Chip sorting device and chip sorting method

A technology for sorting devices and chips, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the decrease in arrangement accuracy, the length of the transmission arm 102 becomes longer, and the moving distance becomes longer, so as to improve the chip sorting accuracy , The effect of shortening chip sorting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

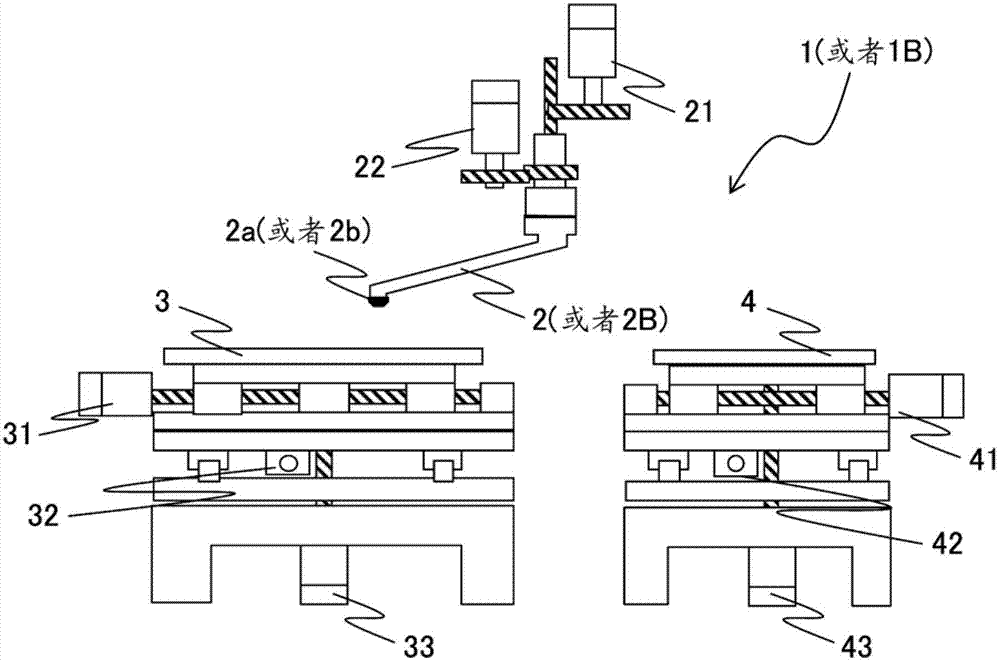

[0054] figure 1 It is a side view schematically showing an example of the configuration of the main part of the chip sorting apparatus in Embodiment 1 of the present invention.

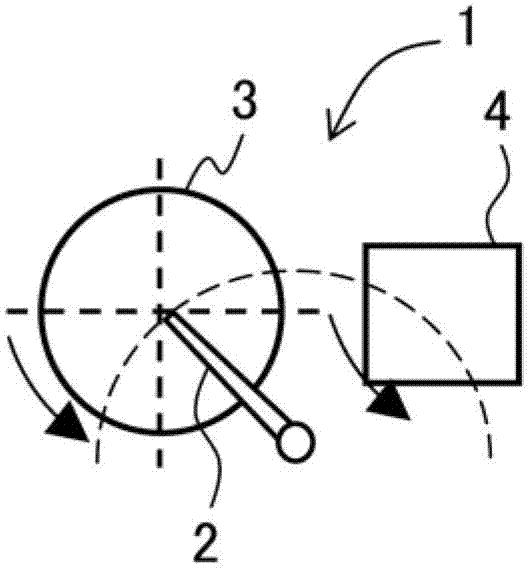

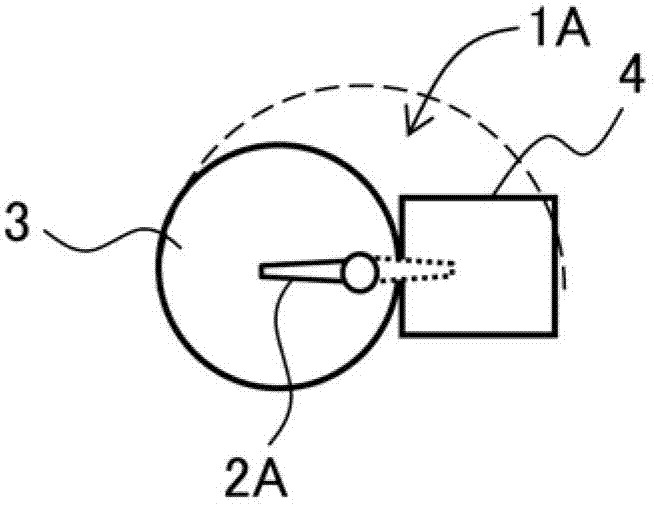

[0055] exist figure 1 Among them, in the chip sorting apparatus 1 of the first embodiment, a transfer arm 2 is provided so as to be freely rotatable and movable in the vertical direction, and the transfer arm 2 is provided with a chuck 2a at the front end portion, and the chuck 2a can One chip is sucked and held from a plurality of LED chips cut from a wafer and attached to an adhesive sheet. The vertical movement of the conveying arm 2 is performed via the rack and the pinion by the rotational drive of the motor 21 for the arm Z axis. In addition, the rotation operation of the conveyance arm 2 is performed by the rotation drive of the motor 22 for arm (theta) rotation via a gear.

[0056] In addition, in the chip sorting apparatus 1, the supply table 3 on which the ring for mounting the pluralit...

Embodiment approach 2

[0092] In the above-mentioned Embodiment 1, the case where the LED chips are sequentially moved from a supply table on which a plurality of LED chips are mounted on a ring to an arrangement table by one transfer arm 2, 2A, or 2B has been described. The plurality of LED chips are the plurality of LED chips cut from the wafer, but in the second embodiment, a case is described in which one transfer arm 2, 2A, or 2B is provided on the opposite side, and two transfer arms 2C pass through in total. , and sequentially move the LED chips from a supply table where a plurality of LED chips are mounted on the ring to an arrangement table, and simultaneously perform a different set of LED chips from a plurality of LED chips mounted on the ring. The operation of sequentially moving the LED chips on the supply table to one array table, wherein the plurality of LED chips are the plurality of LED chips cut from the wafer.

[0093] Figure 12 It is a plan view schematically showing the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com