Cement stabilized soil paver and improvement method thereof

A soil paver and cement stabilization technology, which is applied in the field of improvement of cement stabilized soil paver, can solve the problems of insufficiency of hopper volume and length, affecting construction progress, affecting paving quality, etc., and achieves fast construction speed. , The effect of shortening unloading time and miniaturization of construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

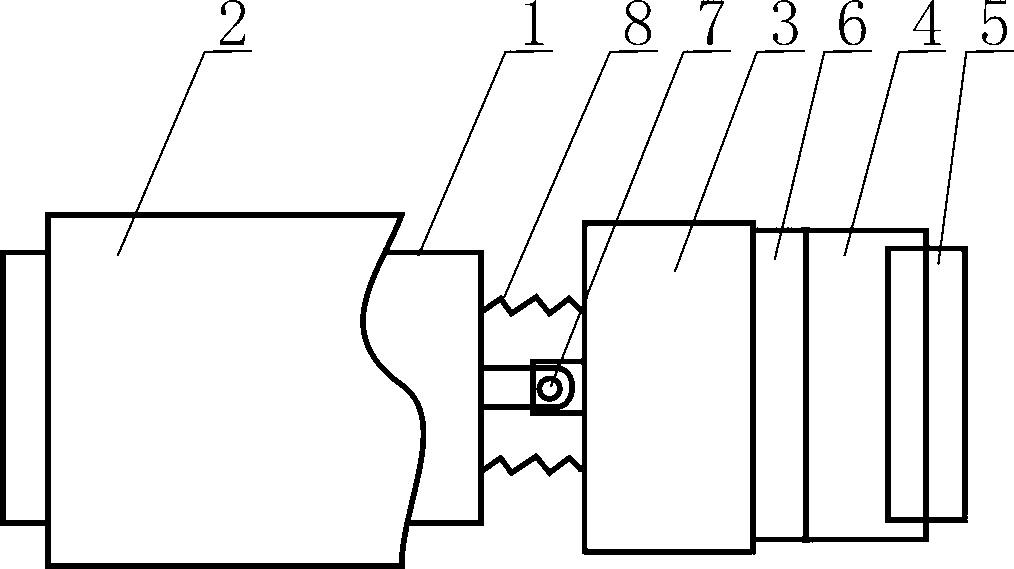

[0015] Such as figure 1 Shown, a kind of cement-stabilized soil paver comprises organic frame 1, hopper 2, push beam 3, wheel base 4 and push roller 5, and described hopper 2 is located on frame 1, and push beam 3 One end of one end is hinged with the frame 1 through the hinge pin 7, and the push roller 5 is arranged on the wheel base 4, and the wheel base 4 is arranged on the other end of the push beam 3, and it is characterized in that: the push beam 3 and the wheel A 20cm thick shaped steel 6 is arranged between the seats 4, and the distance between the push roller 5 and the push beam 3 is increased from the original 35cm to 55cm. The length of the hopper 2 is increased to 200cm, and the volume of the hopper is 3.5m3.

[0016] Buffer springs 8 are provided between the frame 1 and the push beam 3 and on both sides of the hinge pin 7 .

[0017] The improvement method of cement-stabilized soil paver comprises the following steps: A, cutting off the push roller and the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com