Patents

Literature

130 results about "Sorting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

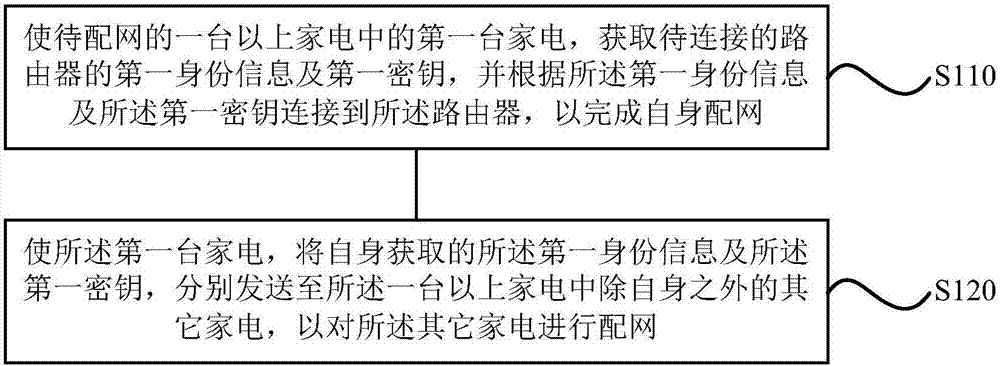

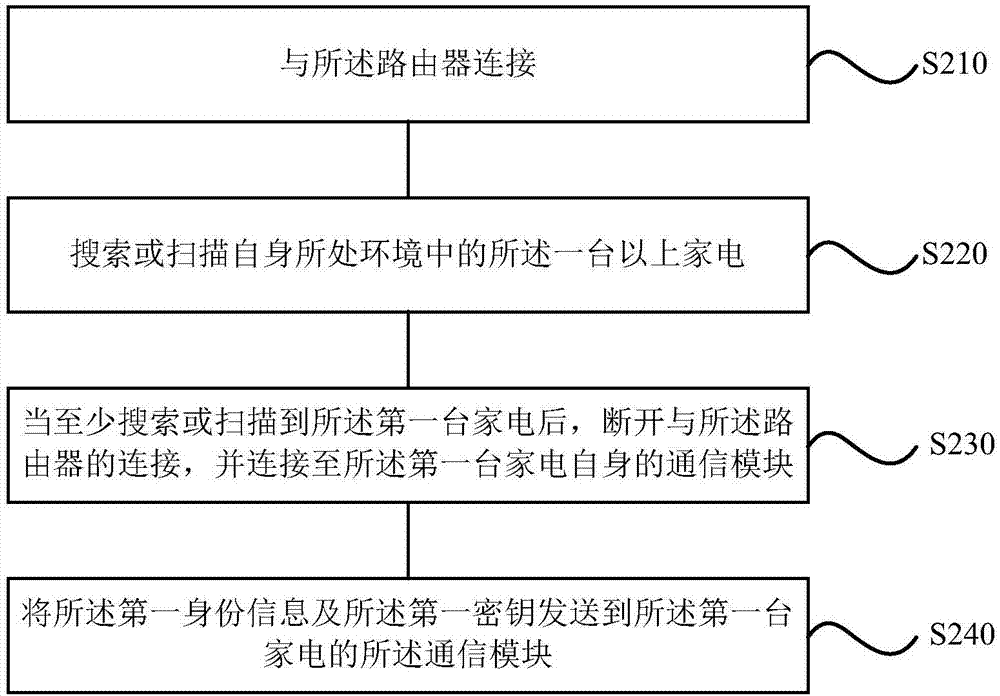

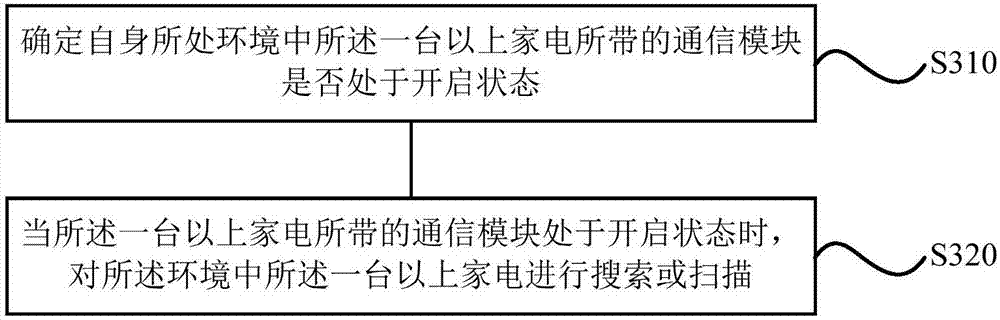

Network distribution method and apparatus, storage medium, terminal and home appliance

InactiveCN107466086ASolve the problem of repeated operation of the distribution network processReduce operation timeAssess restrictionSecurity arrangementDistribution methodComputer terminal

Owner:GREE ELECTRIC APPLIANCES INC

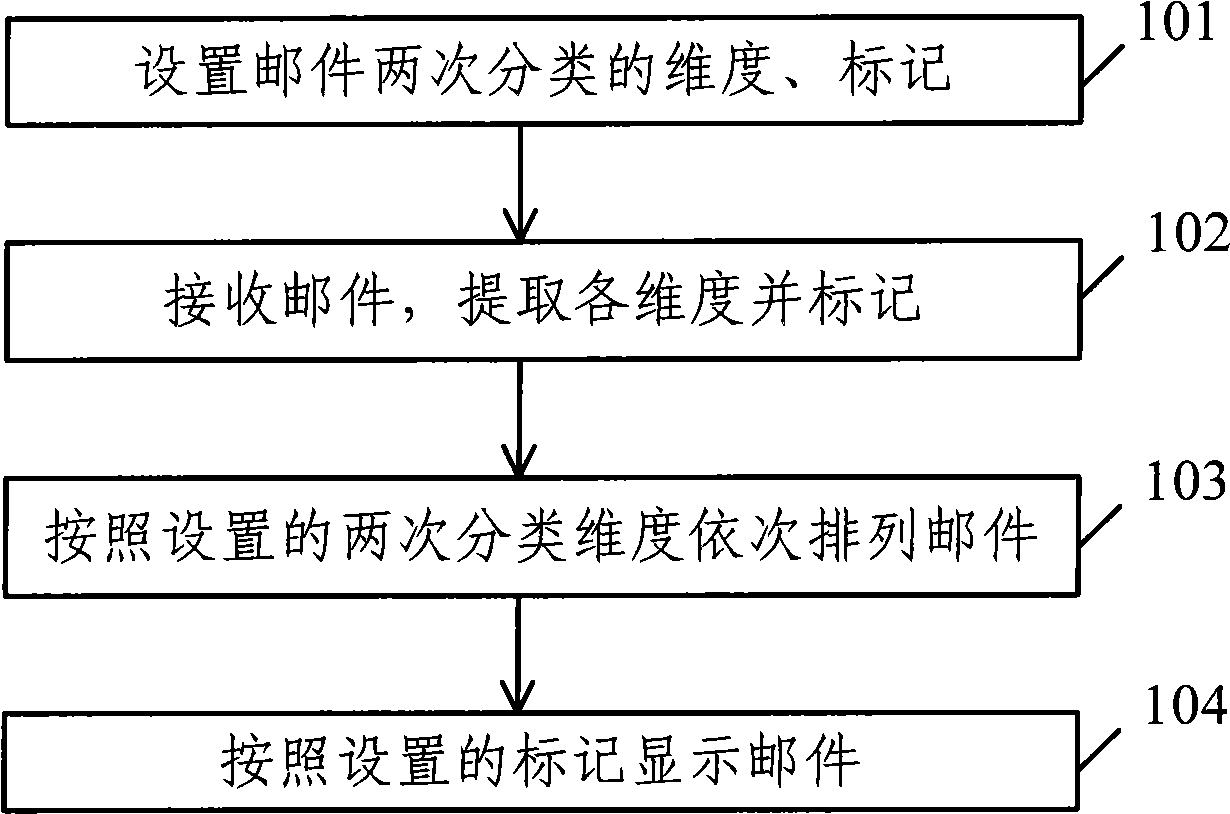

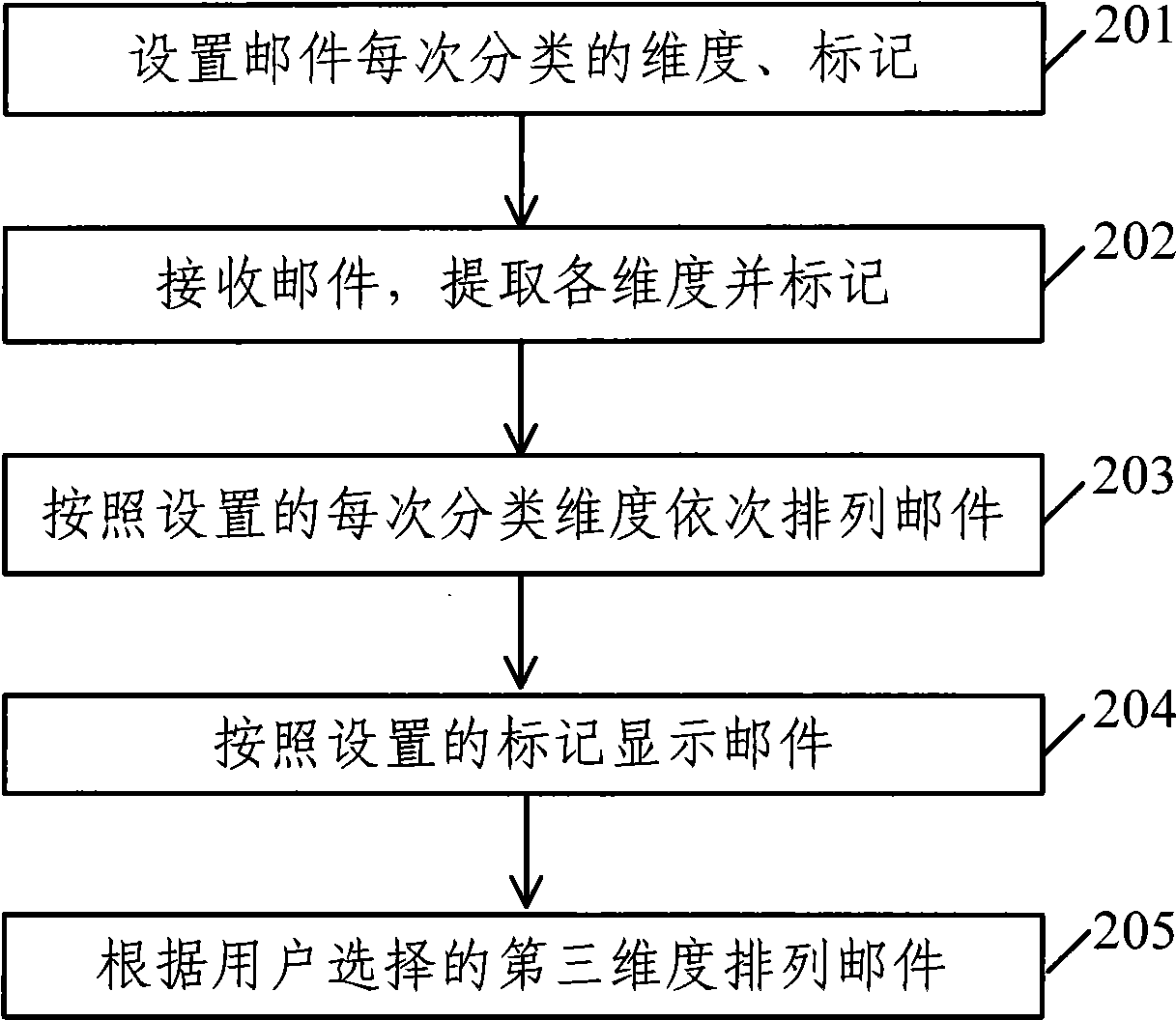

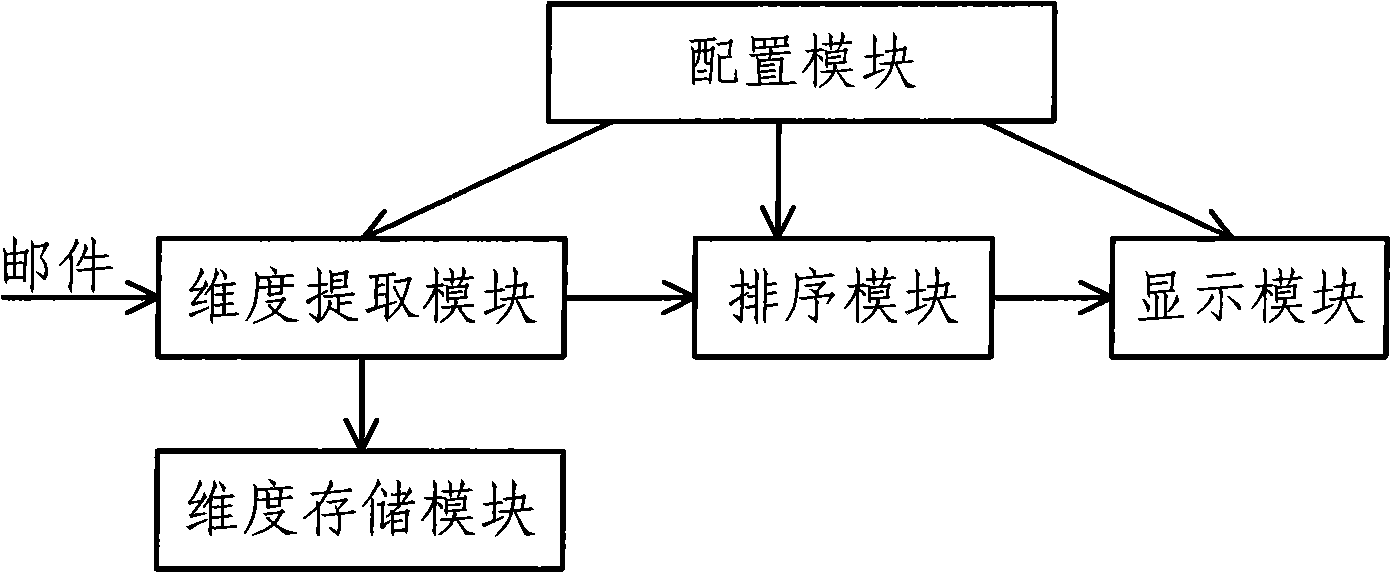

Mail classifying method and apparatus

InactiveCN101488198AEasy to handleImprove work efficiencyOffice automationSorting timeComputer science

The invention discloses a mail sorting method which determines the dimensionalities of two sorting times. Mails are separated into at least two groups according to the dimensionality of the first sorting, and the mails are separated from at least two groups according to the dimensionality of the second sorting. The invention also discloses a corresponding device which comprises a configuration module, a dimensionality storage module, a dimensionality extraction module, a sequencing module and a display module. The technical proposal of the invention is that multi-layer dimensionalities are used for sequence, such that users have a wider selecting range. In addition, the mails are sorted especially according to receiving types so as to cause the users to more rapidly find important mails which are secretly sent and be convenient for the users to firstly sort the mails according to different sorts, thereby enhancing the timeliness of information transfer and the working efficiency of the users.

Owner:LENOVO (BEIJING) CO LTD

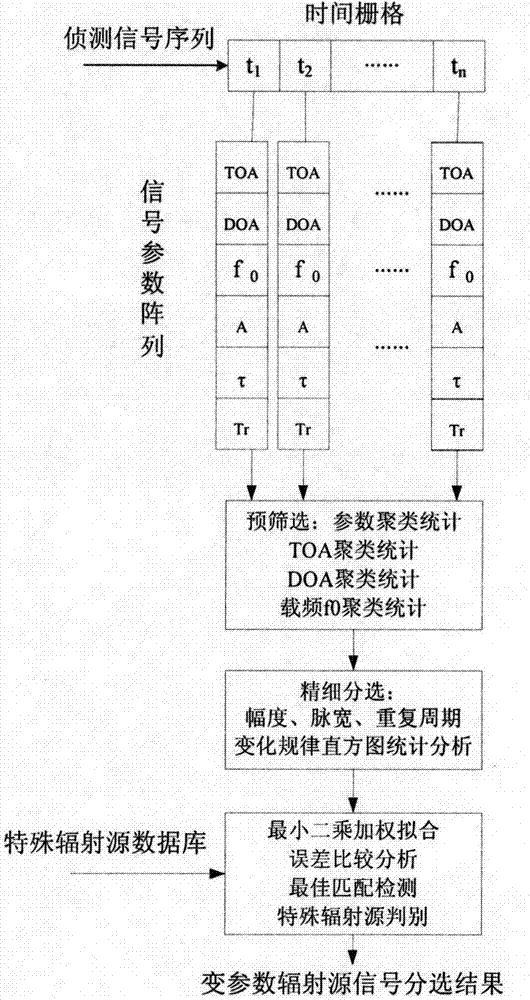

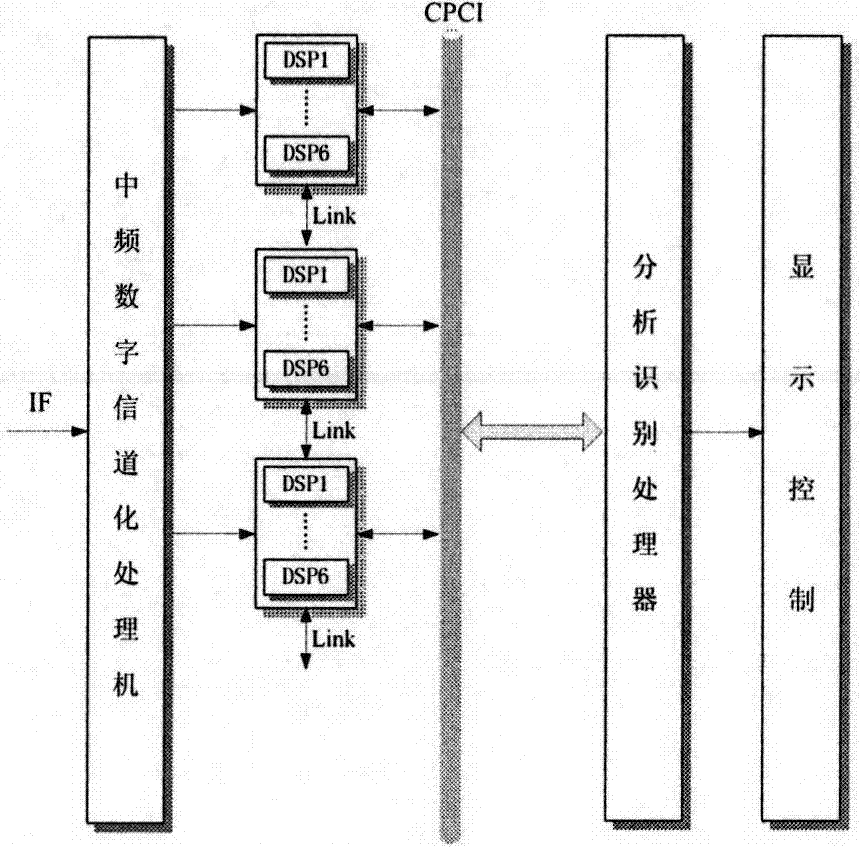

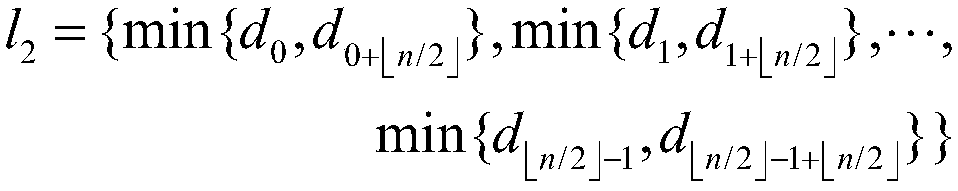

Multi-parameter rasterizing sliding signal statistic screening processing method

The invention relates to a multi-parameter rasterizing sliding signal statistic screening processing method which is used for achieving the effect that a passive signal detection system sorts time-varying parameter complex signal sequences in the dense signal environment. High-density complex pulse signal flows which are detected and interwoven with the parameters changing randomly are subjected to parameter discretization segmentation according to time grids, time-varying parameter vectors of pulse signals are arranged corresponding to the time grids to form a vector parameter array sliding with time, a vector grid matching algorithm is adopted to conduct pre-sorting according to the time of arrival (TOA) and the angle of arrival (DOA) of signals and the carrier parameter change, and then fine sorting is conducted according to the signal pulse width and the repetition period change rule. By means of the method, sorting of the time-varying parameter complex signal sequences is decomposed into multistage vector clustering statistic screening and the least square error estimation processing, and accurate sorting and recognition can be conducted on complex signals of electronic scanning beams and phase control array radar radiation.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

