Construction method for initial supporting arch secondary-lining independent tunnel excavation and structures

A tunnel excavation and construction method technology, which is applied to tunnels, tunnel linings, shaft linings, etc., can solve the problems of low mechanization level, increased leakage probability of secondary lining structures, and slow construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

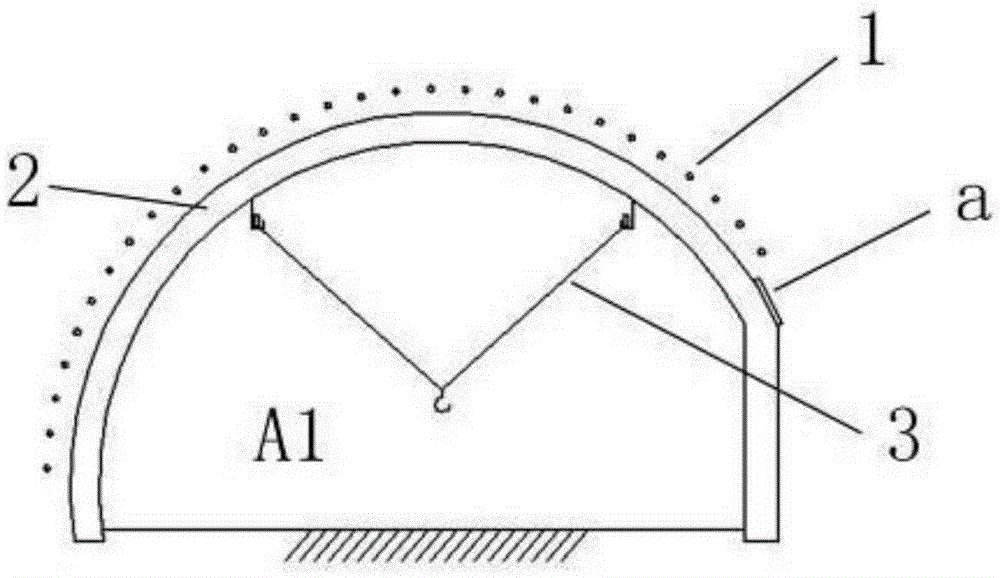

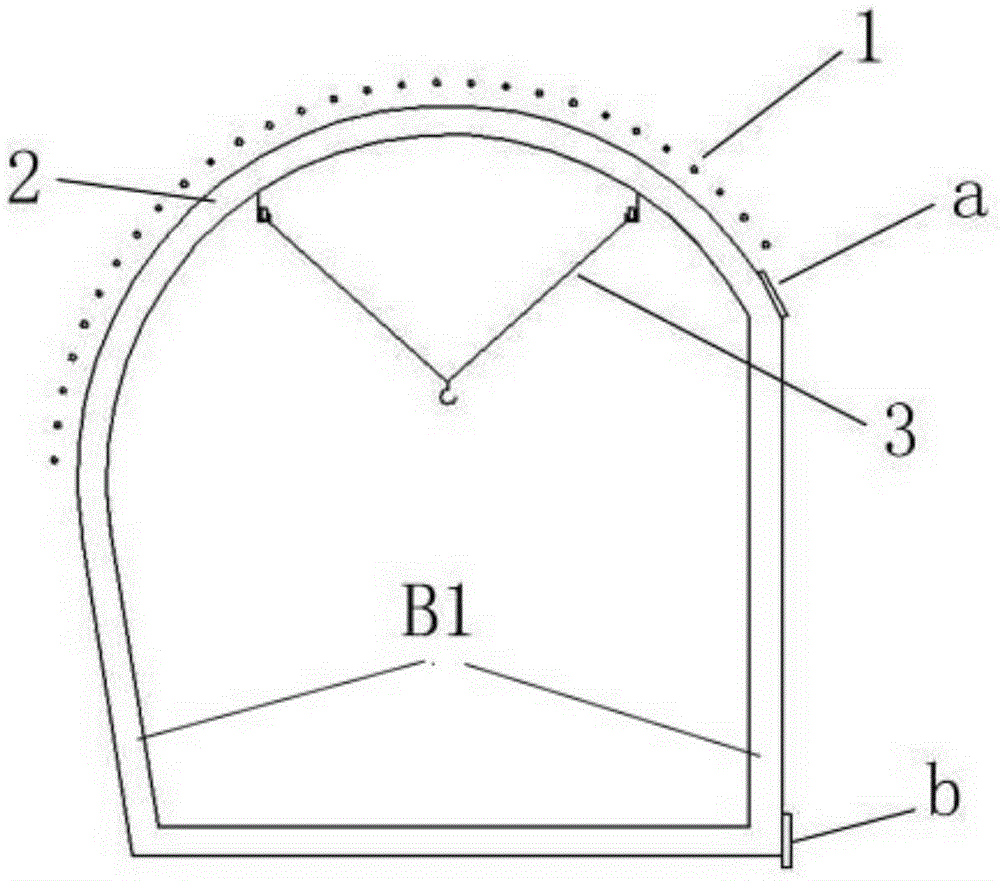

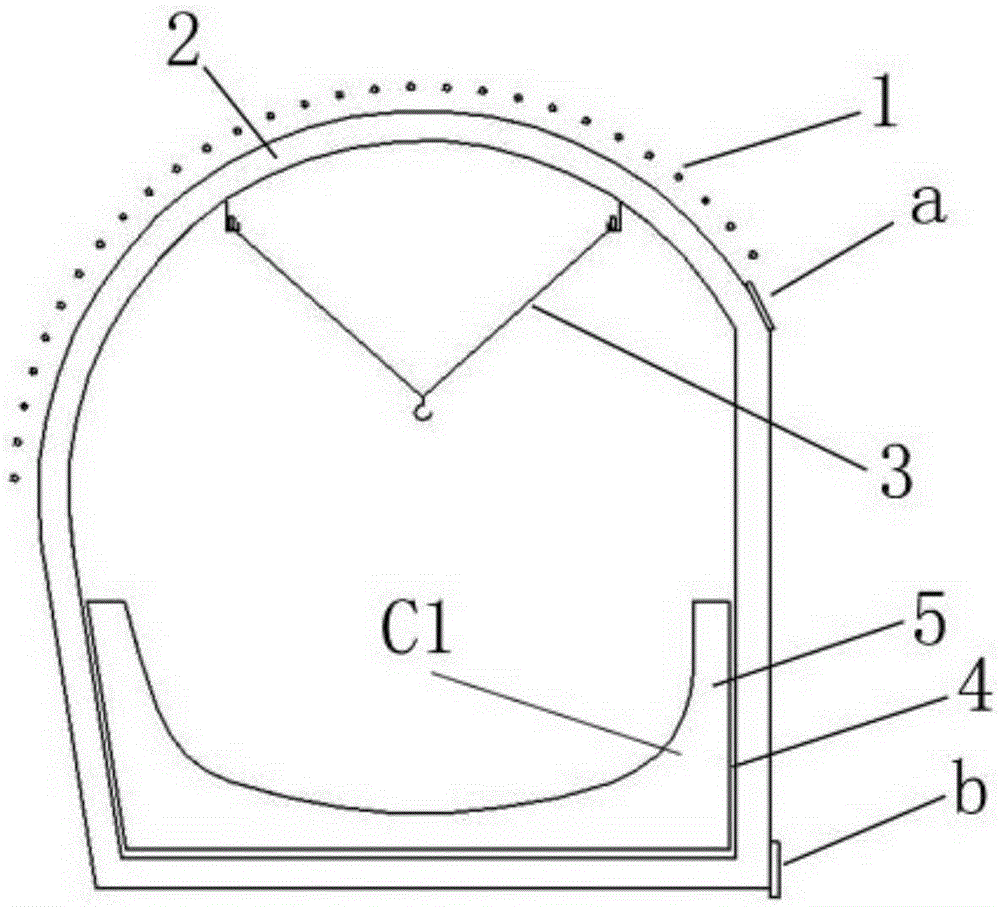

[0120] Such as Figure 1-6 As shown, the construction method for the excavation and structure of the independent tunnel with primary support double arch and second lining provided in this embodiment includes the following procedures:

[0121] (1) Drilling an advanced small conduit 1, and grouting through the advanced small conduit 1 to reinforce the formation;

[0122] (2) Excavate the earthwork; construct the initial support 2, the initial support section steel that constitutes the initial support is divided into the section steel for the cavern’s own use, and the section steel shared by two adjacent caverns. Connecting members a and b are reserved on the self-use part of the chamber; through connecting members a and b, the self-use part of the initial support of the cavern is erected on the common part of the first support of the cavern; for example Image 6 As shown, the connecting member is divided into an upper connecting member a and a lower connecting member b.

[012...

Embodiment 2

[0146] This embodiment is basically the same as Embodiment 1, the difference is:

[0147] Such as Figure 9-Figure 16 As shown, the excavation and structure construction method of the independent tunnel with primary support double-arch and second lining is used to construct the double-arch tunnel, and the specific construction procedures are constructed in sequence according to the following serial numbers:

