Construction method for prefabricated pipe gallery joint water proofing

A construction method and technology of pipe gallery, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as improving the water seepage of prefabricated pipe gallery joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by specific examples.

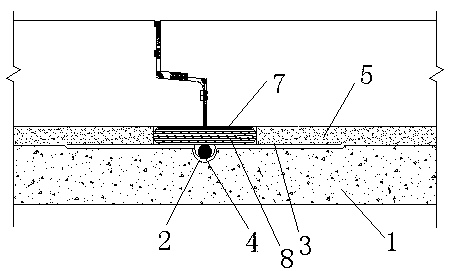

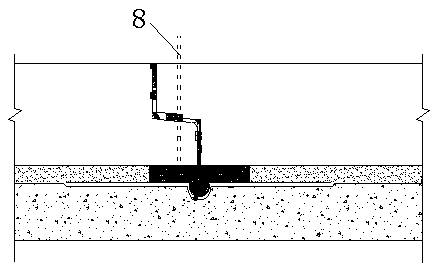

[0019] Such as figure 1 As shown, a construction method for joint waterproofing of prefabricated pipe gallery includes the following steps:

[0020] Step 1. The bottom surface of the pipe gallery is first implemented with a concrete cushion 1, and after measurement and lofting, a groove 2 is reserved at the joint position of the prefabricated comprehensive pipe gallery;

[0021] Step 2. Pre-lay high-performance waterproof membrane 3 on cushion 1. Groove 2 is close to the cushion and is concave. Set an additional layer 1m wide at the joint to enhance the waterproof effect, and then place foam rubber in groove 2. Rod 4 to increase the ductility of the waterproof membrane 3 at the seam when deformed;

[0022] Step 3. Lay the waterproof protective layer 5 with fine stone concrete on the waterproof membrane 3, and reserve a groove with a width of B at the joint position without implementing it. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com