Wall window construction method

A construction method and wall technology, applied in the direction of frame fixing, joint fastening/covering, etc., can solve the problems of inability to ensure air tightness and water tightness, large consumption of filling materials, poor waterproof and thermal insulation effect, etc. Conducive to the quality of glue molding, shortening the construction period, and the effect of filling enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

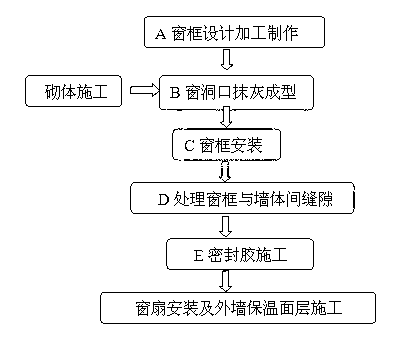

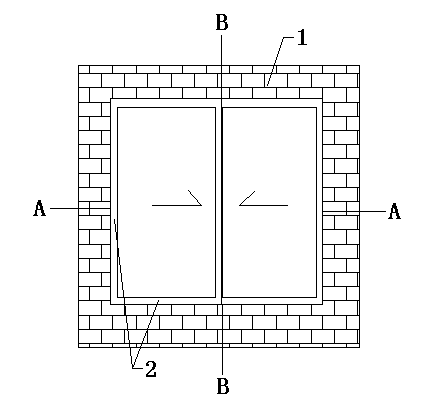

[0032] like figure 1 Shown, a kind of wall window construction method comprises the following steps:

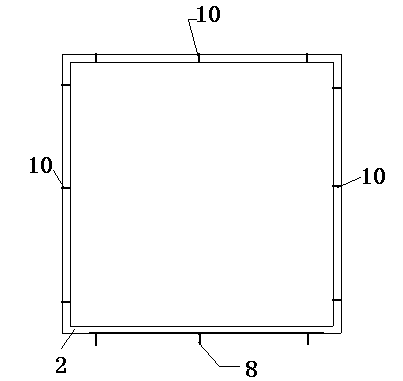

[0033] A. The window frame 2 is processed and manufactured, such as image 3 as shown,

[0034] 1 Raw materials should check their specifications and quality assurance certificates, and only qualified raw materials can be used for processing.

[0035] 2 Fixing holes 10 should be reserved for the window frame during processing.

[0036] 3 After arriving at the installation site, check whether the size of the window and out-of-plane deformation meet the requirements against the design drawing.

[0037] B. Window opening 3 plastering molding

[0038] 1) 1. Requirements for window opening size:

[0039] Window frame size (mm): b×h

[0040] Forming size of the window opening after plastering (mm): [b+(10~16)]×[h+(10~16)];

[0041] 2. The allowable error of flatnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com