Method for reclaiming residue steel and slag of molten steel container

A recycling method and ladle technology, applied in the field of metallurgy, can solve problems such as waste of iron resources, inability to recycle surplus steel and slag, and difficult disposal, and achieve the effects of saving raw materials and energy, improving labor intensity, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

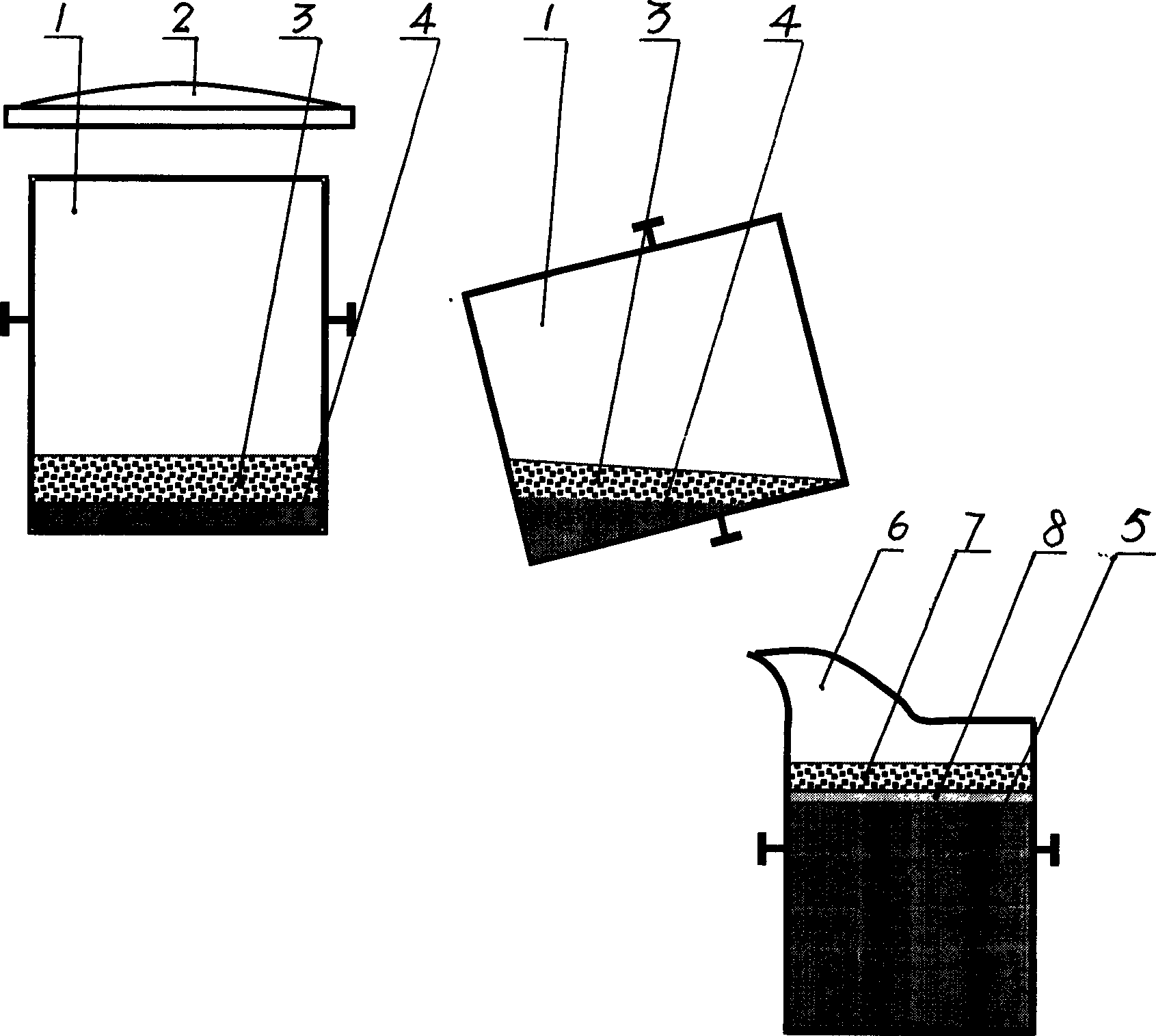

[0020] Such as figure 1 As shown, a method for recovering residual steel and slag from a steelmaking ladle. During steelmaking, when the ladle 1 is tapped, it is immediately moved to the ladle 6 where the molten iron 5 is stored, and then the ladle cover 2 is removed. , then tip over the ladle 1, and pour the liquid residue 3 and the remaining steel 4 in the ladle 1 into the ladle 6 together. Because the temperature of molten iron 5 in ladle 6 is low, and the remaining steel 4 fusing point without mixing is higher, therefore, will form one deck solidification shell 8 on the liquid surface of molten iron 5 of ladle 6, thereby has affected newly added The remaining steel 4 and the remaining slag 3 are mixed with the original molten iron 5 and the molten iron slag 7 in the ladle 6.