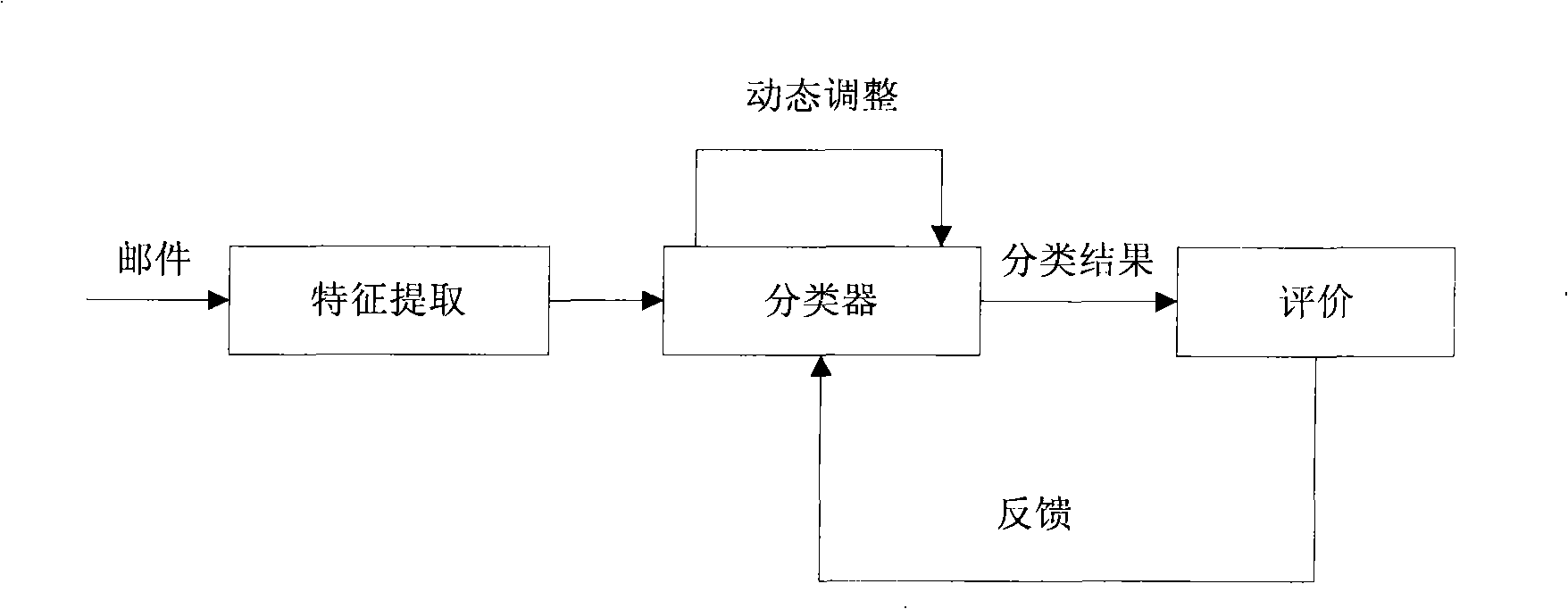

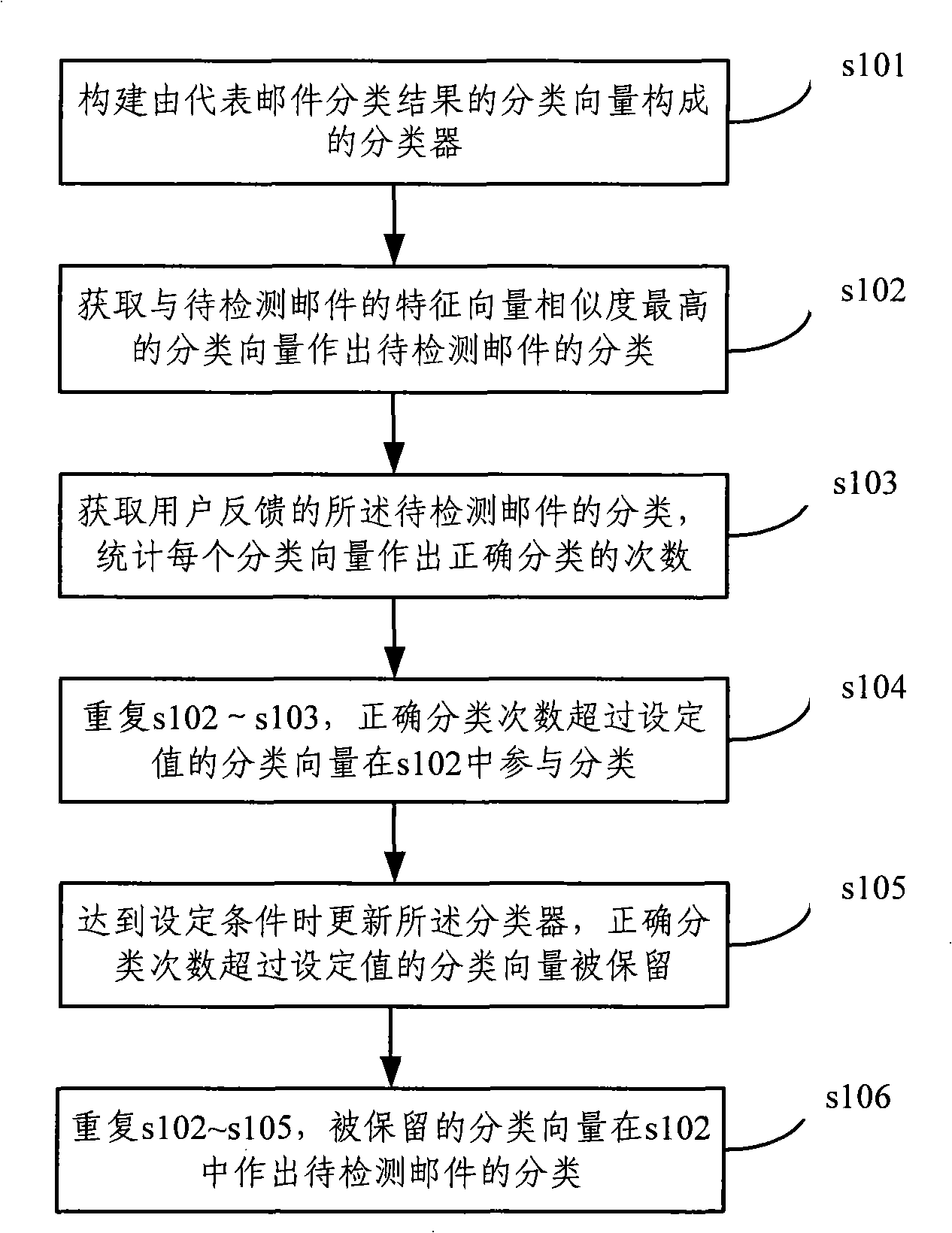

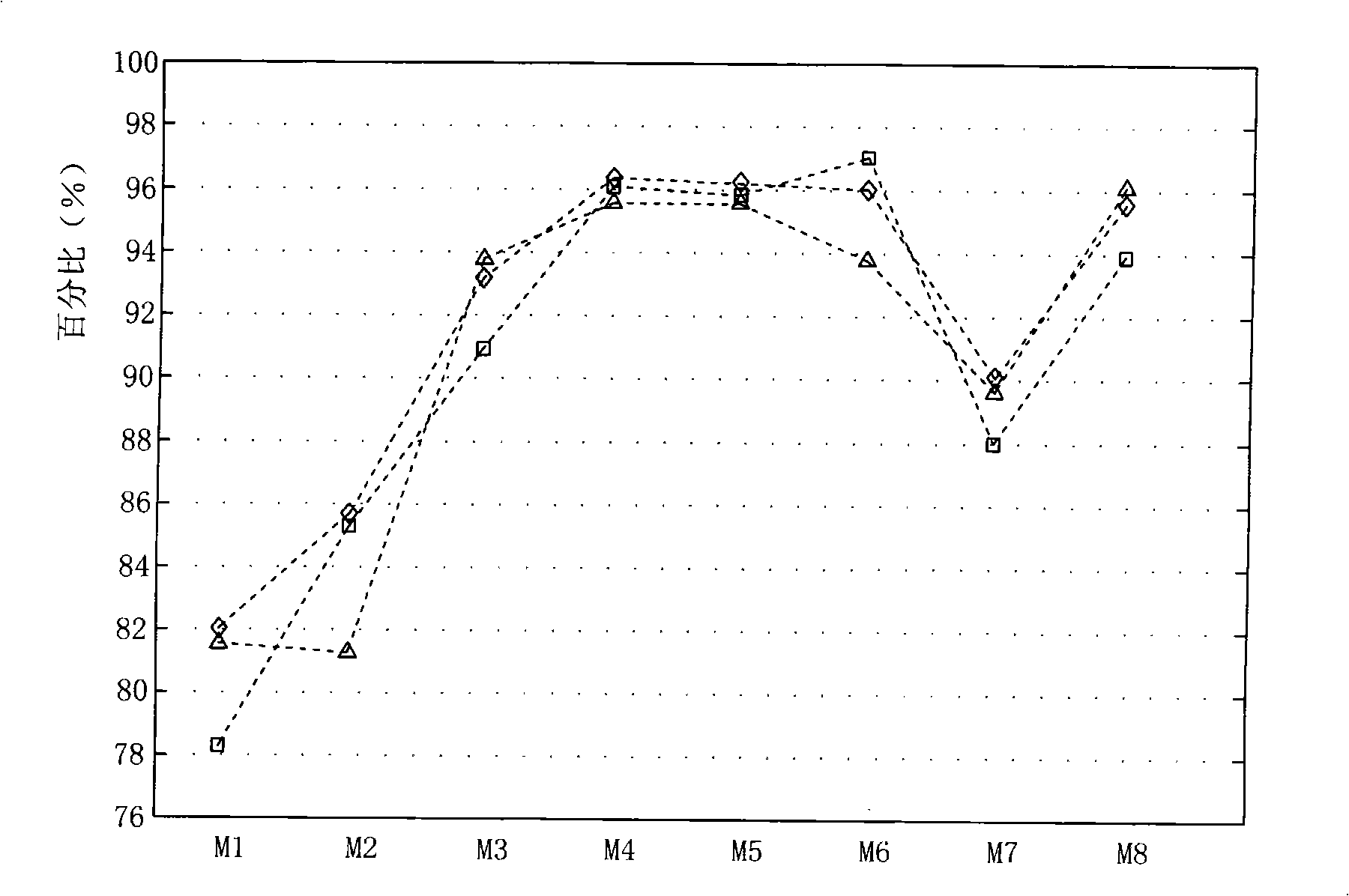

Junk mail detection method and system based on dynamic update of categorizer

InactiveCN101316246AImprove classification effectGuaranteed accuracyData switching networksFeature vectorData stream

The invention relates to a method and a system for detecting junk mails based on the dynamic updating of a sorter, which includes the following steps: the sorter composed of class vector is constructed; the degree of similarity between the characteristic vector and each class vector of the mail to be detected is acquired; the class vector with the highest degree of similarity is sorted; the classification fed by the user on the mail to be detected is acquired; the times of carrying out correct classification of each class vector is counted; the new mail is received and sorted according to the steps and the sorter is updated when the set conditions are met, the class vector is reserved when the correct sorting times exceeds the set value, and the newly-received mail to be detected is sorted; the system includes a sorter updating unit, the sorter is updated when the set conditions are met, the class vector is reserved for participating mail classification in the future when the correct sorting times exceeds the set value. The invention reserves the class vector with good classification effect in the sorter for a period of time, which guarantees the accuracy of the classification and cannot be affected by the limitation of the new a data stream.

Owner:PEKING UNIV

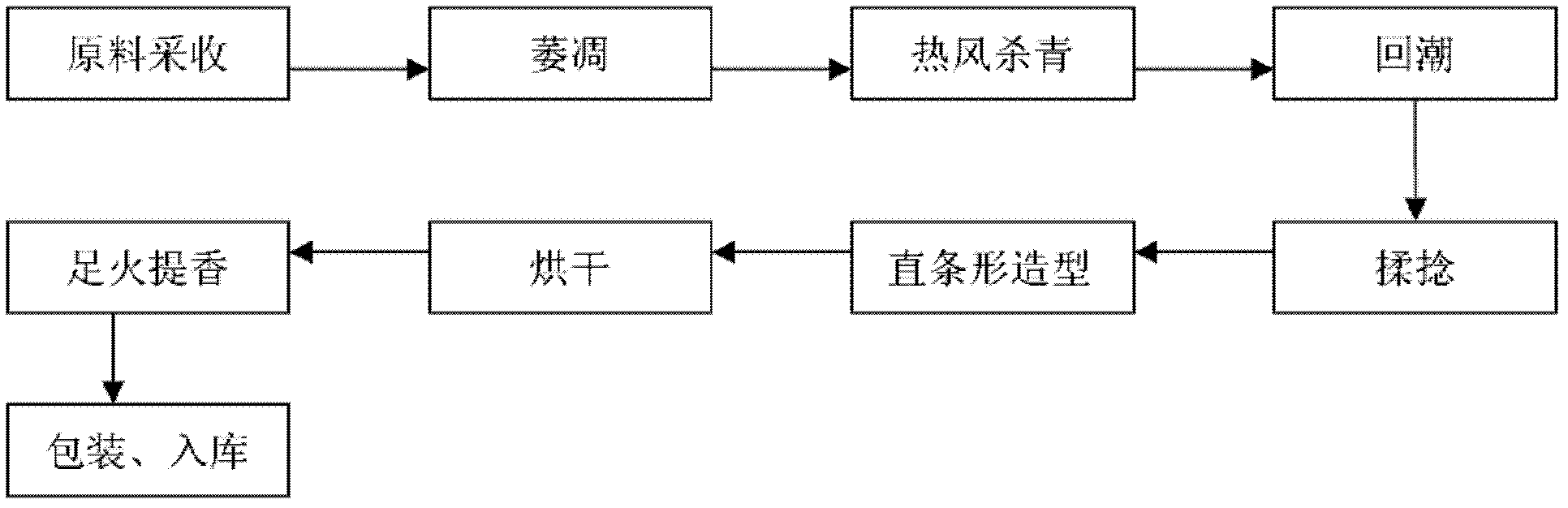

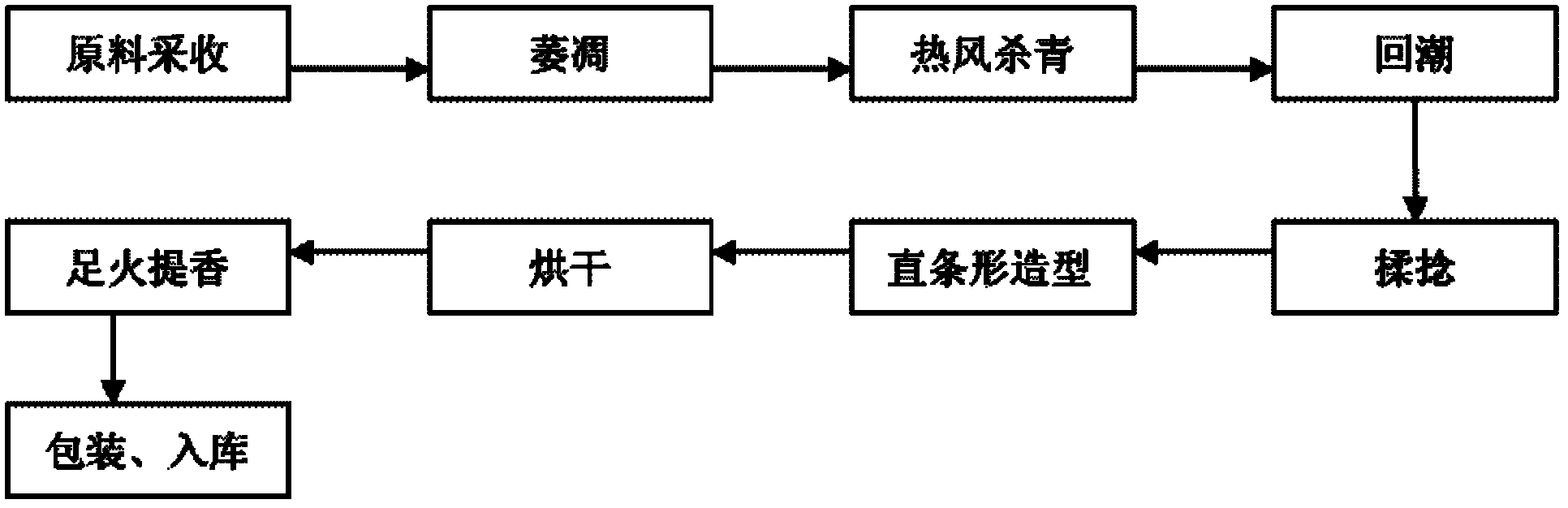

Processing technique for Guire No. 1 green tea

InactiveCN102613324APretty in appearanceEmerald green colorPre-extraction tea treatmentVertical barMoisture regain

The invention discloses a processing technique for Guire No. 1 green tea, which comprises the steps of raw material harvesting, wilting, deactivation of enzymes by hot wind, moisture regain, rolling, vertical-bar shaping, drying, perfuming by complete fire, wherein the three critical steps that guarantee the unique quality of the Guire No. 1 green tea are as follows: fresh leaves are purchased strictly in accordance with the standard of one bud one leaf, the temperature for the deactivation of the enzymes by the hot wind is 280-320 DEG C, the sorting temperature is strictly controlled to be 40-50 DEG C, and the sorting time is controlled to be 8-10 minutes. With the application of the technique, the standardized and scale production of the Guire No. 1 green tea is realized, the processed Guire No. 1 green tea is good in appearance, bright green in color, blooming, yellow green and bright in liquor color, and mellow and sweet in taste, the castanea mollissima fragrance is persistent, leaf bases are light green and even, and the requirements of tea lovers on high-quality tea can be met.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

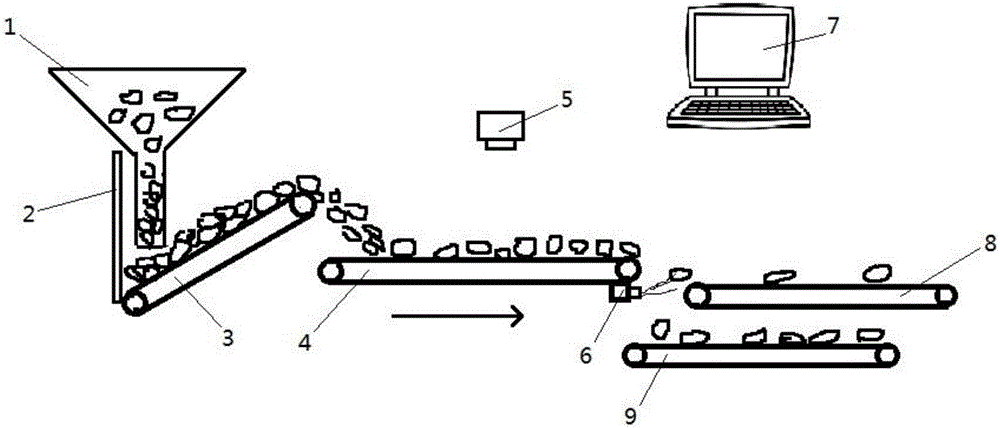

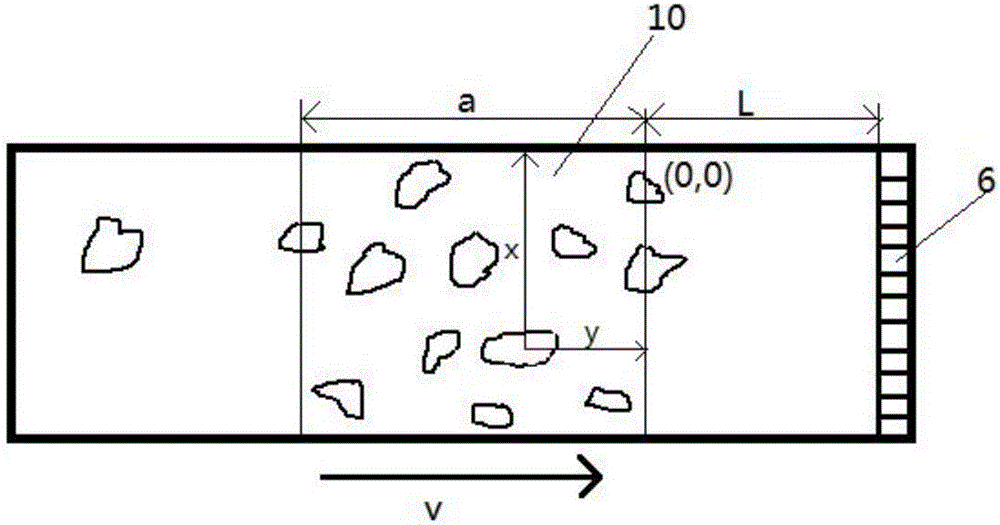

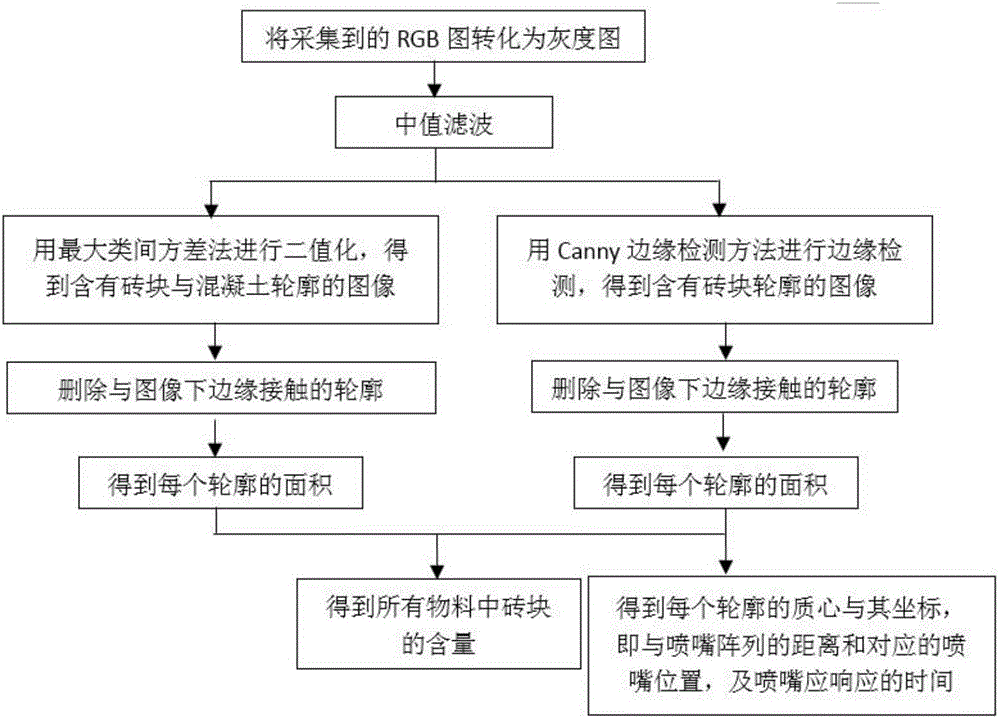

Construction waste sorting method and system

The invention provides a construction waste sorting method and system. The construction waste storing method comprises the following steps: conveying a mishmash through a dispersing conveying belt; acquiring an image of the mishmash conveyed by the dispersing conveying belt, and processing to obtain the content of bricks in the mishmash as well as the position of each brick; and conveying the bricks arriving at the tail end of the dispersing conveying belt to a brick conveyor belt, and conveying the rest particles to another conveyor belt, thus realizing waste sorting. With the adoption of the method and the system, the bricks and concrete can be quickly automatically sorted; the recognizing process is performed earlier than the separating process, so that the sorting time can be accurately controlled; the cost is low; in addition, additional maintenance is avoided; the method and the system are applicable to the actual production environment.

Owner:HUAQIAO UNIVERSITY

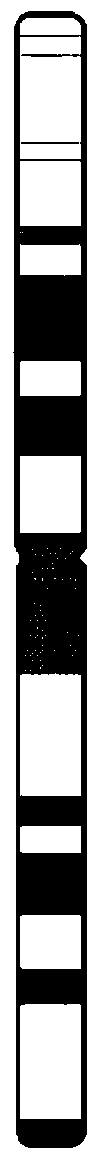

A chromosome recognition method based on depth learning

ActiveCN109300111AAutomatic IdentificationAccurate identificationImage enhancementImage analysisStudy methodsWorkload

The invention discloses a chromosome identification method based on depth learning, belonging to the technical field of chromosome identification. At present, the method of chromosome analysis is basically manual operation, and the examiner needs a lot of training time to master the knowledge of identifying each chromosome type, and the workload is heavier. Even experienced physicians analyze andidentify patients' chromosomes, the process typically takes more than two weeks and takes a longer period of time. And artificial recognition, subjectivity is very strong, easy to be affected by the external environment, the accuracy is not high. As that depth learn method is adopted, the chromosome type can be accurately carry out, Compared with the existing identification technology, the high-efficient identification technology can effectively improve the efficiency of chromosome karyotype analysis, shorten the identification sorting time, complete the automatic classification and sorting ofchromosomes with high accuracy, at the same time, can effectively reduce the work burden of doctors, free from external interference, and the process is simple, reasonable, and can be applied to large-scale outward promotion.

