Flex overturning type auxiliary movable hopper for spreading machine

A technology of movable hopper and paver, which is applied to roads, road repairs, roads, etc. It can solve the problems of high cost of material transfer vehicles, failure to meet unloading requirements, and material leakage during unloading, so as to increase operating productivity and increase hoppers Capacity, smooth discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

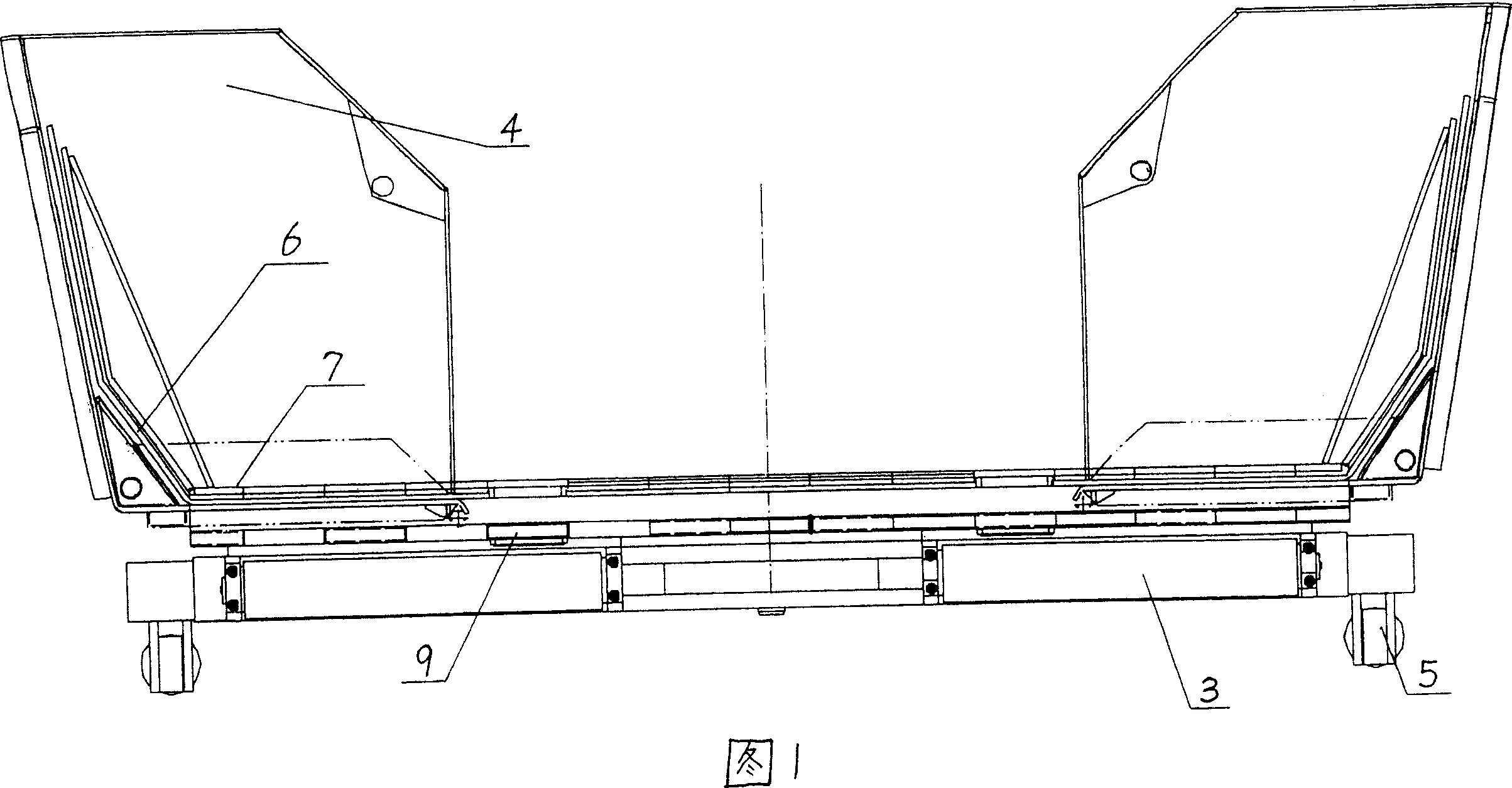

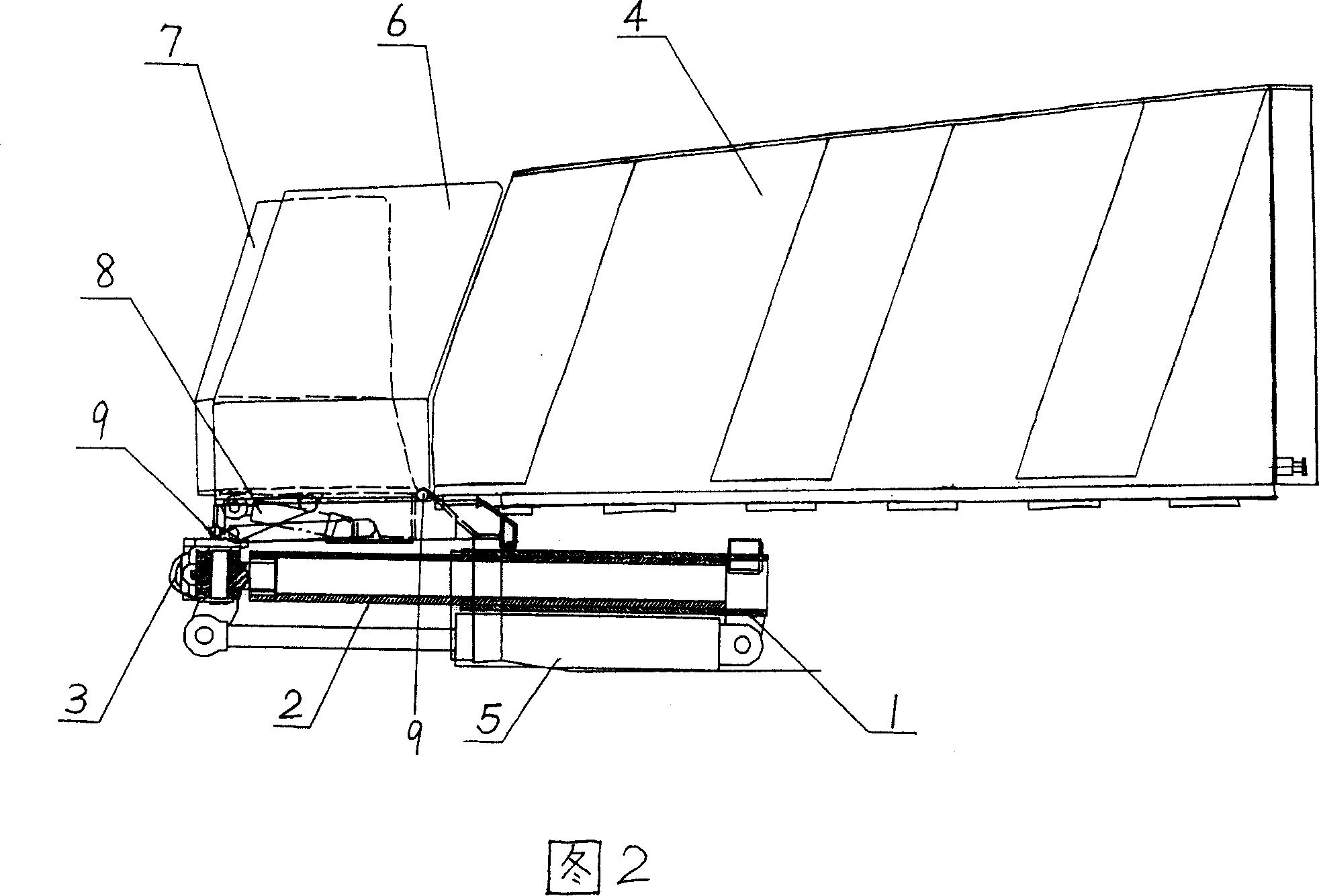

[0017] As shown in Figures 1 and 2, the present invention includes circular or square guide slides 1 fixed on both sides of the paver frame. 3 are hinged, and a movable hopper composed of a fixed bucket 6 and a tipping bucket 7 is installed on the push roller assembly 3. One end of the telescopic oil cylinder 5 is hinged on the guide slideway 1, and the other end is hinged on the push roller assembly 3. The telescopic oil cylinder 5 is fixed inside or outside the guide slideway 1, and the push roller assembly 3 slides back and forth in the guide slideway 1 under the action of the telescopic oil cylinder 5, driving the movable hopper in the main hopper 4 of the paver. The movable hopper is hinged with the push roller assembly 3 through the hinge shaft 9. When the movable hopper expands and contracts in the main hopper 4 with a certain inclination, the movable hopper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com