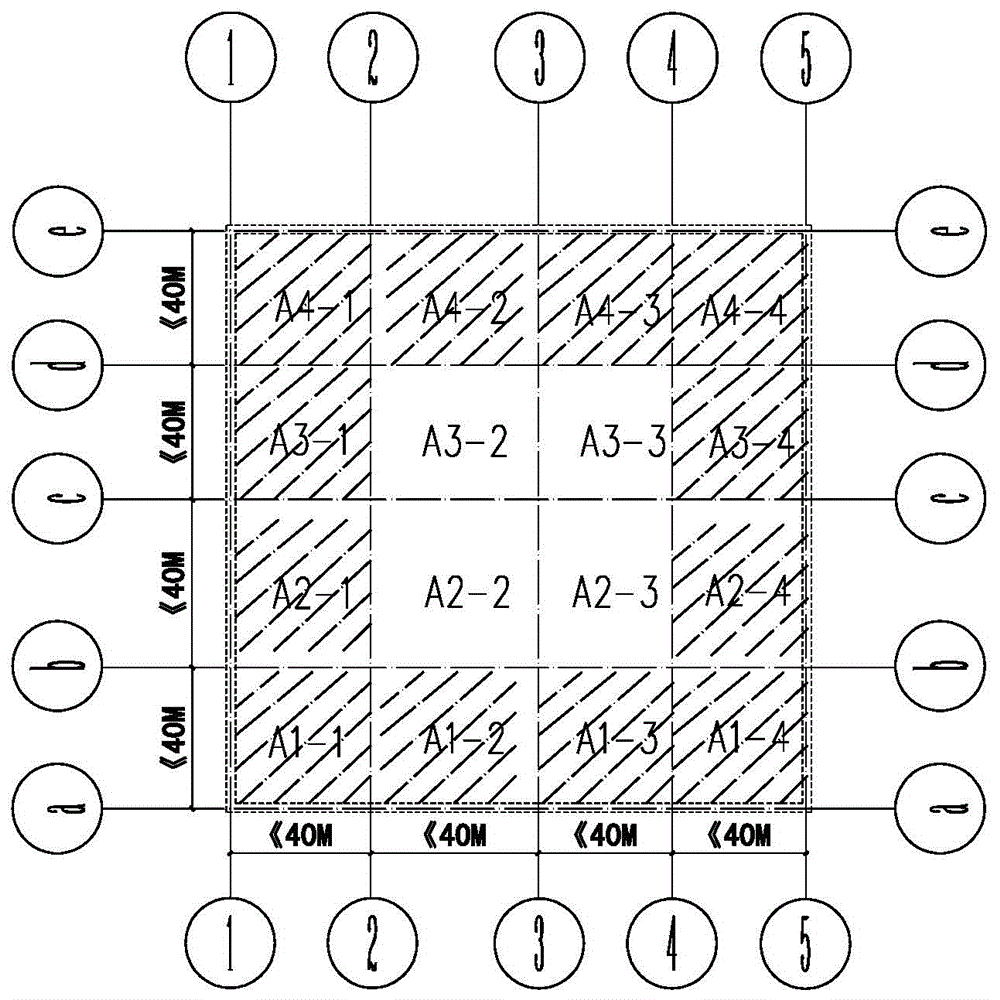

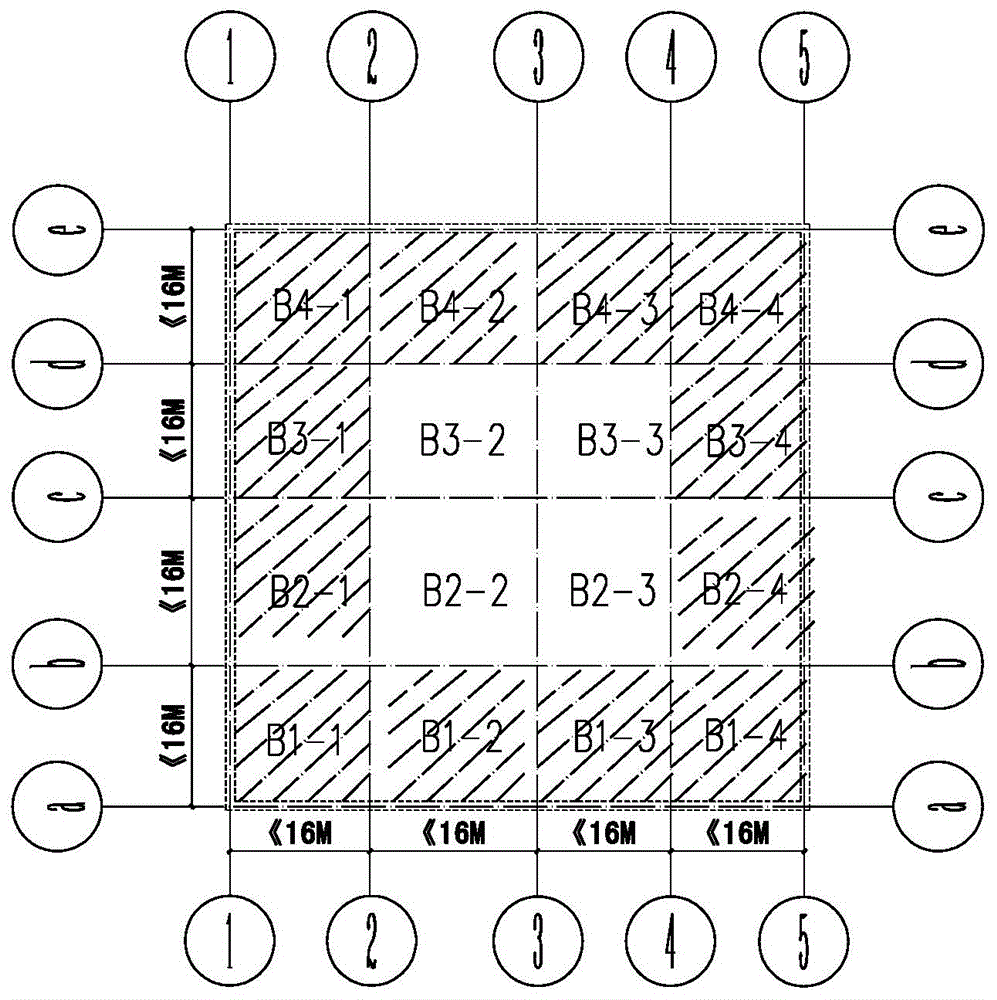

Large-area RC basement structure sequence construction method

InactiveCN104963357AImprove construction efficiencyReduce construction costsArtificial islandsUnderwater structuresBasementRebar

The invention provides a large-area RC basement structure sequence construction method. Firstly, a large-area RC basement is structurally decomposed, and warehouse dividing arrangement, operation conducted according to a rebar binding method, construction joint arrangement, concrete pouring, concrete curing, concrete temperature measurement and briquette retention are sequentially conducted. According to the large-area RC basement structure sequence construction method, a sequence method is adopted for replacing a construction post-cast strip, related work such as RC basement backfill and the like is conducted in advance, engineering construction efficiency is improved, and construction cost is reduced. Construction control is strict, and structural concrete early-stage cracks of the RC basement are effectively controlled. The concrete mixing ratio is optimized, the cement use amount is controlled, and structural concrete shrinkage distortion of the RC basement is effectively controlled. The waterproof quality of concrete of an RC basement structural outer wall and a bottom plate are improved.

Owner:CHINA MCC17 GRP

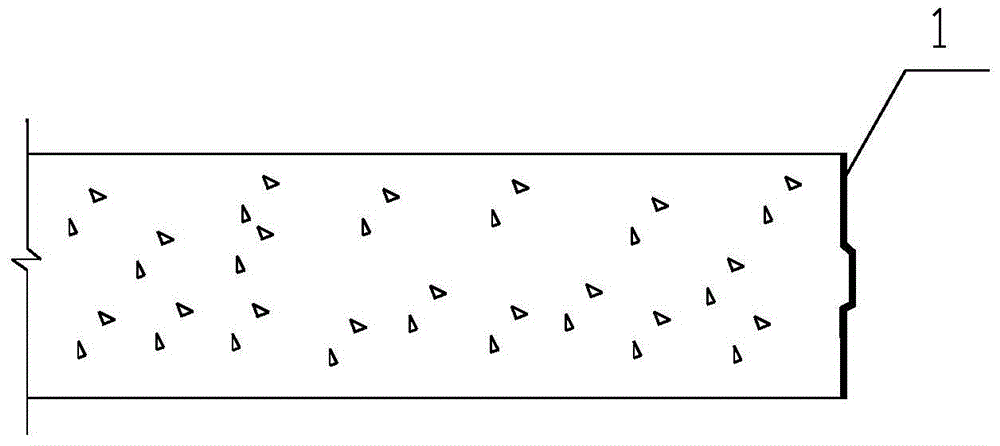

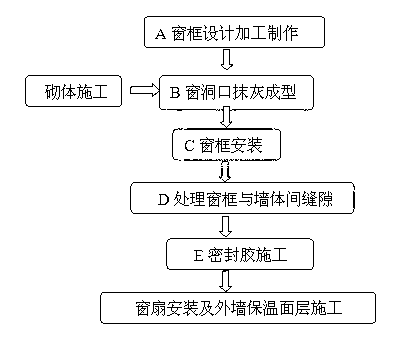

Wall window construction method

ActiveCN103343655AAvoid damageAvoid pollutionFrame fasteningJoints tightening/coveringFoaming agentArchitectural engineering

The invention discloses a wall window construction method. A spigot is painted on a window opening firstly, wherein the balancing thickness of the spigot is about 15mm; a uniform and regular clearance cavity is formed among a small surface of the spigot, a plastering forming surface of a window frame and the window opening; materials behind the window frame and sealants can be packed sufficiently, evenly and densely and be bonded sufficiently and firmly with a base surface which is painted in advance; good air tightness and water tightness are guaranteed, and the waterproof and heat-preserving using effect is also guaranteed. By means of the wall window construction method, an external window can be installed in place at one time, so that the installation speed of the window is greatly increased; the packing materials are filled in the uniform and regular clearance cavity, so that the amount of foaming agents and the sealants for use is also reduced; the window opening check process is optimized, the installation of the window saves time, labor and materials, and the probability that the window is subjected to secondary pollution is greatly lowered; the problem of leakage around the window is solved fundamentally, the waterproof effect is good, the cost is low, maintenance responsibilities are clear, and the maintenance is convenient.