Owner:HANGZHOU DIAGENS BIOTECH CO LTD

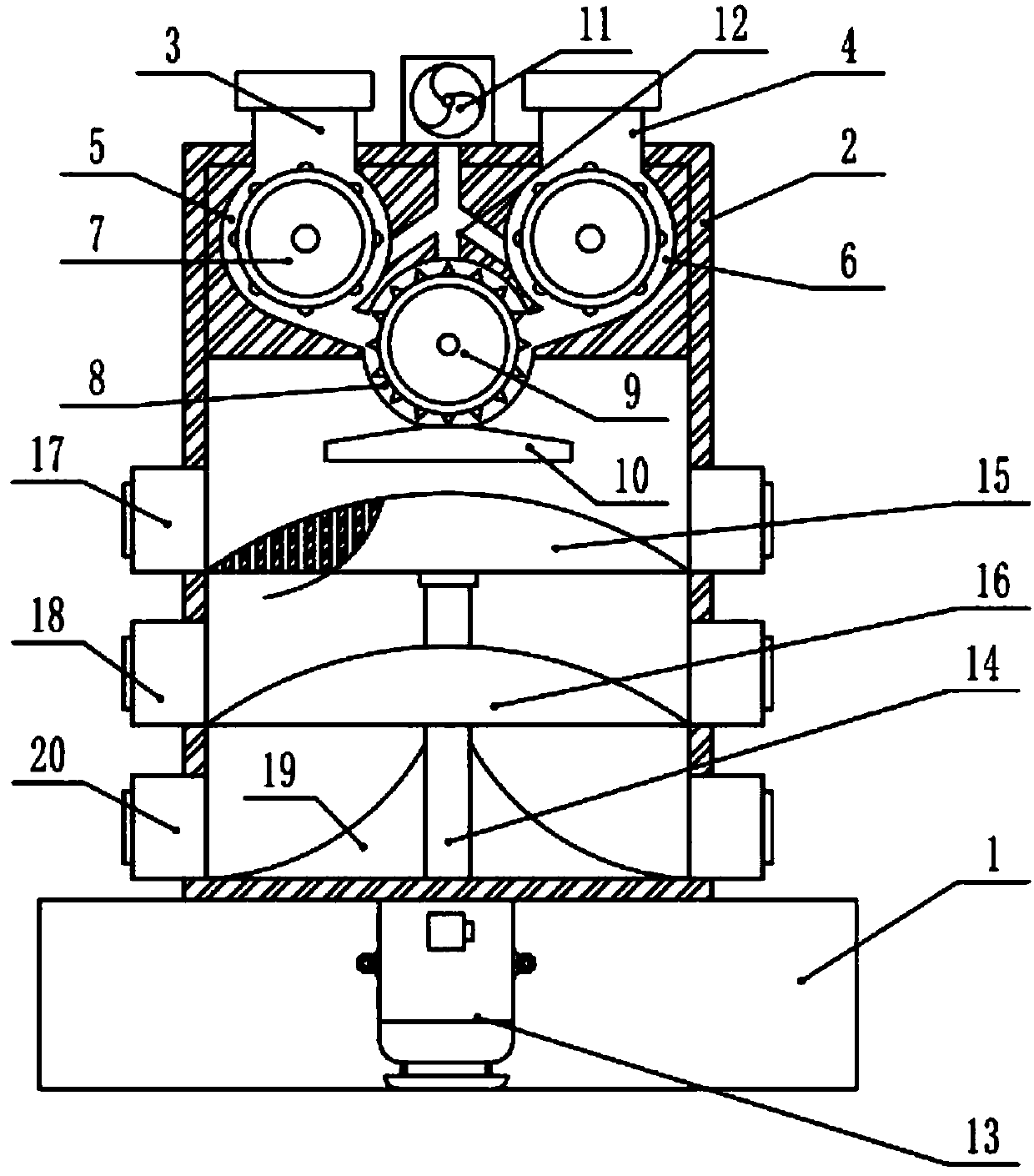

Anti-blocking ultrafine carbon black grinding and screening device for rubber preparation

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

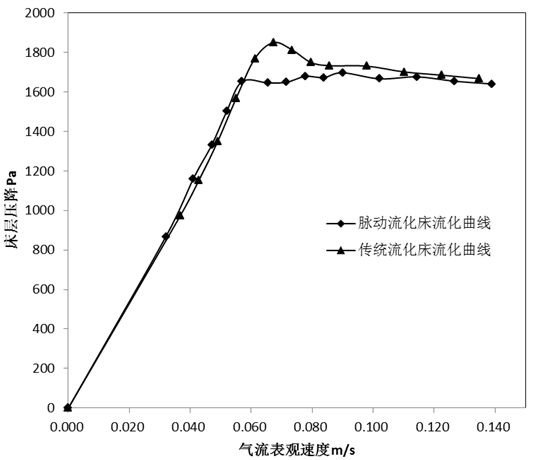

Gas-solid fluidized bed sorting machine based on pulse airflow

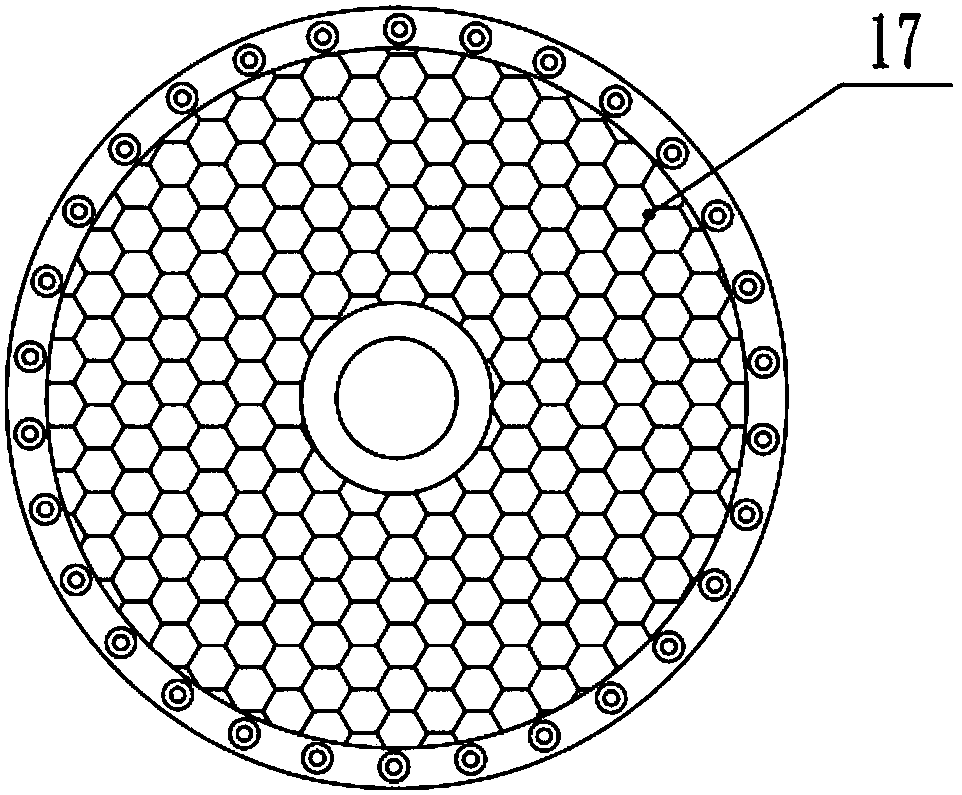

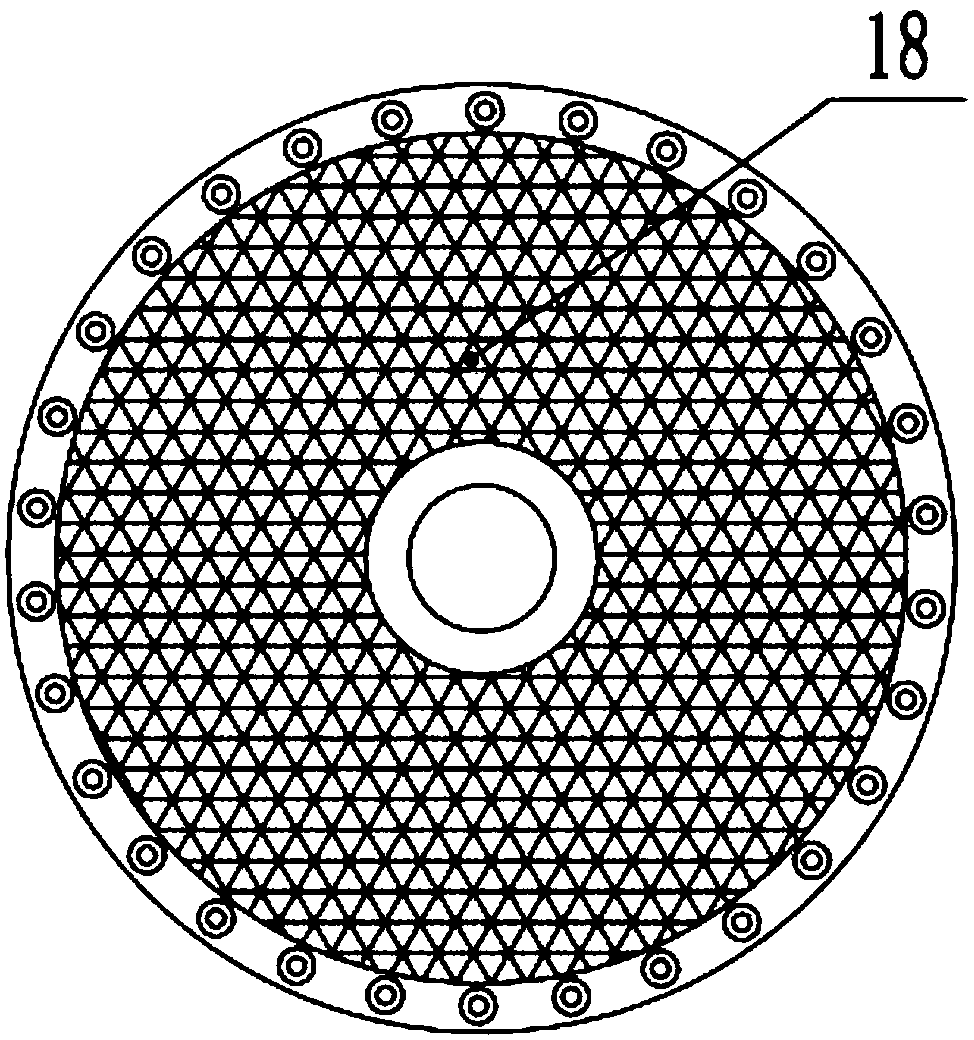

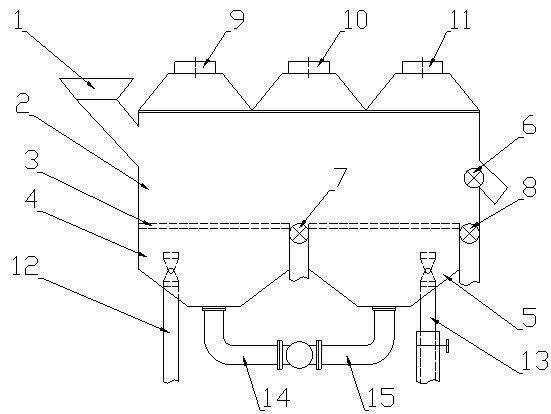

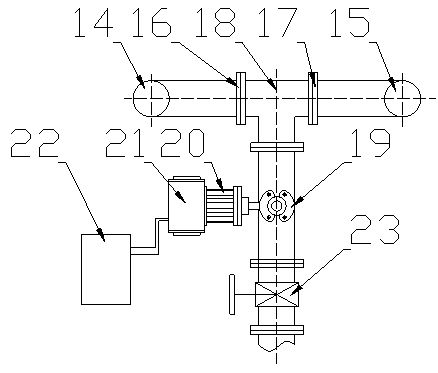

InactiveCN102652940AImprove uniformity and stabilitySimple structureGas current separationFluidized bedEngineering

The invention discloses a gas-solid fluidized bed sorting machine based on pulse airflow. The gas-solid fluidized bed sorting machine mainly comprises a sorting groove, an air distributing plate, a dedusting cover and a support, wherein the tail end of the sorting groove is provided with a light product material discharge wheel; the tail end of a rear air distributing chamber is provided with a rear heavy product material discharge wheel; the tail end of a front air distributing chamber is provided with a front heavy product material discharge wheel; the bottom parts of the rear air distributing chamber and the front air distributing chamber are respectively provided with a rear air tube and a front air tube; the rear air tube and the front air tube are connected with an air inlet tube through a three-way connector; and the air inlet tube is provided with a pulse airflow generator and an airflow quantity regulating valve in sequence. According to the invention, the pulse airflow is introduced into a gas-liquid fluidized bed, materials are conveyed forward relying on the oblique angle of the sorting groove and the effect of the pulse airflow; floating materials and sediment materials are respectively discharged through the light product material discharge wheel and the heavy product material discharge wheels, and the medium circulating quantity is reduced effectively; and the height of a front support leg can be adjusted, the front support leg can be used for regulating the oblique angle of the sorting groove, the regulation of coal conveying speed and sorting time can be realized.

Owner:CHINA UNIV OF MINING & TECH

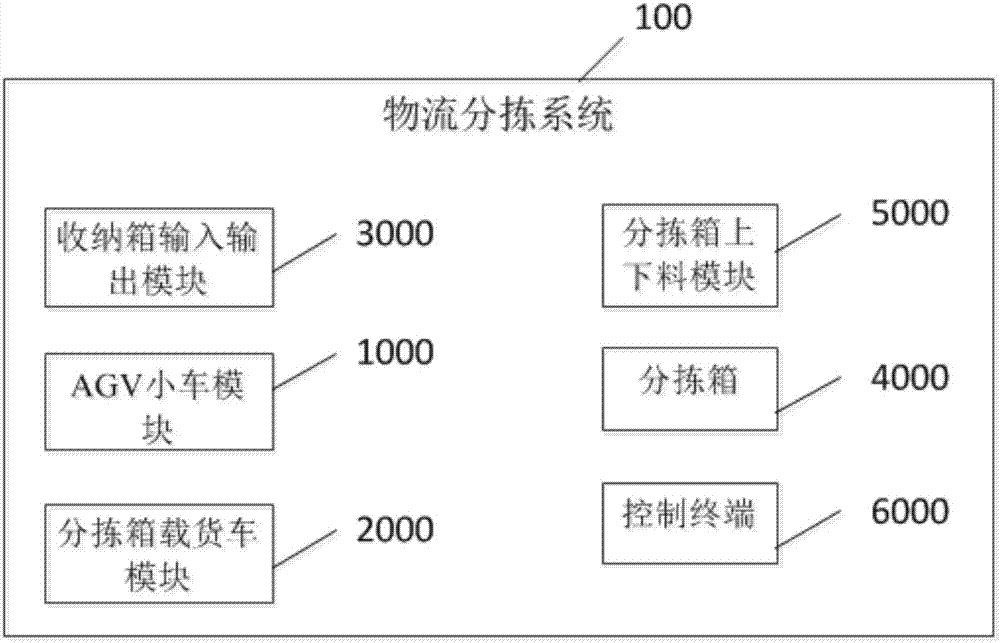

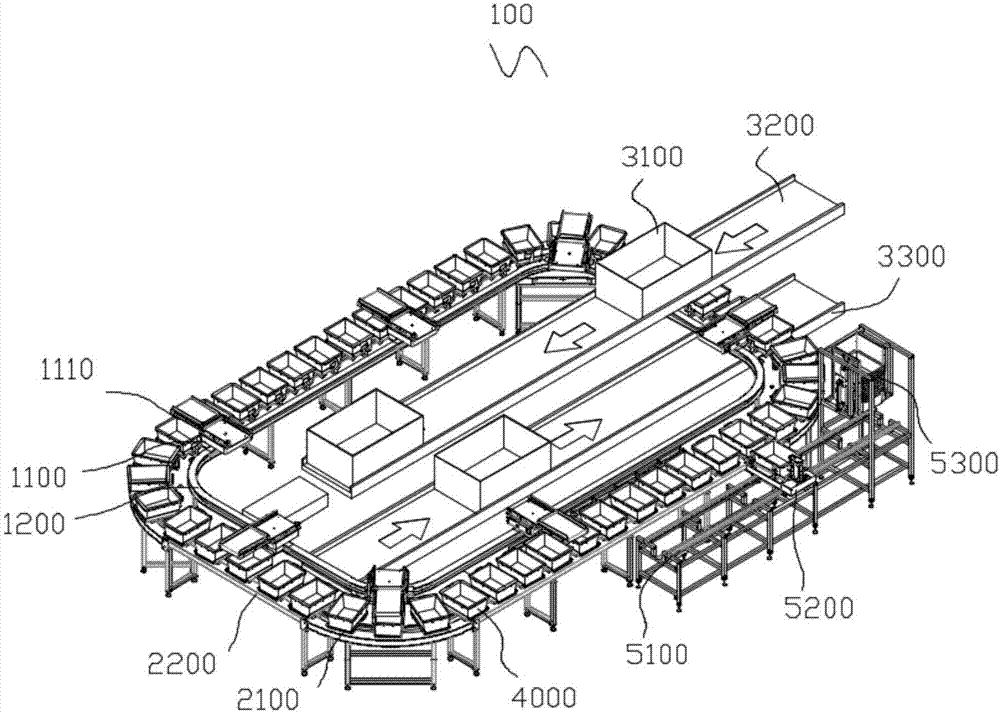

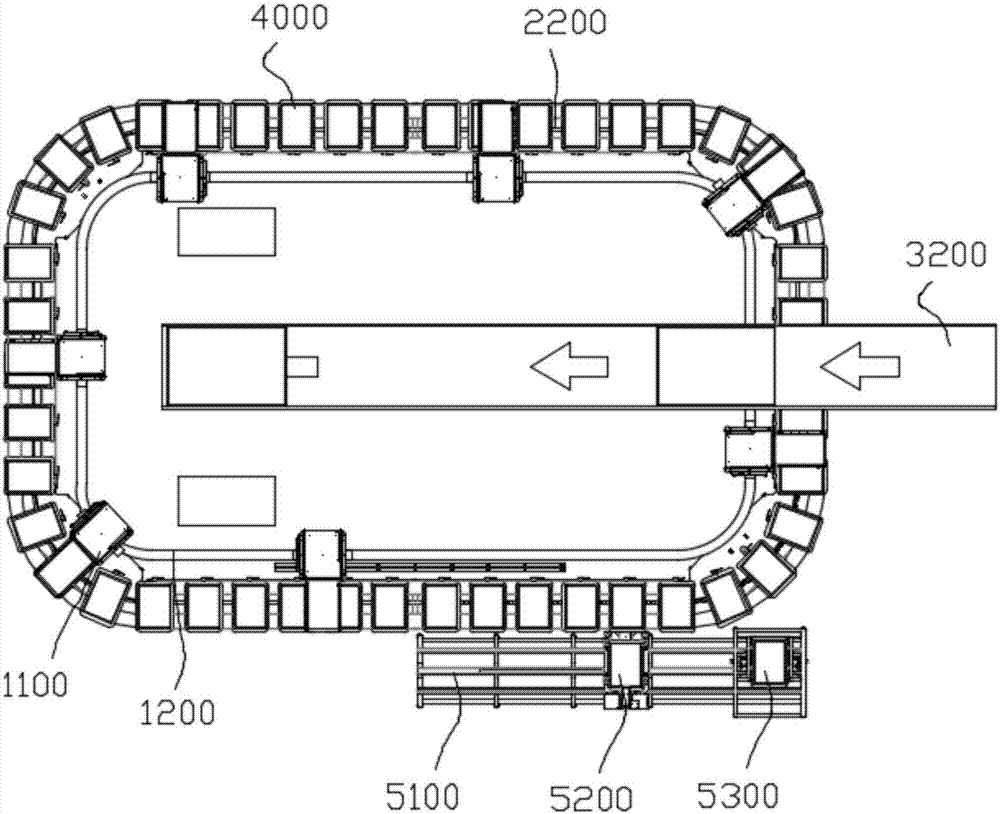

Logistics sorting system and method

The invention provides a logistics sorting system and method. A containing box input and output module inputs containing boxes carrying un-sorted objects to a preset position, and outputs unloaded containing boxes. An AGV receives the objects in the containing boxes in the preset position, and the AGV can catch up with a corresponding sorting box and put objects matched with the sorting box into the sorting box through a first transfer mechanism. A sorting box feeding and discharging module places empty sorting boxes onto a carrying trolley in a no-load state, takes sorting boxes with orders completed out of the carrying trolley, controls a terminal to distribute order information for the sorting boxes, match the objects in the AGV with the sorting boxes, and controls operation of all modules in the logistics sorting system. According to the logistics sorting system and method provided by the invention, the labor cost is reduced, the sorting time is shortened, the working efficiency is improved, automatic sorting is achieved, the sorting accuracy is improved, and the error probability is decreased.

Owner:KINCO ELECTRIC SHENZHEN

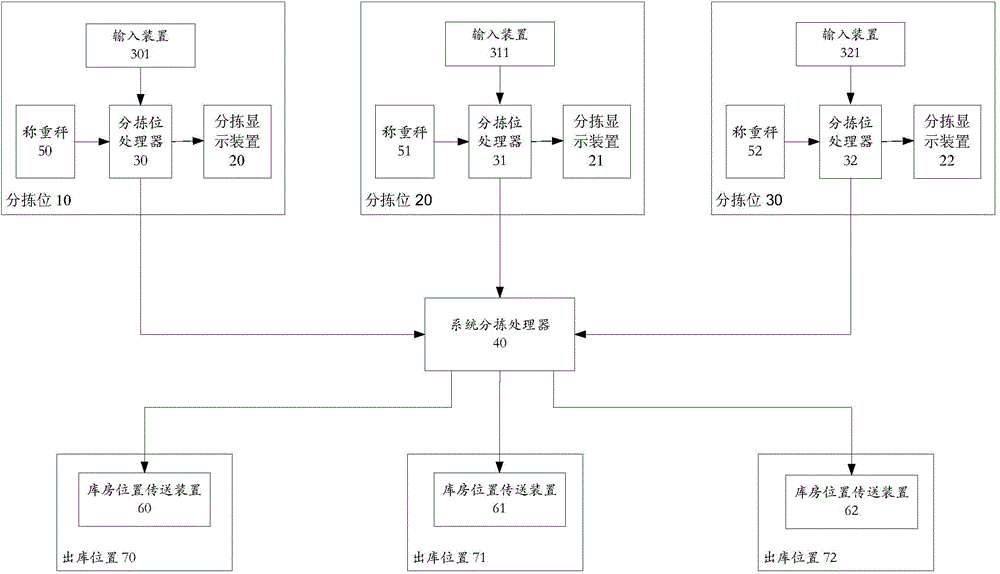

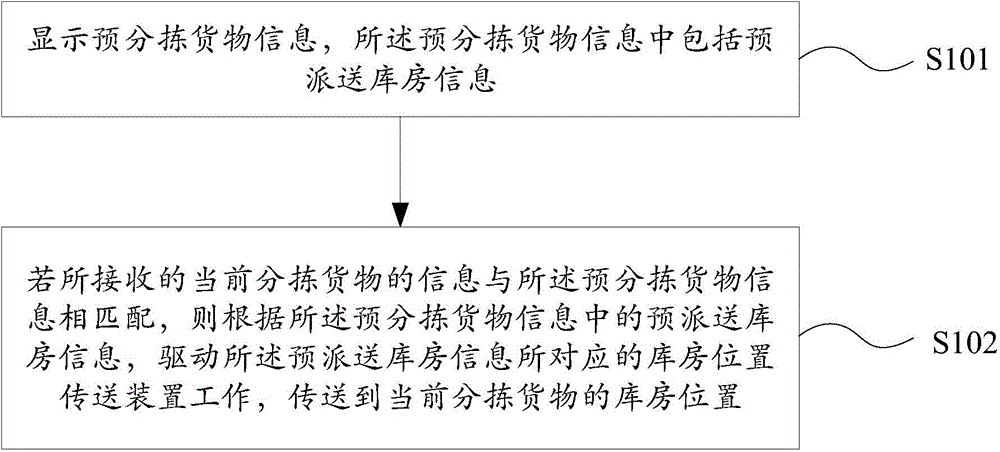

Automatic sorting method and automatic sorting system

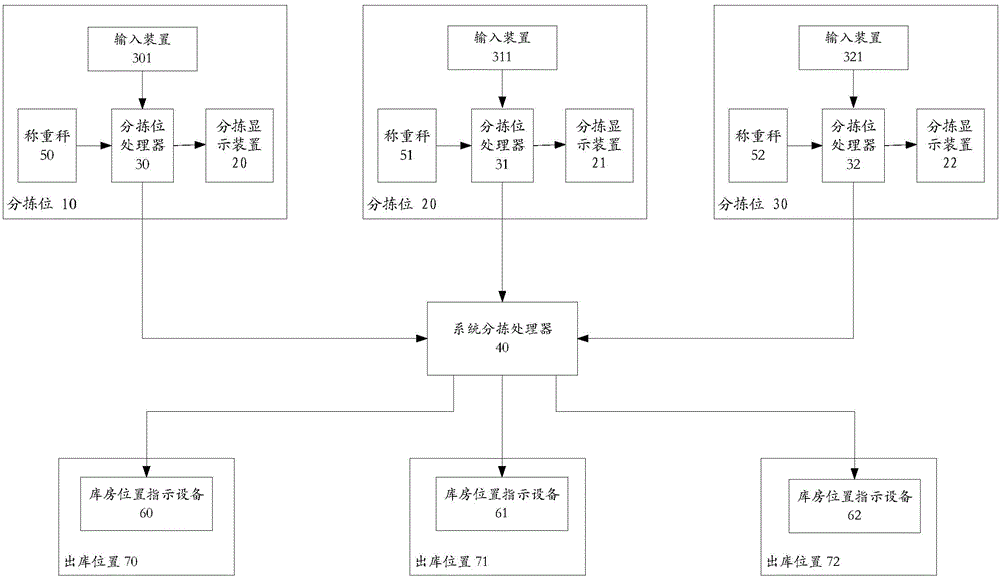

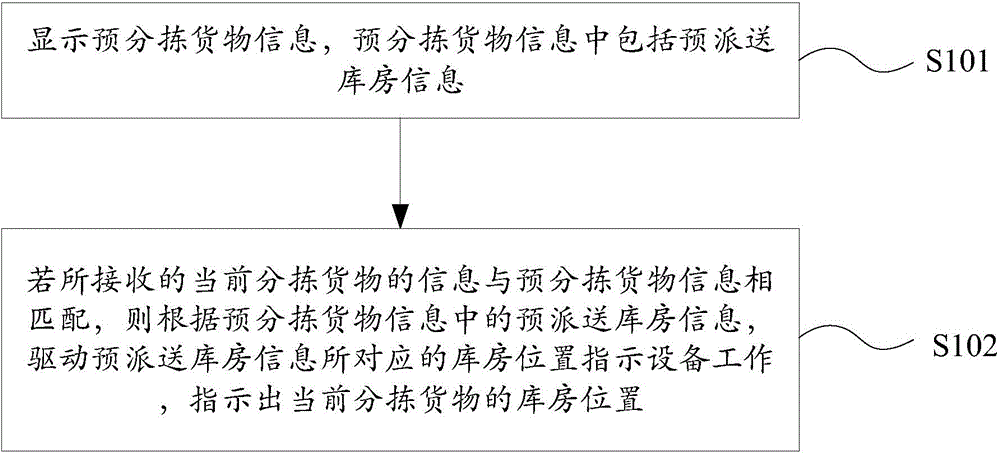

The invention provides an automatic sorting method. The automatic sorting method comprises the following steps: displaying pre-sorted cargo information, wherein the pre-sorted cargo information comprises pre-dispatched storeroom information; and if received currently-sorted cargo information is matched with the pre-sorted cargo information, driving a storeroom position conveying device corresponding to the pre-dispatched storeroom information to operate according to the pre-dispatched storeroom information in the pre-sorted cargo information, thus conveying a currently-sorted cargo to a storeroom position at which the cargo is currently sorted. According to the method, the problems that existing sorting processes are complicated and long in cycle are solved, so that in the cargo sorting process, clear instructions can be given to operators, thereby preventing sorting errors and improving the sorting efficiency; and sorted cargos are subjected to photoelectric indication, so that the piling and arranging processes of cargos are shortened. Therefore, the sorting time is shortened, an artificial taking step is simplified, the deterioration possibility of fresh commodities, especially products of which the quality is greatly influenced by temperature, is reduced, the timely sorting of cargos is ensured, so that the cycle of logistics is prolonged, and the trading effectiveness can be improved.

