Waterproof roll paver and paving method

A technology of waterproof roll material and paver, which is applied to tools used in roof engineering, roofing, construction, etc. It can solve the problems of easy falling off and easy pollution of lap joints, achieve consistent lap width, improve waterproof quality, and save artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of waterproof coil paver, comprising:

[0035] Supporting device for supporting and releasing the waterproof membrane;

[0036] a guiding device for tensioning the waterproofing membrane released from the supporting device;

[0037] The driving device is used to pull the waterproof membrane guided out of the guiding device to lay it on the base surface, and is used to drive the paver to move;

[0038] And a pressing device for compacting the waterproof membrane after paving.

[0039] The waterproof coil paver of this embodiment can make the overlapping edges evenly, the overlapping width is consistent, there is no leakage point, no falling off, and no pollution at the overlapping edges. It can not only realize continuous paving, but also save Artificial, improve work efficiency, greatly improve waterproof quality. The waterproof coil paving machine of the present invention is suitable for paving various waterproof coils, especia...

Embodiment 2

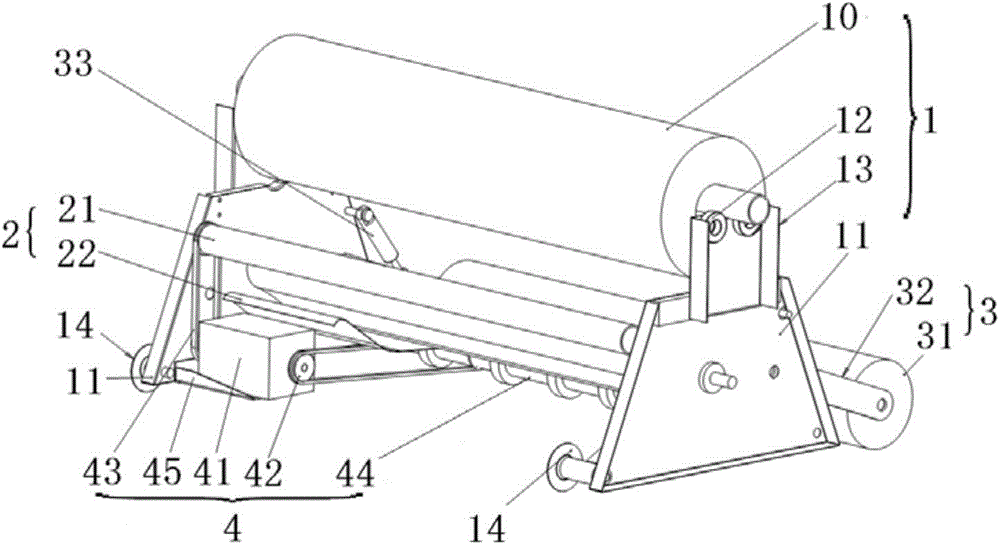

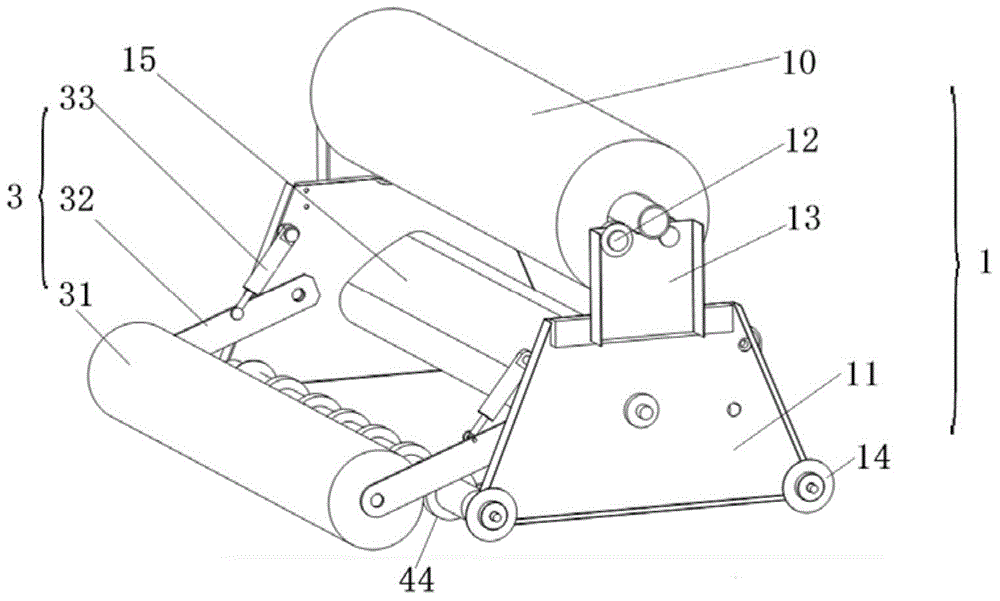

[0041] The present embodiment provides a kind of waterproof coil paver, such as figure 1 , 2 shown, including:

[0042] Supporting device 1, used to support and release waterproof membrane 10;

[0043] The guiding device 2 is used to tension the waterproof coiled material 10 discharged from the supporting device 1;

[0044] The driving device 4 is used to pull the waterproof membrane 10 guided out of the guiding device 2 to lay it on the base surface, and is used to drive the paver to move;

[0045] And the pressing device 3 is used for compacting the waterproof roll material 10 after paving.

[0046] That is to say, when the paver in this embodiment is paving, firstly, one end of the waterproof roll material 10 placed on the support device 1 needs to be pulled to the guide device 2, and the guide device 2 will stretch the waterproof roll material 10 and pull it to the The driving device 4, and then the driving device 4 drives the paver to move while laying the waterproof ...

Embodiment 3

[0067] This embodiment provides a paving method for a waterproof coiled material, which uses the paver in Embodiment 2 for paving, and a film is attached to the surface of the waterproof coiled material. The paving method specifically includes the following steps:

[0068] Draw the moving marking line on the pre-paved base surface in advance, so that the alignment wheel 14 is positioned on the drawn marking line;

[0069] Place the waterproof coiled material on the supporting bearing 12, and pull one end of the waterproof coiled material 10 on the supporting bearing 12 to the bottom of the walking roller 44 after tensioned by the guide roller 21,

[0070] The film on the surface of the waterproof roll material 10 between the support bearing 12 and the guide roller 21 is scratched to separate the film from the waterproof roll material 10,

[0071] Start the motor 41 to drive the paver to move, and at the same time drive the guide roller 21 to guide the waterproof membrane 10 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com