Owner:NANJING CONSTR ENG GRP

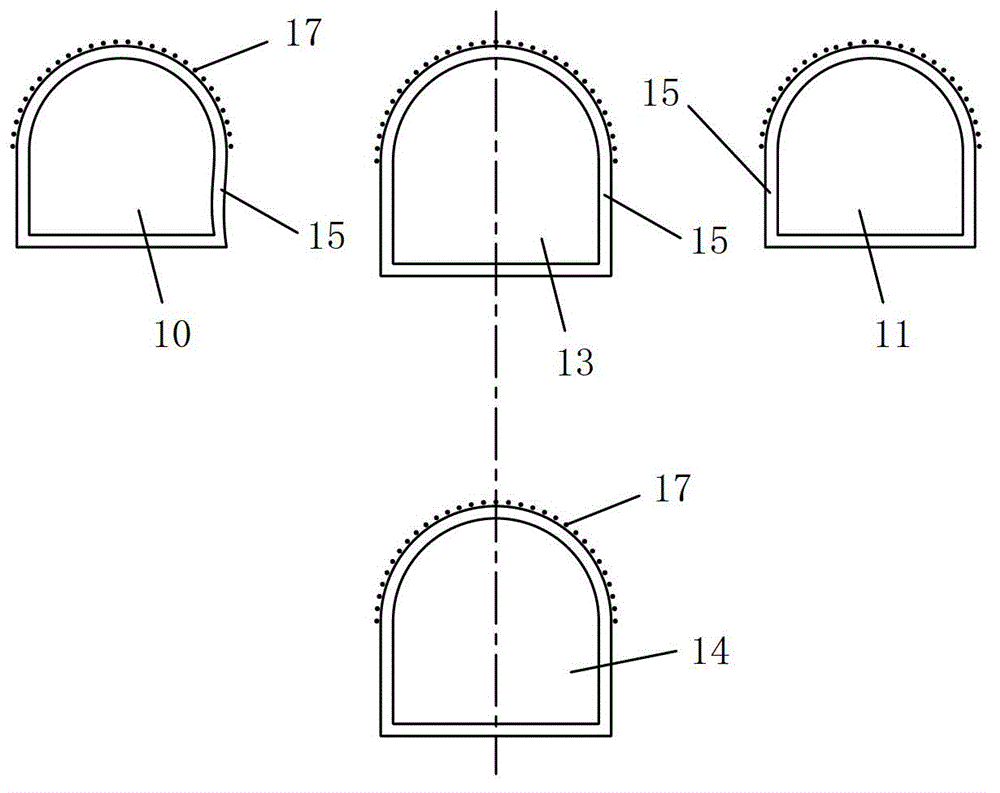

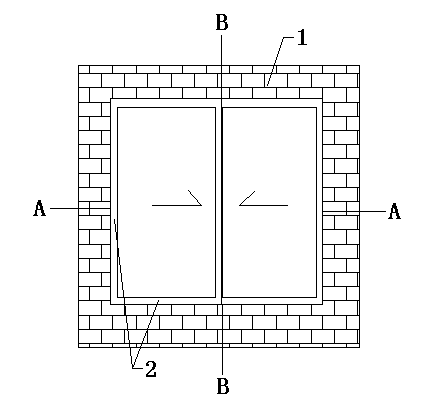

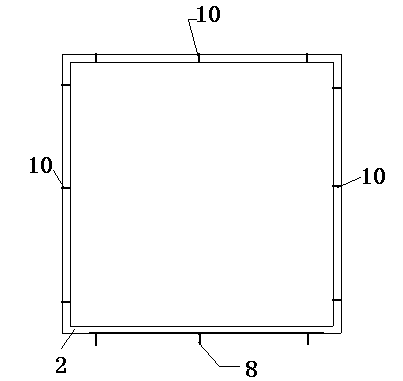

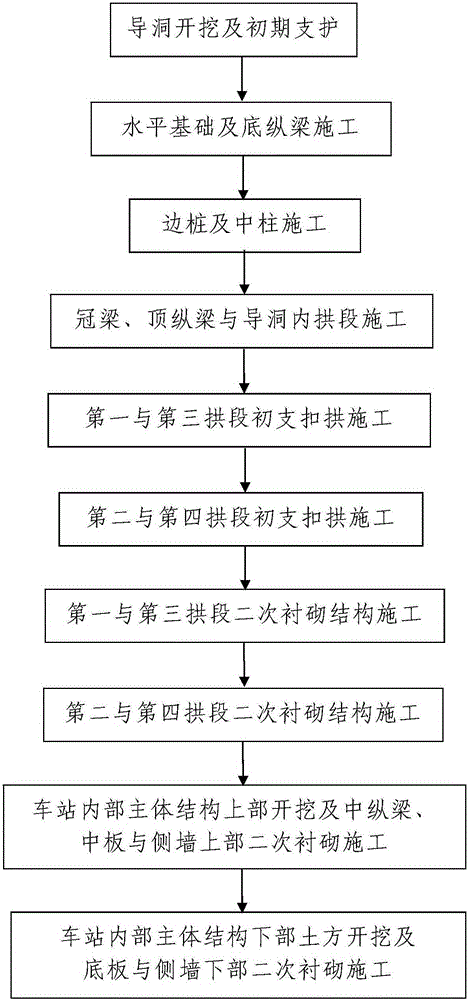

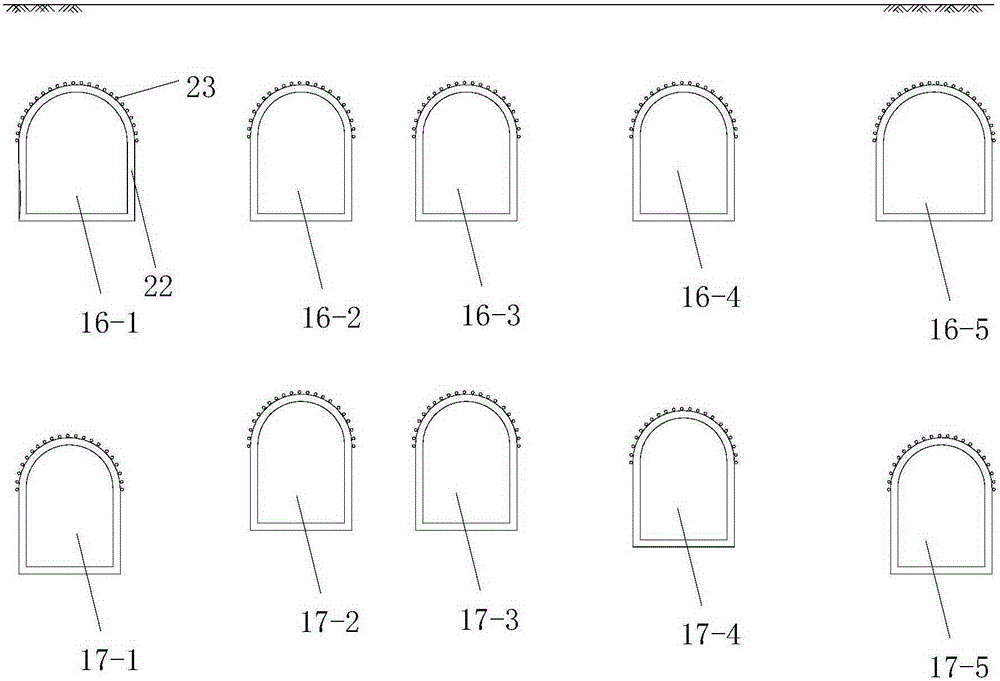

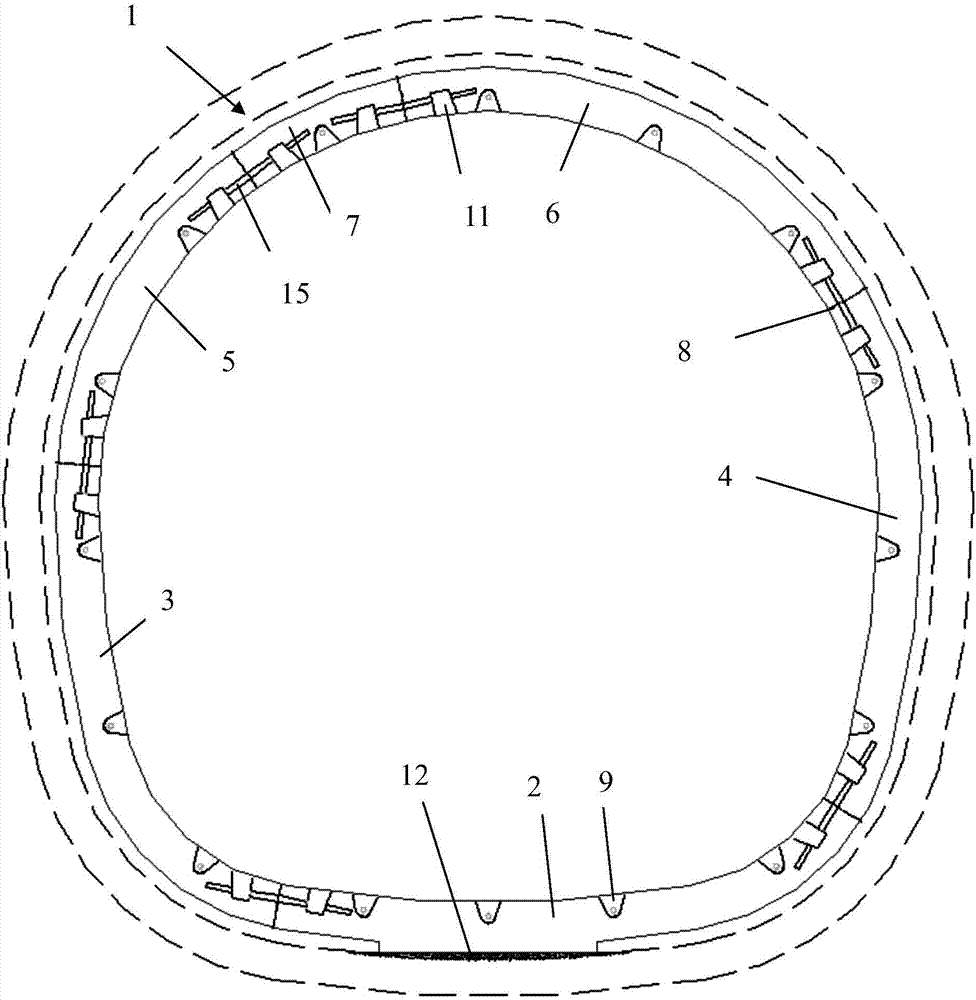

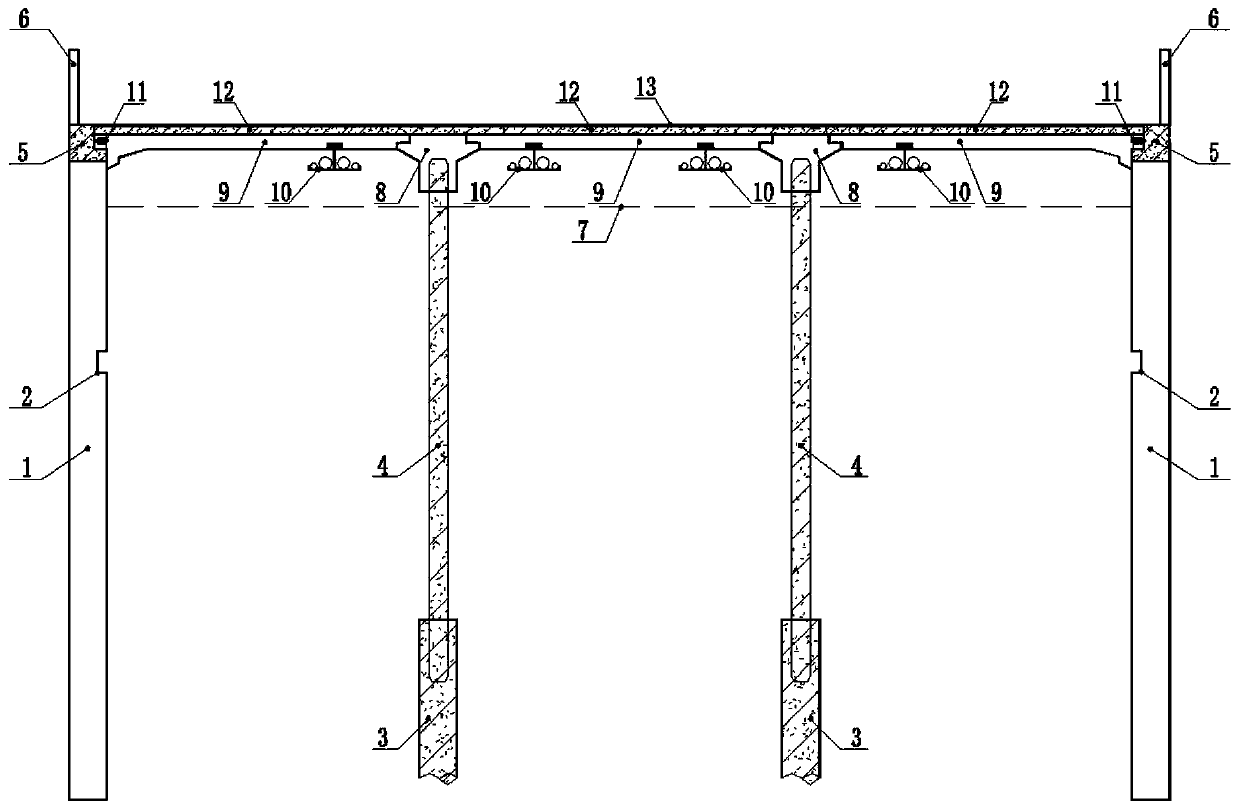

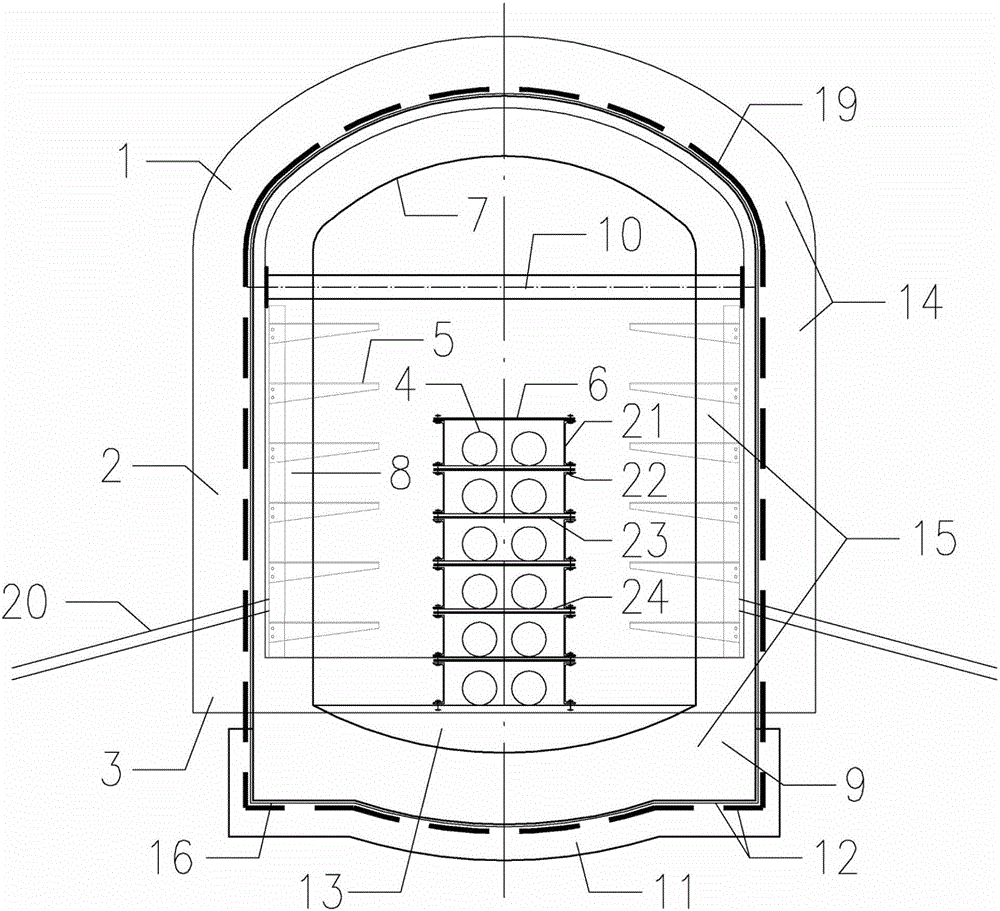

Subway station body structure and four-joint-arch PBA underground excavation construction method thereof

ActiveCN105201516AReasonable structural designStable structureUnderground chambersTunnel liningStructure of the EarthSubway station

The invention discloses a subway station body structure and a four-joint-arch PBA underground excavation construction method thereof. The subway station body structure comprises a station inner body structure, multiple left piles, multiple right piles, three sets of middle columns, middle plates and body arches. The body arches are four-joint arches. The construction method comprises the steps of pilot tunnel excavation and primary support; horizontal base and bottom longitudinal beam construction; side pile and middle column construction; crown beam, top longitudinal beam and pilot tunnel inner arch section construction; first and third arch section primary support buckle arch construction; second and fourth arch section primary support buckle arch construction; secondary lining structure construction of first and third arch sections; secondary lining structure construction of second and fourth arch sections; excavation of the upper portion of the station inner body structure, and secondary lining construction of the middle longitudinal beams, the middle plates and the upper portion of the side wall; earth excavation of the lower portion of the station inner body structure and secondary lining construction of bottom plates and the lower portion of the side wall. The construction is easy, the construction progress is fast, the subway station body structure constructed and formed is firm, and the using effect is good.