Owner:北京任我在线电子商务有限公司

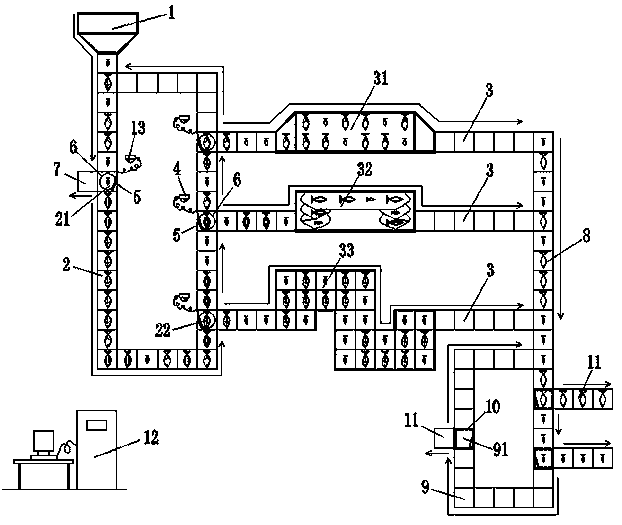

Automatic fish identifying and sorting system and running method thereof

PendingCN109332207ALabor intensiveReduce production efficiencySortingClimate change adaptationEngineeringFish species

The invention provides an automatic fish identifying and sorting system and a running method thereof. An automatic fish identifying function and an automatic fish sorting function are combined, therefore, automatic continuous running can be achieved, the labor intensity is reduced, the error rate is decreased, and the identifying and sorting time is shortened. An inlet system is connected with anidentifying and sorting circular conveying line; the identifying and sorting circular conveying line is provided with a quality identifying area and fish species identifying areas; a fish species identifier and a fish pusher are installed in each fish species identifying area; a quality identifier and a fish pusher are installed in the quality identifying area; an unqualified product conveying line is connected with the quality identifying area; classifying conveying lines are connected with the fish species identifying areas; a transition conveying line is connected with the classifying conveying lines and a weighing and sorting circular conveying line; the weighing and sorting circular conveying line is provided with weighing areas, and a fish pusher and a weighing device are installed in each weighing area; output conveying lines are connected with the weighing areas; and an analytical controller is connected with the fish species identifiers, the quality identifier, the fish pusherand the weighing devices.

Owner:CHINA UNITED ENG

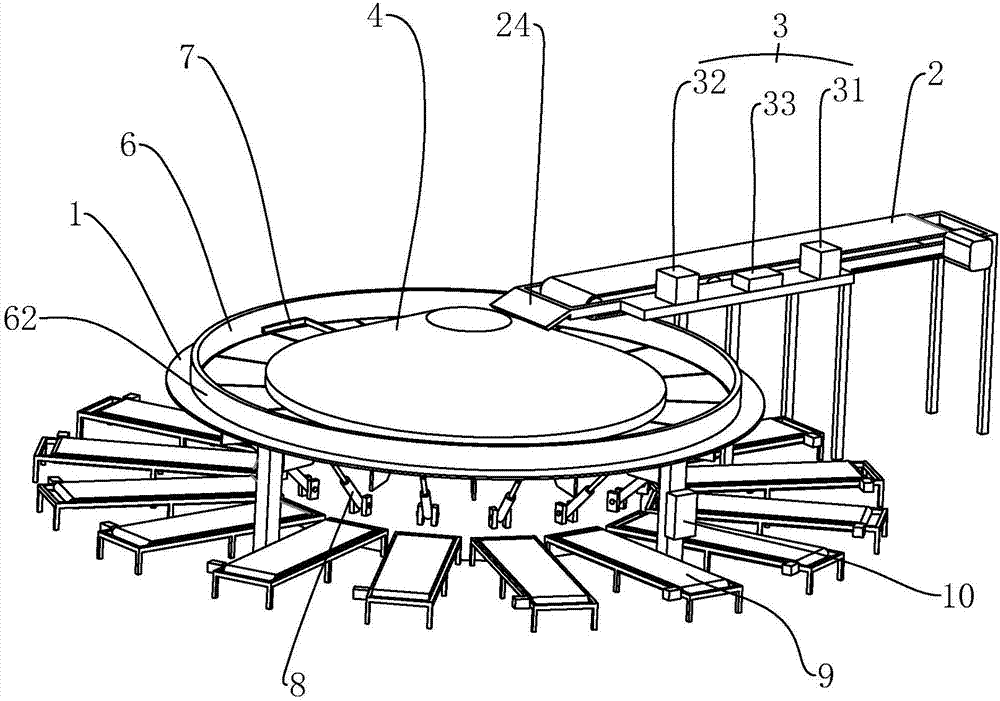

Automatic goods conveying assembly line

ActiveCN107235317AImprove accuracyImproving the function of sorting automation and conveyingControl devices for conveyorsAssembly lineEngineering

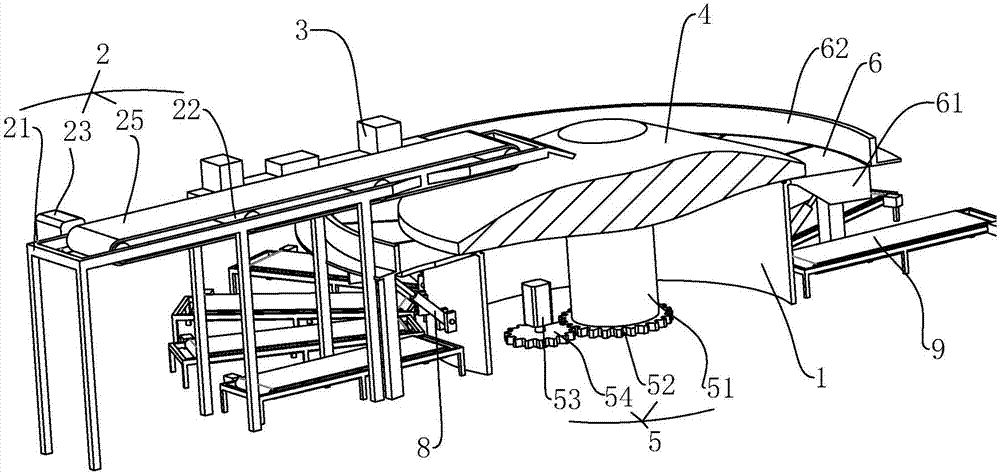

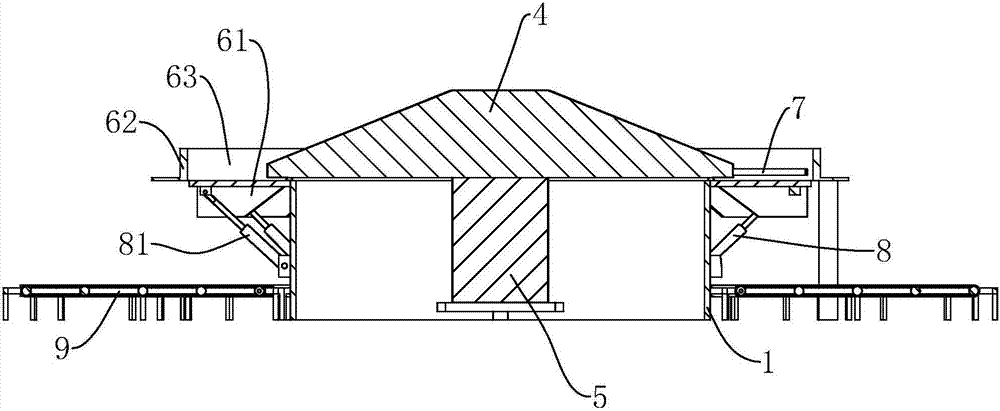

The invention discloses an automatic goods conveying assembly line. The automatic goods conveying assembly line comprises a first conveying device, a scanning device, a rotary table, a drive device, trays, a stirring plate, unloading devices and second conveying devices. The first conveying device and the scanning device are arranged on the rack. The rotary table is arranged on the first conveying device. The drive device is arranged on the rack and used for driving the rotary table to rotate on the rack. The trays are arranged at the lower end of the rotary table and used for bearing goods, and one ends of the trays are rotationally connected with the rack. The stirring plate is fixedly arranged on the circumference face of the rotary table and used for stirring goods to slide on the trays. The unloading devices are arranged on the rotary table and used for driving the trays to rotate on the rack. The second conveying devices are correspondingly arranged under the trays in a one-to-one manner and used for conveying the goods. The multiple trays are circumferentially arranged, and a center processing unit used for controlling the unloading devices to drive the single trays to rotate on the rotary table is in signal connection between the scanning device and the unloading device. The automatic goods conveying assembly line has a goods sorting and automatic conveying function, the sorting accuracy is improved, the sorting time is shortened, and meanwhile the function of reducing of the sorting field area is achieved.

Owner:杭州利邮通信器材有限公司

Efficient sorting method and efficient sorting system

The invention relates to an efficient sorting method which comprises the following steps: displaying pre-sorted cargo information comprising pre-delivery warehouse information; if the received current sorted cargo information is matched with the pre-sorted cargo information, driving indicating equipment of a warehouse position corresponding to the pre-delivery warehouse information to work to indicate the warehouse position of the current sorted cargo according to the pre-delivery warehouse information in the pre-sorted cargo information. The problems that the existing sorting process is complicated and has a long period are solved. In the cargo sorting process, a specific indication can be given to an operator, so that the sorting error is prevented and the sorting efficiency is improved. The sorted commodities are photoelectrically indicated, so that the stacking and arrangement process of cargo is shortened. Therefore, the sorting time is shortened, the manual taking step is simplified, the possibility of deterioration of fresh commodities, especially for products of which the quality is greatly influenced by temperature, is reduced, and the timely sorting of cargo is ensured, and thus the logistics period and the transaction validity are improved.

Owner:北京任我在线电子商务有限公司

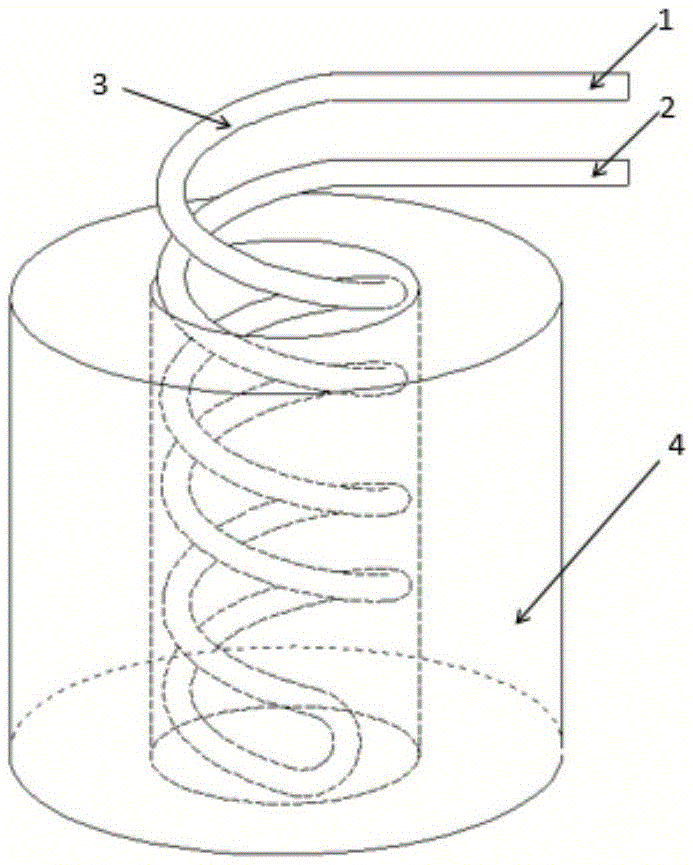

Spiral-capillary-based magnetic cell sorting apparatus and method

InactiveCN105624035ARealize continuous sortingTake advantage ofBioreactor/fermenter combinationsBiological substance pretreatmentsHigh magnetic field strengthMagnetic bead

The invention discloses a spiral-capillary-based magnetic cell sorting apparatus and method, comprising four steps: S1, feeding a sample; S2, separating in a stationary manner; S3, washing at low flow speed; S4, collecting at high flow speed. A spiral capillary placed in the center of a circular magnet is used such that all cell and magnetic bead turbid liquids are near a tube wall of the circular magnet. As the tube wall of the circular magnet has highest magnetic field strength, it is possible to make full use of a magnetic field, improve sorting efficiency and reduce sorting time by using the apparatus. After step S4 is over, the spiral capillary is fully filled with a buffer solution, it is possible to continuously carry out the step S1 of sample feeding and start a next sorting procedure such that cells are continuously sorted; the invention is applicable to sorting of a large quantity of cells.

Owner:ARTHRO ANDA TIANJIN BIOLOGIC TECH +1

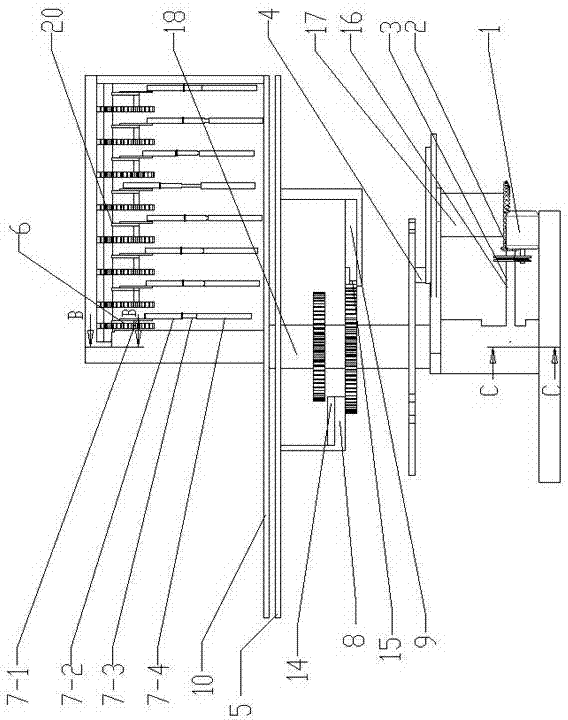

Disc type maize breeding slicer

InactiveCN103240765ARealize automatic sortingImprove cutting efficiencyMetal working apparatusCircular discGear wheel

A disc type maize breeding slicer comprises a working disc, a drive mechanism, a cutting mechanism and a sheave mechanism. The drive mechanism is a horizontally arranged motor, and the motor is connected with a horizontal transmission shaft through belt transmission; the horizontal transmission shaft is connected with the working disc through a bevel gear transmission and the sheave mechanism and connected with a feed tray through a gear-rack transmission; the lower end of a vertical transmission shaft is connected with the horizontal transmission shaft through the bevel gear transmission, and the upper end of the vertical transmission shaft is connected with the cutting mechanism through the bevel gear transmission and a straight toothed spur gear; and the working disc is connected with the feed tray through a hose passage. According to the disc type maize breeding slicer, the multi-kernel simultaneous operation is used, eight maize kernels can be operated simultaneously each time, and compared with the manual operation, the cutting efficiency can be improved by eight times; maize seeds and endosperm are small, manual one-to-one corresponding sorting is time-consuming, and the seeds and the endosperm are sorted automatically by means of the slicer, so that the sorting time can be saved. Accordingly, the labor productivity is improved apparently, and the manual labor is reduced greatly.

Owner:HENAN AGRICULTURAL UNIVERSITY

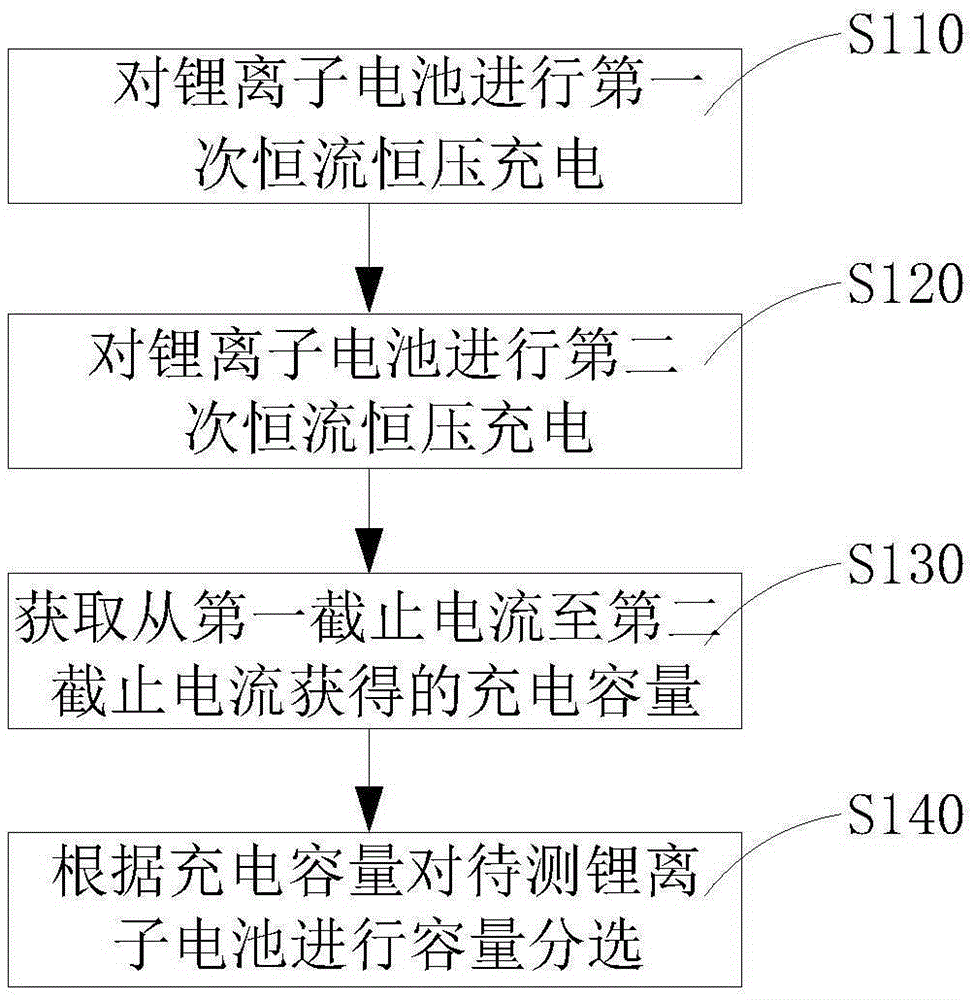

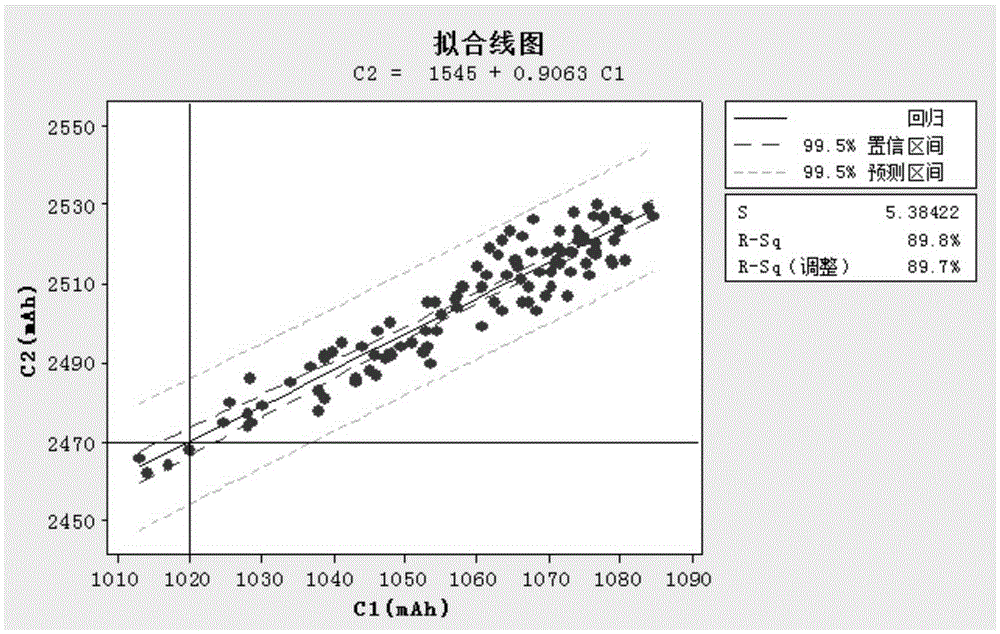

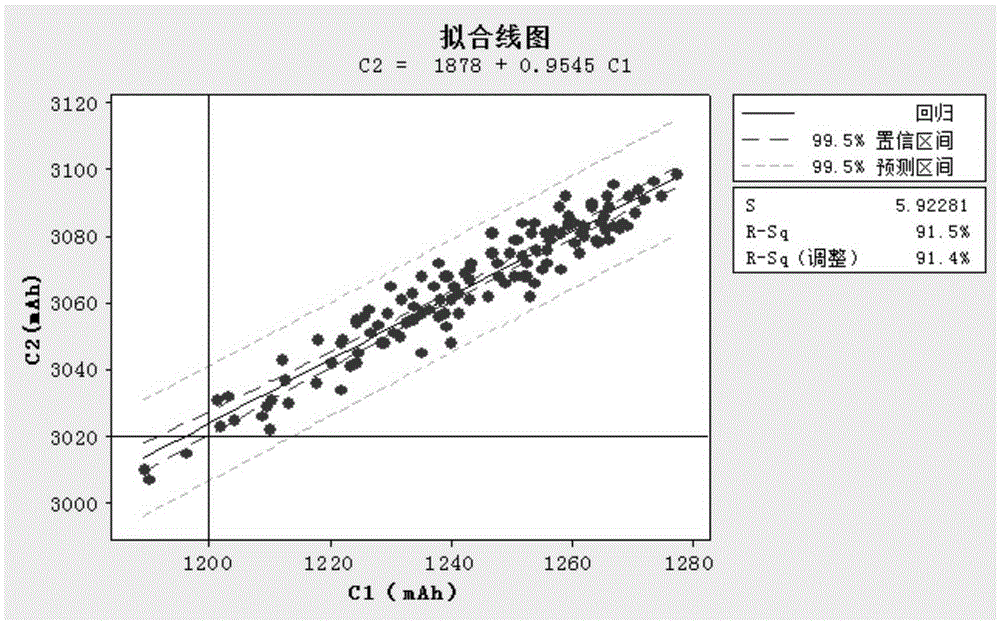

A lithium ion battery capacity sorting method

ActiveCN106654420AReduce sorting timeIncrease productivitySecondary cells charging/dischargingCharge currentPower flow

The invention relates to a lithium ion battery capacity sorting method. The method includes subjecting a lithium ion battery to a first time of constant-current constant-voltage charging until reaching a first voltage and a first cutoff current; subjecting the lithium ion battery to a second time of constant-current constant-voltage charging until reaching a second voltage and a second cutoff current, with the second voltage being greater than the first voltage and being less than or equal to the charging final voltage of the lithium ion battery; acquiring the charging capacity obtained from a charging process in which the charging current of the lithium ion battery turns from the first cutoff current to the second cutoff current; and subjecting the lithium ion battery to capacity sorting according to the charging capacity. The method can perform battery capacity sorting on the lithium ion battery only by charging the lithium ion battery. Compared with traditional capacity sorting methods, the method avoids steps of discharging and a plurality of times charging and discharging, thus reducing the capacity sorting time and increasing the production efficiency.

