Manufacturing method and structure for basement floor without crack, leakage and with oversized area

A technology with a super-large area and a manufacturing method, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of floor subsidence, short service life of the floor, and large deviation of floor surface flatness, etc., to achieve Prevents cracking, improves waterproof quality, and has the effect of long-term waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

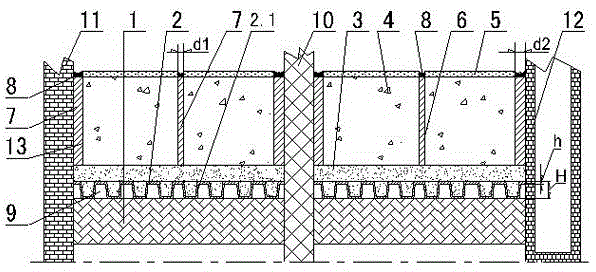

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Embodiments of the present invention: A method for making a crack-free and non-leakage super-large-area basement floor of the present invention can be used to make a super-large-area basement floor with a construction area greater than 10,000 square meters. When the basement floor with a super-large area of 1.5 meters is used, the following methods are used to make it:

[0023] a) First, pour a layer of concrete self-waterproof floor. The concrete self-waterproof floor is poured with impermeable concrete. The thickness of the waterproof floor layer is controlled at 900-1200 mm;

[0024] b) After the concrete self-waterproof floor layer is solidified, lay a layer of drainage slab made of high-impact polystyrene (HIPS) material on the concrete self-waterproof floor layer;

[0025] c), and then pour a layer of plain concrete leveling l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com