Construction waste sorting method and system

A construction waste and sorting system technology, applied in sorting and other directions, can solve the problems of high equipment cost, slow recognition time, difficult time control, etc., and achieve the effect of low system cost and accurate sorting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below through specific embodiments.

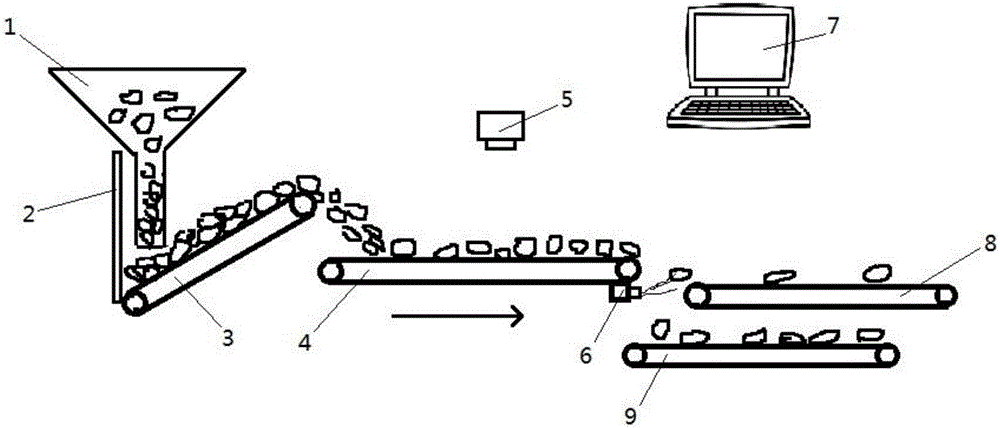

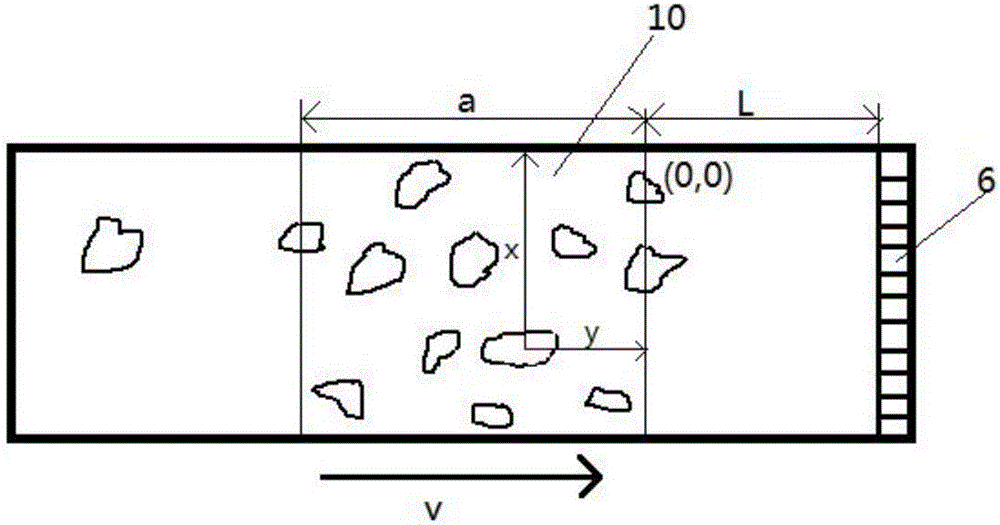

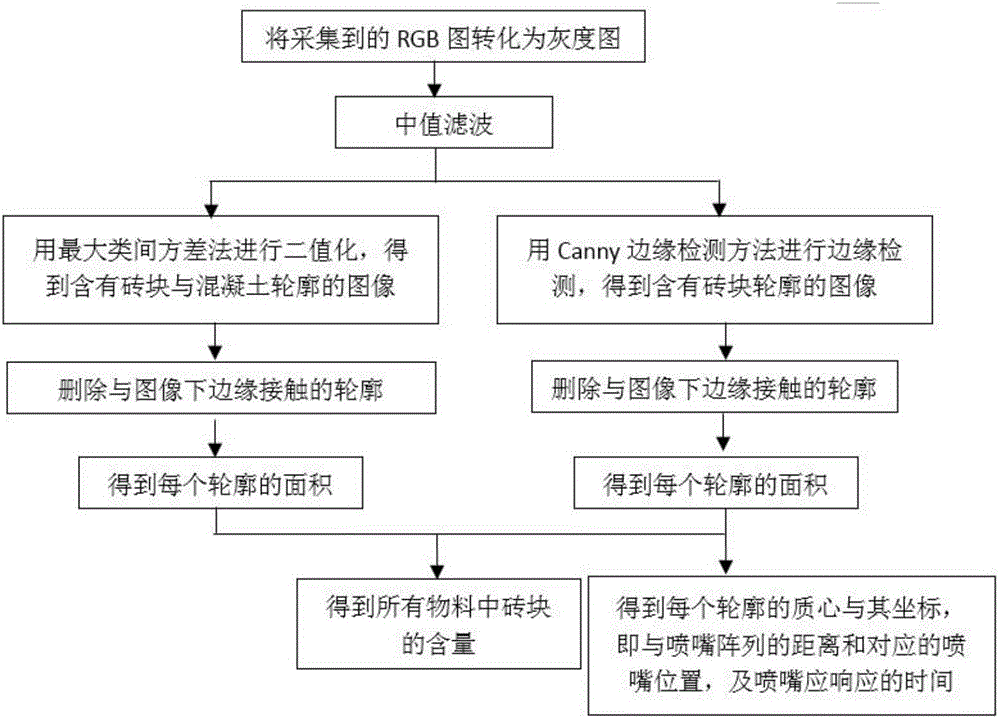

[0040] A sorting system for construction waste, capable of quickly sorting bricks and concrete. refer to figure 1 , figure 2 , including silo 1, baffle plate 2, feeding conveyor belt 3, dispersion conveyor belt 4, image acquisition device, pneumatic nozzle device 6, host computer 7, brick conveyor belt 8 and concrete conveyor belt 9. The silo 1 is used to store the mixture of crushed concrete and bricks to be sorted. The particle size range of the broken concrete and bricks is 30-50mm, the bricks are red, and the concrete is gray. The feeding conveyor belt 3 is inclined upwards, its starting end is below the outlet of the feed bin 1, and its end is positioned above the starting point of the dispersion conveyor belt 4, and the speed of the feeding conveyor belt 3 is slower than that of the dispersion conveyor belt 4, so as to A unit volume of material is dispersed over a larger area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com