Owner:NO 1 ENG LIMITED OF CR20G

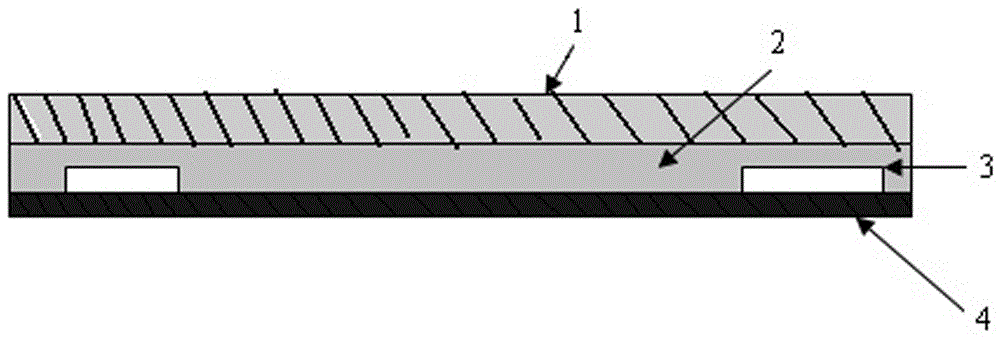

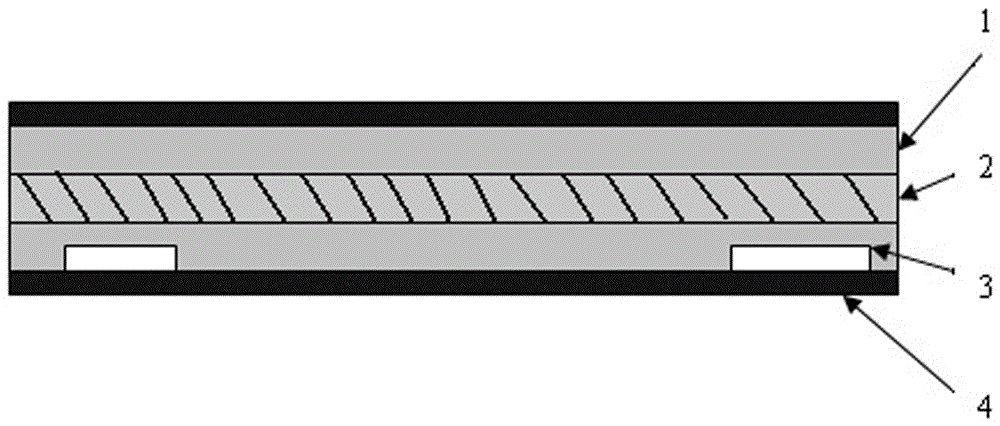

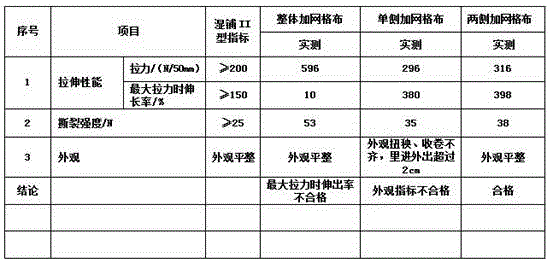

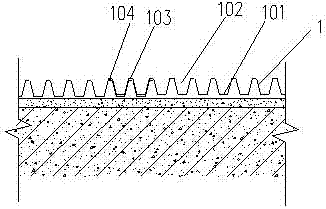

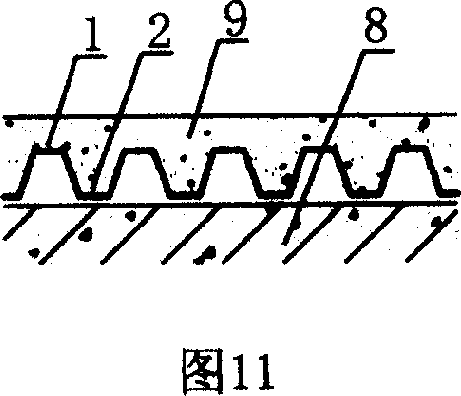

Modified asphalt waterproof coiled material with reinforced overlap edges and production method of modified asphalt waterproof coiled material

InactiveCN107175870AQuality improvementImprove mechanical propertiesRoof covering using flexible materialsSynthetic resin layered productsFiberBituminous waterproofing

The invention relates to a modified asphalt waterproof coiled material with reinforced overlap edges and a production method of the modified asphalt waterproof coiled material. The modified asphalt waterproof coiled material comprises a main body material layer, a modified asphalt layer and an isolating membrane, wherein two strips of fiber cloth are respectively embedded between the parts, which are respectively 0.1-1cm away from the edges of the two sides along the longitudinal direction of the modified asphalt layer, and the isolating membrane, so that the overlap edges are formed. After the method is adopted, the mechanical properties of the overlap edges are obviously improved after the modified asphalt waterproof coiled material is molded, so that the water resistance of the modified asphalt waterproof coiled material is more reliable; the production method provided by the invention solves the problems that in the traditional production process, due to mechanical mismatch of the left side and the right side of the coiled material, the coiled material is neat when being coiled and is twisted when being unfolded, and the like, and improves the quality of the waterproof coiled material.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

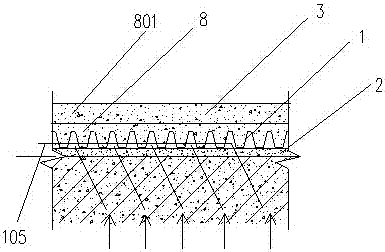

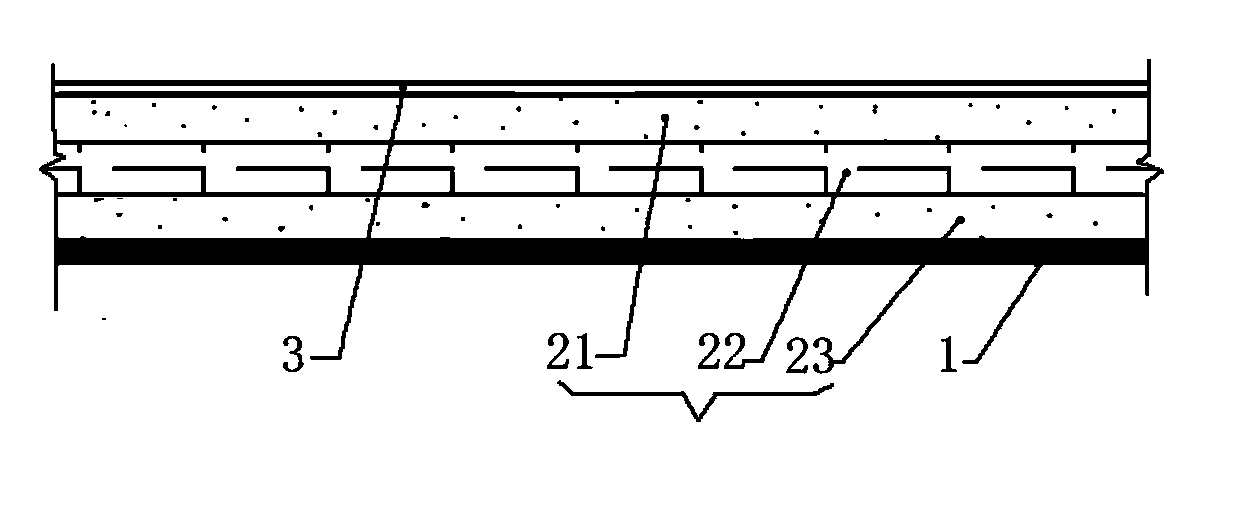

Basement drainage plate and construction method

PendingCN107059946AReduce consumptionReduce energy consumptionProtective foundationBasementSurface layer

The invention discloses a basement drainage plate and a construction method. The basement drainage plate comprises a drainage plate; the drainage plate is arranged at the upper part of a basement baseplate, and is provided with hollow convex points outwards projected; hollow grooves are formed in the other surface of the drainage plate; the drainage plate is buckled and joined with the hollow grooves through the hollow convex points; the hollow convex points are downwards paved; a gap drainage sandwich layer is arranged among the hollow convex points; and concrete is cast in the hollow grooves. The construction method of the basement drainage plate comprises the steps of deep design, construction preparation, substrate treatment, pavement of the drainage plate, casting of the concrete on the drainage plate, construction of reinforcements and surface-layer concrete, and inspection and acceptance. The drainage plate is joined in a basement to achieve large-area standard construction, convenient and fast operation and low cost; the next procedure can be performed after the pavement is finished; the standard material and the standard construction are achieved; the material consumption and the construction energy consumption are reduced; and the national policy requirements of energy conservation and emission reduction are met.

