Waterproof tilted eave of roof parapet and construction method thereof

A construction method and parapet technology, applied in the direction of the roof, roof covering, building components, etc., can solve the problems that the plastering construction cannot be carried out at the same time, affect the overall sensory effect of the roof, and leak at the mouth of the waterproof coiled material, etc., to achieve The overall structure is solid and reliable, the construction quality is easy to control, and the effect of less construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

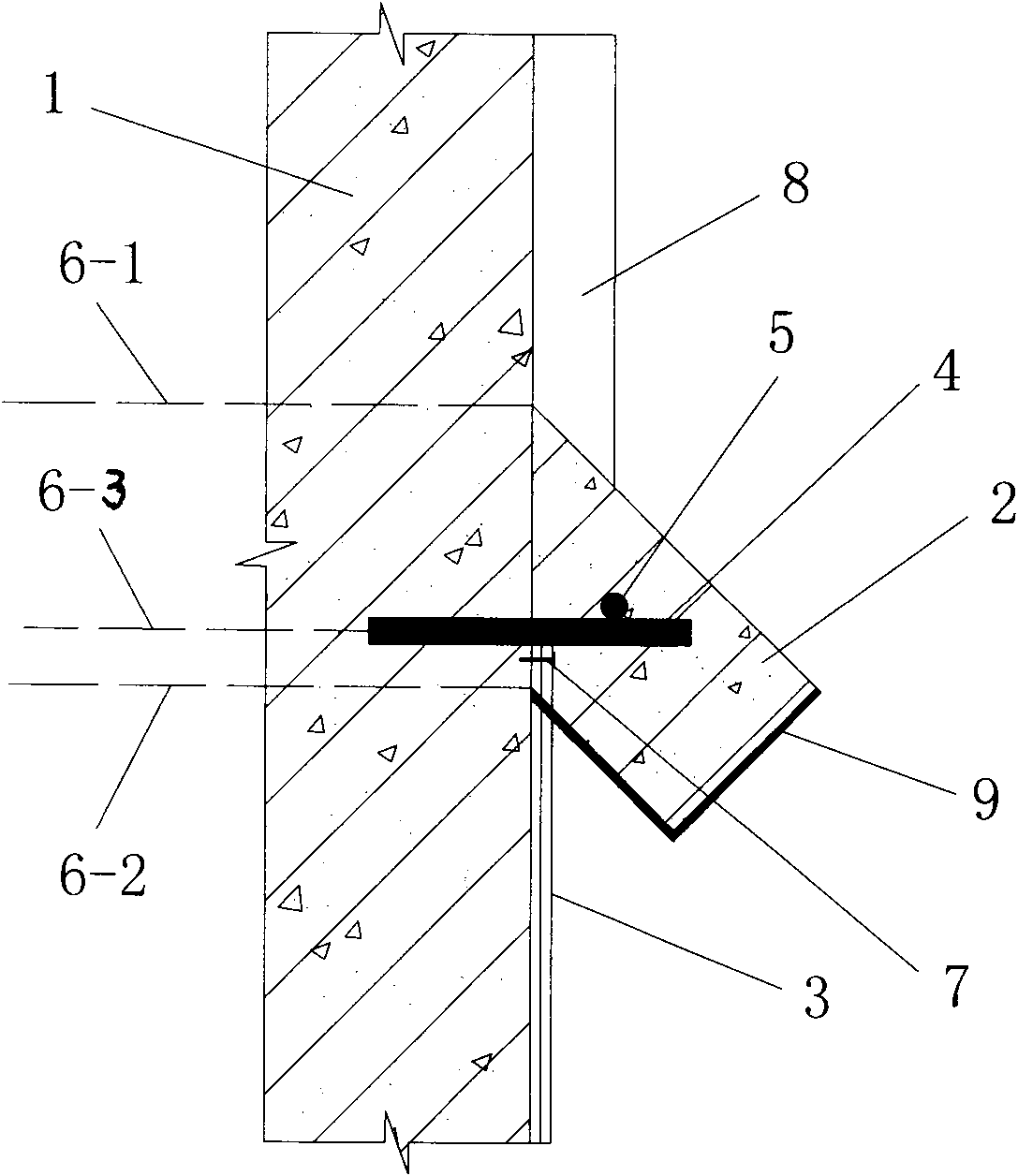

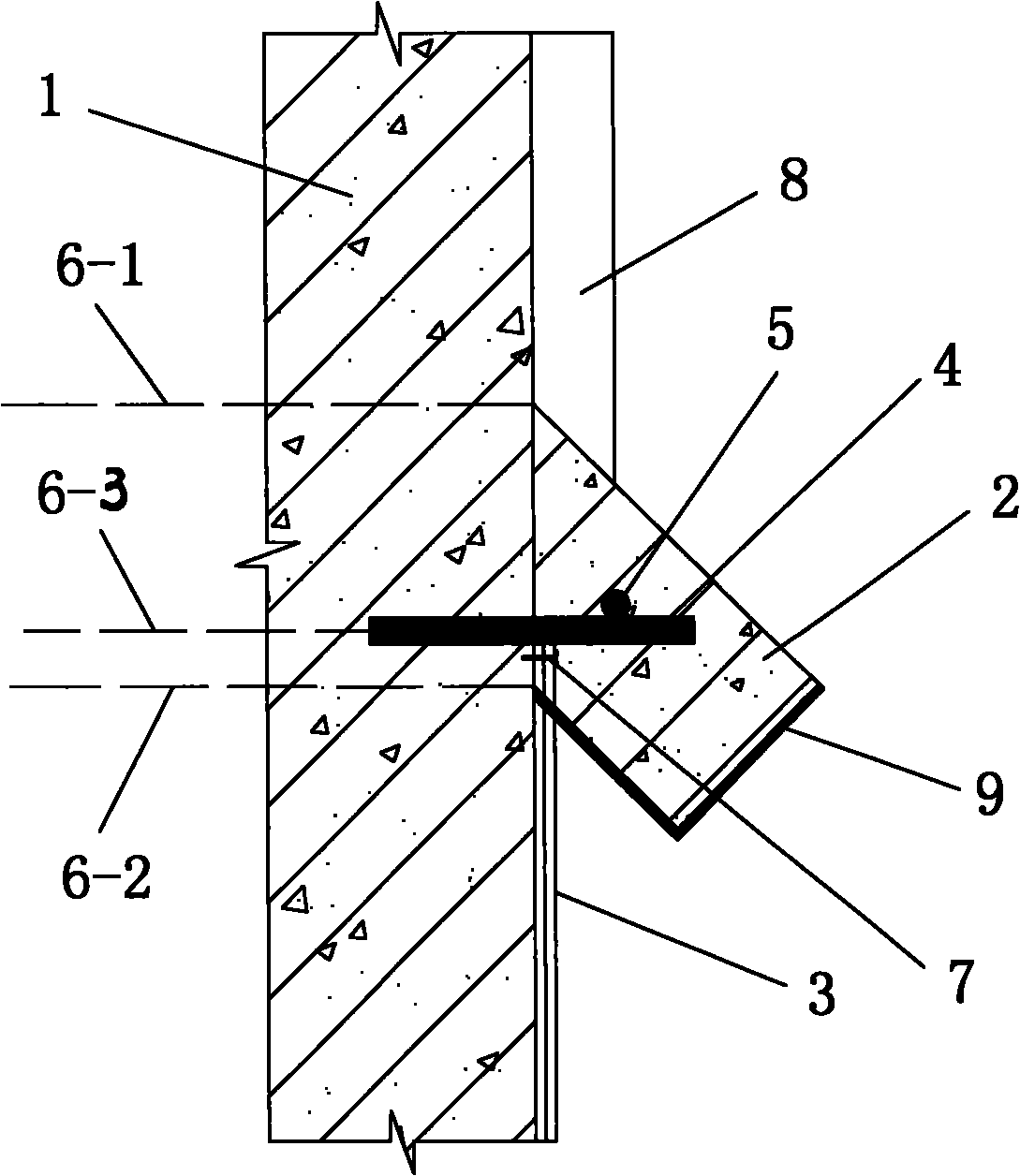

[0039] Such as figure 1 As shown, the roof parapet flashing overturning eaves of the present invention includes the concrete overturning eaves 2 that are laid on the inner wall surface of the completed parapet wall 1 and slope from top to bottom and pre-buried in the concrete overturning eaves. 2 The internal rigid skeleton, the upper closure of the waterproof membrane 3 located under the concrete overhang 2 is firmly pressed between the bottom of the concrete overhang 2 and the wall of the parapet 1, and the waterproof membrane 3 is laid on the parapet On the inner wall surface of 1, the parapet 1 is a reinforced concrete wall and it is firmly connected with the concrete overhang 2 as a whole. The rigid skeleton includes a plurality of horizontal steel bars 4 that are arranged on the same horizontal line and have the same structure and size, and transverse steel bars 5 that are integrally reinforced to the multiple horizontal steel bars 4, and the horizontal steel bars 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com