Logistics sorting system and method

A sorting system and logistics technology, applied in the field of logistics, can solve the problems of increasing labor intensity and wasting time, and achieve the effects of improving work efficiency, realizing automation, and reducing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

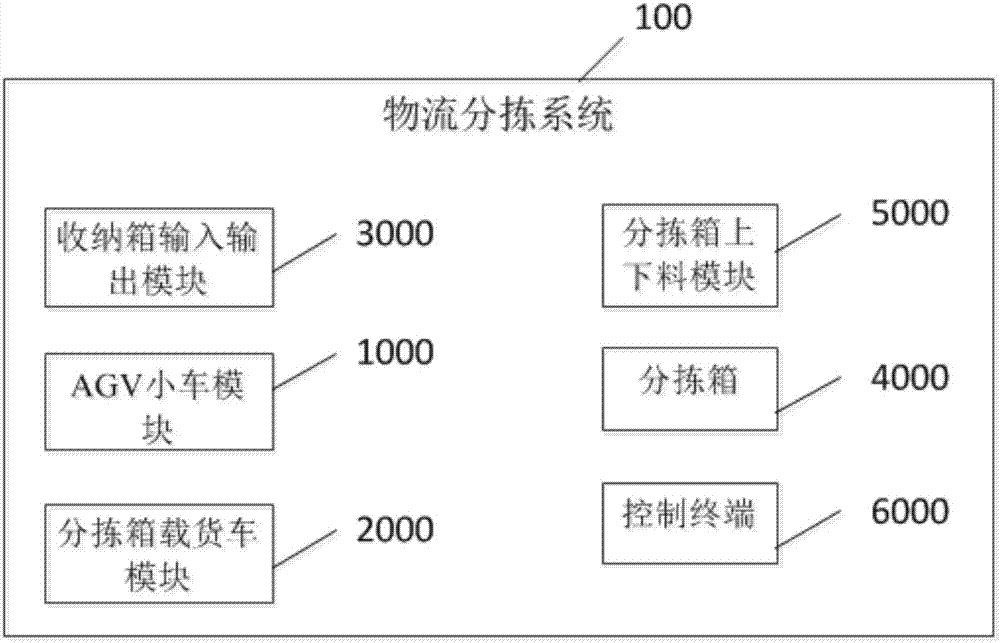

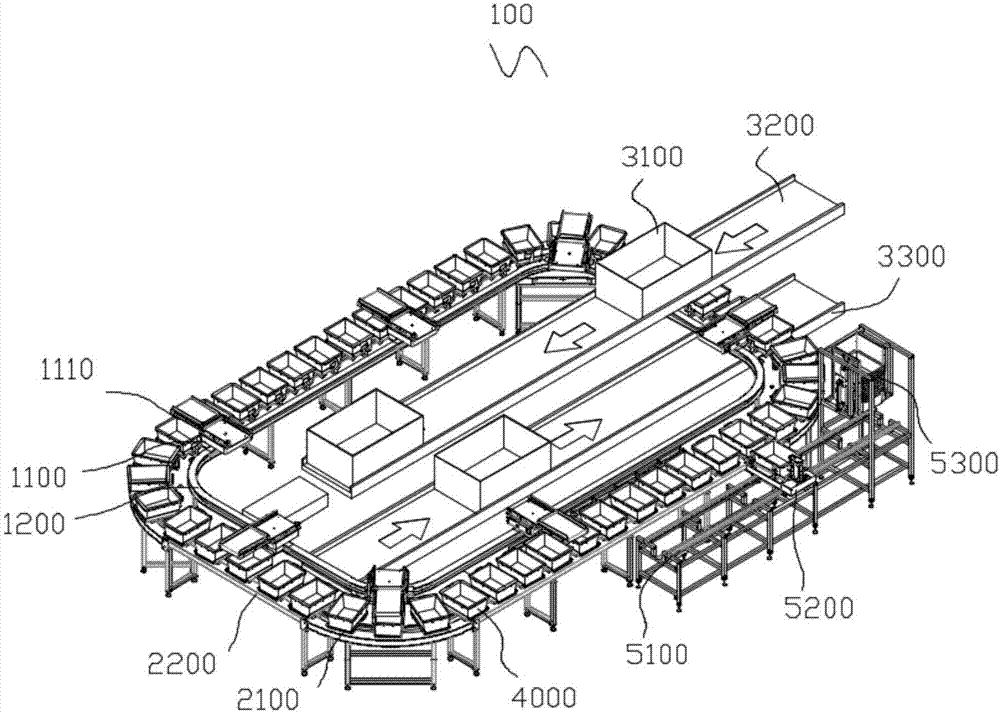

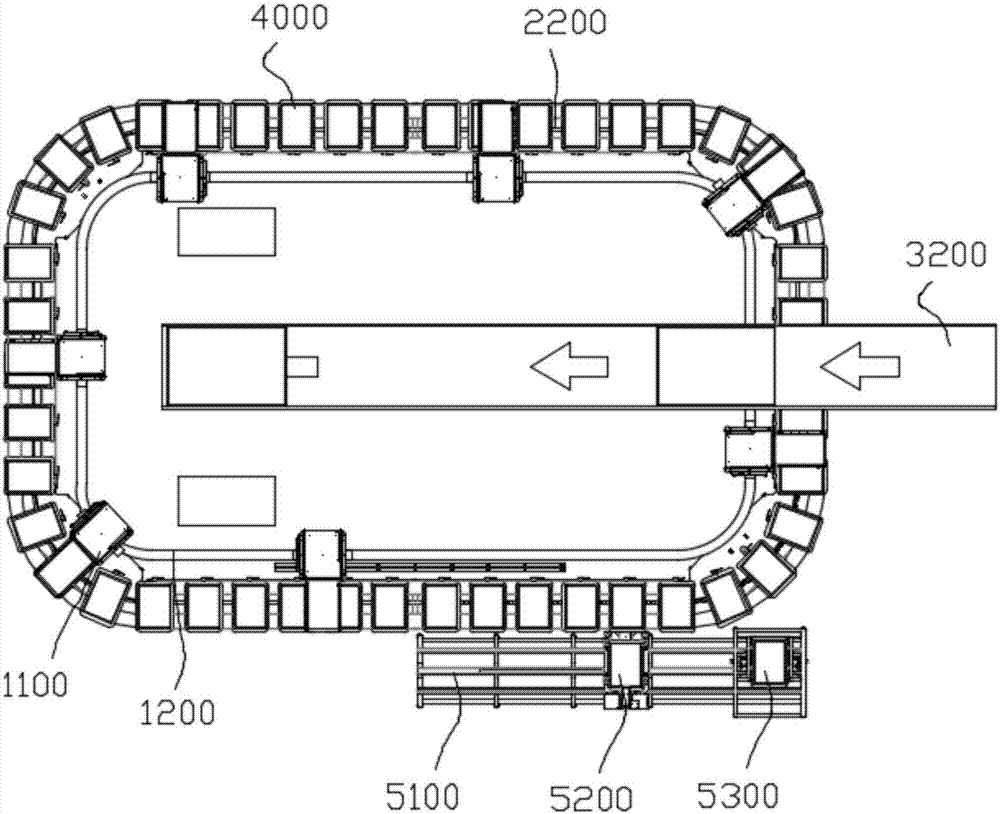

[0040] see figure 1 , figure 2 , image 3 and Figure 4 . This embodiment provides a logistics sorting system 100 for sorting items according to orders. The logistics sorting system 100 is especially suitable as a small and medium-sized logistics sorting system 100, including a storage box input and output module 3000, an AGV Car module 1000, sorting box truck module 2000, sorting box loading and unloading module 5000, control terminal 6000 and other modules.

[0041] In this embodiment, the storage box input and output module 3000 is used to input the storage box 3100 loaded with unsorted items to a preset position, and output the storage box 3100 that has been unloaded. Wherein, the storage box 3100 is a box made of metal, plastic and other materials with a storage function, and the items in the storage box 3100 are items in multiple unsorted orders.

[0042] As a preferred storage box input and output module 3000, it includes a storage box input line 3200 and a storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com