Owner:CHINA HUASHI ENTERPRISES

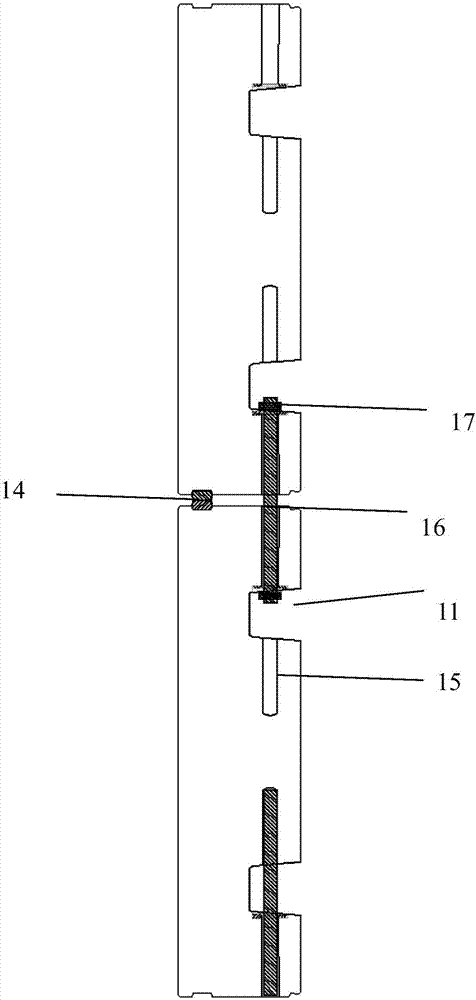

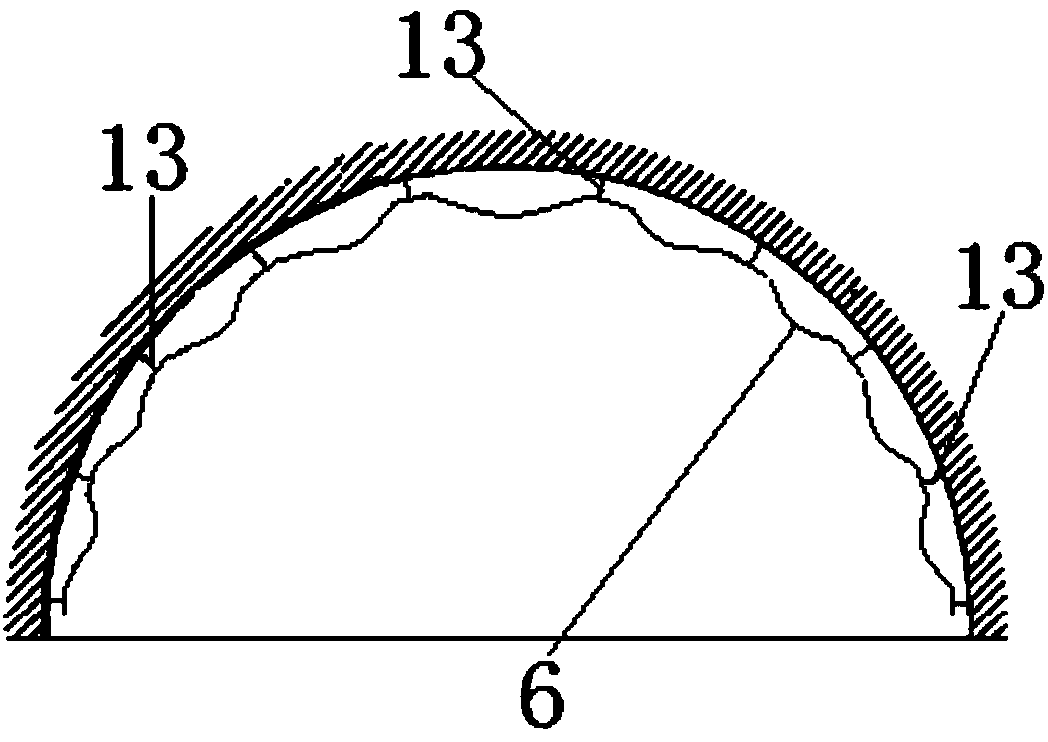

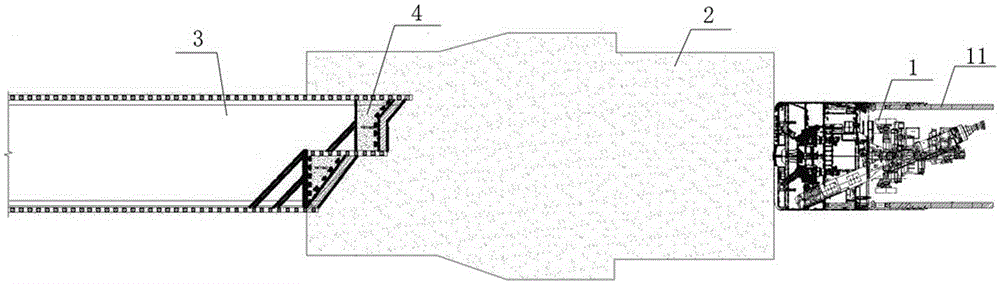

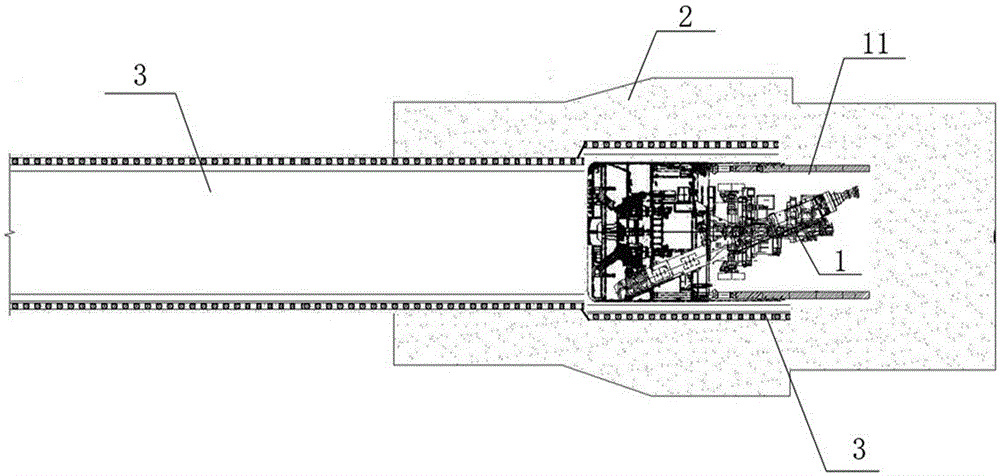

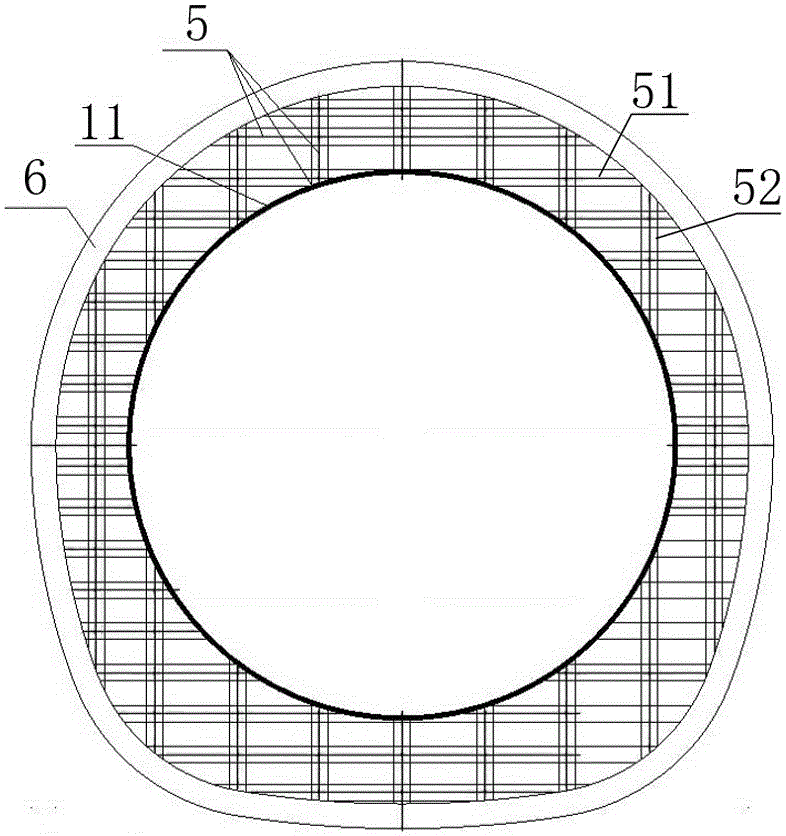

Construction method for initial supporting arch secondary-lining independent tunnel excavation and structures

ActiveCN105332709AImprove waterproof performanceImprove waterproof qualityUnderground chambersTunnel liningUnderground tunnelField monitoring

The invention relates to a construction method for concealed excavation of underground tunnels, in particular to a construction method for initial supporting arch secondary-lining independent tunnel excavation and structures. Tunnels in arch structural forms can be constructed by the aid of the method. The method can be applied to double-arch tunnels, triple-arch tunnels, four-arch tunnels and multi-arch tunnels with the arch quantities higher than four. The method includes general steps of arranging advanced small guide pipes; excavating earth by pneumatic spades in an artificially assisted manner; constructing primary linings and simultaneously reserving connecting components; timely grouting the back of shape steel according to field monitoring data; constructing material transport devices; constructing waterproof layers; erecting support formworks; constructing second linings; detaching the second linings to complete construction. The construction method has the advantages that high risks of construction of special concealed excavation intervals in urban traffic engineering can be reduced, the waterproof quality can be guaranteed, influence on ambient environments can be diminished, the construction speeds can be increased, and the engineering investment can be lowered.

Owner:BCEG CIVIL ENG +1

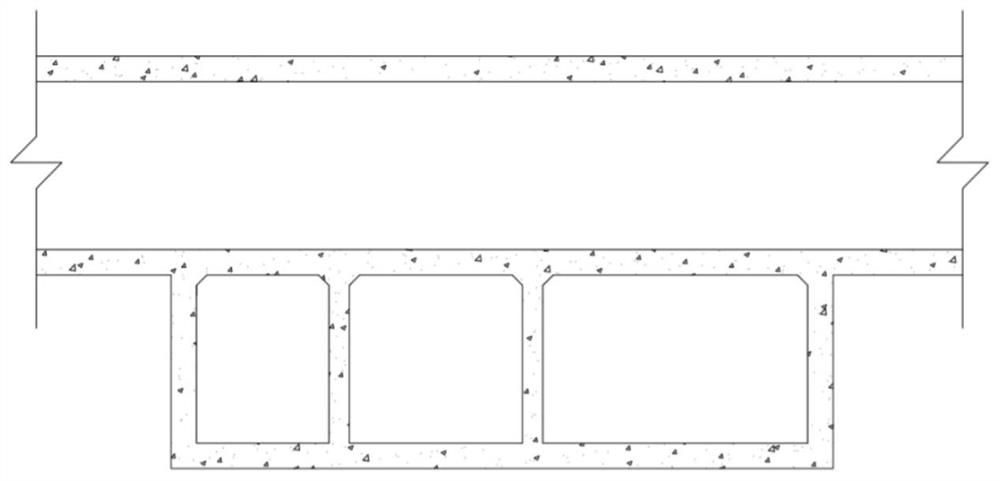

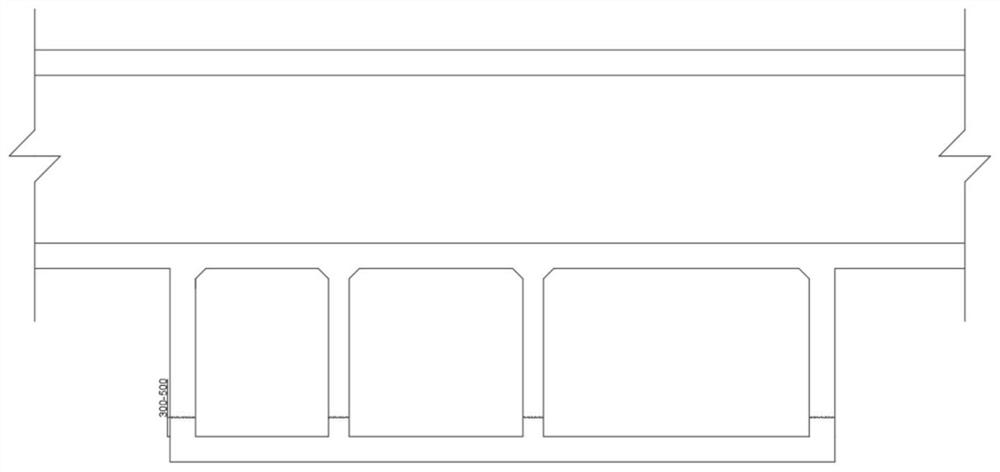

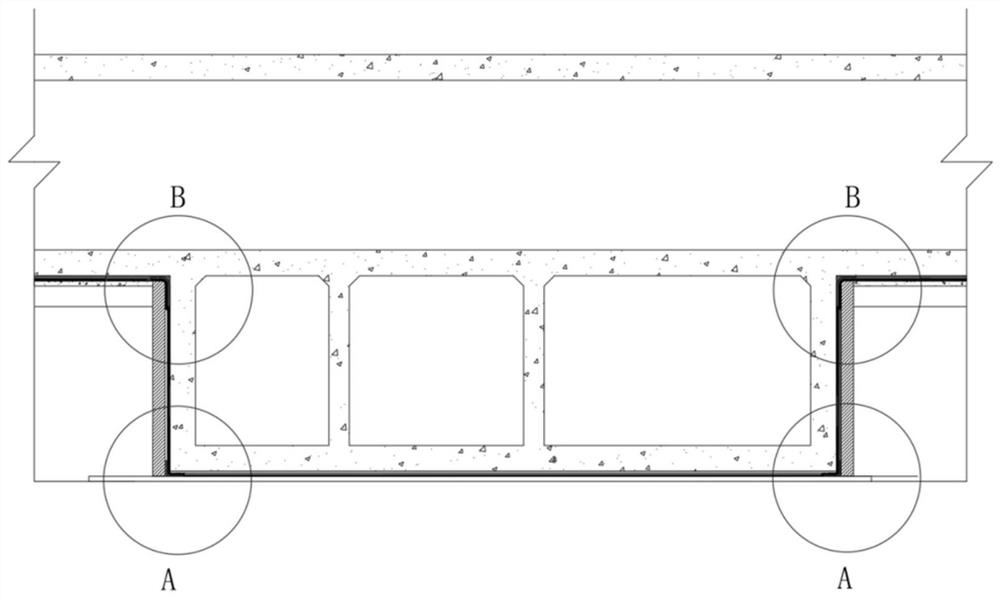

Construction method of main line fabricated secondary lining in subway underground excavation section

ActiveCN106930777AImprove mechanical propertiesImprove construction efficiencyUnderground chambersTunnel liningEngineeringBuilding construction

The invention provides a construction method of a main line fabricated secondary lining in a subway underground excavation section. Construction of a tunnel secondary lining structure is completed in a subway underground excavation section of a structure subjected to primary supporting by means of the method that starting and receiving of a prefabricated pipe piece assembling device and conveying of materials such as a prefabricated pipe piece are conducted through a conventional vertical shaft and a cross channel, and assembling of the prefabricated pipe piece is conducted through a dedicated pipe piece assembling device, flexibility of an underground excavation tunnel is combined, meanwhile the mechanical level and construction work efficiency of an underground excavation secondary lining are improved, an on-site operation environment is improved, safety of on-site operation is improved, the water-proof quality is improved, and industrial production is achieved.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

