Sucker device for waterproof board construction and tunnel waterproof board construction method

A technology of tunnel waterproofing board and construction method, which is applied to tunnels, tunnel linings, shaft equipment and other directions, can solve the problems of large construction workload, difficult to guarantee construction quality, long construction operation time, etc., and achieves high construction efficiency and construction quality. Reliable, labor cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

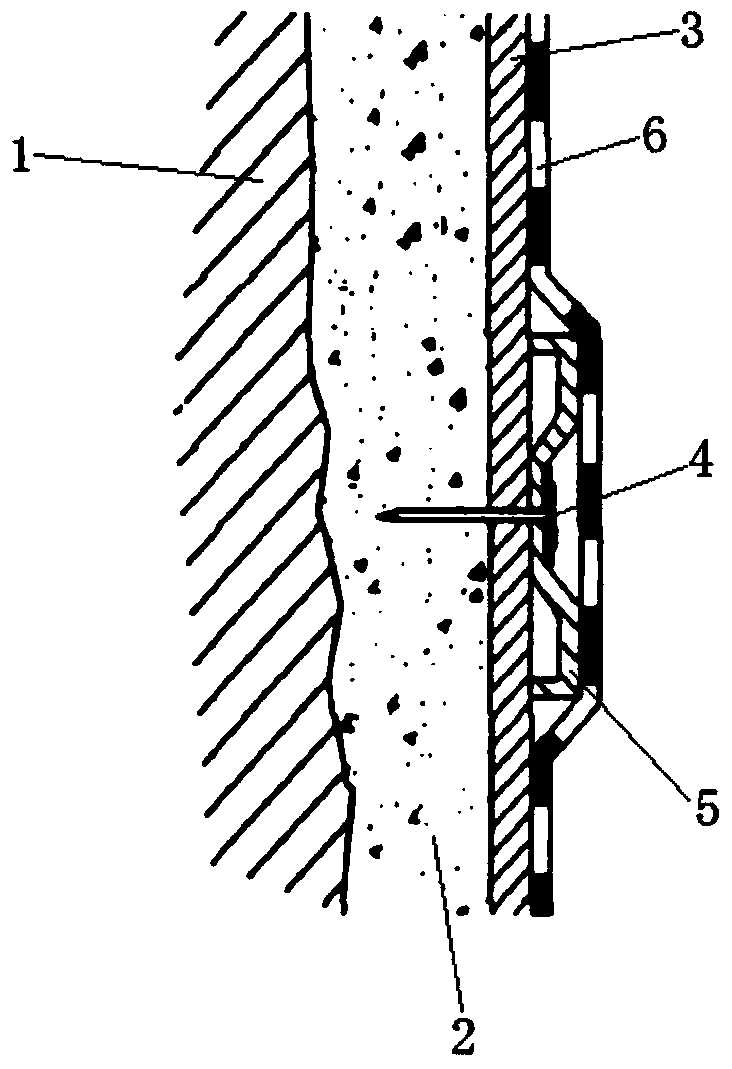

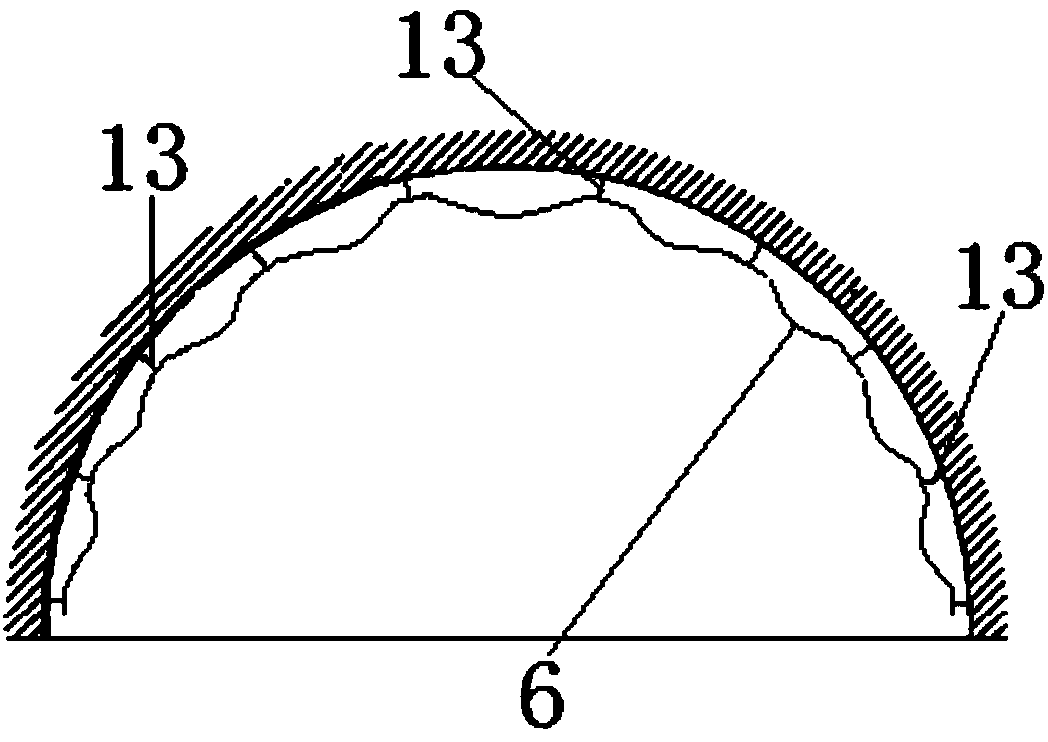

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

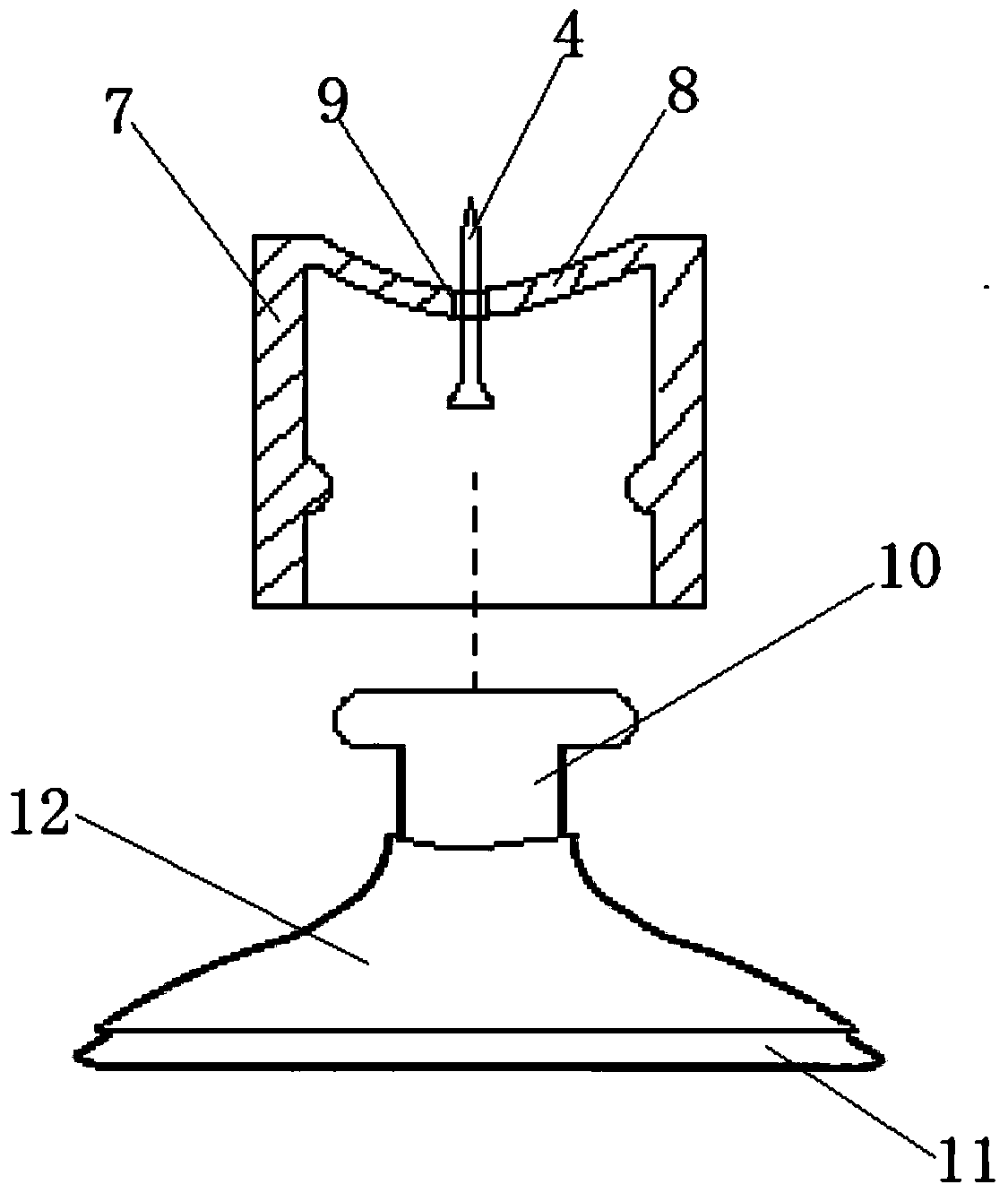

[0031] Such as figure 2 , 3 As shown, the suction cup device 13 for waterproof board construction includes a suction cup body 11 made of soft materials (such as TPU (polyurethane), nitrile rubber, etc.), and a protruding handle 10 is provided on the back of the suction cup body 11 .

[0032] The suction cup body 11 is connected to the fixing part 7, the fixing part 7 is cylindrical, and one end thereof is open, and the handle 10 is clamped in the opening, so as to connect the suction cup body 11.

[0033] The other end of the fixing member 7 is provided with an end face 8, and the end face 8 is provided with a nail hole 9 for fixing the fixing member 7 on the contour surface of the tunnel. The end surface 8 provided with the nail hole 9 is concave, and the concave end surface 8 is made of a material with certain elasticity, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com