Gas-solid fluidized bed sorting machine based on pulse airflow

A technology of pulsating airflow and fluidized bed, which is applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc. It can solve the problem of large vibration mass, narrow application range and poor precision of vibrating fluidized bed and other problems to achieve the effect of high bed density stability, wide range of sorting particle size, and enhanced uniform stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

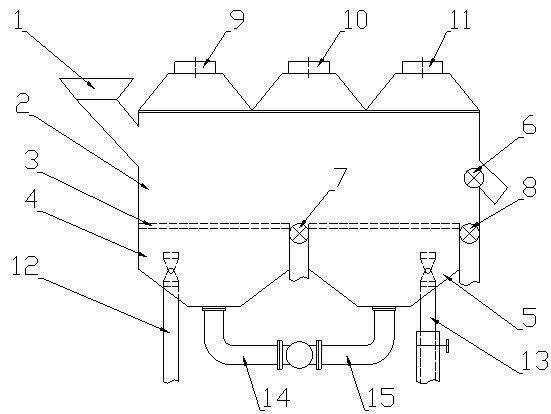

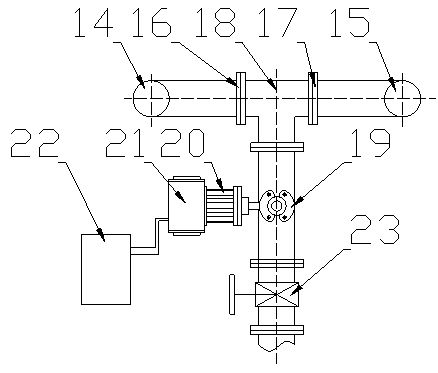

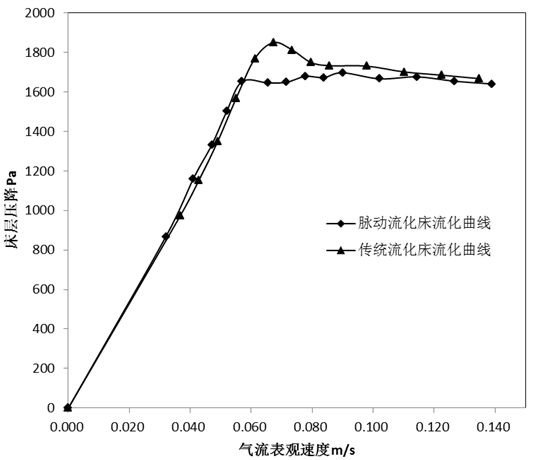

[0017] Such as figure 1 As shown, the gas-solid fluidized bed separator based on pulsating airflow of the present invention mainly contains sorting tank 2, light product discharge wheel 6, rear heavy product discharge wheel 7, front heavy product discharge wheel 8, cloth Air panel 3, rear air distribution chamber 4, front air distribution chamber 5, rear support leg 12, front support leg 13, resistance conversion device 19, and air flow regulating valve 23 form. The air distribution plate 3 is installed between the sorting tank 2 and the rear air distribution chamber 4 and the front air distribution chamber 5, and the top of the sorting tank 2 is provided with 1# dust removal cover 9, 2# dust removal cover 10, 3# dust removal cover 11 3 dust covers, the lower part of the sorting tank 2 is provided with a bracket that can adjust the horizontal inclinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com