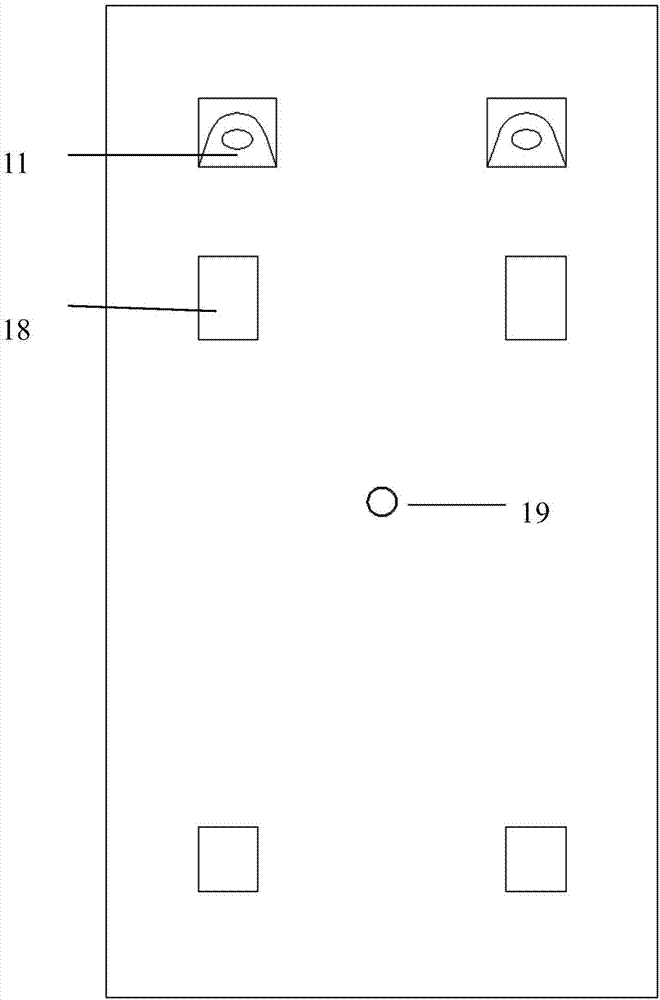

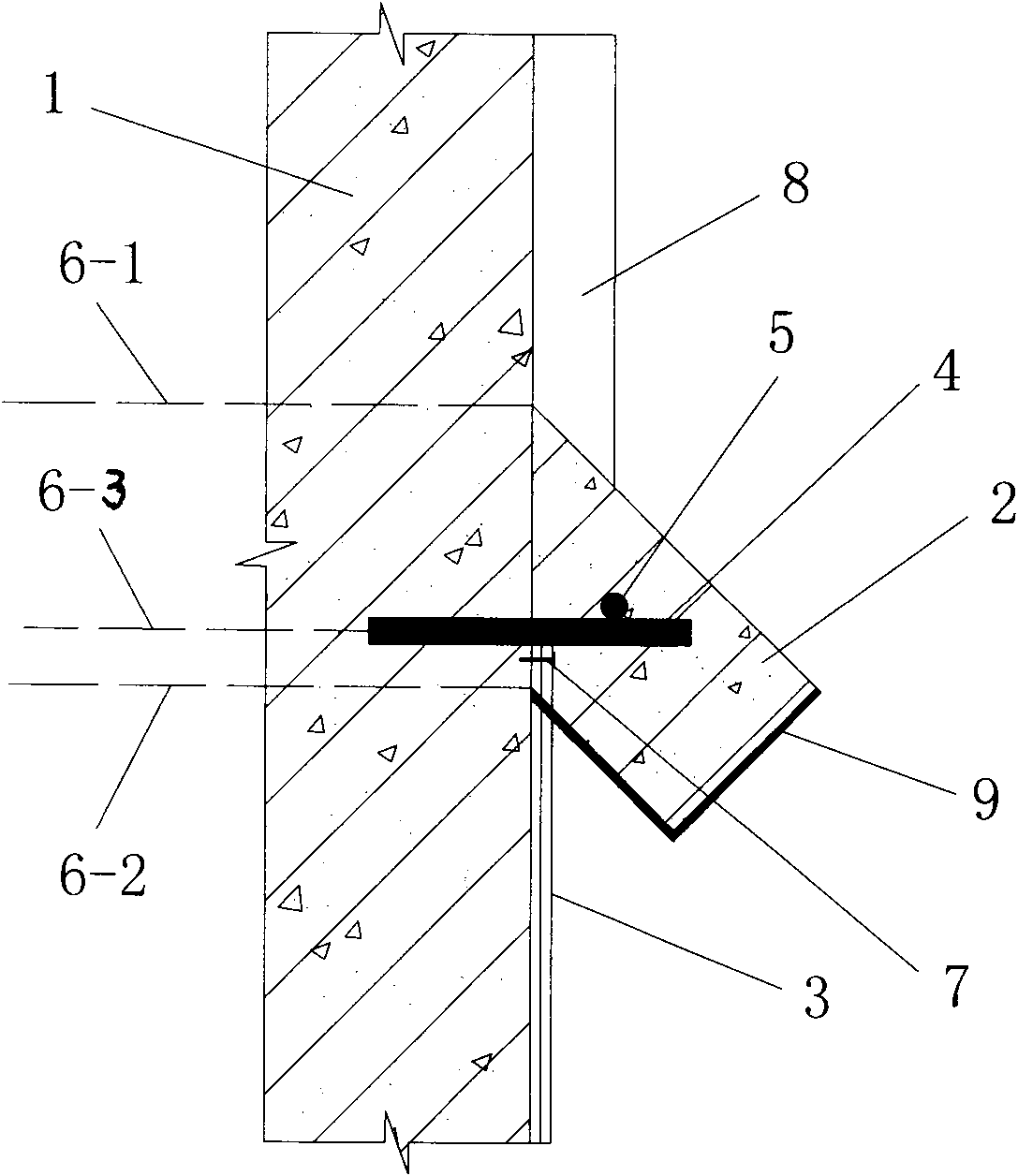

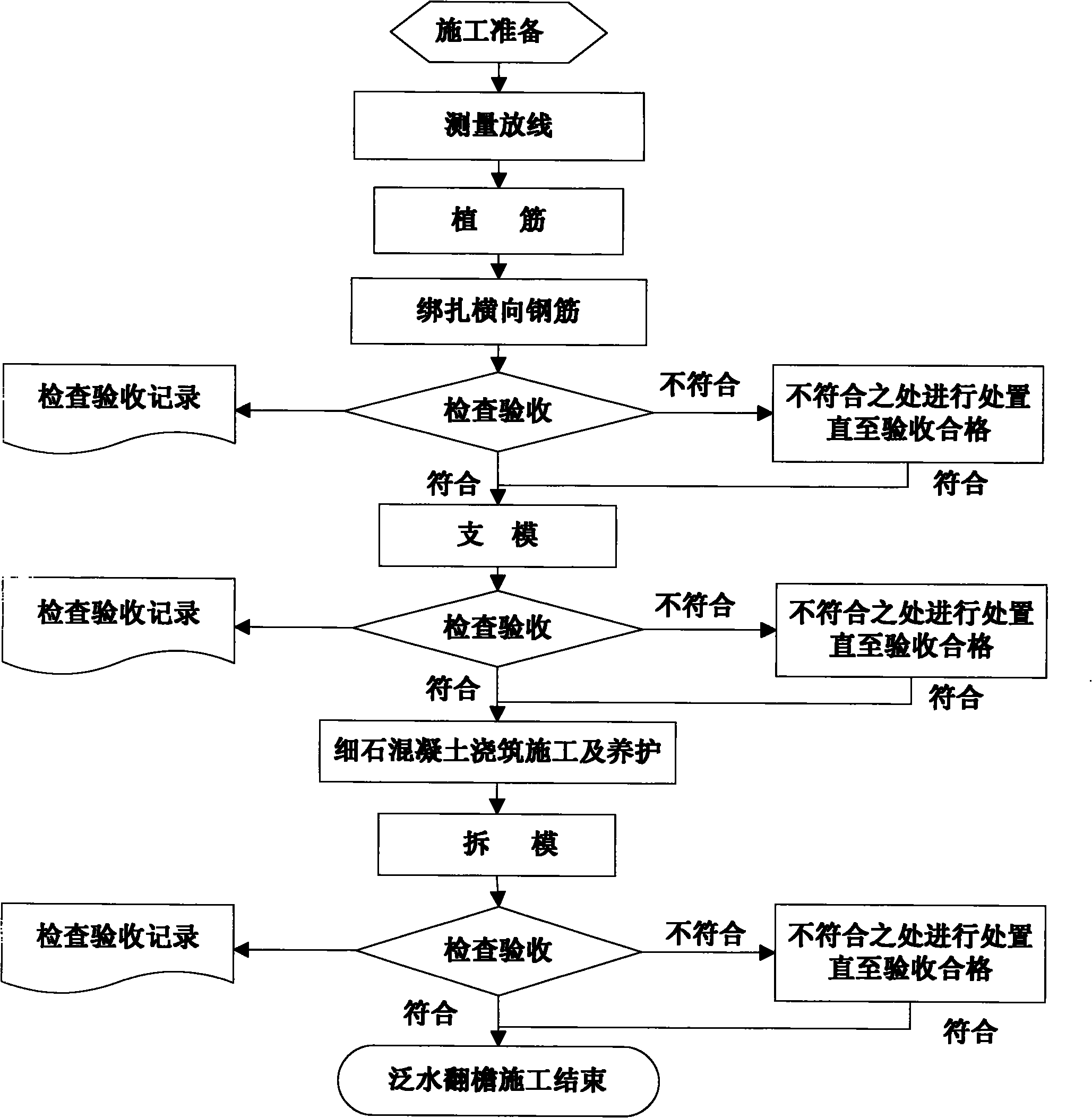

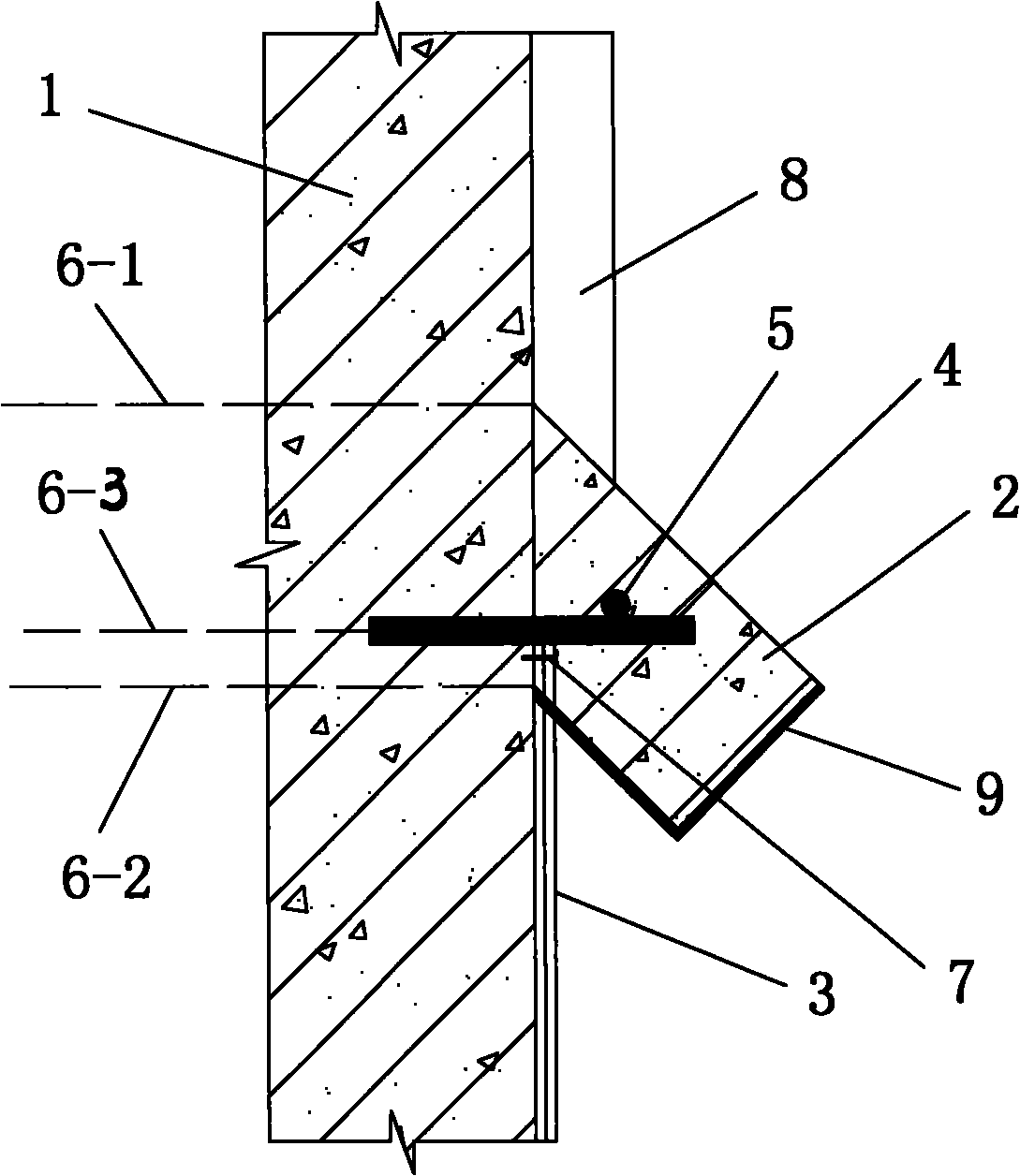

Waterproof tilted eave of roof parapet and construction method thereof

ActiveCN101929224AEasy constructionEasy to operateRoof coveringBuilding insulationsReinforced concreteEaves

The invention discloses a waterproof tilted eave of a roof parapet and a construction method thereof. The waterproof tilted eave comprises concrete tilted eaves and rigid skeletons, wherein the concrete tilted eaves are distributed on the inner wall surface of the parapet and are tilted from top to bottom, the rigid skeletons are embedded in the concrete tilted eaves, the upper closed end of a waterproof coiled material positioned below the concrete tilted eaves is firmly pressed between the bottom of the concrete tilted eaves and the parapet, and the parapet is a reinforced concrete wall and is firmly connected with the concrete tilted eaves into a whole. The construction method of the waterproof tilted eave comprises the following steps: 1, measuring and paying off; 2, carrying out rigid skeleton construction; 3, erecting a formwork; 4, carrying out concrete pouring construction; 5, curing the concrete; and 6, removing the formwork. The invention has the advantages of reasonable design, simple construction, low input cost and high work efficiency, and the constructed waterproof tilted eave has beautiful appearance and good waterproof effect, thereby effectively solving the problems of short serviceable life, easy aging and cracking, poor waterproof effect, poor overall visual effect of the roof, high maintenance cost and the like in the traditional waterproof structure.

