Method of multipurpose of aluminium foil air layer in building and aluminium-plated plate with supports

A multi-purpose, fulcrum technology, applied in the direction of construction, building structure, insulation layer, etc., can solve the problem that there is no ordinary plastic plate with fulcrum to form an air layer, and achieve the effect of improving the waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] (1) Implementation of the product

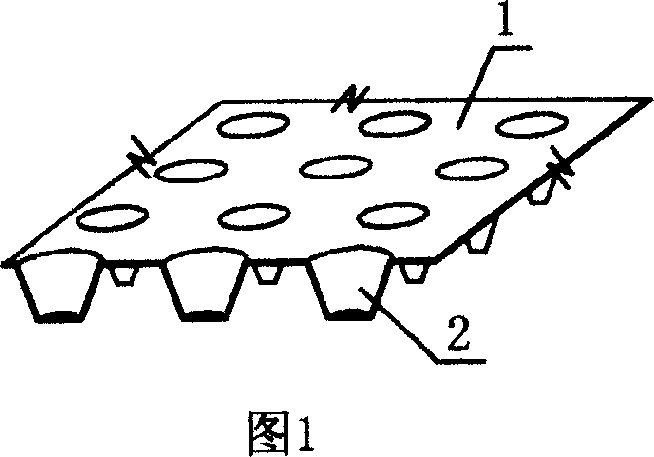

[0026] From Figure 1 and Figure 2, it can be seen that the plastic plate 1 is thermally molded on the mold with a single-sided fulcrum to make a fulcrum 2, and the aluminum film is on the outer surface of the fulcrum;

[0027] From Figure 3 and Figure 4, it can be seen that compared with Figure 1 and Figure 2, there are only more grooves 4, and the groove 4 is mainly to improve the rigidity of the product and to have a better combination with the paint layer when it is used as a wall paint base force. In the technical scheme of the following illustration, any single-sided fulcrum plate can be used as (Figure 1) product or (Figure 3) product, and the aluminum film is on the outer side of the fulcrum;

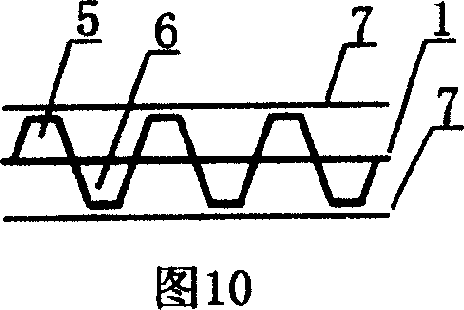

[0028] From Fig. 5 and Fig. 6, it can be seen that the upper fulcrum 5 and the lower fulcrum 6 are thermally molded on the upper and lower fulcrum molds with the plastic flat plate 1, which can be double-sided or single-sided aluminized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com