A kind of construction method of cement stabilized base expansion joint and cement stabilized base

A technology of cement stabilization and construction method, which is applied in the field of expansion joint construction of cement-stabilized base and cement-stabilized base. The effect of years of service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

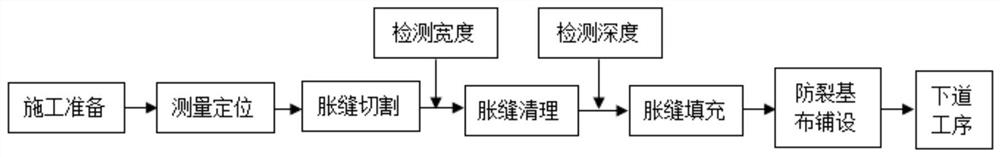

[0045] This embodiment provides a cement-stabilized base expansion joint construction method, please refer to figure 1 , which includes the following steps:

[0046] (1) Construction preparation

[0047] Before the expansion joint construction, the unconfined compressive strength of the cement-stabilized base must meet the design requirement of 3MPa, and the surface pollutants should be cleaned to remove debris.

[0048] (2) Measurement positioning

[0049] Keep the distance between two adjacent expansion joints at about 80m, and confirm the position of the expansion joints on the water-stabilized base on site. The expansion joint should be perpendicular to the direction of the route, and the cutting surface should be vertically downward.

[0050] (3) Expansion seam cutting

[0051] Place the cutting machine in place according to the reference line of measurement and positioning, and center and level it. Start the cutting machine, after the saw blade is running normally, ...

Embodiment 2

[0059] This embodiment provides a cement-stabilized base expansion joint construction method, please refer to figure 1 , which includes the following steps:

[0060] (1) Construction preparation

[0061] Before the expansion joint construction, the unconfined compressive strength of the cement-stabilized base must meet the design requirement of 3MPa, and the surface pollutants should be cleaned to remove debris.

[0062] (2) Measurement positioning

[0063] Keep the distance between two adjacent expansion joints at about 100m, and confirm the location of the expansion joints on the water-stabilized base on site. The expansion joint should be perpendicular to the direction of the route, and the cutting surface should be vertically downward.

[0064] (3) Expansion seam cutting

[0065] Place the cutting machine in place according to the reference line of measurement and positioning, and center and level it. Start the cutting machine, after the saw blade is running normally,...

Embodiment 3

[0073] This embodiment provides a construction method for cement-stabilized base expansion joints, the specific steps of which are roughly the same as those in Example 1, the difference being that: before paving the gravel seal on the cement-stabilized base, no anti-cracking is carried out at the expansion joints Operation of base cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com