Open caisson construction method

A caisson and construction method technology, applied in construction, caisson, infrastructure engineering, etc., can solve the problems of large construction surface, shaft deviation, long construction period, etc., and achieve the effect of improving construction efficiency, ensuring construction quality, and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

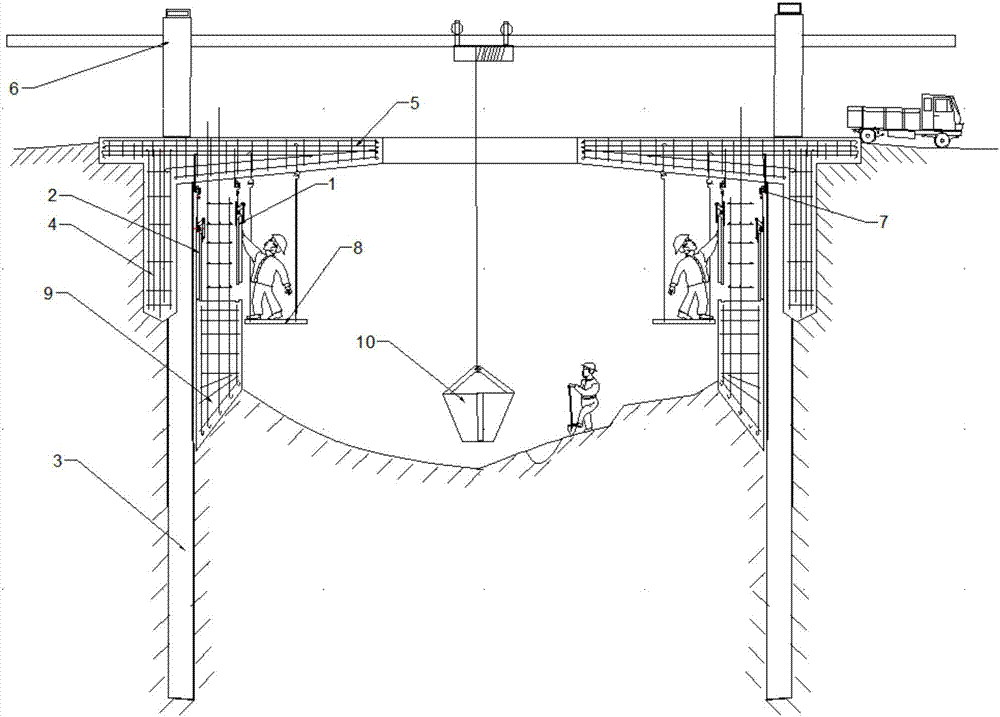

[0040] The invention provides a caisson construction method, the working principle of which is to use this method to reduce the working surface on the ground and reduce the influence of the weather on the construction, and to use the inner formwork of the well wall and the outer formwork of the well wall to sink into the ground together with the concrete well wall to avoid The removal of formwork is eliminated to ensure the quality of the wellbore, and the method of taking soil and pouring the wellbore simultaneously improves the construction efficiency; using steel pipe piles as guides ensures the construction quality, thus solving the problem of repeated disassembly and assembly of scaffolding in the prior art And the problems of heavy workload, large construction area, high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com