Horizontal type cigarette carton sorting mechanism

A kind of cigarette, horizontal technology, which is applied in the field of horizontal cigarette sorting mechanism, can solve the problems of pulling out cigarettes, direction and speed, shutdown, unreliable work, etc., so as to save sorting time and improve Sorting efficiency, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

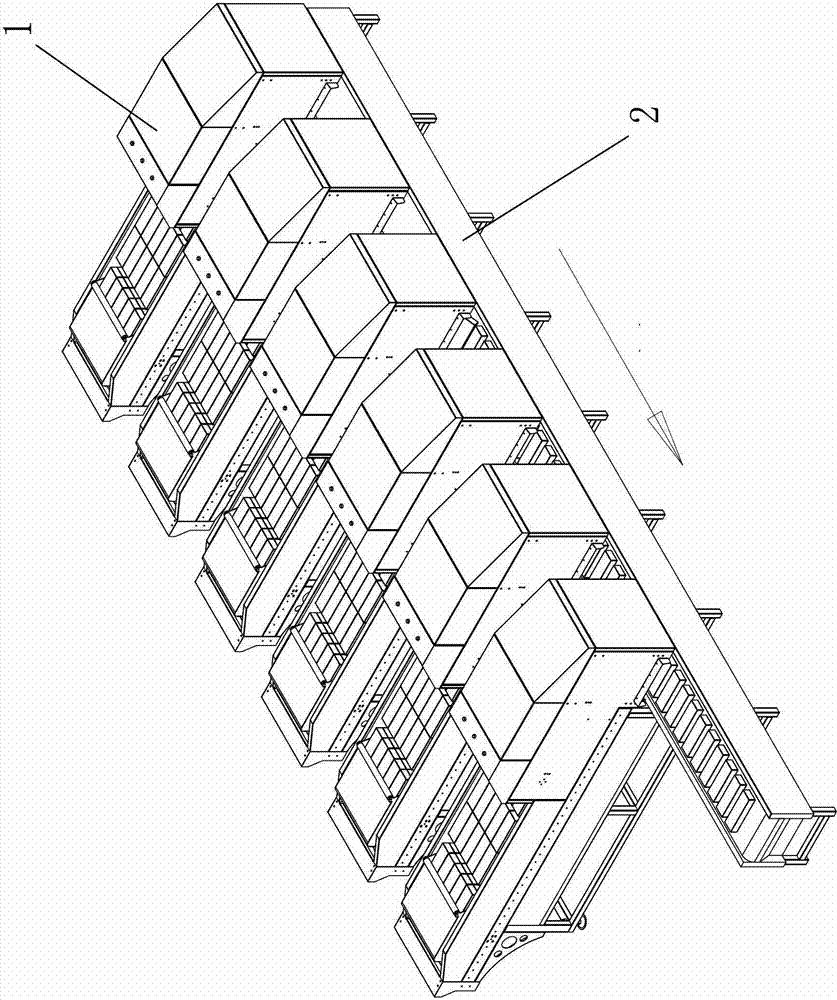

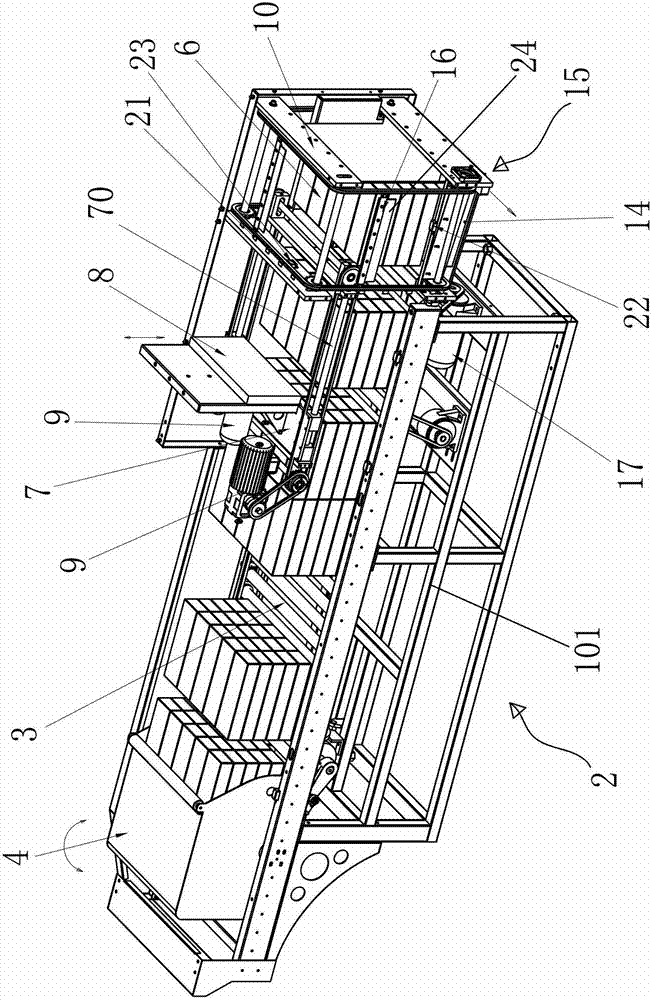

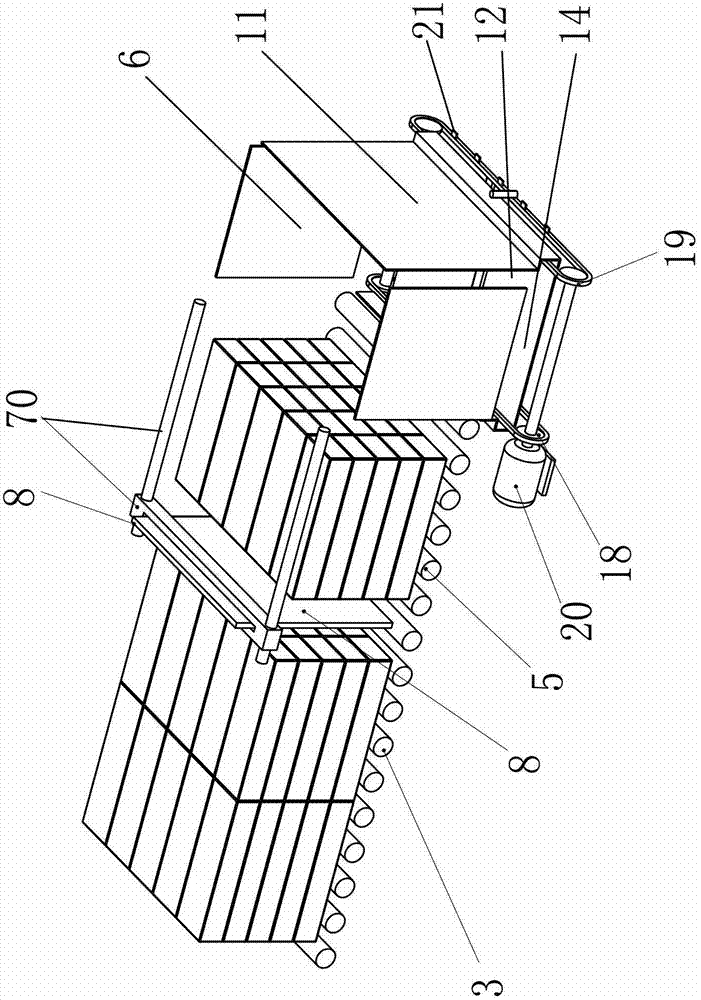

[0022] like figure 1 , figure 2 As shown, a horizontal cigarette sorting mechanism referred to in the present invention includes a sorting device 1 and a main conveying belt 2, the sorting device 1 is installed on one side of the main conveying belt 2, and the sorting device 1 is installed on one side of the main conveying belt 2. The device 1 includes a frame 101, on which a conveying raceway 3 is arranged, the front end of the conveying raceway 3 is provided with a replenishment dump 4, and the rear end of the conveying raceway 3 is connected with a separating raceway 5, wherein The outlet end of the separation raceway 5 is provided with a sorting bin 6, and above the separation raceway 5 is provided with a pushing mechanism 7 that pushes a stack of cigarettes into the sorting bin 6, and the pushing mechanism 7 includes a vertically movable and horizontal Moving push plate 8, power unit 9 and guide rail 70, described push plate 8 is installed on the guide rail 70, and desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com