Owner:ZHENGZHOU BAK BATTERY CO LTD +1

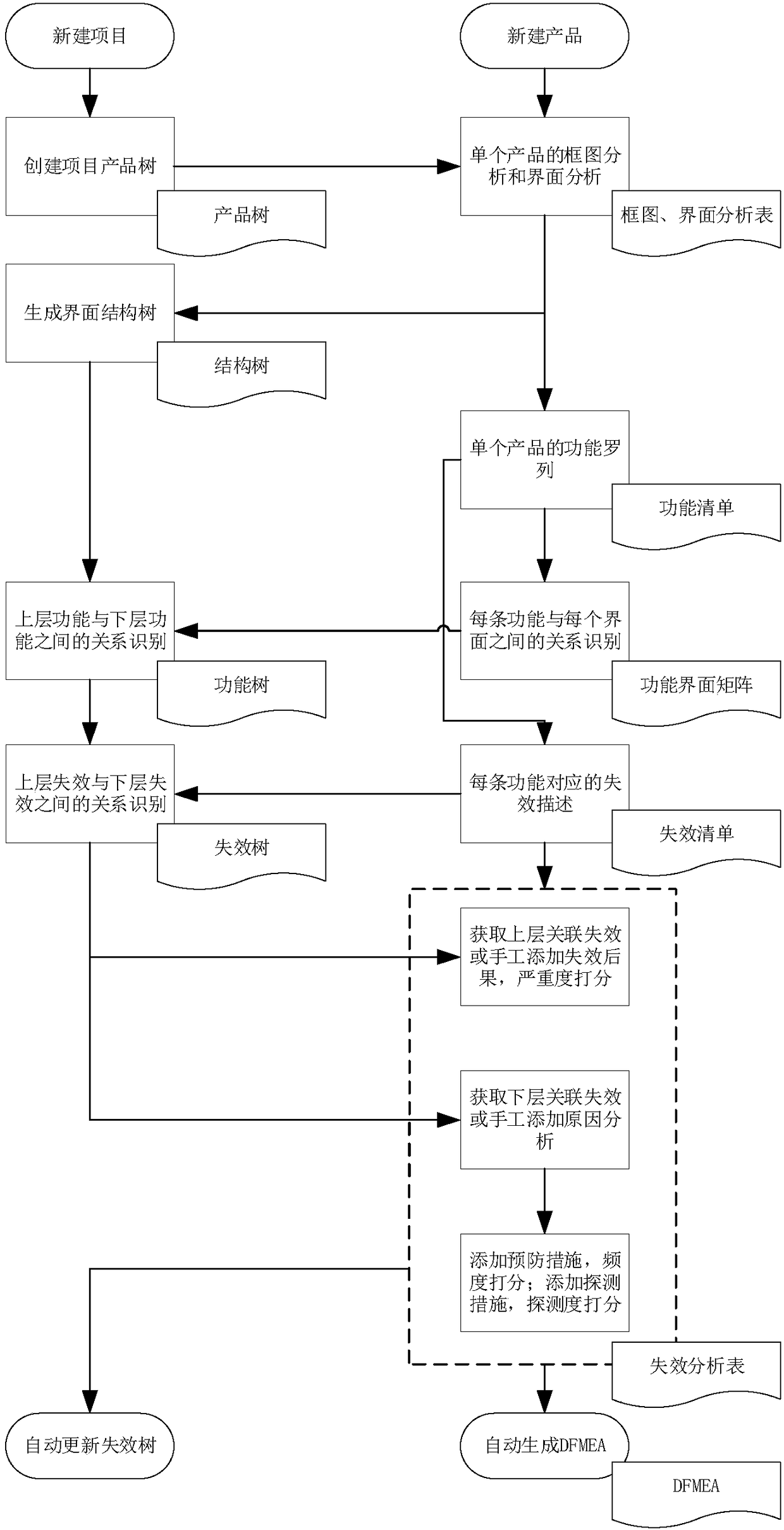

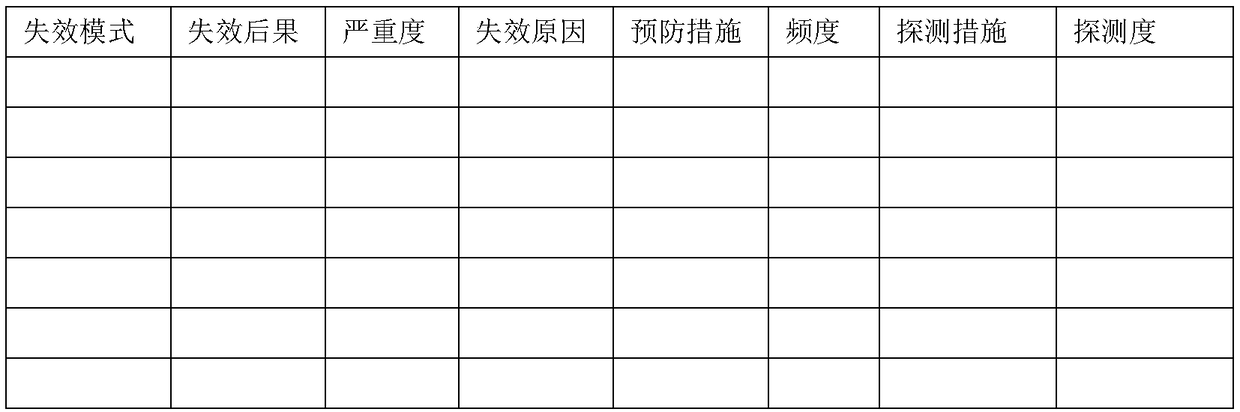

Structured DFMEA analysis method

PendingCN108197349AQuality improvementShorten the timeSpecial data processing applicationsStructured analysisWorkload

The invention relates to the technical field of failure analysis and provides a structured DFMEA analysis method. The method comprises the steps of creating a project; displaying all levels of productstructures contained in the project in a tree form manner to form a product tree; performing interface analysis on a single product by adopting a block diagram and an interface analysis table; and determining an internal interface and an external interface of the product. A structured analysis thought is creatively adopted; functional requirements and failure modes of an upper product and a lowerproduct are effectively sorted and combined skillfully, and finally a high-quality DFMEA report is automatically formed; and the manual filling and sorting time of working staffs is greatly shortened, and the workload is reduced.

Owner:聪脉(上海)信息技术有限公司

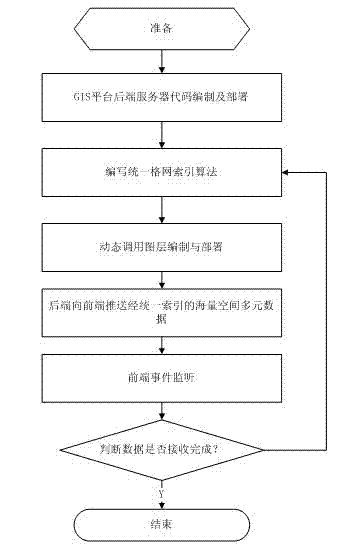

GIS (Geographic Information System) platform based spatial massive multivariate data unified index method

ActiveCN104268201AEfficient queryEfficient retrievalGeographical information databasesSpecial data processing applicationsPower gridResource management

The invention belongs to the technical field of GIS (Geographic Information System) engineering and intelligent decision making and particularly relates to a GIS platform based spatial massive multivariate data unified index method. The GIS platform based spatial massive multivariate data unified index method comprises the following steps of compiling and deploying codes of a back-end server of a GIS platform; compiling a grid spatial index method according to received geographical coordinate information of associated equipment sources; calling layer data according to the received massive multivariate data; performing dynamic calling on layer compiling and deployment and dynamically calling on the layer data according to logical processing of the received massive multivariate data; monitoring GIS platform events; display data at the front end of an GIS platform. The GIS platform based spatial massive multivariate data unified index method can greatly quicken the data searching degree, obviously reducing inquire grouping and the sorting time and effectively improve the GIS platform analysis display efficiency and provides a brand new solution scheme for power grid equipment resource management and GIS platform analysis.

Owner:SHANDONG LUNENG SOFTWARE TECH

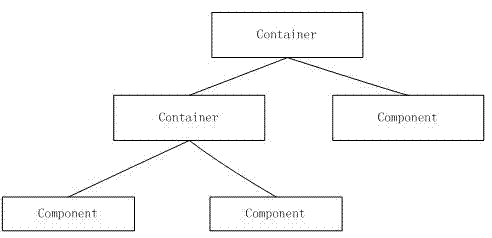

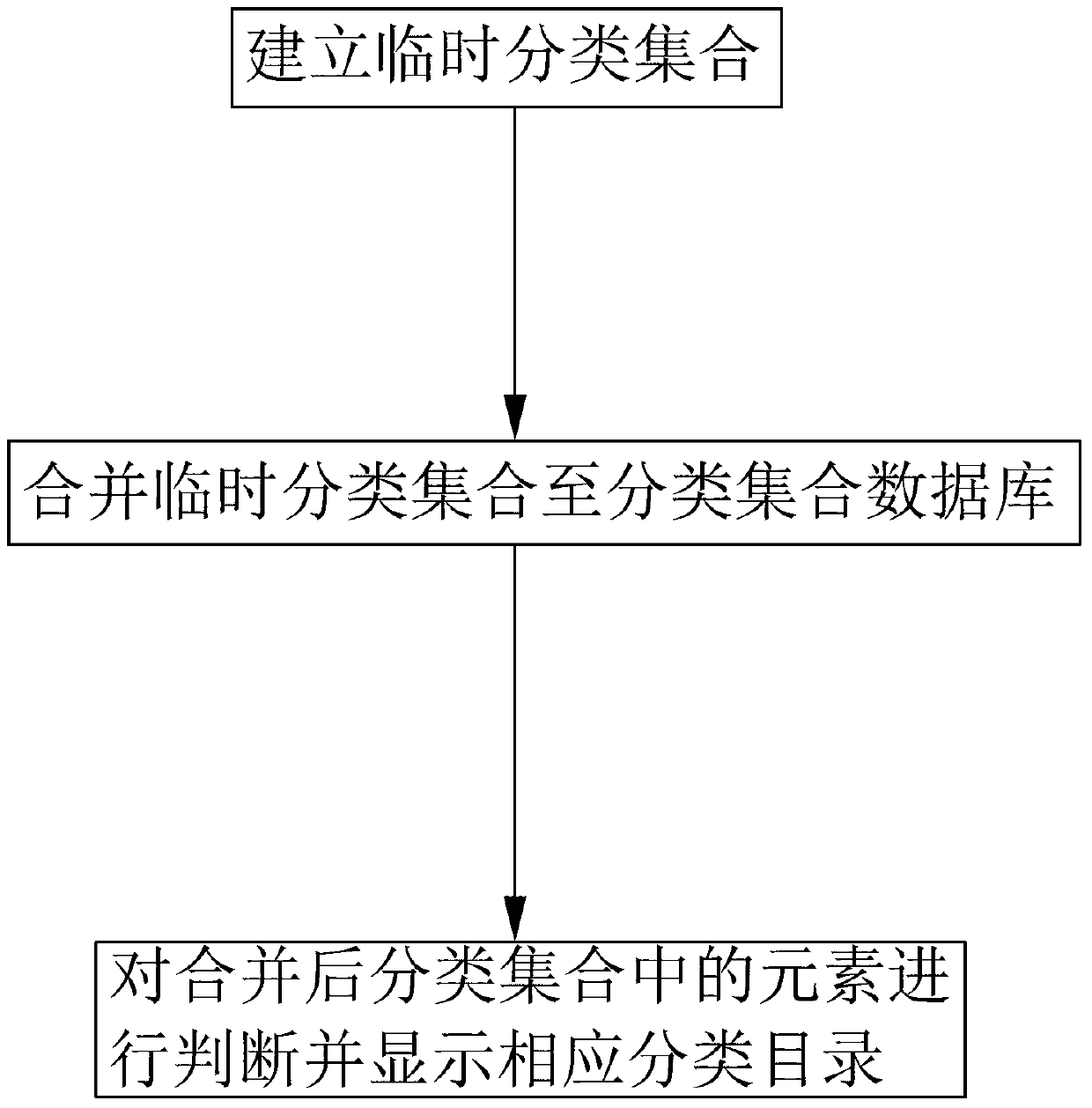

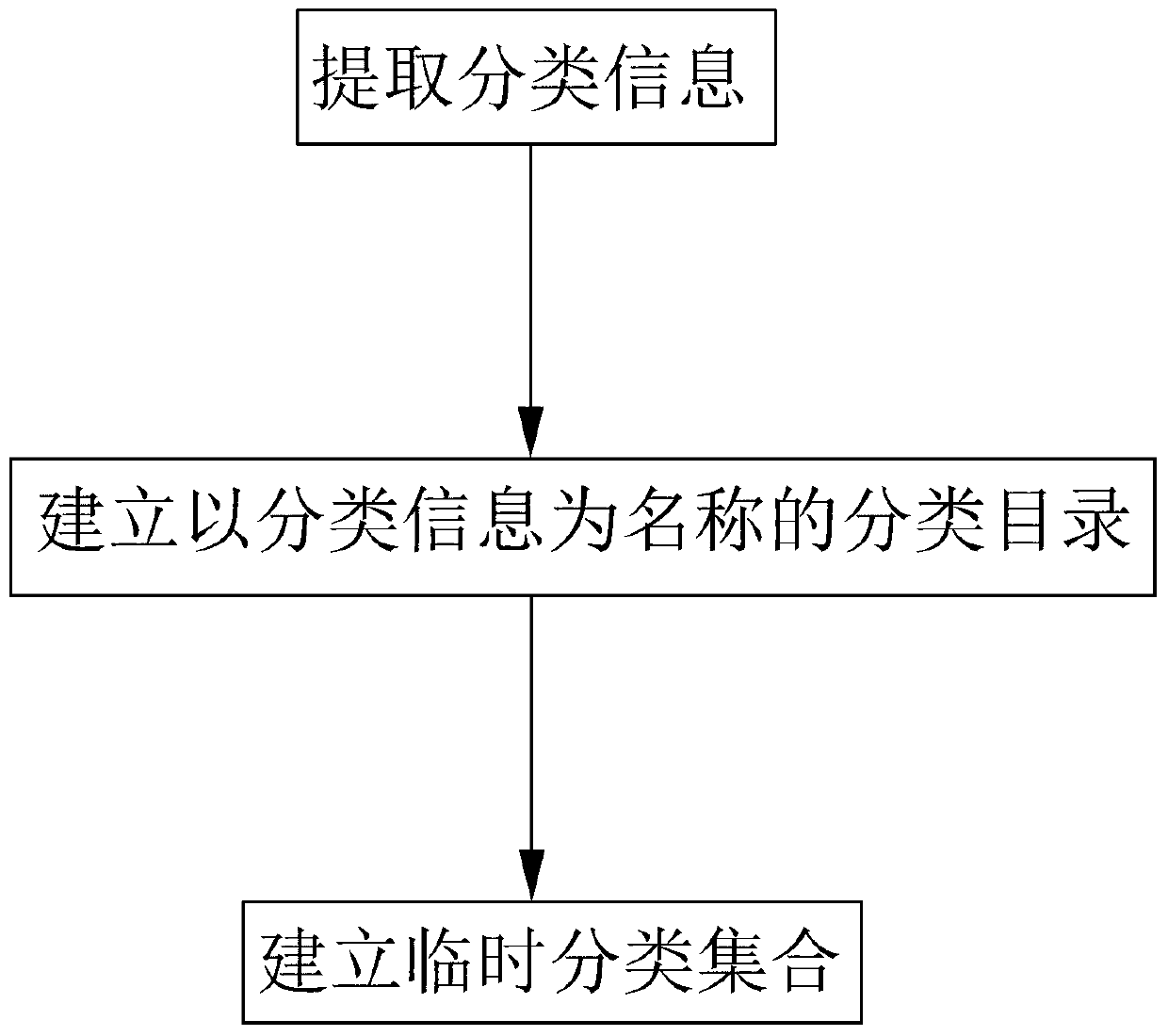

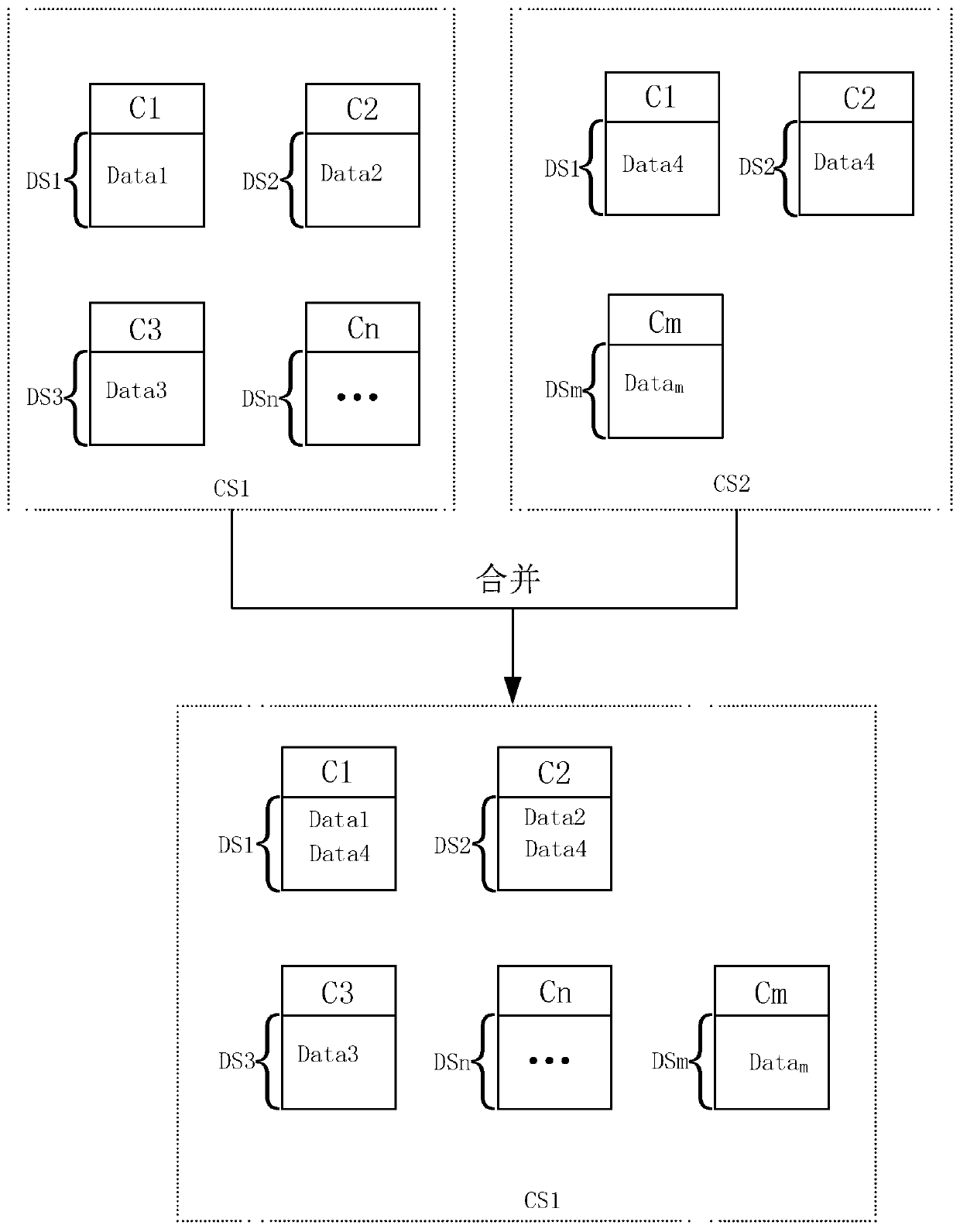

Method, system and device automatically conducting sort operation based on data types

ActiveCN103279497AReduce sorting timeImprove operating experienceSpecial data processing applicationsAs elementSorting time

The invention discloses a method, system and device automatically conducting sorting operation based on data types. The method comprises the steps of extracting sorting information from received file data or existing file data, establishing a sorting catalogue with the sorting information as the name, classifying corresponding file data into the corresponding sorting catalogue, forming a temporary sorting set with the sorting catalogue and the corresponding file data as elements, and merging the temporary sorting set to a set sorting data base. If the number of the file data contained in the sorting catalogue of the elements in the merged set is larger than or equal to a set parameter, displaying the sorting catalogue. The sorting method involves no manual operation, collating sorting time is saved, during later use, a user only needs to search information in a corresponding catalogue and can find out the information quickly and conveniently, and searching time is further saved.

