Heat reflection type colored spray-quick-setting rubber-asphalt waterproof coating material and preparation method therefor

A technology of quick-setting rubber asphalt and waterproof coating, applied in rosin coatings, coatings, conjugated diene coatings, etc. The effect of alleviating the heat island effect, simple construction and fast film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

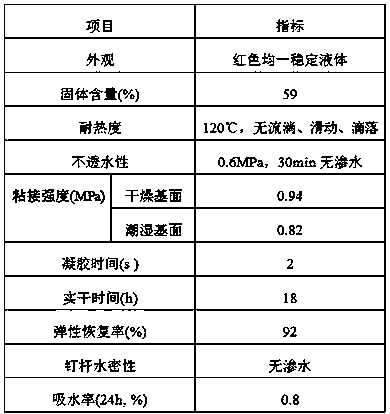

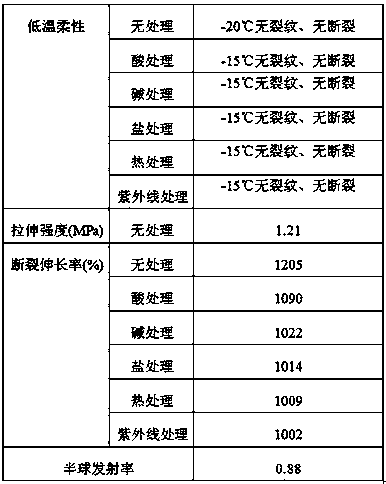

Embodiment 1

[0048] Preparation of heat-reflective color spray quick-setting rubber asphalt waterproof coating:

[0049] The waterproof coating includes A component and B component;

[0050] The preparation of the A component comprises the following four steps:

[0051] (1) Preparation of cement

[0052] The raw material components of the cement include, by weight, 25 parts of aromatic oil, 3 parts of plasticizer, 70 parts of petroleum resin, and 2 parts of rosin resin.

[0053] Put the aromatic oil, plasticizer and petroleum resin into the reaction kettle in proportion and mix them, heat to 170-180°C, stir for 1.5 hours, add rosin resin, and continue stirring for 2 hours to obtain the cement.

[0054] The aromatic hydrocarbon oil: produced by Guangdong Wanhong Jiuding Petroleum Technology Co., Ltd., the model is A-60.

[0055] The plasticizer is DOP.

[0056] The petroleum resin is C5 hydrogenated petroleum resin.

[0057] The rosin resin is hydrogenated rosin produced by Shangha...

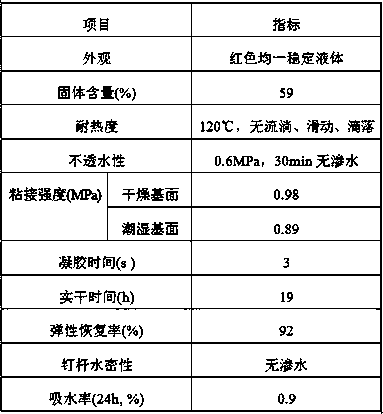

Embodiment 2

[0086] Preparation of heat-reflective color spray quick-setting rubber asphalt waterproof coating:

[0087] The waterproof coating includes A component and B component;

[0088] The preparation of the A component comprises the following four steps:

[0089] (1) Preparation of cement

[0090] The raw material components of the cement include, by weight, 30 parts of aromatic oil, 5 parts of plasticizer, 63 parts of petroleum resin, and 2 parts of rosin resin.

[0091] Put the aromatic oil, plasticizer and petroleum resin into the reaction kettle in proportion and mix them, heat to 170-180°C, stir for 1.5 hours, add rosin resin, and continue stirring for 1.5 hours to obtain the cement.

[0092] The aromatic hydrocarbon oil: produced by Guangdong Wanhong Jiuding Petroleum Technology Co., Ltd., the model is A-60.

[0093] The plasticizer is DOP.

[0094] The petroleum resin is C5 hydrogenated petroleum resin.

[0095] The rosin resin is non-crystalline rosin from Guangzhou Son...

Embodiment 3

[0124] Preparation of heat-reflective color spray quick-setting rubber asphalt waterproof coating:

[0125] The waterproof coating includes A component and B component;

[0126] The preparation of the A component comprises the following four steps:

[0127] (1) Preparation of binder

[0128] The raw material components of the cement include, by weight, 30 parts of aromatic oil, 5 parts of plasticizer, 62 parts of petroleum resin, and 3 parts of rosin resin.

[0129] Put the aromatic oil, plasticizer and petroleum resin into the reaction kettle in proportion and mix them, heat to 170-180°C, stir for 1.5 hours, add rosin resin, and continue stirring for 1 hour to obtain the cement.

[0130] The aromatic oil: produced by Guangdong Wanhong Jiuding Petroleum Technology Co., Ltd., the model is A-60.

[0131] The plasticizer is DBP.

[0132] The petroleum resin is C5 hydrogenated petroleum resin.

[0133] The rosin resin is non-crystalline rosin from Guangzhou Songbao Chemical C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com