Owner:陕西建工第十一建设集团有限公司

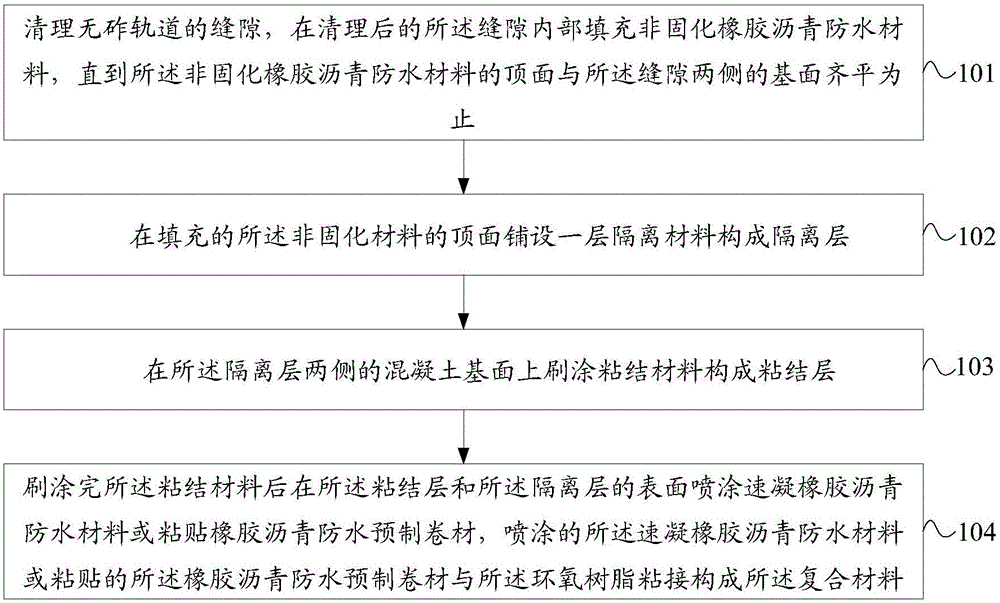

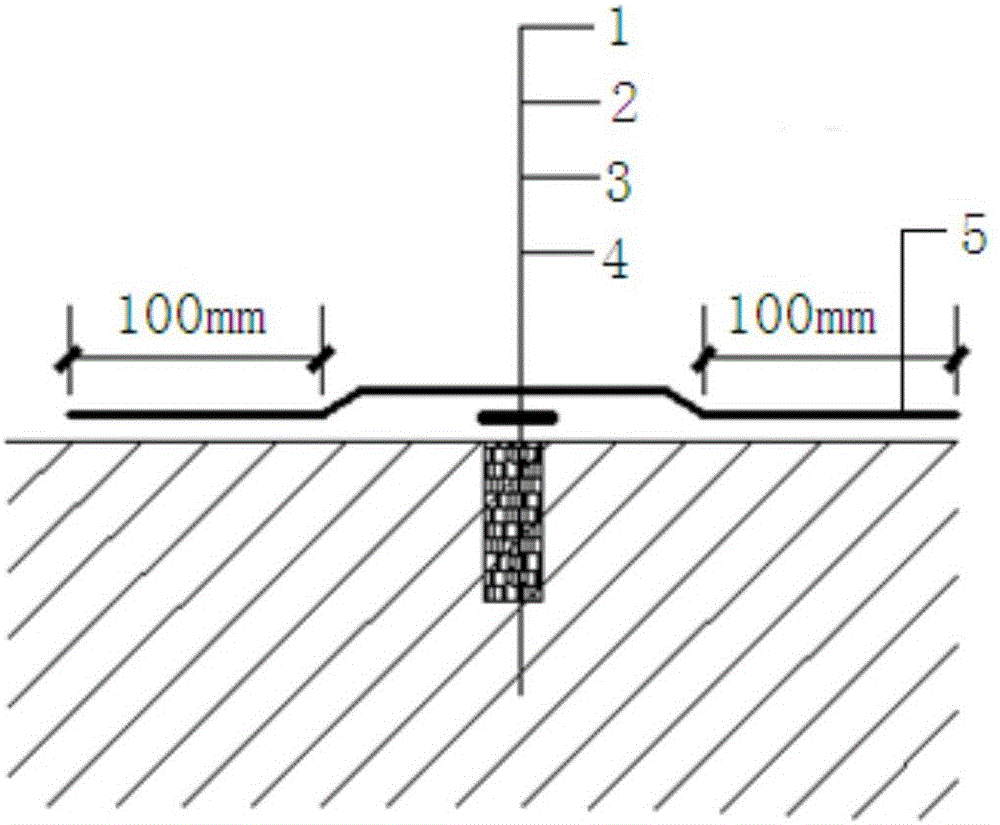

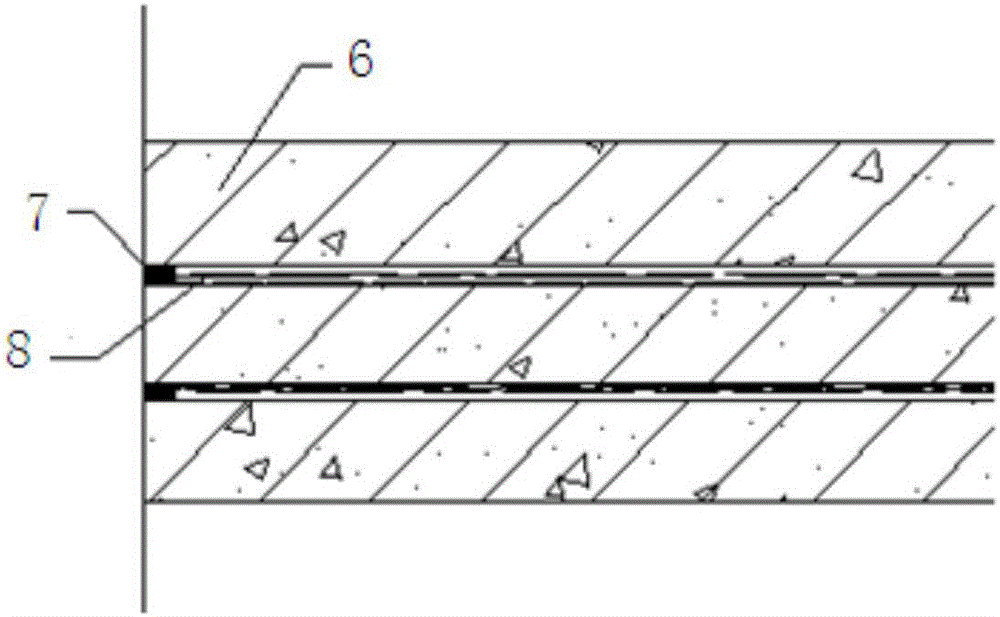

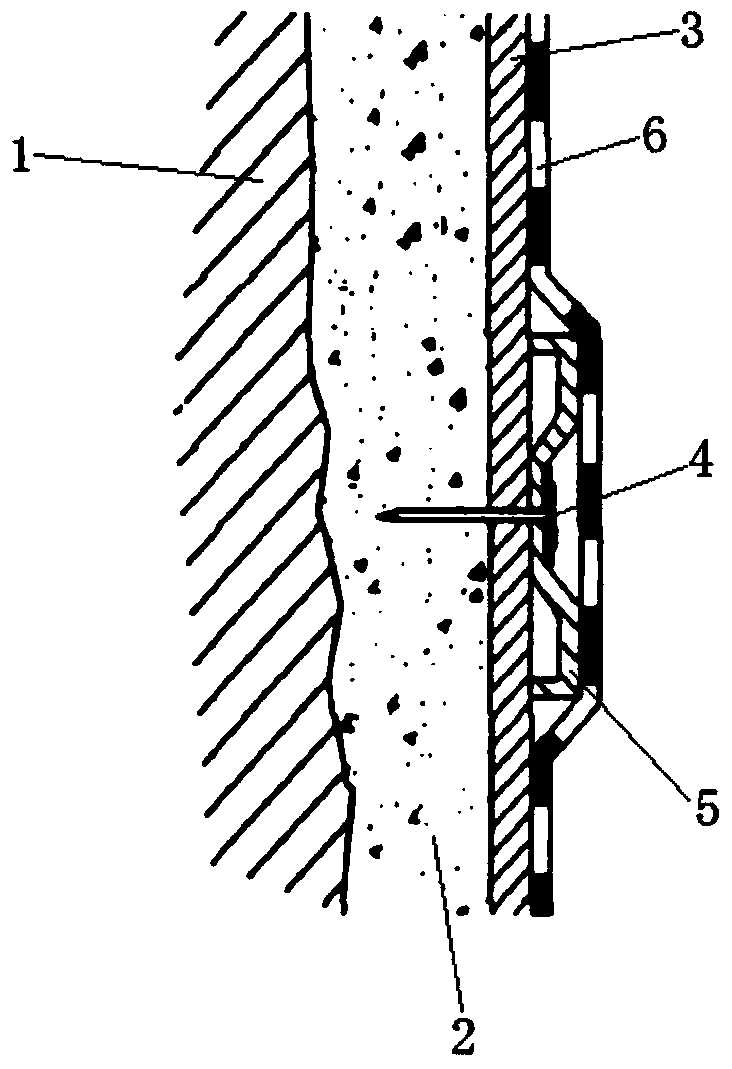

Composite material and method for conducting ballastless track waterproof maintenance by adopting composite material

ActiveCN105002794AStrong adhesionResist strong shear stressBuilding insulationsTrack maintainenceBituminous waterproofingShear stress

The invention provides a composite material and a method for conducting ballastless track waterproof maintenance by adopting the composite material. The method comprises the steps that a gap of a ballastless track is cleaned, and the cleaned gap is filled with a non-curing rubber asphalt waterproof material; an isolation material is laid on the top face of the non-curing rubber asphalt waterproof material to form an isolation layer; concrete base surfaces on the two sides of the isolation layer are coated with binding materials to form binding layers; after the concrete base surfaces are coated with the binding materials, the surfaces of the binding layers and the isolation layer are coated with rapid hardening rubber asphalt waterproof materials or sticky rubber asphalt waterproof prefabricated coiled materials. According to the composite material and the method for conducting ballastless track waterproof maintenance, the good adhesive force of the gap maintained through the method is ensured, powerful shearing stress caused when a train passes the gap at high speed can be effectively resisted, and the composite material is flexible, can effectively resist concrete vibration caused when the train passes the gap at high speed, is not prone to brittle surface factures, and ensures safety usage of the ballastless track.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

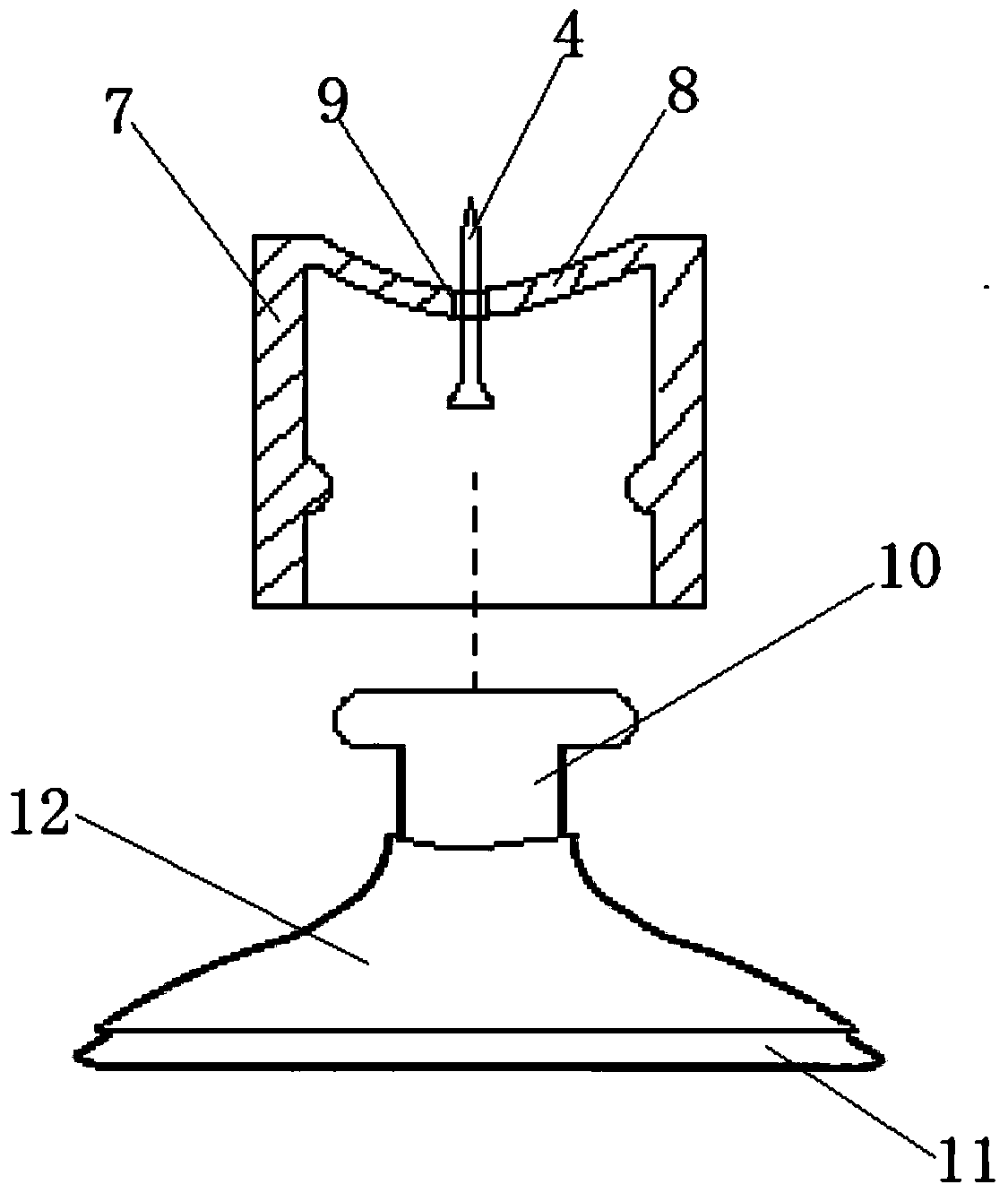

Sucker device for waterproof board construction and tunnel waterproof board construction method

InactiveCN103912291AAvoid welding damage and other damageReduce volumeUnderground chambersTunnel liningAdhesiveArchitectural engineering

The invention discloses a sucker device for waterproof board construction and a tunnel waterproof board construction method. The sucker device comprises a sucker body made by a soft material, and a fixing member, a protruding handle is arranged on the back of the sucker body, the sucker body is connected at one end of the fixing member through the handle, a fastener hole is arranged at the other end of the fixing member, and an adhesive is coated on the adsorption surface of the sucker body. During laying, geotechnical cloth is laid on a tunnel profile face, the fixing member of the sucker device is fixed outside the geotechnical cloth by enabling a fastener to penetrate the fastener hole, the handle of the sucker device is connected on the fixing member in a clamped manner, release paper on the surface of the sucker body is torn off, a waterproof board is upwards jacked and pressed on the sucker body of the sucker device to enable the sucker body to suck the waterproof board, and then the waterproof board is fixedly connected to complete laying of the waterproof board. The waterproof board can be fixed by only pressing the waterproof board on the sucker device when the waterproof board is lifted by adopting the sucker device, so that steps for welding and fixing the waterproof board are not needed.