Owner:ZHUHAI KINGSOFT OFFICE SOFTWARE +1

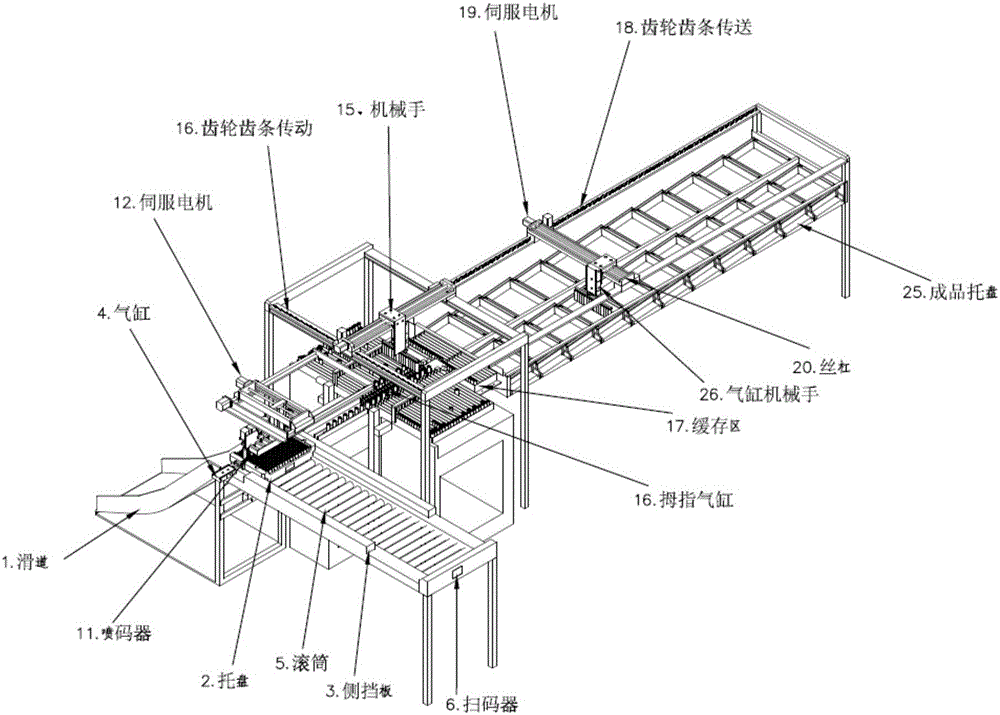

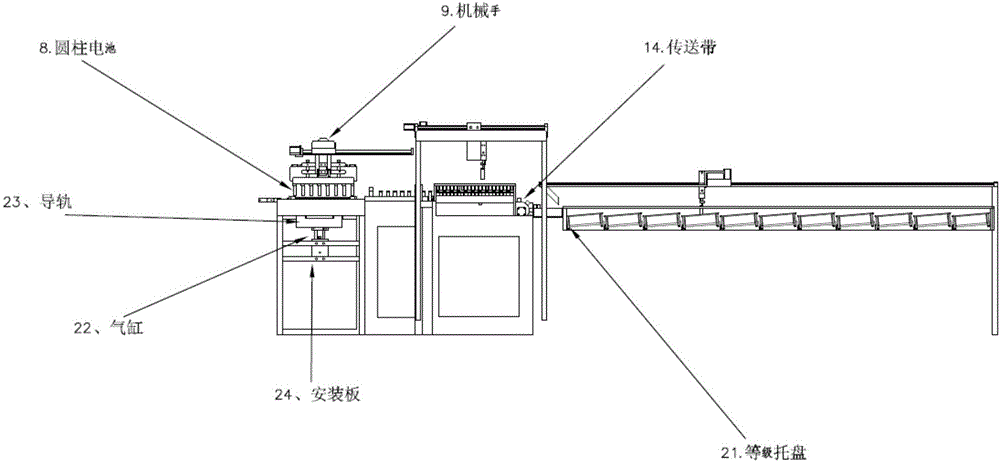

Automated sorting device for cylindrical lithium-ion batteries

InactiveCN105742716AIncrease labor intensityLow costFinal product manufactureElectrolyte accumulators manufactureAssembly lineEngineering

The invention provides an automated sorting device for cylindrical lithium-ion batteries. The automated sorting device integrates code scanning, code spraying and grouping functions for the lithium-ion batteries. A form of an assembly line is adopted; the procedures of loading, absorbing, code scanning, transferring, grading and the like for the batteries are reasonably and skillfully arranged; and the action time of each procedure is reasonably controlled, so that the sorting time of the batteries is effectively shortened; the problems of high labor intensity of a worker and high production cost are greatly solved; and the automated sorting device can be widely applied to producing and manufacturing of 18650 cylindrical lithium-ion batteries and the like.

Owner:江苏拓新天机器人科技有限公司

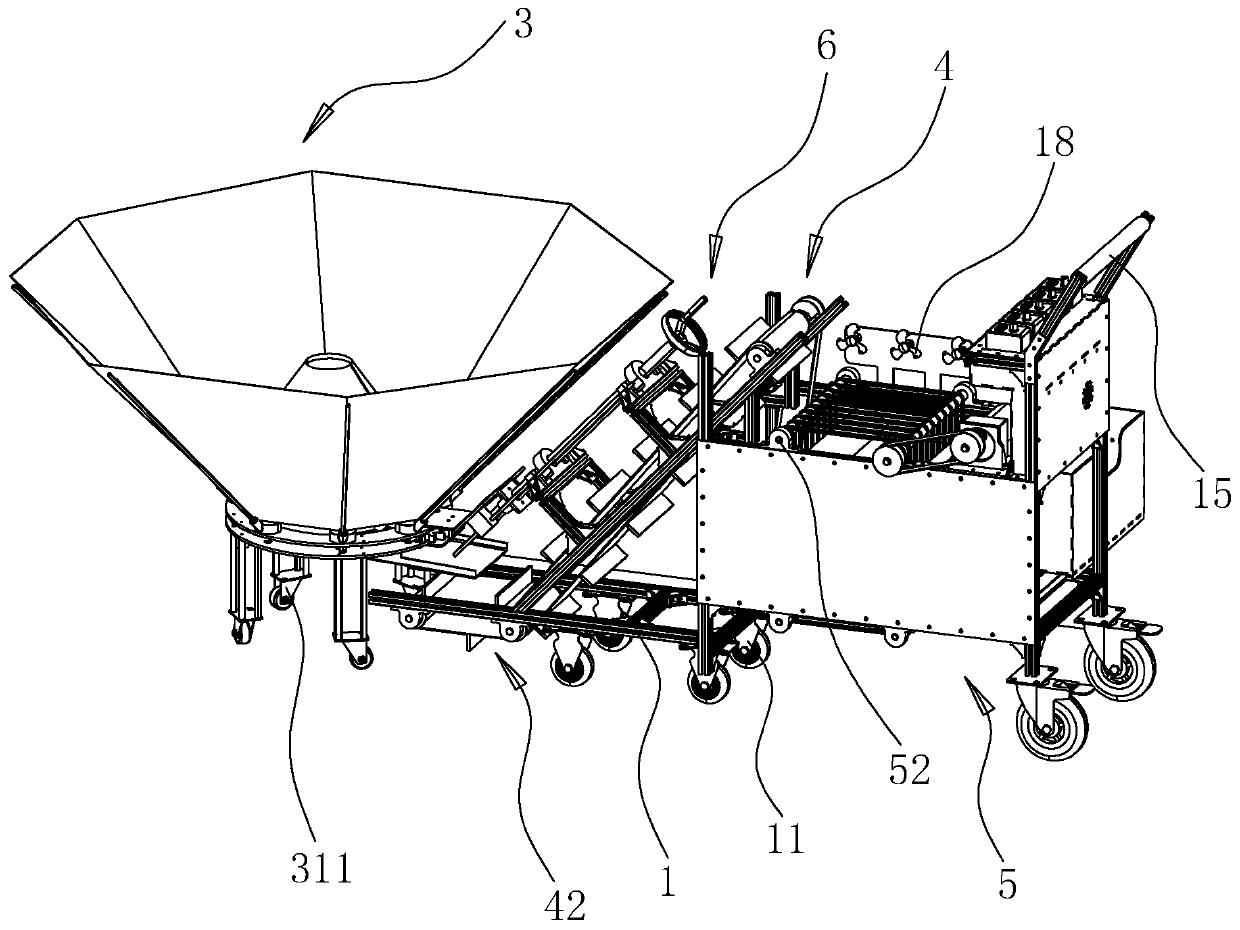

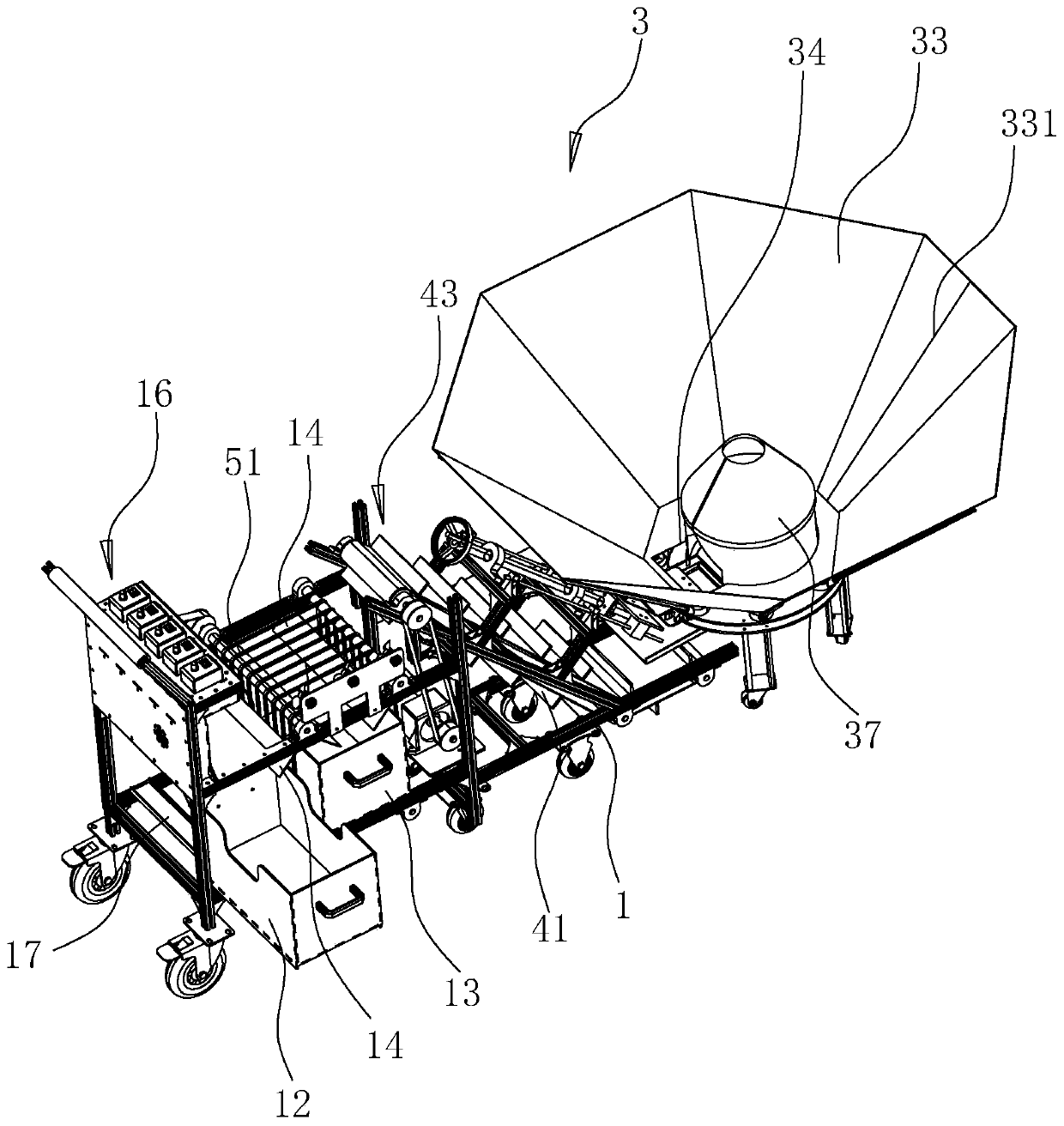

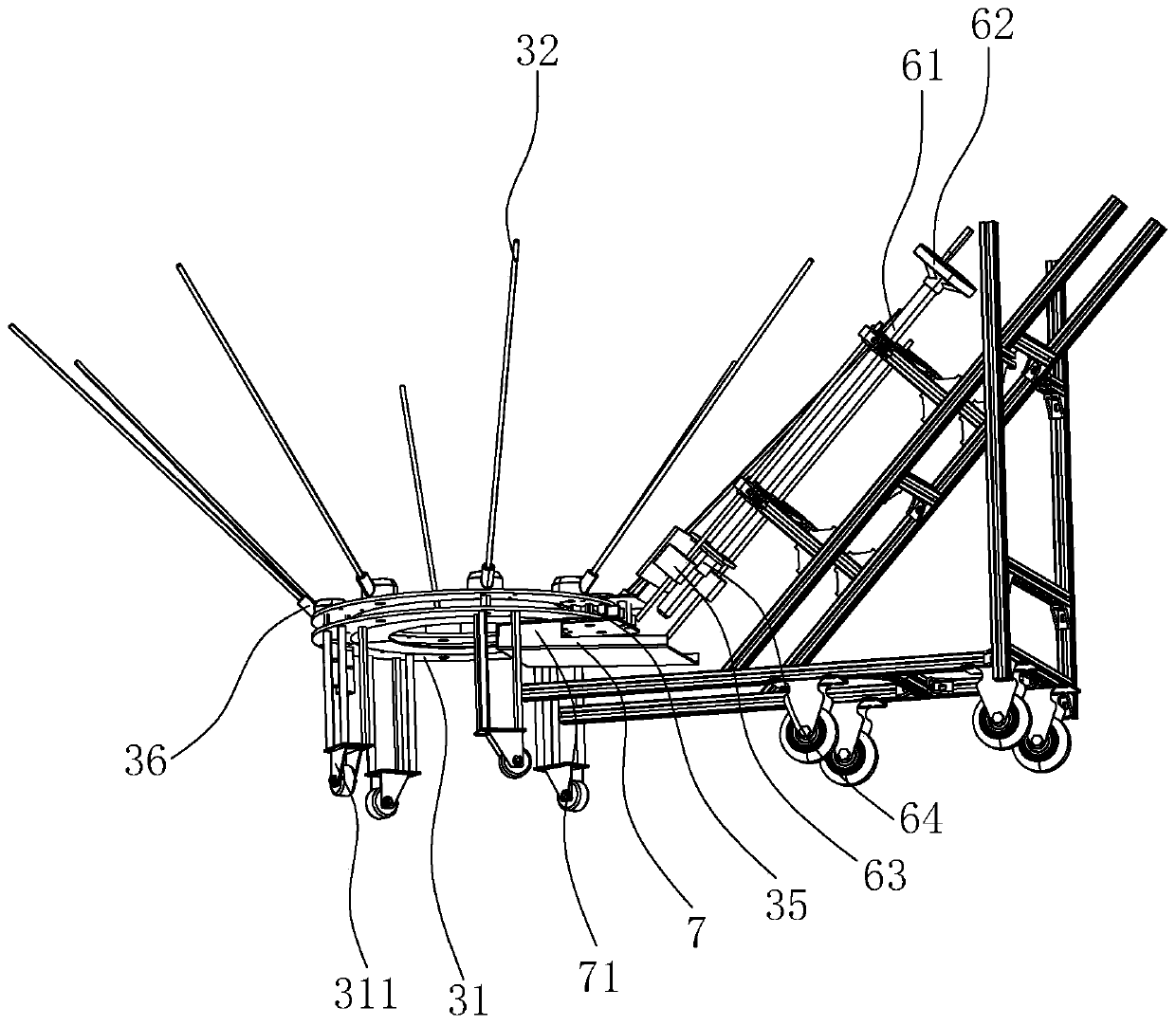

Integrated cherry picking and sorting machine

PendingCN109964647AShorter picking timeReduce sorting timeGas current separationFood treatmentConveyor beltSorting time

The invention provides an integrated cherry picking and sorting machine, and belongs to the field of fruit and vegetable picking and sorting equipment. For the problem that the picking and sorting time is longer due to the fact that picking and sorting of cherries cannot be completed by same equipment in the prior art, the following technical scheme is proposed that the integrated cherry picking and sorting machine comprises a bracket and a vibration holder, wherein the bracket is provided with a collector, a conveyor belt and a sorting system; the vibration holder makes the trunk shake to shake off the cherries; the collector is used for receiving the falling cherries, and comprises two semicircular fan-shaped trays, multiple supporting rods and collection cloth, and a conveying port is formed in the bottom of the collection cloth, so that the cherries fall onto the conveyor belt; the sorting system comprises rolling shafts and sorting belts, and the cherries conveyed by the conveyorbelt move along with the sorting belts or fall off from gaps between the sorting belts, so that the cherries of different sizes are sorted. The integrated cherry picking and sorting machine has the advantages that the function of picking and sorting the cherries is integrated, the time for picking sorting the cherries is shortened, and the human cost is reduced.

Owner:浙江机电职业技术学院

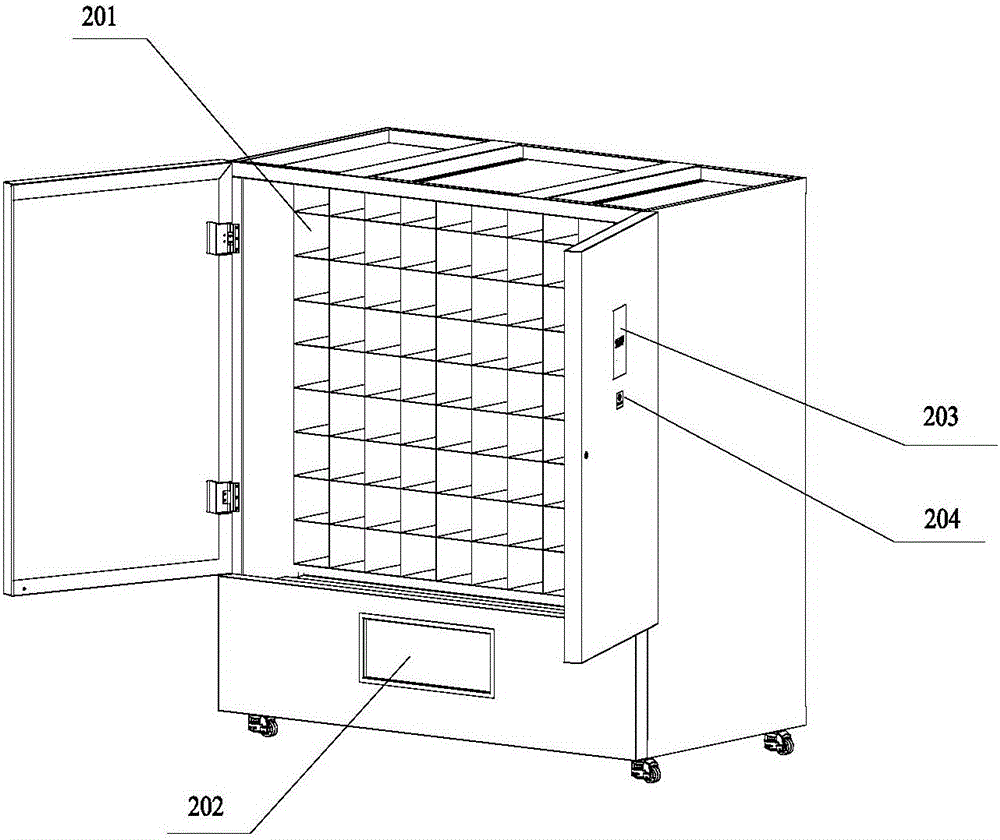

Goods distribution cabinet

ActiveCN106297056AImprove distribution efficiencyEject smoothlyApparatus for meter-controlled dispensingSorting timeMechanical engineering

The invention provides a goods distribution cabinet. The goods distribution cabinet comprises a cabinet body, a controller and at least one pushing mechanism, wherein the inside of the cabinet body is partitioned into a goods pickup region and at least one storage region; the goods pickup region is used for receiving fallen goods to be picked up; the pushing mechanism is arranged in each storage region; each pushing mechanism comprises a push plate, an elastic element, a fixed plate and an electrically-controlled locker; the electrically-controlled locker comprises a first part and a second part; one end of the elastic element and the first part are fixedly arranged on the push plate; the other end of the elastic element and the second part are fixedly arranged on the fixed plate; the fixed plate is fixedly arranged on the peripheral side walls of the storage region; the first part is locked on the second part; after the first part or the second part receives a control instruction sent by the controller, the first part and the second part are unlocked, and the push plate pushes the goods to be picked up outwards under the action of the elastic element. The goods distribution cabinet is not limited by the sizes of goods; by adopting the goods distribution cabinet, the goods sorting time can be saved, and the goods distribution efficiency is increased.

Owner:ZHEJIANG RIVAMED SCI & TECH CO LTD

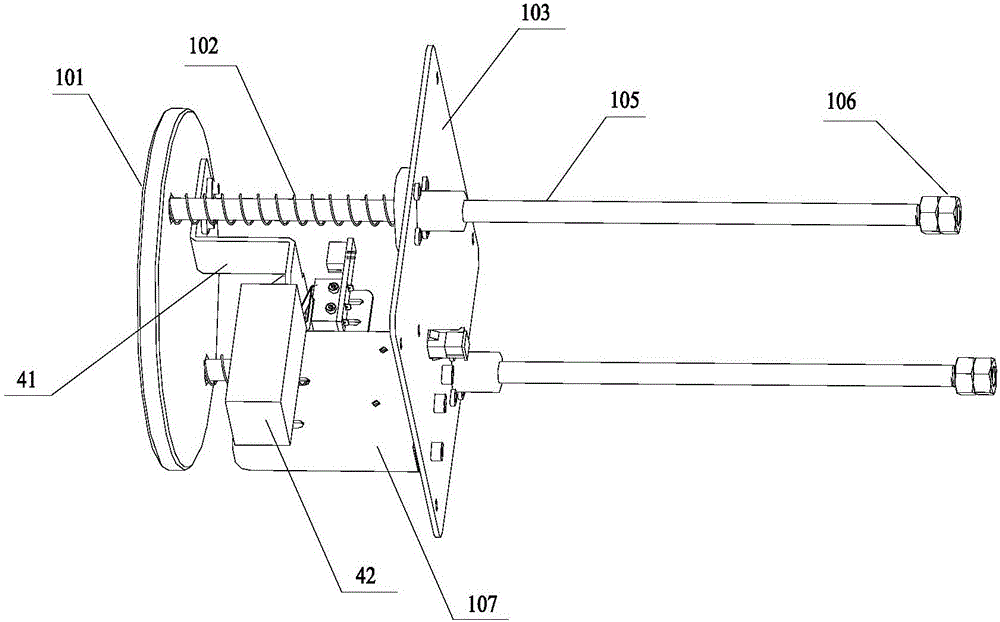

Chip sorting device and chip sorting method

InactiveCN102790001AReduce sorting timeImprove classification accuracySemiconductor/solid-state device manufacturingClassification methodsSemiconductor chip

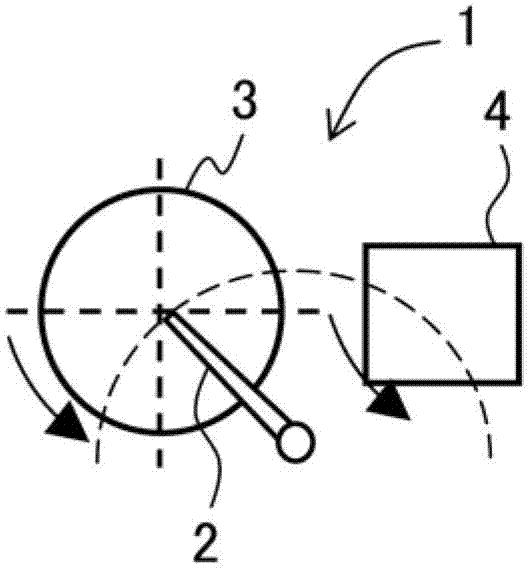

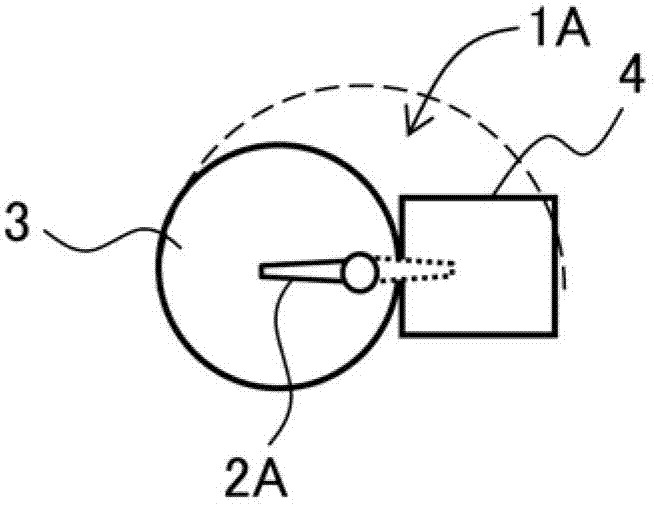

The invention relates to a chip sorting device and a chip sorting method. Chip sorting time can be shortened and chip sorting accuracy can be improved. The chip sorting device (1) moves LED chips to an arranging work bench (4) through a conveying arm (2) from a supply workbench (3) which is carried with a plurality of LED chips being used as semiconductor chips after a wafer is cut. The length of the conveying arm (2) is at least half of the combined length of a radius of the supply workbench (3) and half of the length of a long edge of the arranging work bench (4). The supply workbench (3) moves along X-Y direction and selects a conveyed LED chip and rotates a regulated angle (90DEG), and thereby a selection area of the conveyed LED chip can be set. The supply workbench (3) and the arranging work bench (4) are respectively provided with a rotation mechanism.

