Coiled material level-laying forming machine and laying method of waterproof coiled material

A technology of waterproofing membrane and forming machine, which is applied to tools for roofing, roofing, construction, etc., can solve the problems of slow inspection speed, low laying efficiency, not tightness, etc., to improve work efficiency, improve waterproof quality, continuous paving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

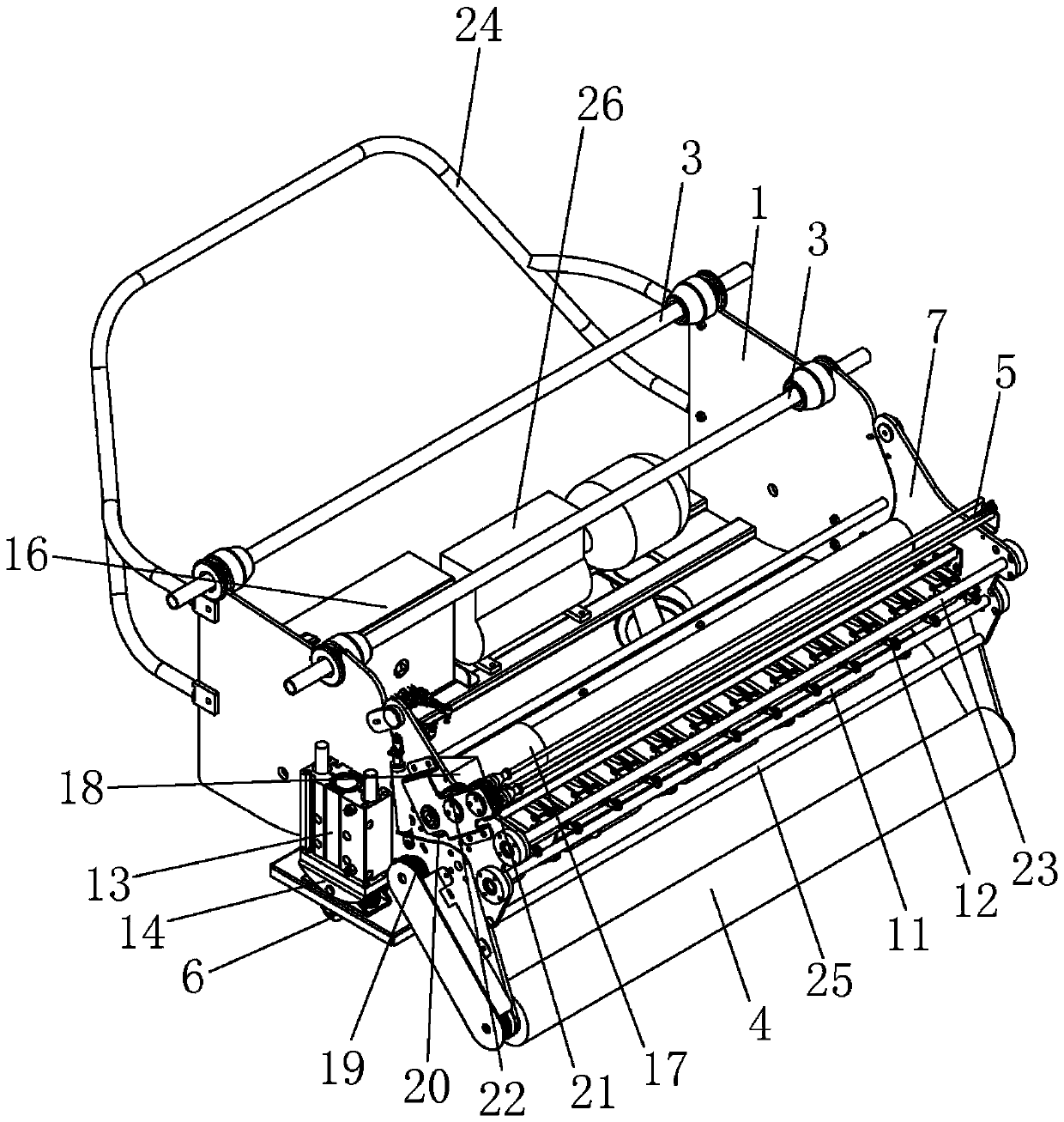

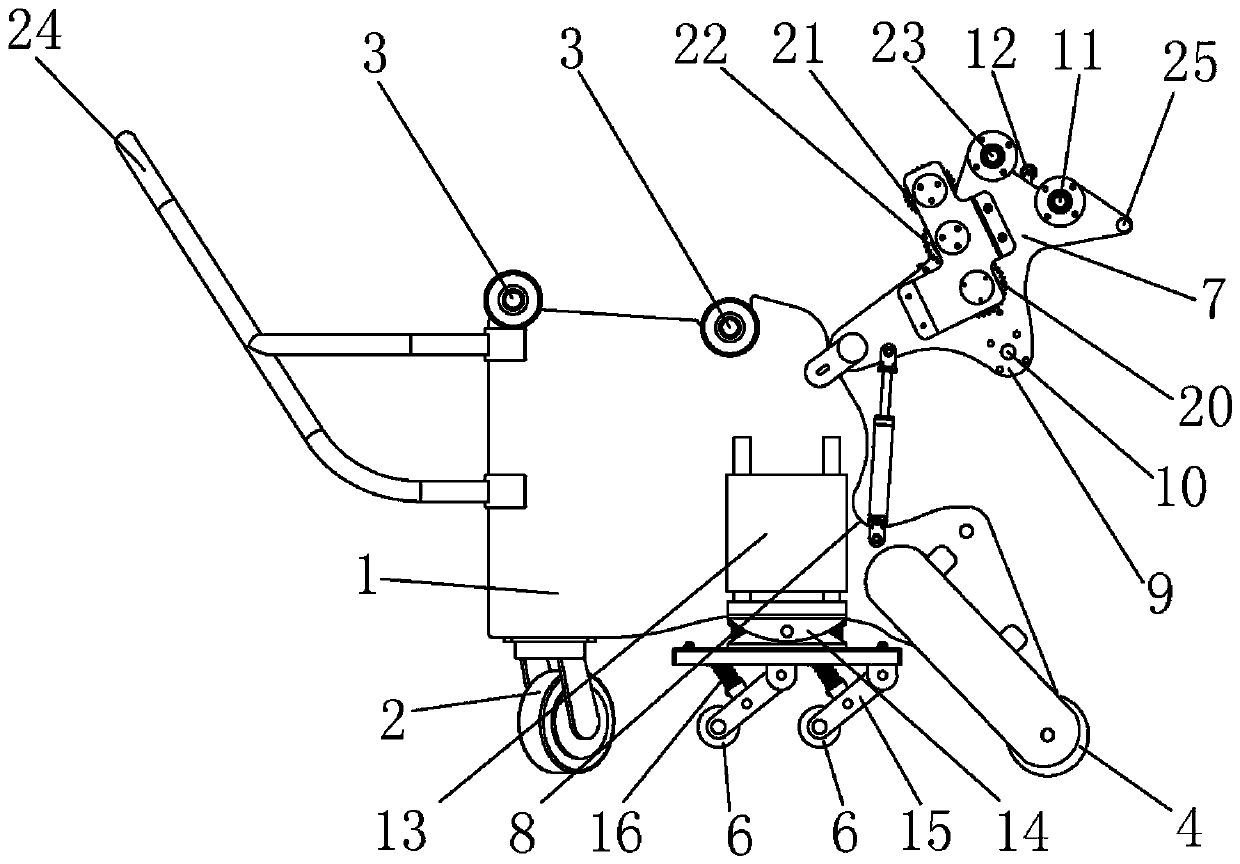

[0020] refer to figure 1 , figure 2 , a coil flat-laying forming machine, including a frame 1 and casters 2 installed at the bottom of the frame 1, a push handle 24 is also installed on the frame, and the frame 1 is hingedly installed from top to bottom There are parallel waterproof coiled material support rollers 3, protective film winding rollers 5, waterproof film layer laying rollers 4 and lower pressing rollers 6, and the lower pressing rollers 6 are connected with a pressure regulating device for adjusting the pressing pressure, A protective film detection device installed on the frame 1 is also arranged between the protective film winding roller 5 and the waterproof film laying roller 4, and the protective film detection device is used to detect the integrity of the protective film, so The waterproof coiled material support roller 3 is used to support and release the waterproof coiled material, the protective film winding roller 5 is used to reclaim the protective fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com