Subway station body structure and four-joint-arch PBA underground excavation construction method thereof

A technology of main structure and subway station, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of increasing the ground area required for construction, increasing the workload of demolition and modification, and early investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

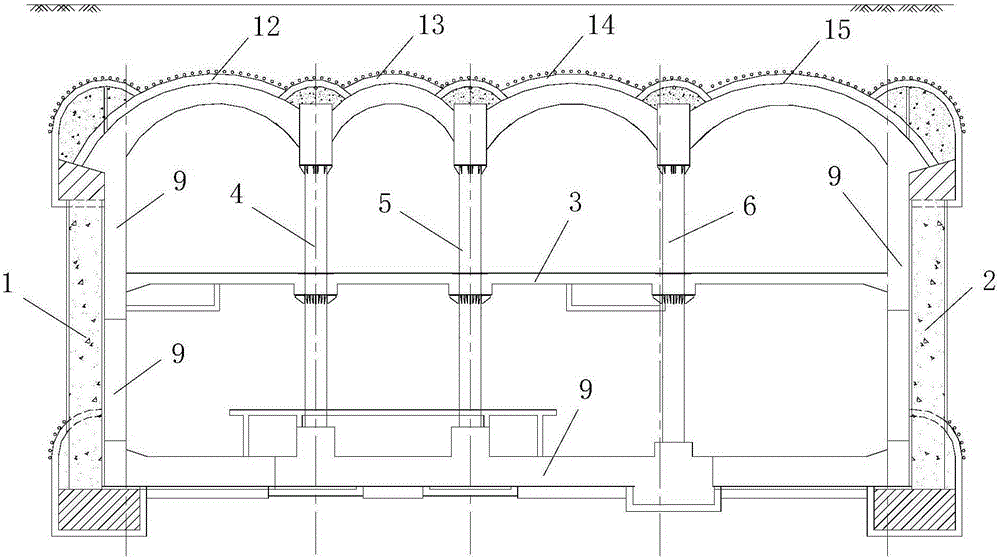

[0094] Such as figure 1 The main structure of a subway station shown includes an internal main structure of the station formed by excavation, a plurality of left piles arranged on the left side of the main internal structure of the station from front to back, and a plurality of piles are arranged on the station from front to back. The right pile 2 and the three groups on the right side of the internal main structure are arranged from left to right in the central column of the internal main structure of the station, the middle slab 3 laid in the middle of the internal main structure of the station and laid in the horizontal direction. For the main arch directly above the main structure of the station, the three groups of the center pillars are located between the left pile 1 and the right pile 2, and each group of the center pillars includes a plurality of longitudinally along the main structure of the station. The middle pillars are arranged from front to back in the length dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com