Detection method for solar battery piece with qualified hot spot temperature range

A technology of solar cell and hot spot temperature, which is applied in the field of solar cells to achieve the effect of rich data volume, low cost and short test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

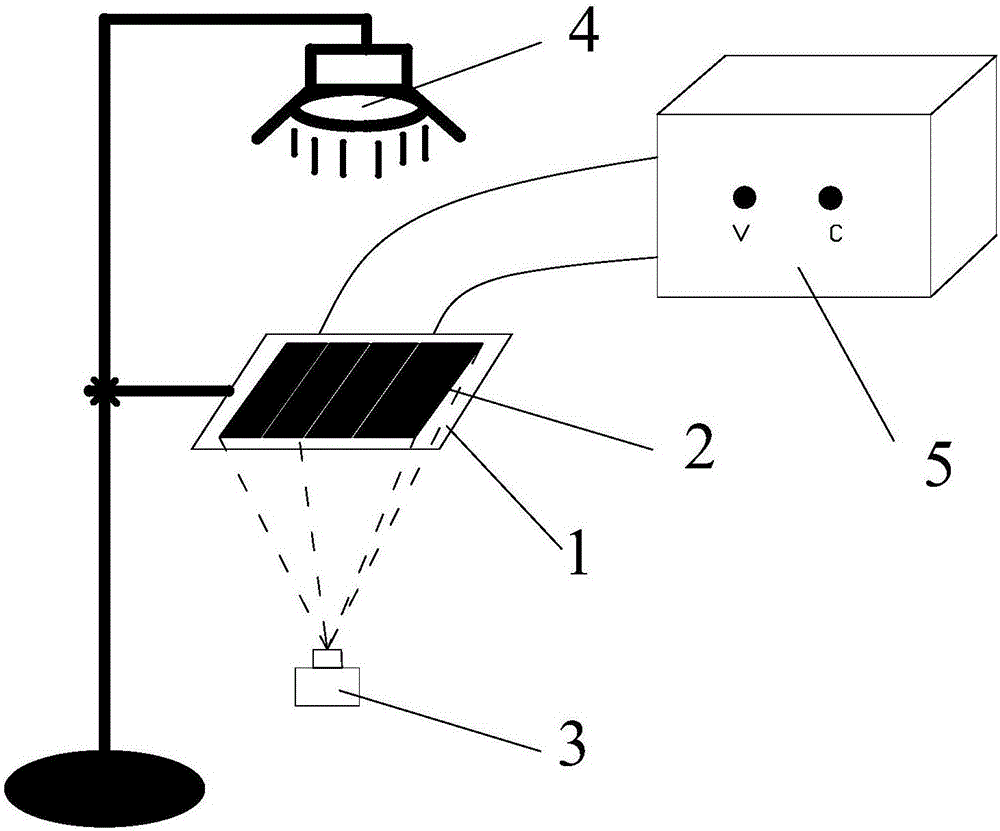

[0049] A method for detecting solar cells with a qualified hot spot temperature range, comprising the steps of:

[0050] (1) Establish qualified hot spot temperature range:

[0051] ①Provide 29 solar cells as test samples;

[0052] ② measure the hot spot temperature T of each solar cell in the test sample 片 ;

[0053] ③ Assemble the solar cells in the test sample into 29 laminates respectively;

[0054] ④ measure the hot spot temperature T of each solar cell sheet in the laminate 组件 ;

[0055] ⑤ Take 180°C (T 0 ) is the hot spot qualified temperature of the solar laminate;

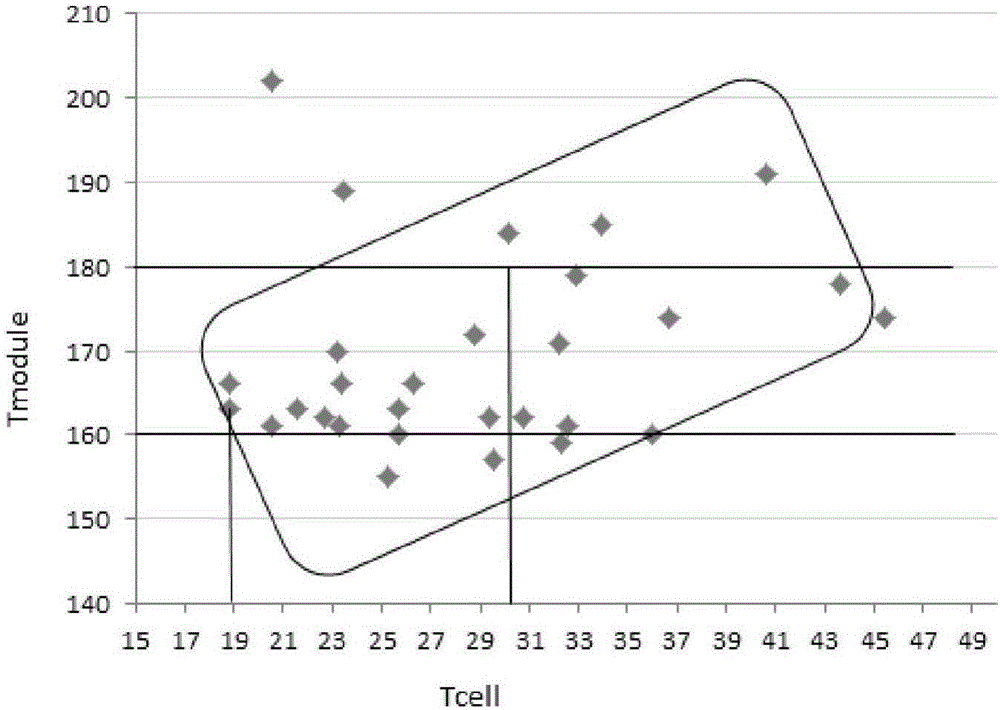

[0056] ⑥ with T 片 as the abscissa, with T 组件 As the ordinate, draw an X-Y point diagram, such as figure 2 ;

[0057] ⑦ Put T 组件 =T 0 The abscissa of the first point of is marked as T 片 ’, the abscissa is at T 片 ’ The following range is the qualified hot spot temperature range;

[0058] (2) Test the hot spot temperature T of the solar cell 片测 ;

[0059] (3) Judgment T 片测 ≤ T 片 ', then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com