[0148] A2 Drill the small conduit 1 ahead of the left cavern, excavate the upper soil layer of the left cavern, construct the upper half of the left cavern primary branch 2, and install the material transportation device 3;

[0149] B2 Excavate the lower soil layer of the left cavern, and construct the lower half of the left cavern primary branch 2;

[0150] C2 Drill the small conduit 1 ahead of the right cavern, excavate the upper soil layer of the right cavern, construct the upper half of the primary support 2 of the right cavern, and install the material transportation ...

Embodiment 3

[0157] This embodiment is basically the same as Embodiment 1, the difference is:

[0158] Such as Figure 17-Figure 27 As shown, the excavation and structure construction method of the independent tunnel with primary support, multiple arches and two linings is used to construct a three-arch tunnel, and the specific construction procedures are constructed in sequence according to the following serial numbers:

[0159] A3 Drill the small conduit 1 ahead of the left cavern, excavate the upper soil layer of the left cavern, construct the upper half of the left cavern initial branch 2, and install the material transportation device 3;

[0160] B3 Excavate the lower soil layer of the left cavern, and construct the lower half of the left cavern primary branch 2;

[0161] C3 Drill the small conduit 1 ahead of the middle cavern, excavate the upper soil layer of the middle cavern, construct the upper half of the first branch 2 of the middle cavern, and install the material transportati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com