A lithium ion battery capacity sorting method

A lithium-ion battery, charging capacity technology, applied in secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problem of long capacity sorting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

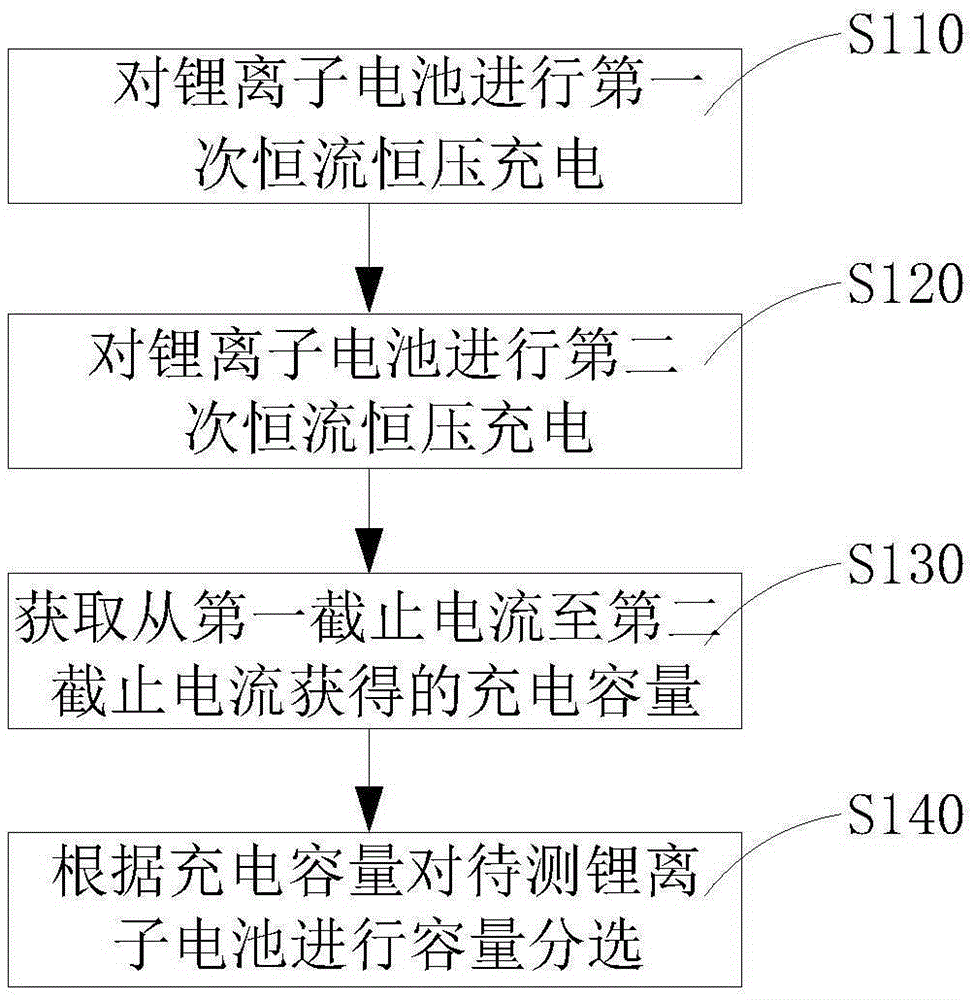

[0023] In order to more clearly explain the lithium ion battery capacity sorting method provided by the present invention, the following specific description will be made in conjunction with the examples. figure 1 It is a flowchart of a lithium ion battery capacity sorting method according to an embodiment.

[0024] Such as figure 1 Shown, lithium-ion battery capacity sorting method comprises the following steps:

[0025] S110 , charging the lithium-ion battery at a constant current and constant voltage for the first time. Wherein, constant current charging is performed with the first charging current and charged to the first voltage, and then constant voltage charging is performed and the charging is stopped when the charging current decreases to the first cut-off current.

[0026] Specifically, in order to ensure that the lithium-ion battery forms a stable SEI film (solid electrolyte interface, solid electrolyte interface film) during formation, the first charging current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com