Automatic goods conveying assembly line

An automatic conveying and assembly line technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems that affect the efficiency of goods conveying, error-prone, and occupy a large area, so as to improve the automatic conveying effect of sorting , reduce manpower and sorting time, and reduce the effect of sorting site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

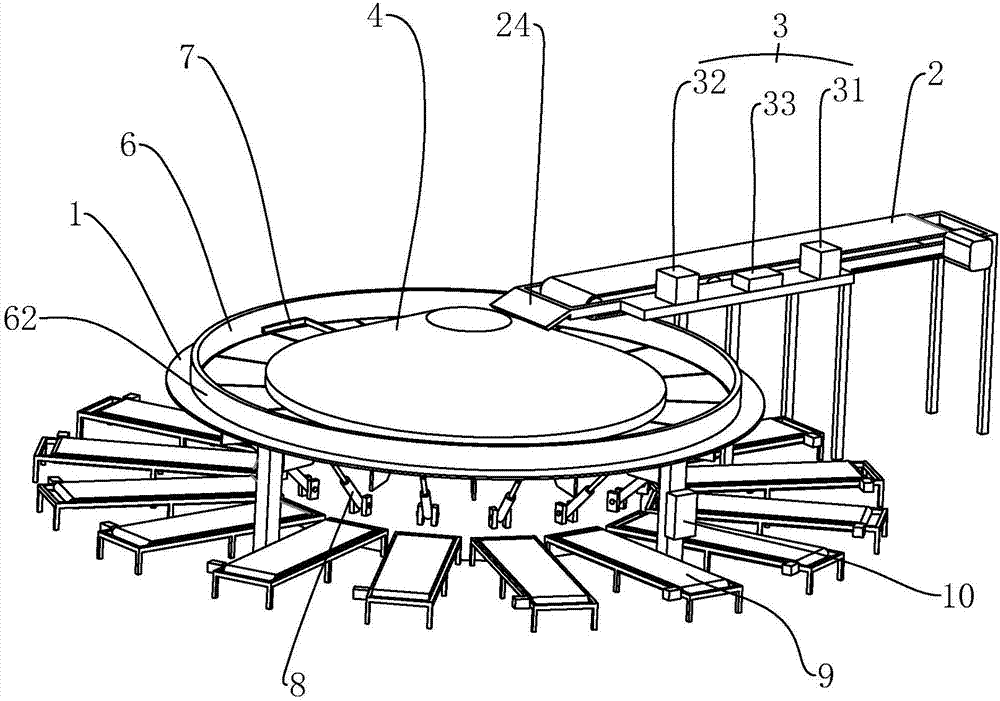

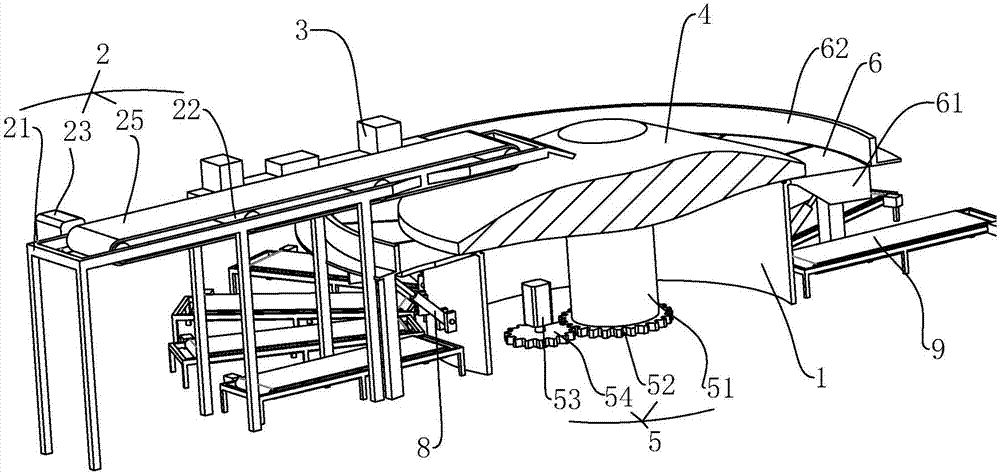

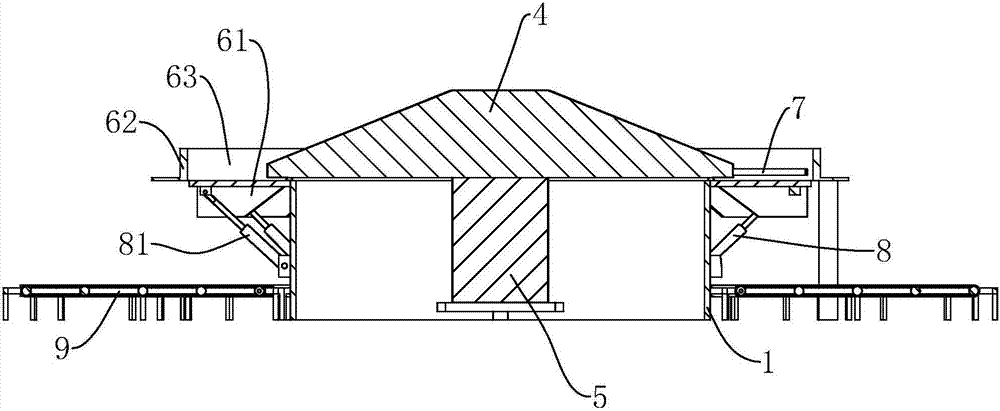

[0035] Embodiment 1: a kind of goods automatic conveying assembly line, such as figure 1 with figure 2 As shown, it includes a frame 1, a first conveying device 2 arranged on the frame 1 for conveying goods, a scanning device 3 arranged on the frame 1 for identifying goods information on the first conveying device 2, and a scanning device 3 arranged on the first conveying device 2. A conveying device 2 discharge end and a turntable 4 arranged in the shape of a circular platform, a driving device 5 arranged on the frame 1 for driving the turntable 4 to rotate on the frame 1, and a plurality of horizontally arranged at the lower end of the turntable 4 for supporting Goods and one end of the pallet 6 that is connected to the frame 1 in rotation, is fixedly arranged on the peripheral surface of the turntable 4 and is used to move the toggle plate 7 that the goods slide on the pallet 6, and is arranged on the turntable 4 for driving the pallet 6 to communicate with the machine. T...

Embodiment 2

[0046] Embodiment 2: An automatic delivery line for goods, as shown in Embodiment 6, is different from Embodiment 1 in that the first delayer 34 is connected to the signal of the scanner 32, that is, the scanner 32 is started indirectly, when When the first delayer 32 is activated, the scanner 32 is controlled to be activated to perform the scanning process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com