Owner:邓卫东

Composite fabricated underground structure and reverse construction method thereof

PendingCN110004981AQuality improvementImprove qualityArtificial islandsProtective foundationWater leakagePre stress

The invention discloses a composite fabricated underground structure. The composite fabricated underground structure comprises underground walls, steel structure clamping grooves, prestressed jacks, and main structure standing columns; prefabricated top longitudinal beams, prefabricated top plates, top plate cast-in-place layers, and top plate waterproof layers jointly form composite waterproof prestressed top plates; prefabricated middle longitudinal beams, prefabricated middle plates, and middle plate cast-in-place layers jointly form composite middle plates; prefabricated cushion layers, bottom plate waterproof layers and cast-in-place bottom plates jointly form composite waterproof bottom plates; the underground walls, side wall waterproof layers, and side wall cast-in-place layers jointly form composite waterproof walls; the composite waterproof prestressed top plates, the composite prestressed middle plates, the composite waterproof bottom plates and the composite waterproof walls are all effectively connected, and the full-package waterproof full-composite fabricated underground structure is formed; thus the problem of water leakage of the fully fabricated underground structure is solved, the limitation of the application range of the fabricated underground structure is broken, the composite fabricated underground structure can be applied to the areas with water-rich stratums, complicated surrounding environment and high deformation control, and the extensive application of the prefabricated structure in underground engineering can be effectively promoted.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

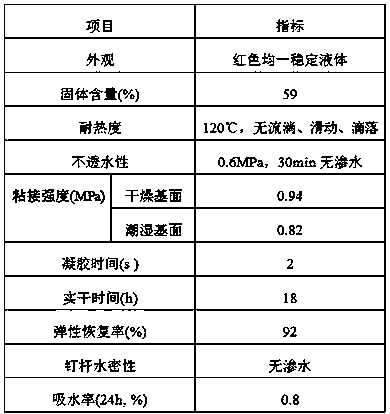

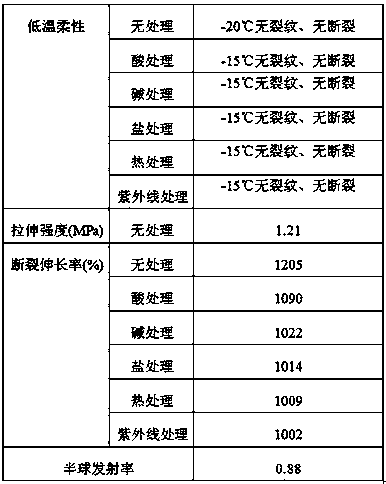

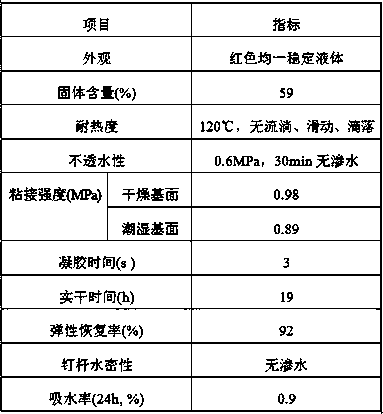

Heat reflection type colored spray-quick-setting rubber-asphalt waterproof coating material and preparation method therefor

ActiveCN109280452AHigh solid contentWater-based environmental protectionRosin coatingsConjugated diene hydrocarbon coatingsNano zinc oxideAsphalt

The invention provides a heat reflection type colored spray-quick-setting rubber-asphalt waterproof coating material. The waterproof coating material is characterized by comprising a component A and acomponent B, wherein the component A comprises the following ingredients: emulsified modified asphalt, fillers, an infrared reflection pigment, nano zinc oxide, a dispersant, latex, a bactericide, water and color paste. The component B is prepared through mixing calcium chloride, sodium chloride and water according to the mass ratio of 7.8: 0.2: 92. The waterproof coating material is aqueous andenvironmentally friendly and is high in adhesion and high in bonding strength.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL +3

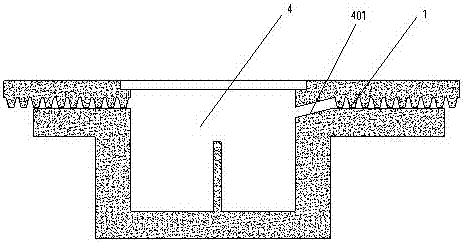

Open caisson construction method

The invention discloses an open caisson construction method. Through the open caisson construction method, the ground work face is reduced, and the influence of the weather on the construction is reduced; the manner that a well wall inner formwork and a well wall outer formwork sink into the ground along with a concrete well wall is used, so that form stripping is avoided, and well bore quality is ensured; a soil taking and well bore pouring synchronization manner is adopted, so that construction efficiency is improved; a steel pipe pile is taken as the guidance, so that construction quality is ensured, and therefore the problems of large workload caused by repeated dismounting and mounting of a scaffold and a formwork, large construction area, high requirement on construction safety, long construction period, no guide measures and having difficulty in ensuring engineering quality in the prior art are solved; and the aims of improving the construction efficiency, ensuring construction quality and ensuring construction safety are achieved.

Owner:张士普

Sleeved inner liner reinforcing structure for electrical operation of cable tunnel and construction method thereof

InactiveCN106337688AReasonable structural designImprove stabilityUnderground chambersTunnel liningStructural engineeringStructural stability

The invention belongs to the technical field of tunnels and underground engineering design and construction and especially relates to a sleeved inner liner reinforcing structure for electrical operation of a cable tunnel and a construction method thereof. The sleeved inner liner reinforcing structure comprises an original arch portion, an original side wall, a base plate cushion, an inverted arch, an inner liner arch portion, an inner liner side wall, a cable support, a cable and a sidewalk base plate. The construction method has following steps: (1) a middle cross arm is erected at the middle of the tunnel; (2) excavation downwards is executed to the bottom of the tunnel original base plate; (3) the structure inverted arch is cast and the sidewalk base plate is cast on the inverted arch; (4) the cable is shifted to a middle position of the tunnel; (5) a water proof layer on the original tunnel inner wall surface is laid and the inner liner arch portion and the inner liner side wall are cast with molds; (6) the cable support and the cable are reinstated and a pavement structure is cast. The invention can ensure the effective control of the strata deformation and the structural stability in the complex environment of the city, and realize the normal operation of the cable in the tunnel during the reinforcement construction stage to ensure the safety of the tunnel structure and power supply and prolong the service life of the cable tunnel.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

FS101, FS102 underground rigid composite waterproof construction method

InactiveCN109056843ASolve the complex construction processImprove waterproof qualityProtective foundationRebarMaterials science

The invention discloses a FS101, FS102 underground rigid composite waterproof construction method. The main process flow is as follows: excavating a foundation pit -> cushioning a concrete layer -> smearing a FS101 waterproof mortar -> binding steel bars -> pouring a FS102 waterproof concrete bottom plate, exterior wall and top plate -> smearing the FS101 waterproof mortar on the exterior wall ->backfilling soil. According to the construction method, the problems of low traditional construction speed and underground structure leakage are effectively solved, the method is easy and convenient to operate, an underground construction period is shortened, a waterproof cost of underground engineering is reduced, a waterproof guarantee degree of underground engineering can be improved, the waterproof life of underground engineering can be prolonged, and the reduction and conservation of power consumption, and green construction are really achieved.

Owner:CHINA MCC17 GRP

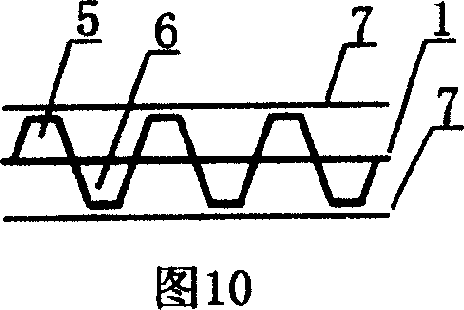

Asphalt-free energy-saving environment-friendly polymer waterproof roll and preparation method thereof

InactiveCN104070719ASimple structureGood extensibilitySynthetic resin layered productsLaminationPolyesterCooking & baking

The invention discloses an asphalt-free energy-saving environment-friendly polymer waterproof roll and a preparation method thereof. The waterproof roll is of a multilayer composite structure, and comprises an upper isolation layer, a middle core layer and a lower protective film layer, wherein the core layer comprises an upper adhesive layer, a lower adhesive layer and a middle non-woven fabric isolation layer; the non-woven fabric isolation layer is a polymer polyester fiber non-woven fabric; the upper adhesive layer and the lower adhesive layer are provided with a special asphalt-free waterproof adhesive; the special waterproof adhesive comprises the following components in parts by weight: 14-35 parts of 1301# SBS thermoplastic butadiene styrene rubber, 10-18 parts of petroleum resin, 20-50 parts of 460# naphthenic oil and 10-20 parts of talcum powder. The waterproof roll does not contain asphalt, has energy-saving and environment-friendly effects, is convenient to manufacture and use and high in practicality and has a good waterproof effect; blast burner baking is not needed, so that fire hazard is reduced, and the safety in the manufacturing and using process is guaranteed.

Owner:中联天盛建材集团有限公司

Manufacturing method and structure for basement floor without crack, leakage and with oversized area

InactiveCN104060628AAvoid crackingImprove waterproof qualityArtificial islandsProtective foundationReinforced concreteFloor slab

The invention discloses a manufacturing method and a structure for a basement floor without crack, leakage and with an oversized area. According to the method and the structure, disclosed by the invention, a concrete self waterproof floor board layer is firstly poured, and the concrete self waterproof floor layer is poured by adopting leakage resisting concrete; a drain board layer made from high impact polystyrene (HIPS) is paved on the concrete self waterproof floor board layer; then, a plain concrete leveling layer is poured on the drain board layer; a reinforced concrete layer of which the thickness is from 160 to 260mm is poured on the plain concrete leveling layer, the reinforced concrete layer is divided into small integrated reinforced concrete layers by expansion joints, and extruded polystyrene board materials are filled in the expansion joints; a polyurethane coating layer is painted on each small integrated reinforced concrete layer of the reinforced concrete layer, and silicone weather-proof glue is filled in a gap between every two adjacent polyurethane coating layers. The structure has the advantages of difficulty in sinking, no crack, no leakage and the like.

Owner:CHINA CONSTR FOURTH ENG DIV

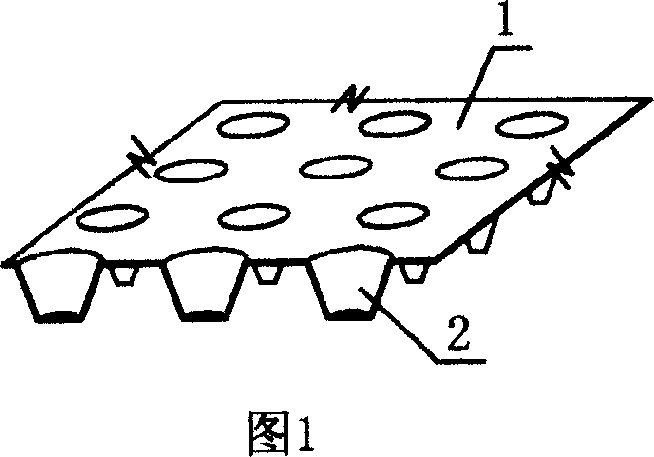

Method of multipurpose of aluminium foil air layer in building and aluminium-plated plate with supports

InactiveCN1955387AImprove waterproof qualityMeet energy saving requirementsCovering/liningsClimate change adaptationBasementLeaking water

An air layer formed by aluminum foil is made between a substrate and a surface layer of roof, wall, floor, etc for saving energy, draining leaked water or condensed water, passing the electric lines through it, isolating sound and moisture, etc. A series of 3 aluminum plated plates with fulcrums is also disclosed.

