Modified asphalt waterproof coiled material with reinforced overlap edges and production method of modified asphalt waterproof coiled material

A technology of modified asphalt and waterproof membrane, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc. It can solve problems such as twisted seedlings, uneven thickness of membranes, and irregular winding. Achieve the effect of improving quality, improving mechanical properties, waterproof and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

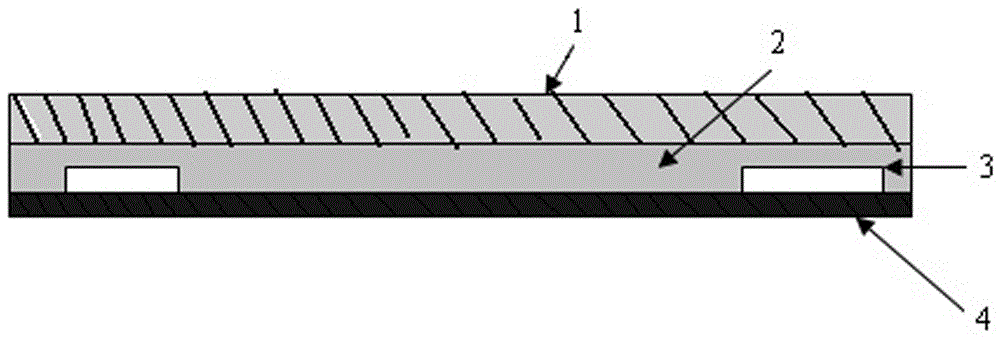

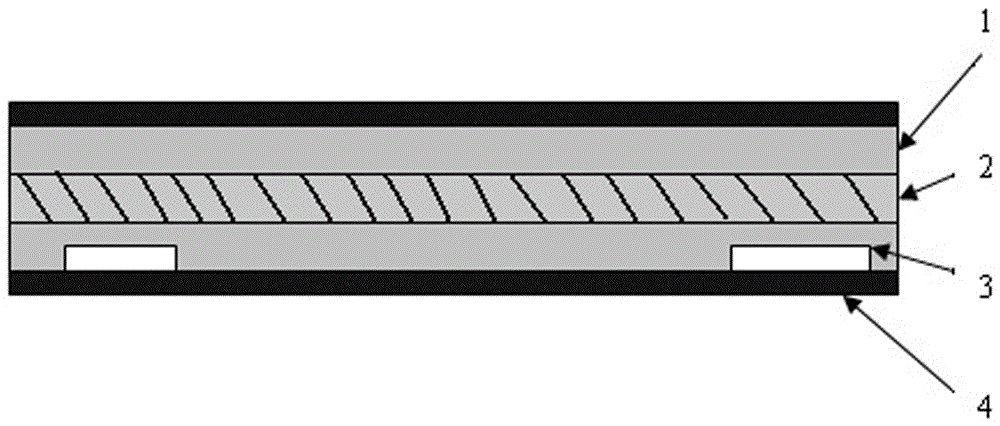

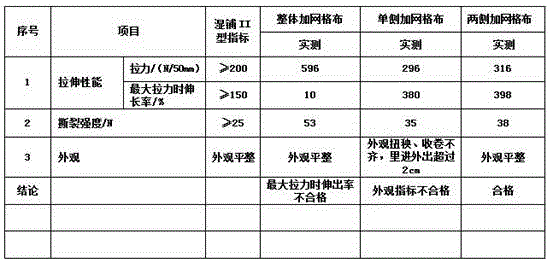

Image

Examples

Embodiment 1-1

[0039] Add 40 parts of No. 70 petroleum asphalt into the reaction kettle, add 8 parts of SBS rubber modifier, raise the temperature to 110-115°C, stir for 30 minutes, then raise the temperature to 180-185°C, continue stirring for 1 hour, add 0.5 parts of aluminum zirconium acid Ester waterproof bridging agent, stir for 30 minutes, cool down to 120-130°C to get reactive modified asphalt, apply it on non-woven fabric to make waterproof membrane.

Embodiment 1-2

[0041] Add 60 parts of No. 90 petroleum asphalt into the reaction kettle, add 12 parts of SBR rubber modifier, raise the temperature to 115-120°C, stir for 30min, then raise the temperature to 185-190°C, continue stirring for 1.5h, add 2 parts of chlorinated Trioctyltin, stirred for 30 minutes, cooled to 120-130°C to obtain reactive modified asphalt, which was applied on non-woven fabric to make waterproof membrane.

Embodiment 1-3

[0043] Add 66 parts of No. 90 petroleum asphalt into the reaction kettle, add 4 parts of SBS rubber modifier and 12 parts of SBR rubber modifier, raise the temperature to 115-120°C, stir for 30min, then raise the temperature to 185-190°C, and continue the stirring reaction After 1.5 hours, add 3 parts of di-n-butyl ethyl phosphate, stir for 30 minutes, and cool down to 120-130°C to obtain reactive modified asphalt, which can be applied to non-woven fabrics to make waterproof membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com