Owner:SHARP KK

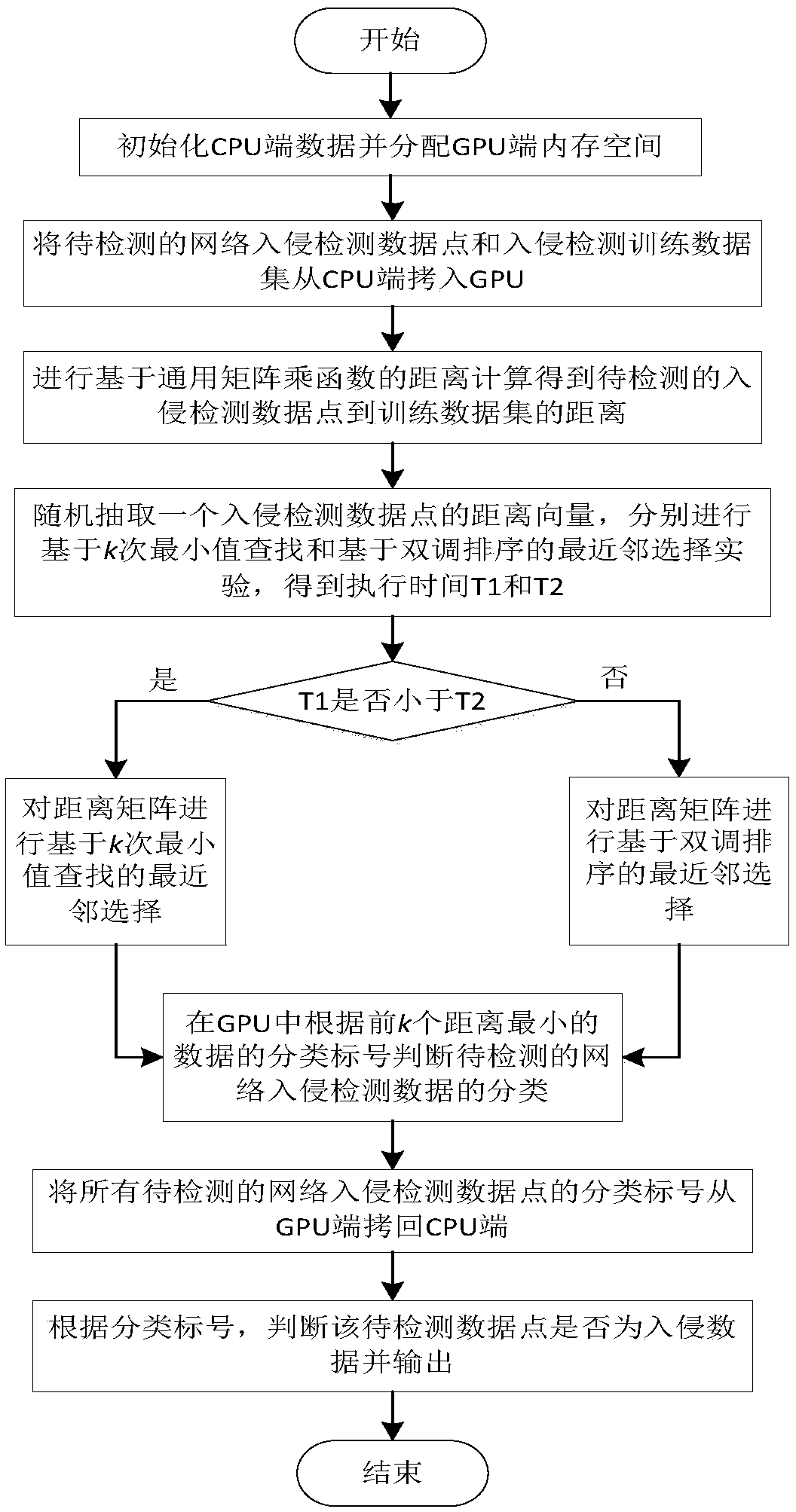

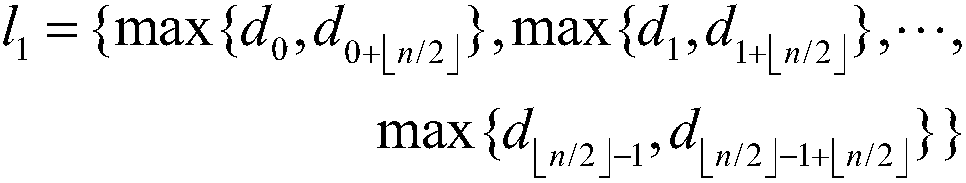

Parallel acceleration method for KNN algorithm-based network intrusion detection

ActiveCN108600246ADistance calculation implementationFast operationCharacter and pattern recognitionTransmissionData setComputational model

The invention provides a parallel acceleration method for KNN algorithm-based network intrusion detection. A CUDA parallel computing model is adopted in the method. The method comprises the steps thatfirstly, parallel analysis is conducted on KNN algorithm-based network intrusion detection, and when the distances between network intrusion detection data points and a training data set are computed, a general matrix multiplication function provided by the CUDA is adopted for acceleration, so that the computing speed is increased; secondly, in the distance sorting stage, a selection mechanism for two parallel sorting strategies is provided, the sorting algorithm needing the shorter sorting time can be flexibly selected for distance sorting according to the sorting result of a few data; and finally, in the classification stage of the intrusion detection data points, counting is conducted by adopting a CUDA-based atom addition operation. The experiment result shows that the acceleration method is valid, and the parallel acceleration performance of network intrusion detection is effectively improved on the condition that the detection rate is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

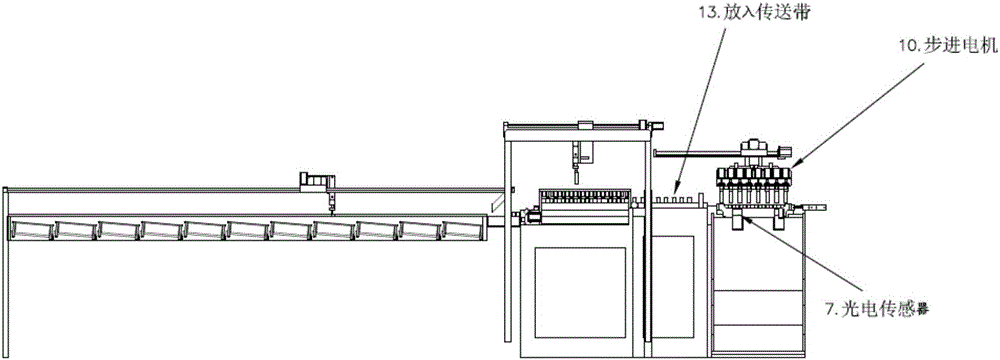

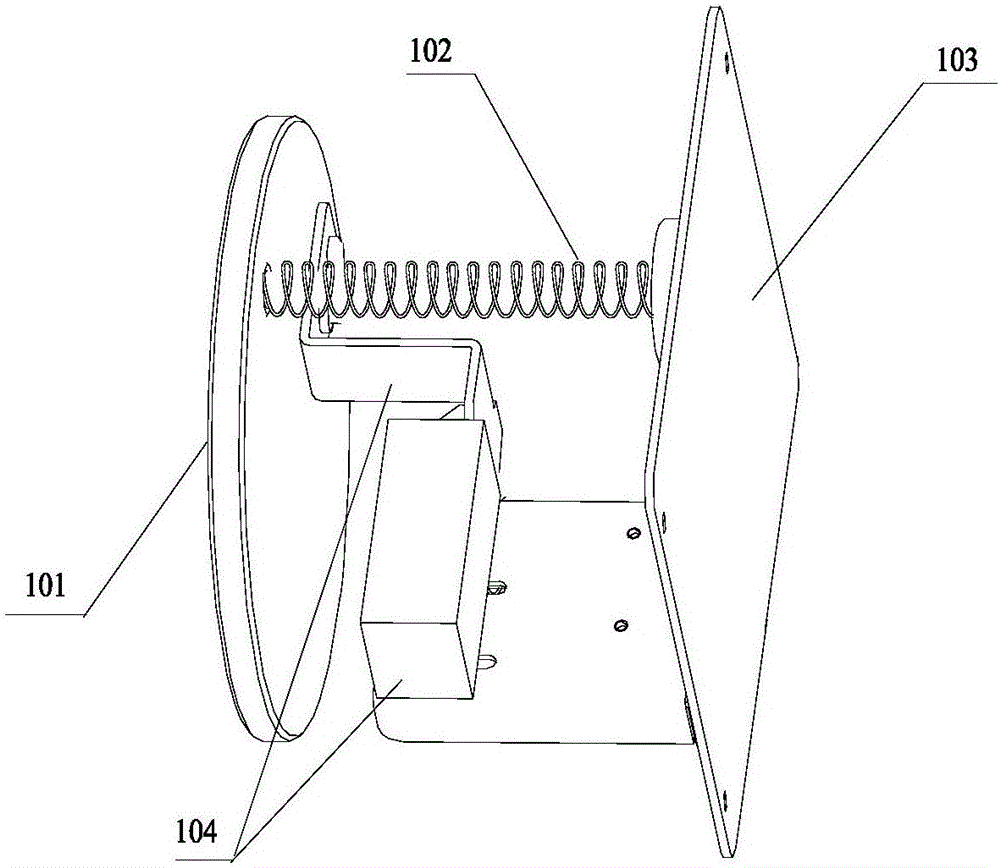

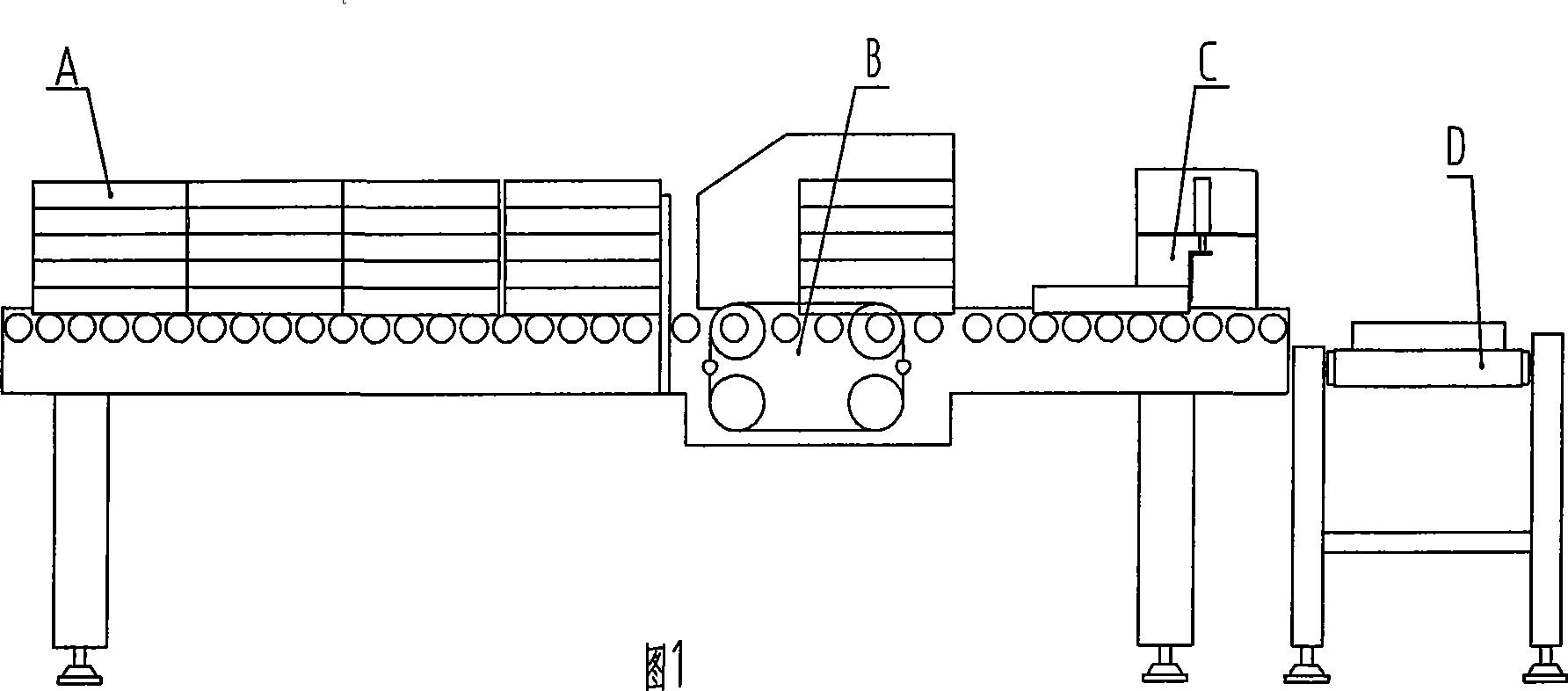

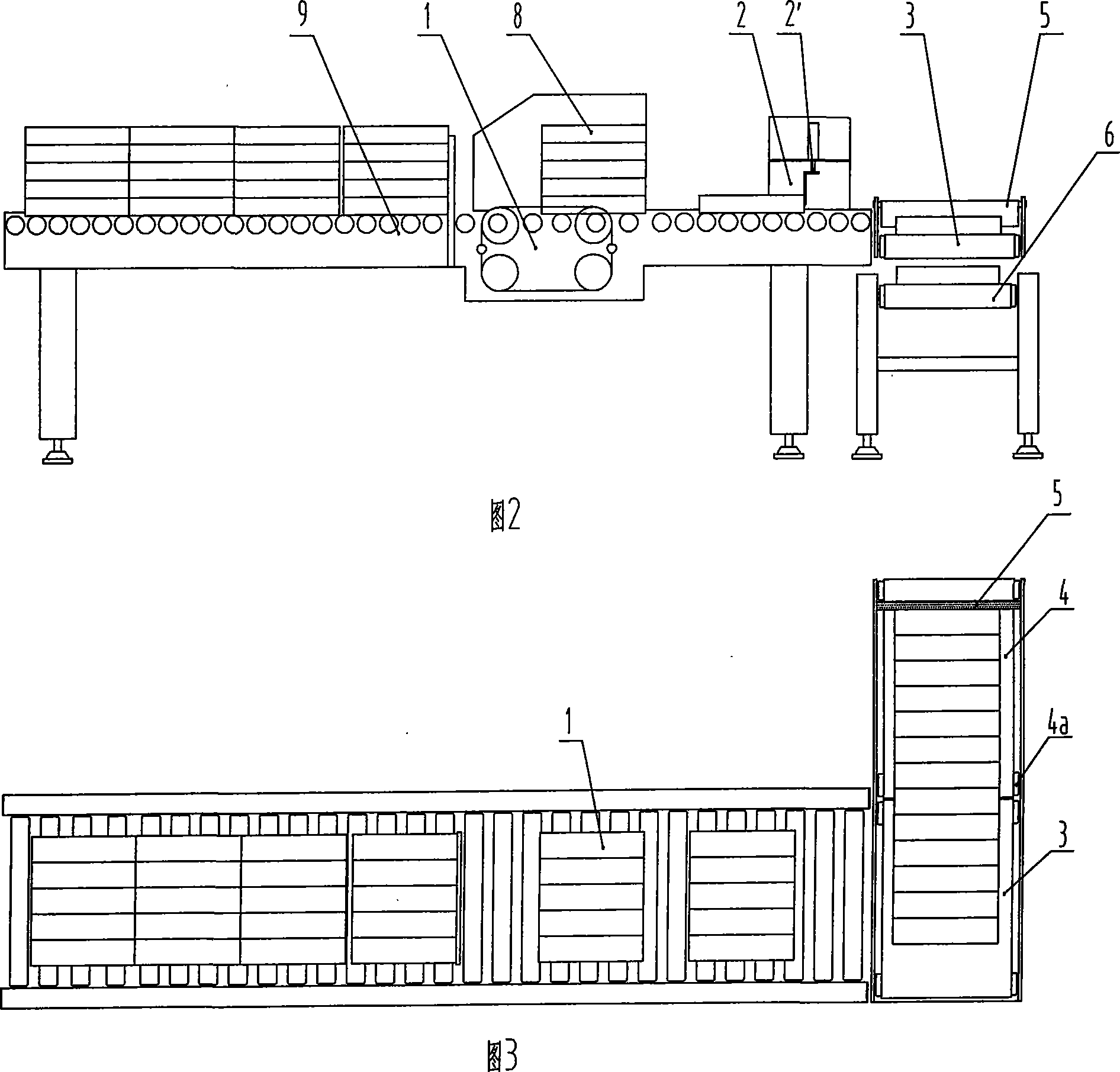

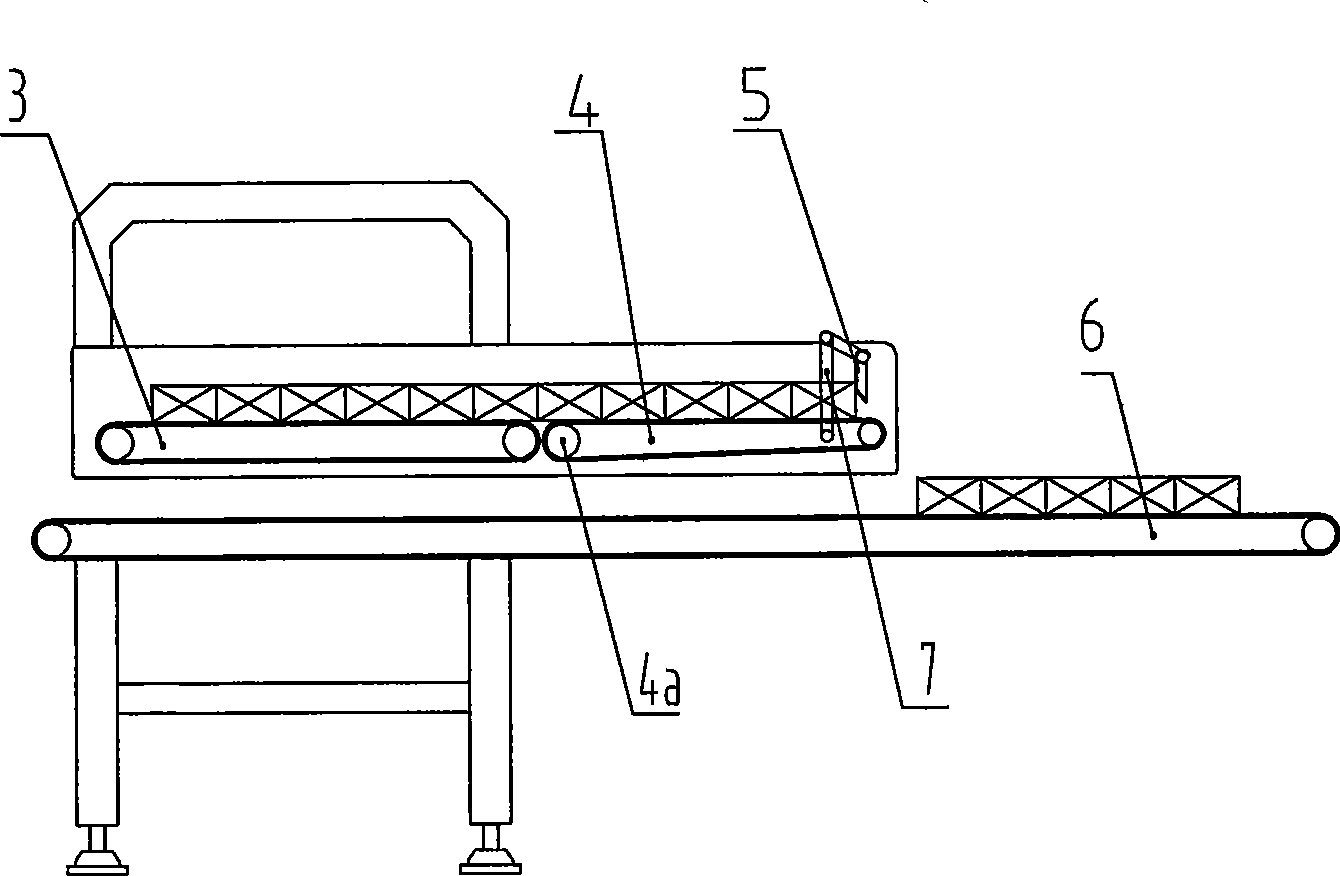

Tobacco carton distributing apparatus capable of pre-sorting

ActiveCN101397088AShorten order lengthReduce sorting timeDe-stacking articlesConveyor partsOrder formCarton

The invention provides a tobacco carton distributing device which can carry out pre-sorting operation. The outlet end of a tobacco carton distributing mechanism (2) is provided with a pre-sorting cache conveying mechanism that comprises a horizontal fixed conveying mechanism (3), and a swing conveying mechanism (4) which is sequentially arranged behind the fixed conveying mechanism and can swing upwards and downwards by taking the inlet end as a pivot (4a); a cache material retaining mechanism (5) is arranged above the outlet end of the swing conveying mechanism (4). The tobacco carton distributing device can effectively shorten the sorting time and improve the sorting efficiency, ensures the pre-sorted tobacco cartons are connected together closely, effectively shortens the order form length of the order from on a central conveying mechanism, and can effectively improve the gestures of the tobacco cartons which are distributed to a subsequent central conveying mechanism.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

