Rotary magnetic cell separation method

A magnetic separation and rotary technology, applied in the field of cell separation, can solve the problems of cell damage and long cell separation time, and achieve the effects of reducing damage, improving sorting efficiency and reducing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

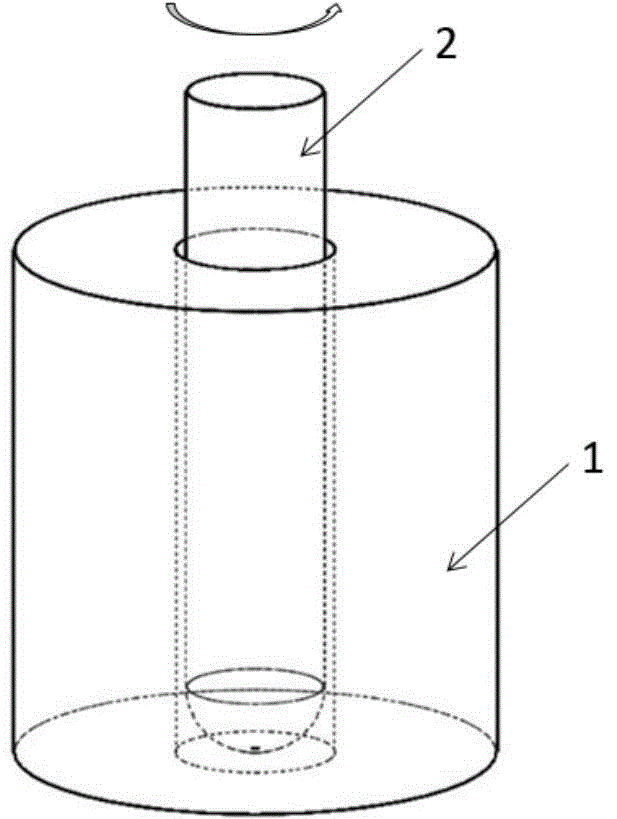

[0019] Such as figure 1 Shown, among the figure 1 is ring magnet, and 2 is test tube.

[0020] The rotary cell magnetic separation method of the present invention comprises the following steps:

[0021] Step 1, put the sample: Put the turbid solution containing the target cells, labeled magnetic beads and stray cells into the test tube 2, and then insert the test tube into the middle of the ring magnet 1;

[0022] Step 2, rotating and separating: the test tube 2 is rotated in a certain way around the central axis of the ring magnet 1, and the rotation stops after a period of time;

[0023] Step 3, static separation: keep still for a period of time;

[0024] Step 4, cell collection: remove the supernatant.

[0025] In step 1, the magnetic field strength at the center of the ring magnet is 500-950mT.

[0026] Rotating in a certain way in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com