Owner:邹新建

Subsurface tunnel reverse shield receiving method

The invention discloses a subsurface tunnel reverse shield receiving method. The subsurface tunnel reverse shield receiving method comprises the following steps that firstly, a subsurface tunnel is constructed in front of the preset receiving position of a shield; secondly, soil of the shield receiving section is reinforced; thirdly, after a shield tunneling machine tunnels to the shield receiving position, cover removing construction is conducted on the closed working face of the subsurface tunnel; fourthly, a section is excavated towards the shield receiving position along the subsurface tunnel, and excavating is conducted until a shield cutter disk is exposed out completely and part of a shield shell is exposed out; fifthly, end sealing is conducted on a tunnel face between an underground excavation primary support and the shield shell; sixthly, the interior of the subsurface tunnel is reinforced; seventhly, components, except the shield shell, of the shield tunneling machine are dismounted in the tunnel and conveyed out; eighthly, waterproof construction in the subsurface tunnel and waterproof construction in the shield shell are conducted, and then remaining secondary lining construction is conducted. The subsurface tunnel reverse shield receiving method solves the technical problems existing in disassembling, dismounting and conveying of the shield tunneling machine in a cave at the section without the condition of hoisting receiving.

Owner:BCEG CIVIL ENG

Polyester reinforcement and preparation method thereof as well as waterproof membrane

ActiveCN104647845AExtended service lifeImprove waterproof qualitySynthetic resin layered productsBituminous layered productsPolyesterCorn starch

The invention provides a polyester reinforcement and a preparation method of the polyester reinforcement. The polyester reinforcement belongs to the technical field of waterproof membranes, and can solve the problem that the waterproof effect of an existing waterproof membrane can be reduced due to improper construction in a construction process. The polyester reinforcement provided by the invention is obtained by impregnation of a non-woven fabric in impregnation liquid, and the impregnation liquid contains a fluorine-containing waterproof agent and a corn starch adhesive. After water enters the end surface of the waterproof membrane in the construction process, the polyester reinforcement provided by the invention can effectively prevent the water from wetting and penetrating the interior of the waterproof membrane, so that the service life of the waterproof membrane is effectively prolonged, the waterproof effect of the waterproof membrane is effectively improved, the risk of water seepage is reduced, and the hidden danger of water seepage is eliminated.

Owner:TIANDINGFENG NONWOVENS CO LTD

Construction method for prefabricated pipe gallery joint water proofing

ActiveCN108547327APrevent infiltrationImprove waterproof qualityArtificial islandsProtective foundationArchitectural engineeringAtmospheric pressure

The invention particularly discloses a construction method for prefabricated pipe gallery joint water proofing. The construction method is characterized by comprising the steps that a groove is reserved at the joint of a prefabricated pipe gallery main body structure when a waterproof protection layer is constructed, an uninflated strip-shaped inflating bag is pre-laid at the bottom of the reserved groove, and self-adhering rubber waterstop is pre-laid on the strip-shaped inflating bag; after a prefabricated pipe gallery is installed, the strip-shaped inflating bag is inflated, and the self-adhering rubber waterstop is firmly adhered to the joint of the prefabricated pipe gallery main body structure through air pressure; the inflated air bag is deflated and then detached; and a grouting pipe is laid on one side of the reserved groove, an exhaust pipe is arranged on the other side of the reserved groove, a high-performance waterproof roll is arranged on the side wall to be adhered firmly from the outer side of a bottom plate of the prefabricated pipe gallery in a reverse wrapping mode, a closed space is formed under the bottom plate, and then waterproof mortar is injected to fill the gap of the bottom plate. Therefore, the condition that underground water permeates into the pipe gallery through the inserting joint along the gap can be avoided, and the waterproof quality is improved.

Owner:CHINA MCC20 GRP CORP

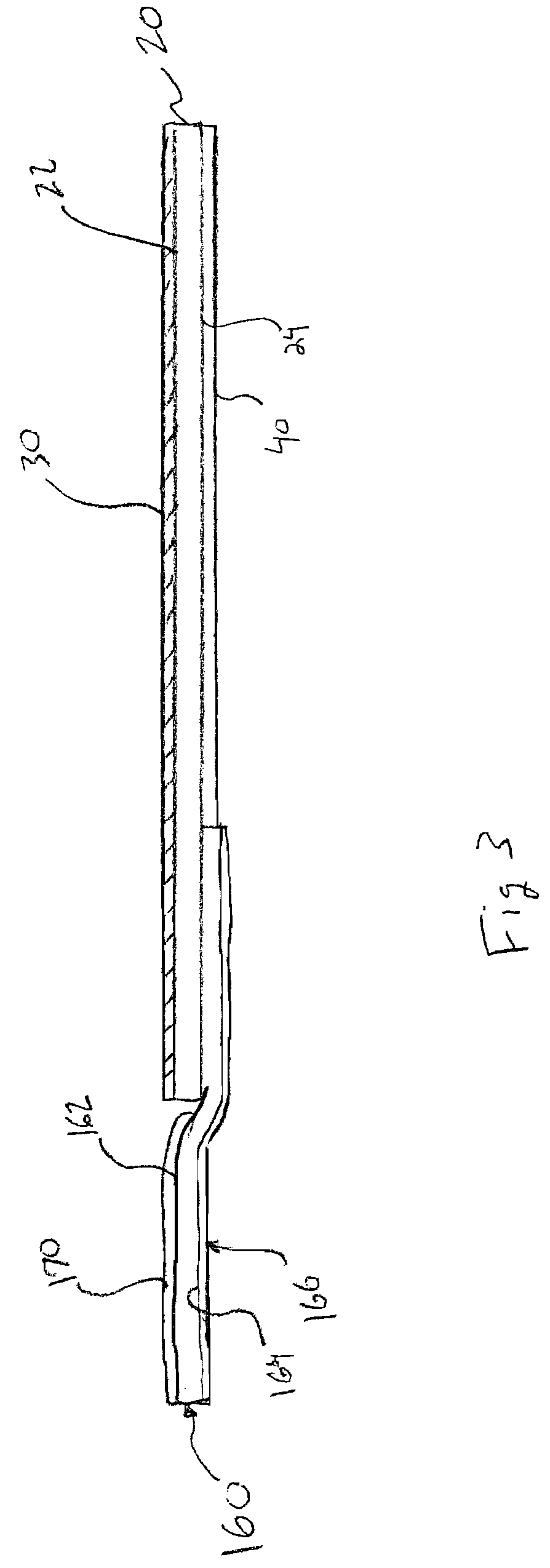

Flexible Wicking Membrane

InactiveUS20080010917A1Prevent penetrationImprove consistencyJoints tightening/coveringWing framesAs DirectedFront edge

Disclosed herein are various waterproof membranes that may be applied to a sill surface of an opening in a building structure to waterproof that surface as well as direct water that penetrates through the opening out of the structure. Generally, one or more flexible waterproof membranes are adhesively applied to the sill surface for purposes of waterproofing that surface. Such membranes may further incorporate a back dam structure that is disposed proximate to the rearward edge of a sill plate (i.e., disposed toward the interior of the structure) to direct water towards the front edge of the sill plate (i.e., toward the outside of the structure). Further, such membranes may include wicking material on one or more surfaces to allow for directing water out of a building structure. In various arrangements, one or more flexible membranes may be utilized to create an open fronted sill pan.

Owner:PROTECTO WRAP

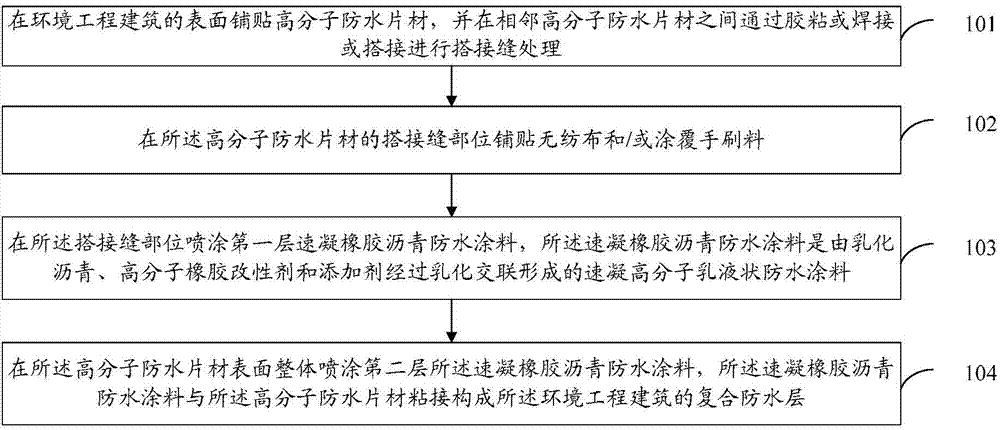

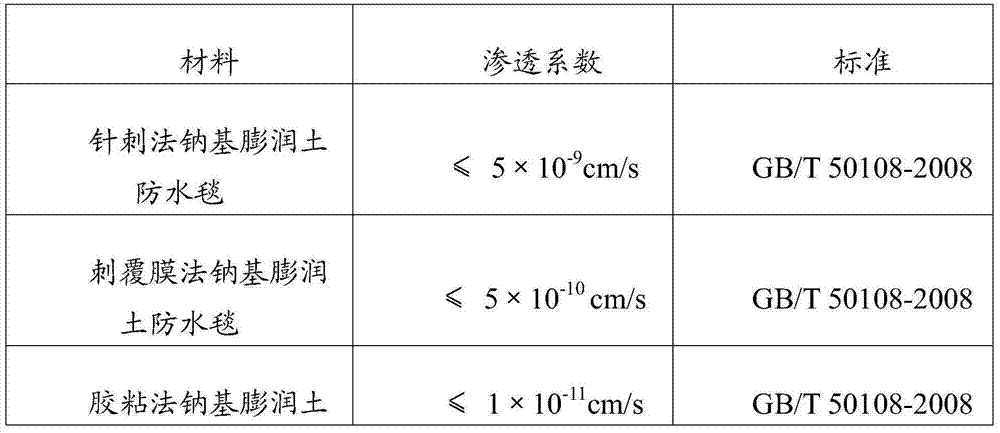

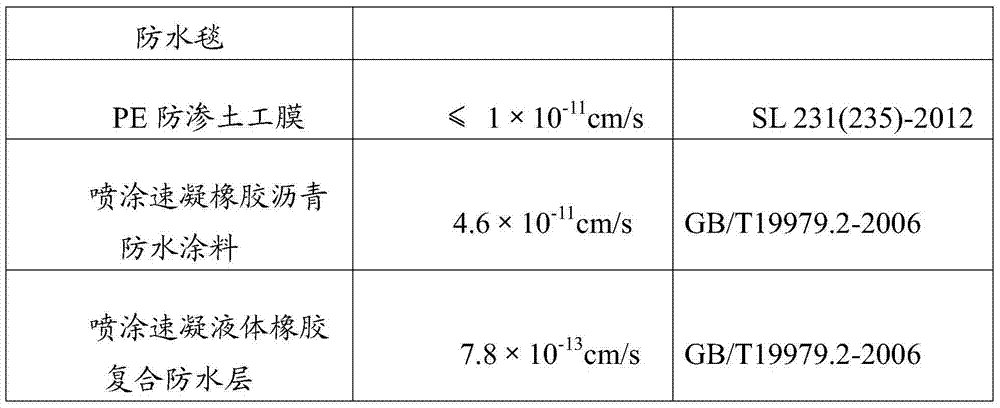

Composite waterproof layer for environmental engineering and preparing and constructing method thereof

ActiveCN104264715AMake up for deficienciesReduce the risk of water leakageLamination ancillary operationsLaminationLap jointEngineering

The invention provides a composite waterproof layer for environmental engineering and a preparing and constructing method thereof. The preparing and constructing method comprises the steps that polymer waterproof sheets are laid on and attached to the surface of an environmental engineering building, and lap joint seam processing is conducted between the adjacent polymer waterproof sheets in a glue bonding or welding or lap joint mode; the lap joint seam parts of the polymer waterproof sheets are provided with non-woven fabric in a laying and attaching mode or is coated with hand brush materials; first layers of rapid hardening rubber asphalt waterproof coatings are sprayed on the lap joint seam parts, and the rapid hardening rubber asphalt waterproof coatings are rapid hardening polymer emulsion state waterproof coatings formed by emulsified asphalt, a polymer rubber modifier and an additive in an emulsification crosslinking mode, a second layer of rapid hardening rubber asphalt waterproof coating is integrally sprayed on the surfaces of the poly waterproof sheets.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Cross pipe gallery outer waterproof construction method

ActiveCN112376610AAchieve gap-free layingSimple construction methodArtificial islandsProtective foundationArchitectural engineeringStructural engineering

The invention discloses a cross pipe gallery outer waterproof construction method. According to the construction method, construction joints are formed by a certain distance in side walls of a main pipe gallery and side walls of a secondary pipe gallery above the top faces of bottom plates, a concrete cushion layer is laid at the bottom of a foundation pit, guide walls are built from two sides ofthe side walls of the main pipe gallery, and soil outside the guide walls is tamped to be flat below the top faces of the guide walls; the concrete cushion layer is laid to be flush with the top surfaces of the guide walls, and guide walls are built on two sides of the side walls of the secondary pipe gallery on the concrete cushion layer of a bottom plate of the secondary pipe gallery; waterproofcoiled materials of a bottom plate and the side walls of the main pipe gallery and the bottom plate of the secondary pipe gallery are pre-laid; a waterproof reinforcing layer is pre-laid at the external corner part of a top plate of the secondary pipe gallery; waterproof treatment is performed on the intersection part between the side walls of the secondary pipe gallery and the top plate of the main pipe gallery; and waterproof treatment is conducted on the side walls above the bottom plate of the secondary pipe gallery, and protection of the waterproof coiled materials is achieved. By meansof the method, gapless laying of the waterproof coiled materials at a cross pipe gallery is achieved, coiled material stress concentration and damage to the waterproof coiled materials are reduced, the waterproof effect is good, construction is easy, and the construction period is shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com