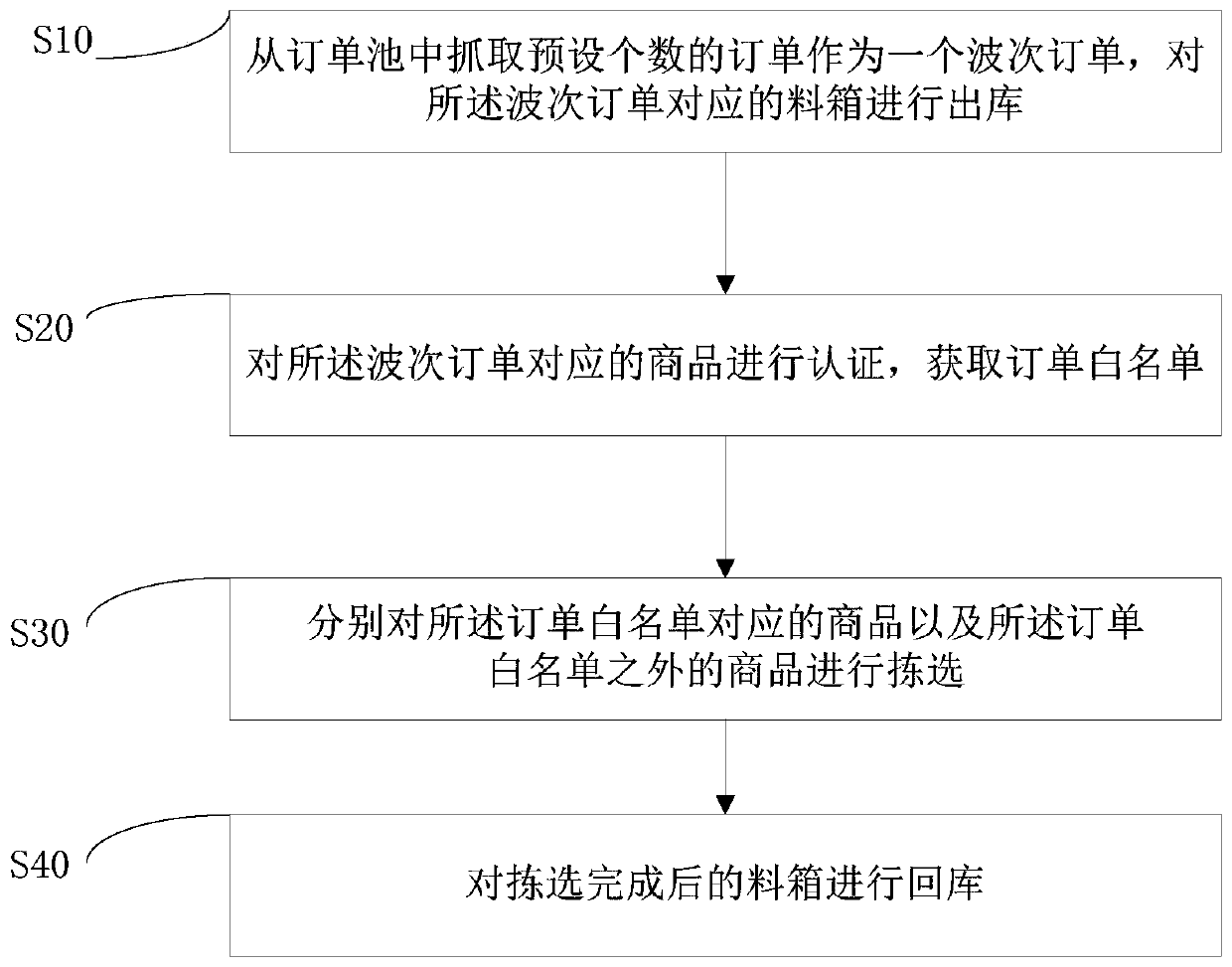

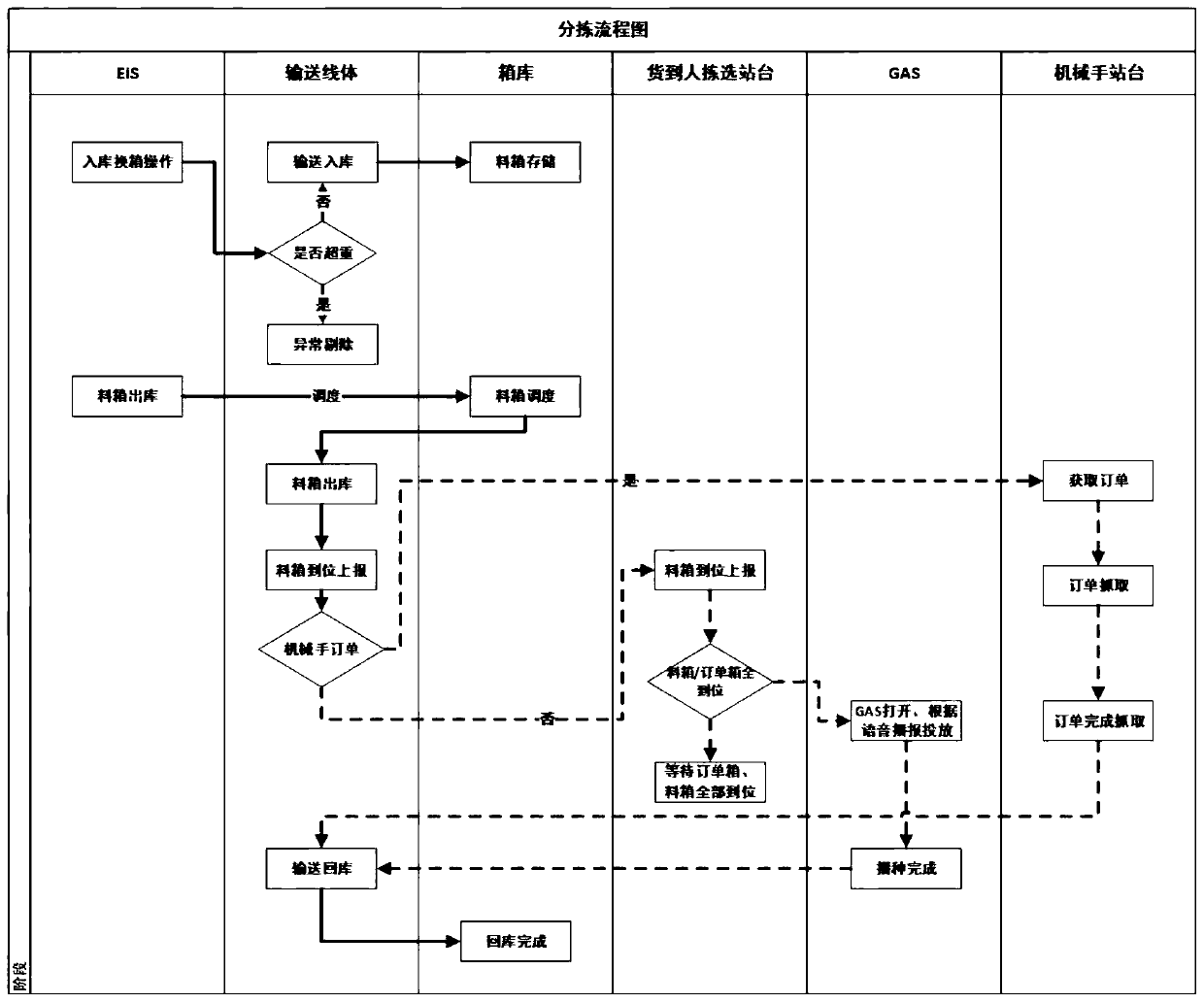

Intelligent sorting method and system

ActiveCN110264323AImprove order picking timeImprove order picking efficiencyBuying/selling/leasing transactionsResourcesSorting timeComputer science

The invention discloses an intelligent sorting method and system, belongs to the field of logistics automation, and the intelligent sorting method and system solve the problems of low sorting time efficiency, low labor efficiency, low efficiency per square meter and high sorting cost in the prior art. The method comprises the steps that orders with the preset number are grabbed from an order pool to serve as a wave picking order, and material boxes corresponding to the wave picking order are delivered out of a warehouse; a commodity corresponding to the wave picking order is authenticated to obtain an order white list; commodities corresponding to the order white list and commodities outside the order white list are picked respectively; and the sorted material boxes are returned to the warehouse. The time efficiency of order picking, the labor efficiency of order picking and the storage efficiency are improved, and meanwhile the picking cost is reduced.

Owner:智芯科技(湖北)有限公司

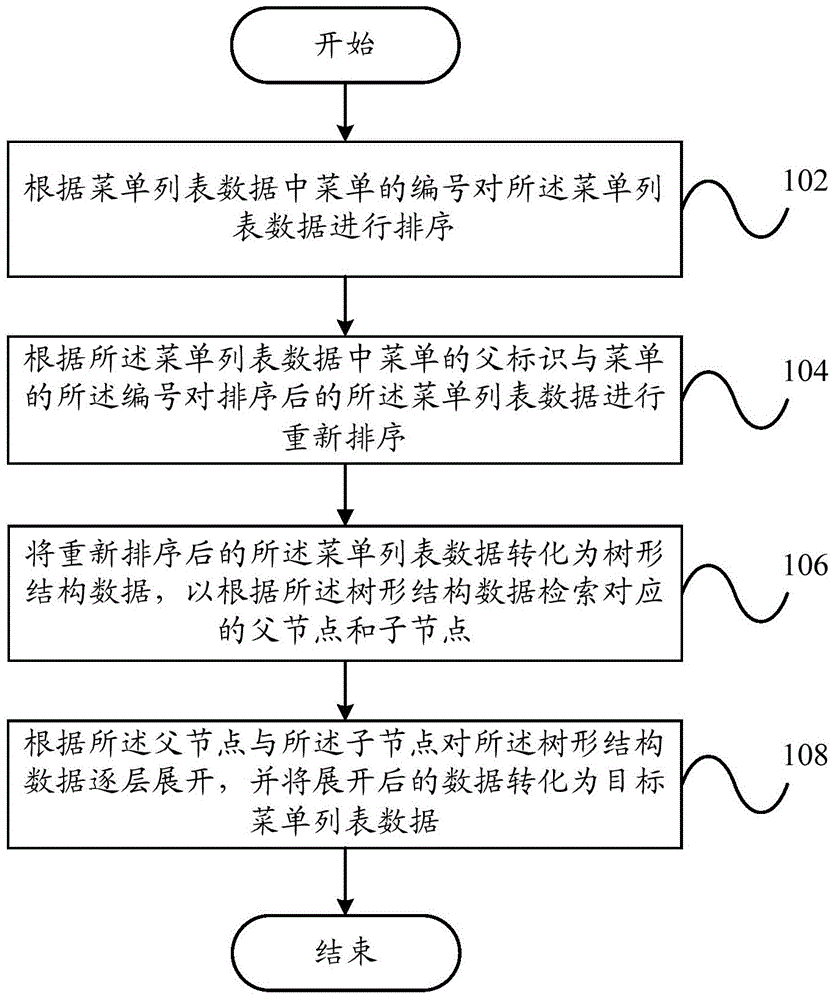

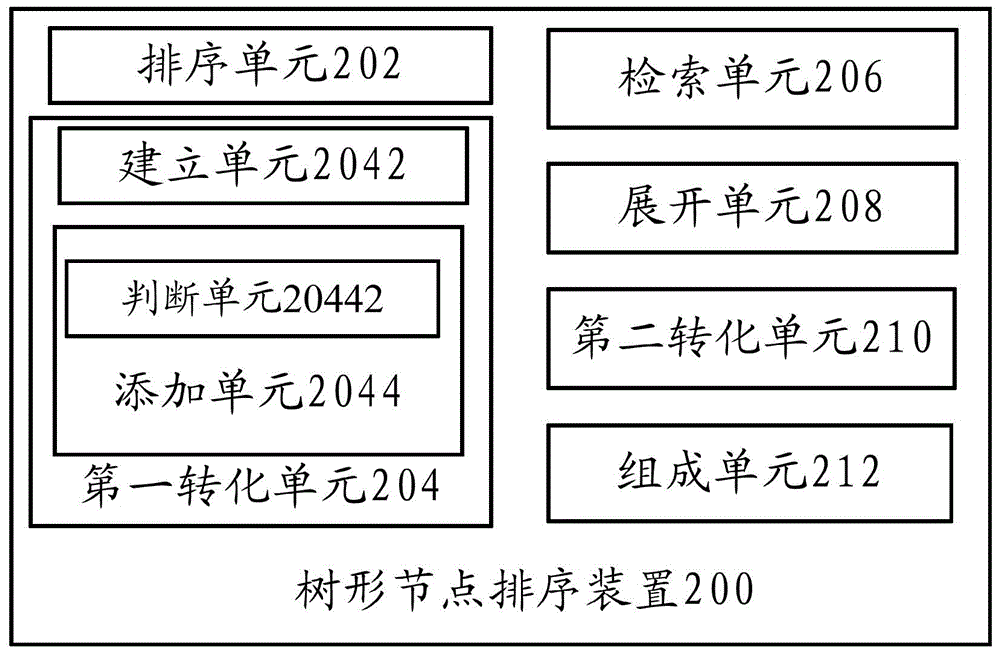

Tree node sorting method and tree node sorting device

ActiveCN104102694ASorting speed is fastImprove sorting experienceSpecial data processing applicationsData retrievalSorting time

The invention provides a tree node sorting method and a tree node sorting device. The tree node sorting method comprises the steps of sorting menu list data according to serial numbers of menus of the menu list data; resorting the sorted menu list data according to parent marks of the menus of the menu list data and the serial numbers of the menus; transforming the resorted menu list data into tree structure data, and retrieving corresponding parent nodes and child nodes according to the tree structure data; expanding the tree structure data layer by layer according to the parent nodes and the child nodes, and transforming the expanded data into target menu list data. By the technical scheme of the invention, sorting time of the tree structure data can be greatly shortened, the application of recursive program is reduced, the sorting speed is greatly increased, and the sorting experience of a user is effectively improved.

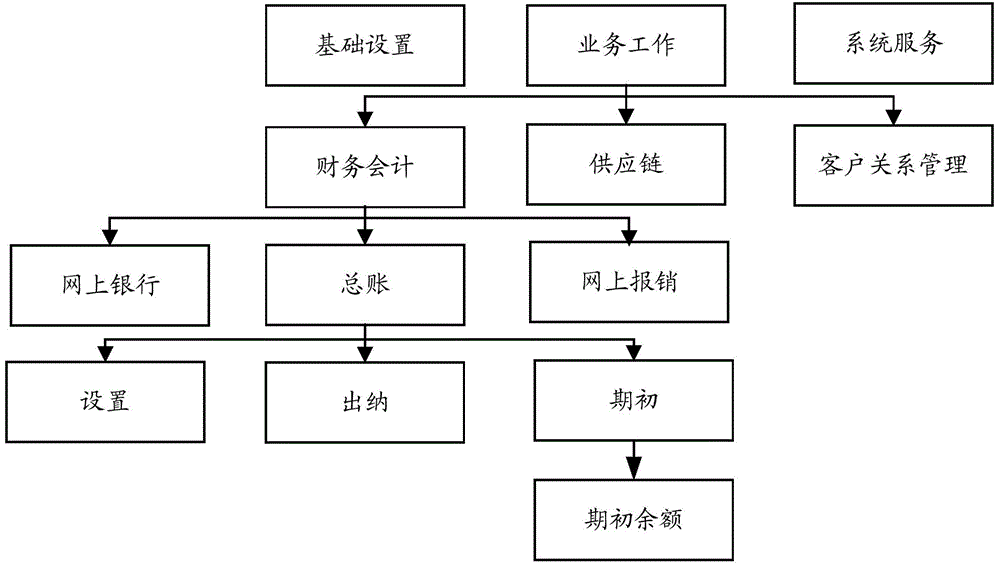

Owner:YONYOU UP INFORMATION TECH

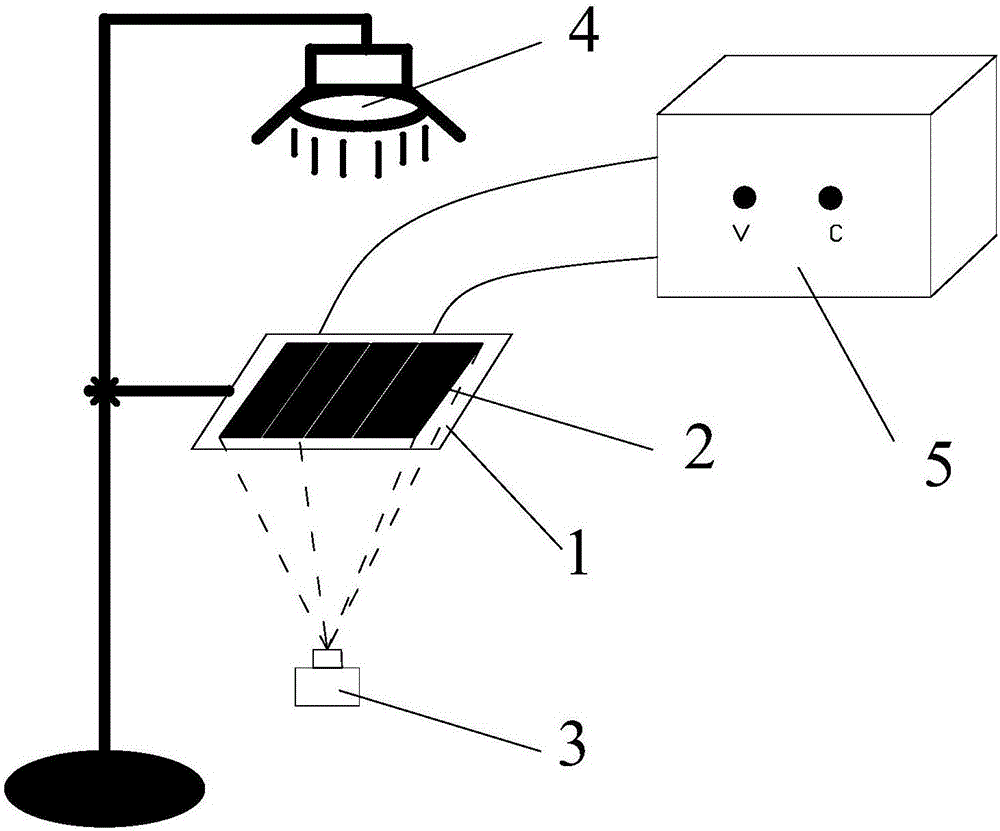

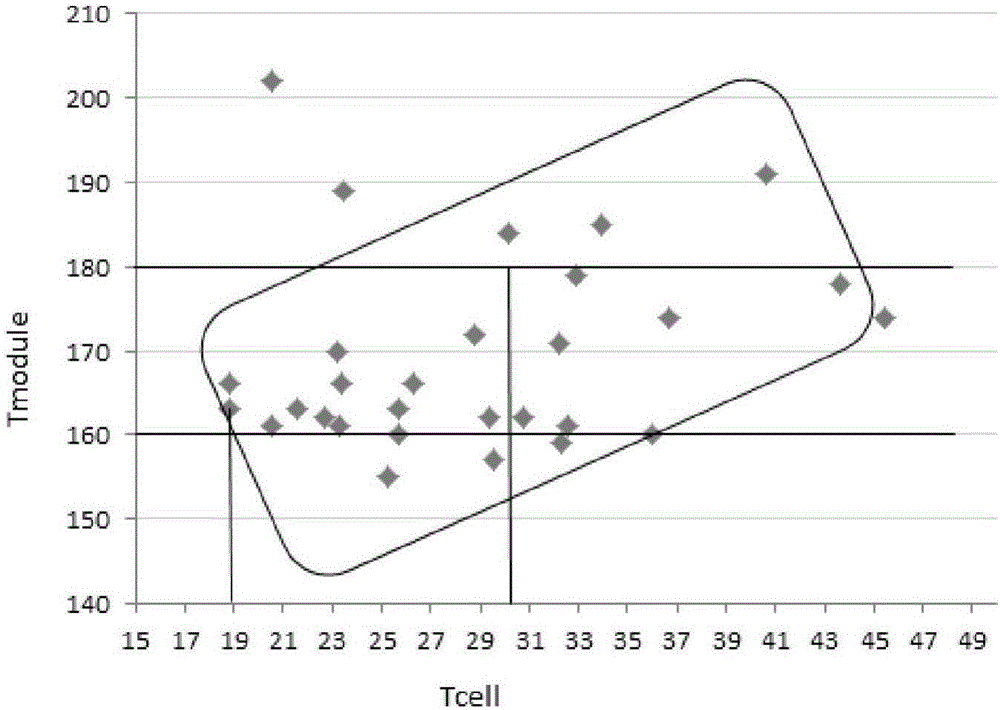

Detection method for solar battery piece with qualified hot spot temperature range

ActiveCN106057702ALow costShort test cycleSemiconductor/solid-state device testing/measurementTest sampleEngineering

The invention relates to a detection method for a solar battery piece with a qualified hot spot temperature range. The method comprises the following steps: (1), building the qualified hot spot temperature range; (2), testing the hot spot temperature T<piece measurement> of the solar battery piece; (3), judging that the hot spot temperature of the solar battery piece is qualified if the hot spot temperature T<piece measurement> is determined to be not greater than T'<piece>, or else, judging that the hot spot temperature of the solar battery piece is not qualified. The method provided by the invention is low in cost, and is short in testing period (the sorting time consumption of a conventional method at a module side is 5h, and the sorting time consumption of an improved method is 0.5h). Meanwhile, the number of test samples is not limited, and the method can achieve the testing of a large number test samples, so as to obtain abundant data. Moreover, the hot spot temperature, measured through the method, of the module is accurate and reliable.

Owner:盐城阿特斯阳光能源科技有限公司

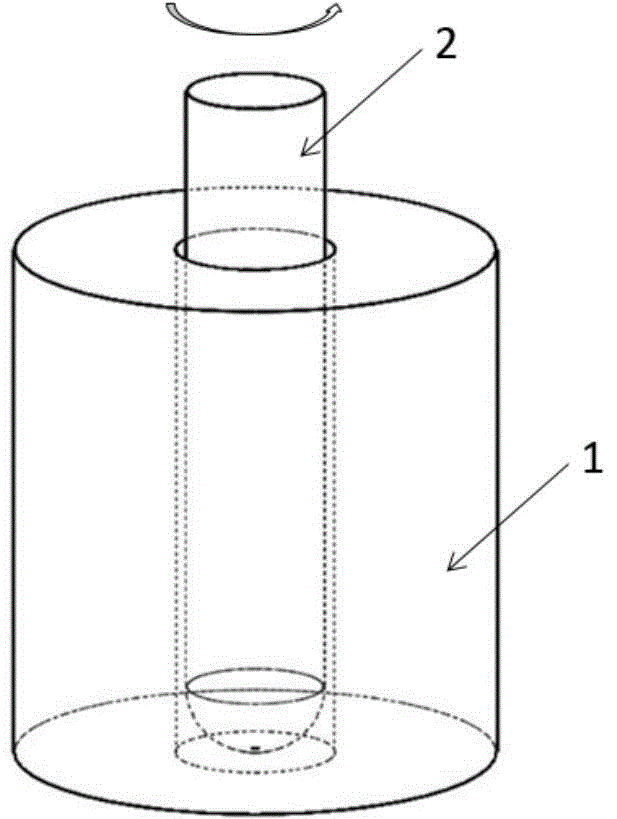

Rotary magnetic cell separation method

InactiveCN104928280AAvoid damageReduce sorting timeTissue cultureElectrical/wave energy microorganism treatmentMagnetic beadEngineering

The invention discloses a rotary magnetic cell separation method. The method includes the four steps of sample placing-in, rotary separation, static separation and cell collection. Magnetic beads are enabled to move in a direction away from axis under action of centrifugal force through a mode of enabling a test tube filled with cells and magnetic bead suspension liquid to rotate in an annular magnet, and distance from the magnetic beads to the annular magnet is shortened. The closer a position is from the annular magnet, the higher the strength of a magnetic field, and the larger the magnetic beads are adsorbed. The magnetic beads are stably adsorbed around the magnet through a stage of static separation. By the above mode, sorting time can be reduced greatly, sorting efficiency can be improved, and damage to the cells can be reduced effectively.

Owner:ARTHRO ANDA TIANJIN BIOLOGIC TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com