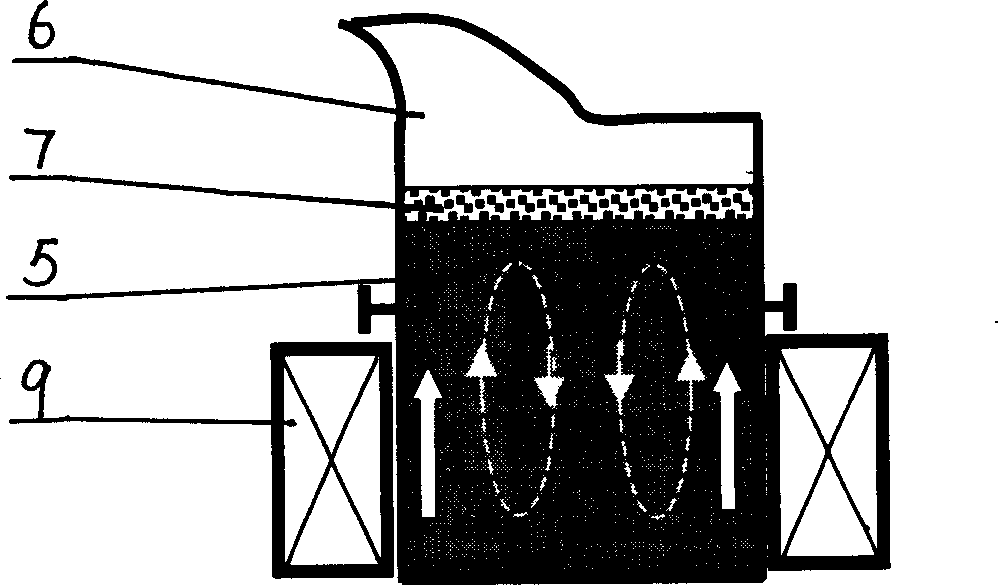

[0021] In this embodiment, in order to fully mix the newly added remaining steel 4 and remaining slag 3 with the original molten iron 5 and molten iron slag 7 in the ladle 6, electromagnetic stirrin...

Embodiment 2

[0024] The present invention also can adopt the mechanical stirring method of ladle, when steel ladle 1 is tapped out, and after the liquid residue 3 in ladle 1 and remaining steel 4 are poured into ladle 6 together, adopt mechanical stirring device to stir again, Fully mix the newly added residual steel 4 and residual slag 3 with the original molten iron 5 and molten iron slag 7 in the ladle 6 . Such as Figure 5 As shown, a mechanical stirring device 10 immerses a stirring paddle 11 made of refractory material into the molten iron 5 of a certain depth in the ladle 6 from the upper part of the ladle 6 to stir the molten iron to make the molten iron rotate. Under the action of the stirring blade 11, the molten iron is well stirred and fully mixed, and the solidified shell 8 on the liquid surface of the original molten iron 5 dissolves and disappears rapidly due to the lowering of the melting point.

[0025] Certainly, in the present embodiment, also can adopt the method that ...

Embodiment 3

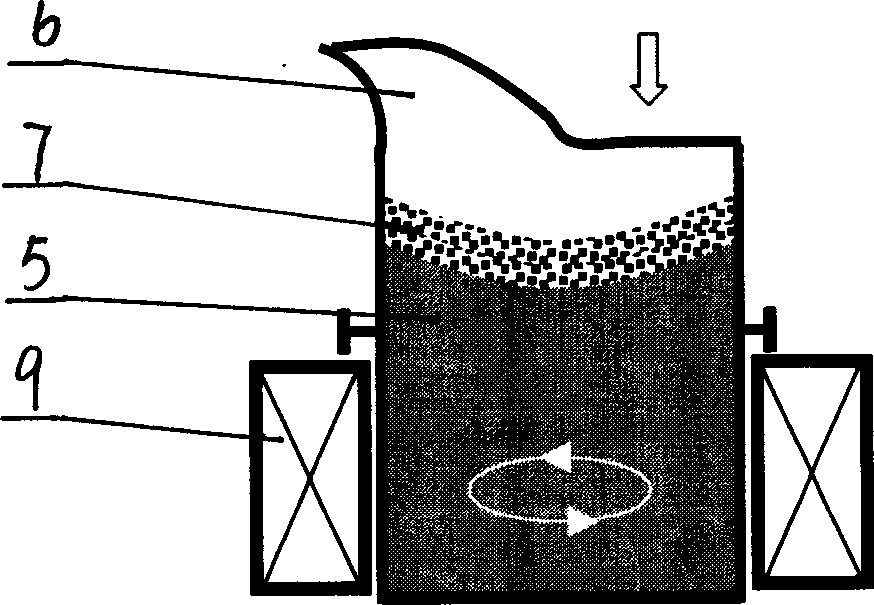

[0027] In the reclaiming method of remaining steel and residual slag in steelmaking ladle described in the invention, also can adopt the method that ladle electromagnetic stirring and mechanical stirring combine, as Figure 7 As shown, the lower part of the ladle 6 is provided with an electromagnetic stirring device 9, and the upper part is provided with a mechanical stirring device 10, so as to strengthen the stirring and mixing of the molten iron 5 and the slag. Before the stirring paddle 11 is inserted into the molten iron 5 for stirring, the electromagnetic stirring device 9 is used to stir to weaken the solidification shell 8 on the liquid level of the molten iron 5 , and then the mechanical stirring device 10 is used to strengthen the mixing of the molten iron 5 and the molten iron slag 7 .

[0028] In addition, in the present invention, the method of blowing oxygen to the liquid surface of the molten iron 5 in the molten iron ladle 6 can also be adopted to quickly elimin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com