Pipeline welding line radiographic inspection device

A radiographic flaw detection and pipeline technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of large workload of on-site disassembly, assembly and transfer, bulky pipeline weld scanning equipment, and increased inspection costs, and achieves good compatibility and environmental protection. The effect of adaptability, improving labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

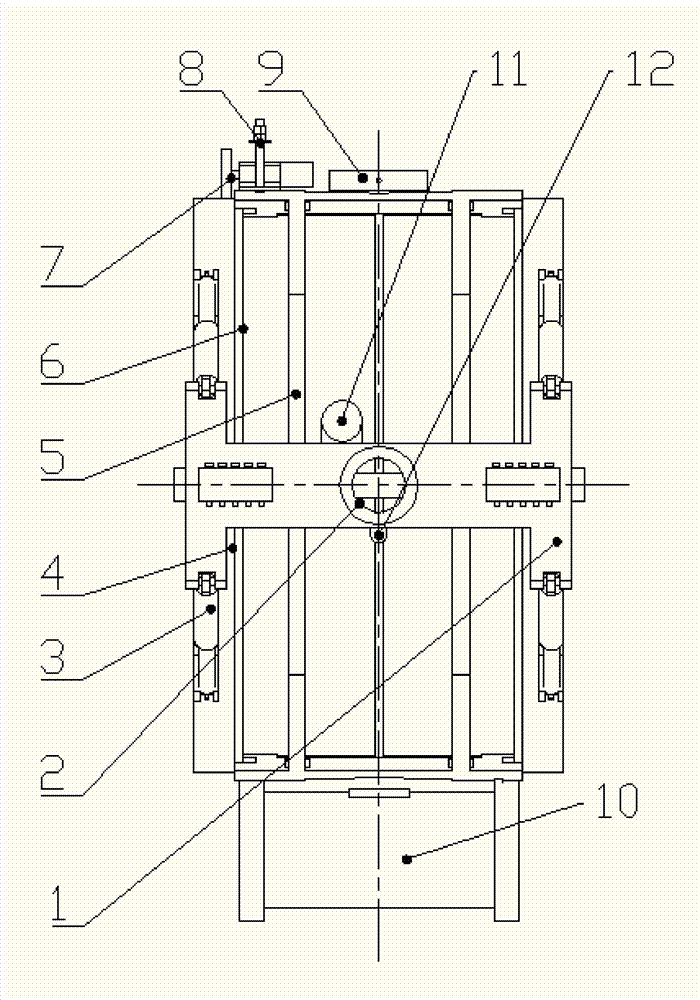

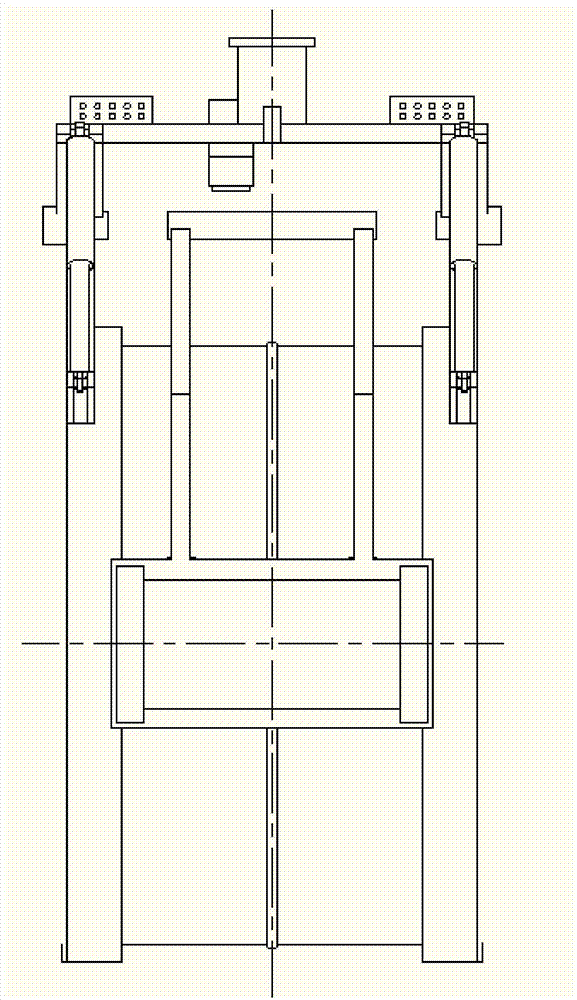

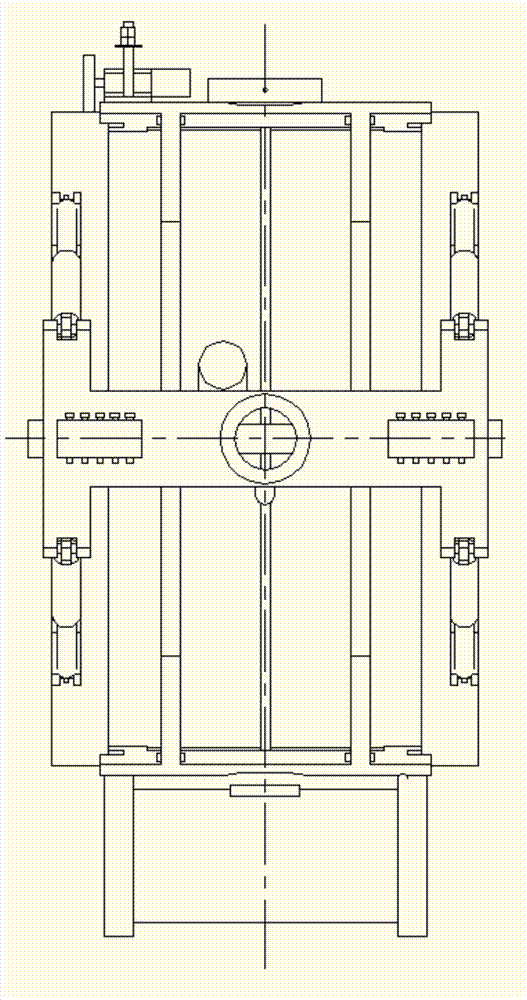

[0029] Such as figure 1 As shown, it includes installation base 1, hinge joint 2, telescopic actuator 3, fixed half ring 4, moving inner ring 5, circular motion track 6, motor reducer assembly 7, X-ray generator 8, flat panel detector 9 , Infrared positioning detector 10, locking in place detector 11, camera 12, inner ring connecting mechanism, outer ring locking mechanism, rotary shaft, friction wheel, pressing device.

[0030] The installation base frame 1 and the hinge joint 2 are integrally connected by threads, and serve as the basic carrier of the device. The cylinder body of the telescopic actuator 3 is connected with the installation base 1 through bolts, and the cylinder rod of the telescopic actuator 3 is connected with the outer ring locking mechanism through bolts. Under the action of the telescopic actuator 3, the outer ring locking mechanism is wound back The rotating shaft rotates to realize the opening and closing movement of the locking mechanism of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com