Electric melting furnace of circular bottom inserted electrode

An electric melting furnace and electrode technology, applied in the direction of electric furnace, furnace type, furnace, etc., can solve the problems of large floor space, low degree of automation, and large amount of flue gas contained in glass melting furnaces, and achieve long life of melting furnaces and high degree of automation High, slow erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

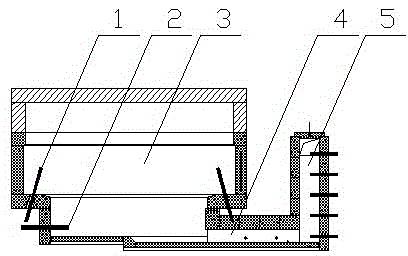

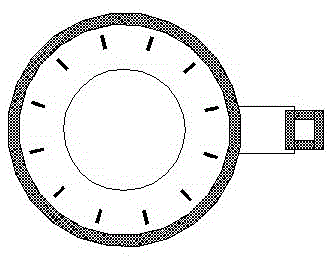

[0011] Depend on figure 1 , figure 2 As shown in the figure, it can be seen that the electric melting furnace with circular bottom insertion electrode of the present invention is composed of melting part 3 , liquid flow hole 4 , ascending path 5 , bottom insertion electrode 1 and start electrode 2 .

[0012] The melting part 3 is two superimposed boxes made of refractory materials. The cross section of the melting part 3 is circular, and the height of the melting part 3 is four meters. The big box forms a ladder, and the height of the small box is two meters. The bottom of the small box is provided with a flow hole 4, and what is connected with the flow hole 4 is an ascending path 5.

[0013] The electrodes are passed from the bottom to the top from the bottom to form the bottom insertion electrode 1. The bottom insertion electrodes 1 are evenly distributed with twelve groups of electrodes centered on the vertical axis. Each group of bottom insertion electrodes 1 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com