Automated sorting device for cylindrical lithium-ion batteries

A lithium-ion battery and sorting device technology, which is applied in the directions of non-aqueous electrolyte storage battery, electrolyte storage battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high labor intensity, high production cost, shortening battery sorting time, etc. Improve the effect of high labor intensity, high production cost and shorten sorting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

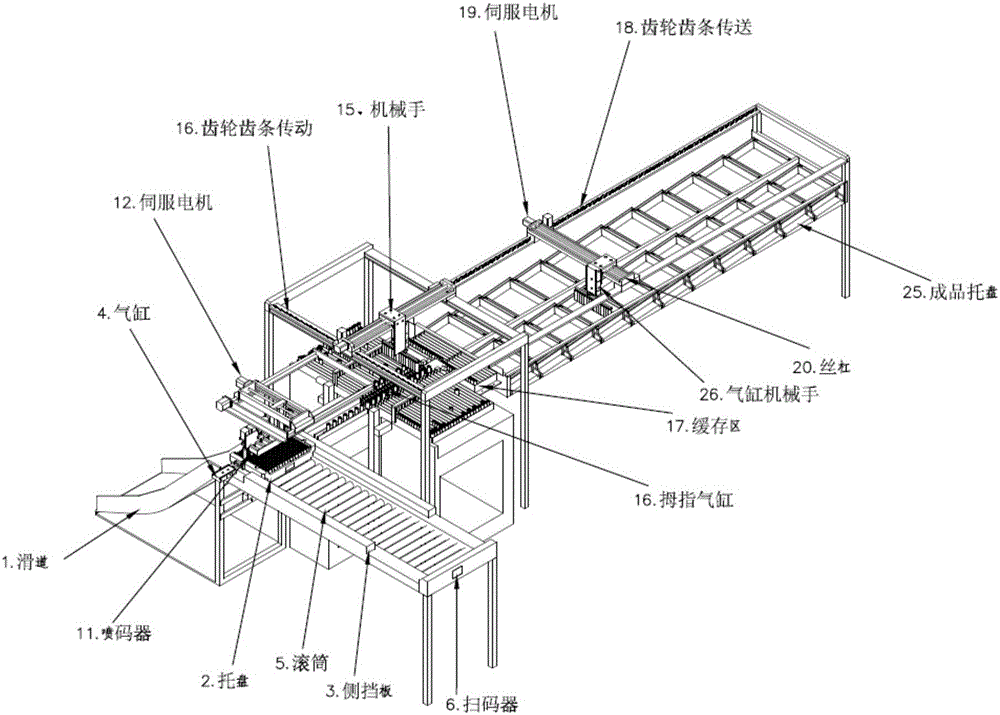

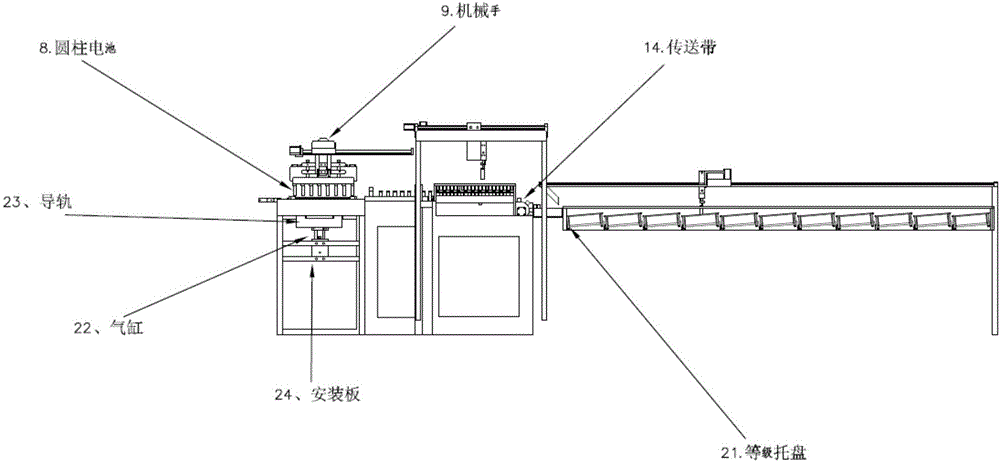

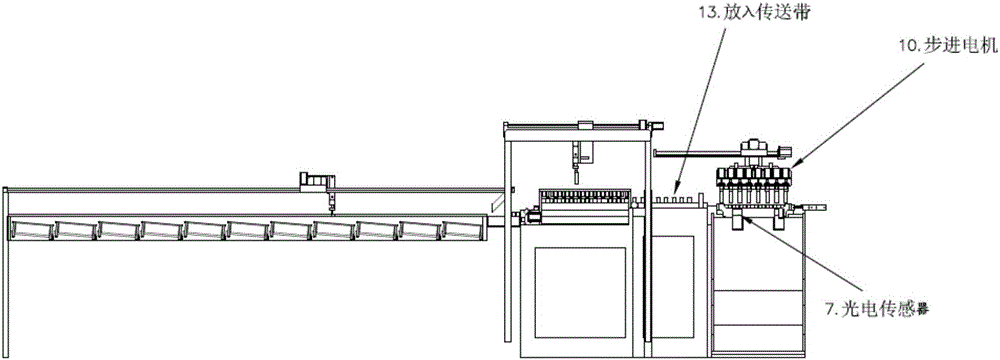

[0034] An automatic sorting device for cylindrical lithium-ion batteries, comprising:

[0035] The code scanner (6) located on the conveyor manually puts the tray (2) filled with 18650 lithium-ion batteries into the designated position of the conveyor, and scans the barcode of the tray;

[0036] The conveyor also includes a roller (5) and side fences (3) on both sides of the roller (5).

[0037] Conveyor rollers (5) transport the trays, and after the trays (2) reach the end of the conveyor, the cylinder (4) located on one side of the conveyor pushes the trays to the other side and is next to the side fence (3), the side fences The purpose of installing the plate (3) is to effectively position the pallet (2);

[0038] At the same time, the cylinder (22) positioned under the conveyor stretches out to block the pallet, and the cylinder (22) below the conveyor is fixed by the mounting plate (24) on the pillar, and the cylinder is connected with the guide rail (23), and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com