Engineering material vehicle and slip form paver

A material vehicle and engineering technology, applied in the direction of roads, road repairs, roads, etc., can solve the problems of increased vehicle cost, vehicle size, low construction efficiency, and poor quality, so as to improve work efficiency and construction quality, and evenly pave operations , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

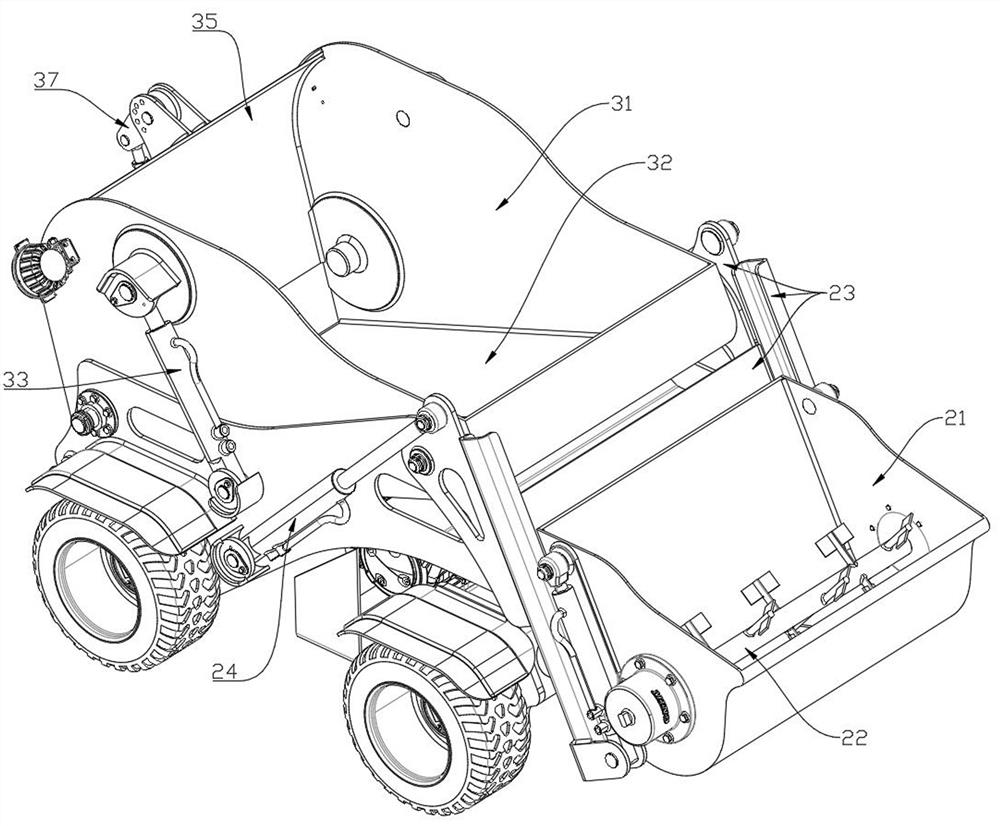

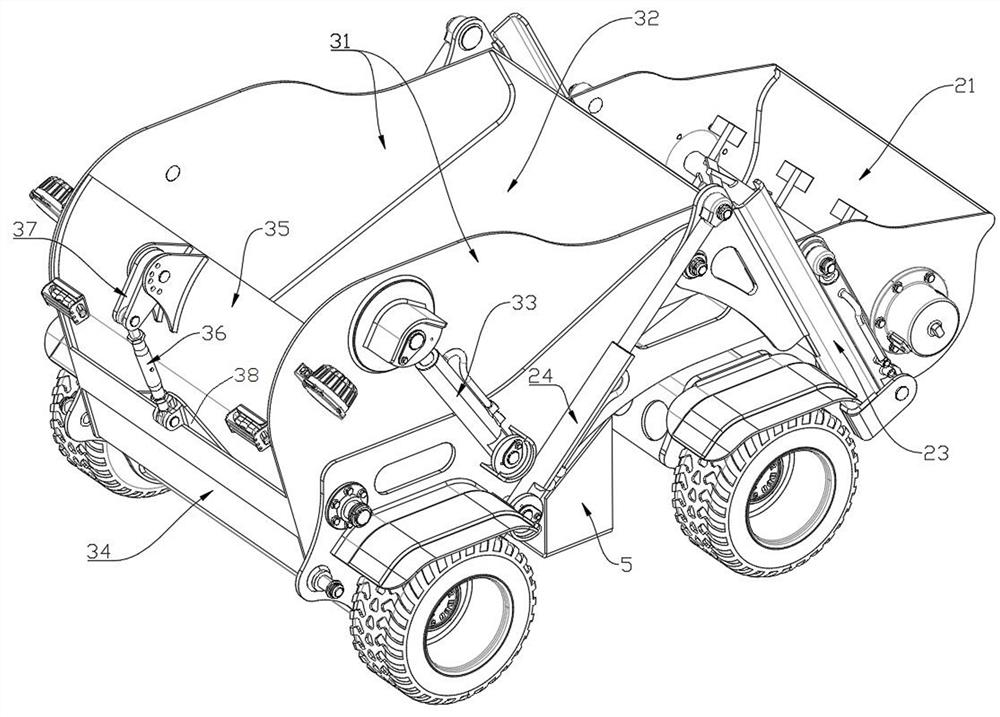

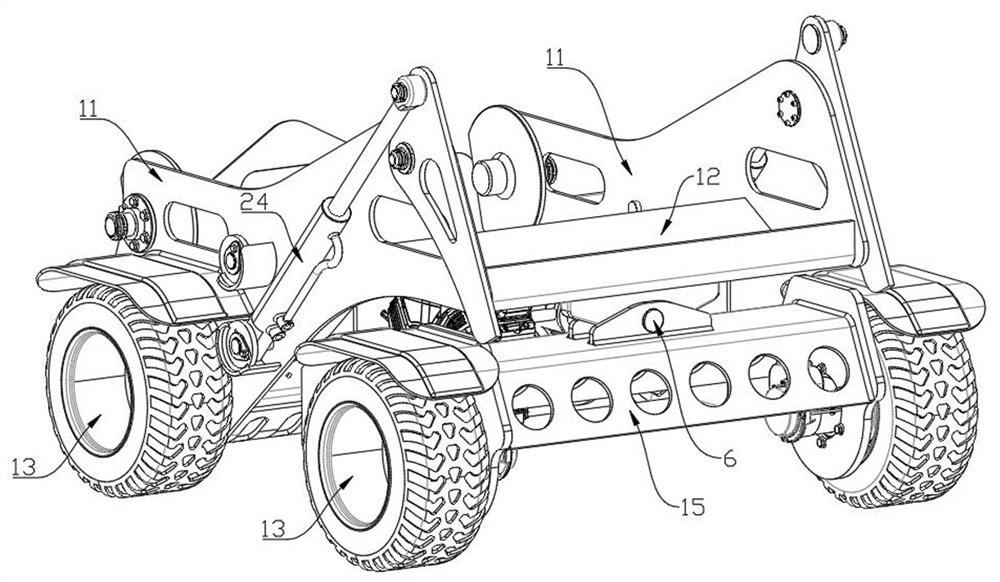

[0033] The engineering material truck of this embodiment includes a vehicle frame 1 , a discharge hopper mechanism 2 , a conveying hopper 3 and a power assembly 5 .

[0034] The vehicle frame 1 is a plate beam structure, which is convenient for integrated installation of accessories such as the discharge hopper mechanism 2, the conveying hopper 3, and the sliding mold attachment 4. Such as image 3 and Figure 4 As shown, the vehicle frame 1 includes side panels 11 and bottom panels I12 arranged left and right. The bottom of the vehicle frame 1 is arranged with a front bridge 15 and a rear bridge 14 front and back, one of the front bridge 15 or the rear bridge 14 is hinged with the vehicle frame 1, and the other is fixedly connected with the vehicle frame 1; Wheels 13 are mounted on both sides of the front bridge 15 and the rear bridge 14 respectively. Such as image 3 As shown, in this embodiment, the front bridge frame 15 is hinged on the bottom plate 12I through the pin...

Embodiment 2

[0041] The engineering material truck of this embodiment includes a vehicle frame 1, a discharge hopper mechanism 2, a delivery hopper 3 and a power assembly 5, and its structural arrangement is similar to that of the engineering material truck of Embodiment 1. The structure is different.

[0042] The unloading hopper 21 of the unloading hopper mechanism 2 of the present embodiment is fixedly connected on the unloading frame 23, and can also be set as an adjustable height installation position (such as setting an array of mounting holes with different heights on the unloading frame 23). In the present embodiment, no chute is provided on the unloading rack 23 and no pulleys are provided on the unloading hopper 21, and the unloading rack 23 is retained to turn over the unloading structure of the oil cylinder I 24 to reduce manufacturing costs.

[0043]The slip form paver 4 configured in the slip form paver of this embodiment is different from that of the slip form paver of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com