Joint-crossed hidden reinforcement structure in the middle of traditional wooden building and production method

A reinforced structure and cross-node technology, which is applied in the direction of building construction, construction, and building maintenance, can solve the problems of destroying the appearance of the building and failing to meet the requirements of the original appearance of the building, and achieve improved pull-out resistance, good reinforcement effect, and energy saving. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

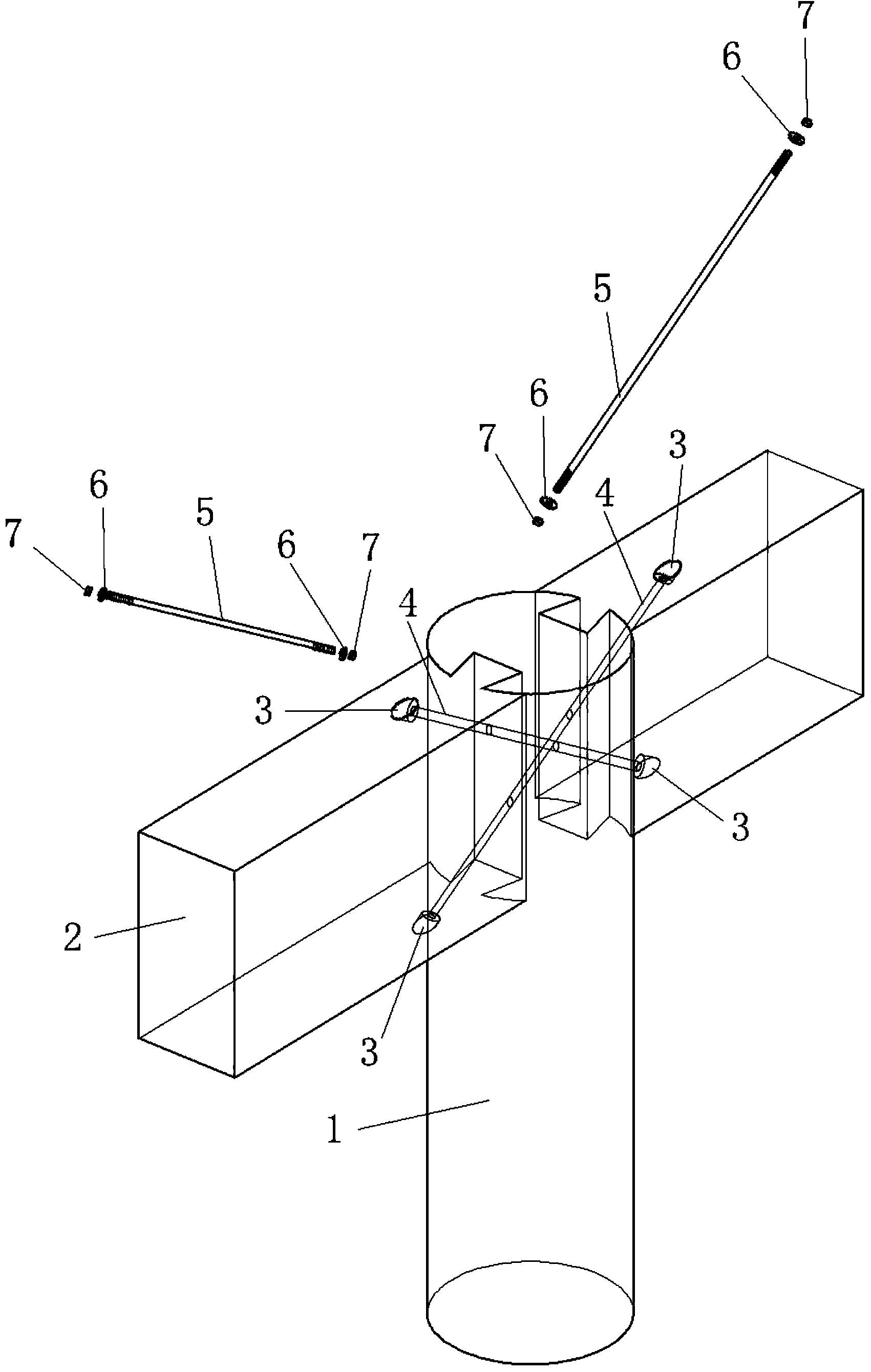

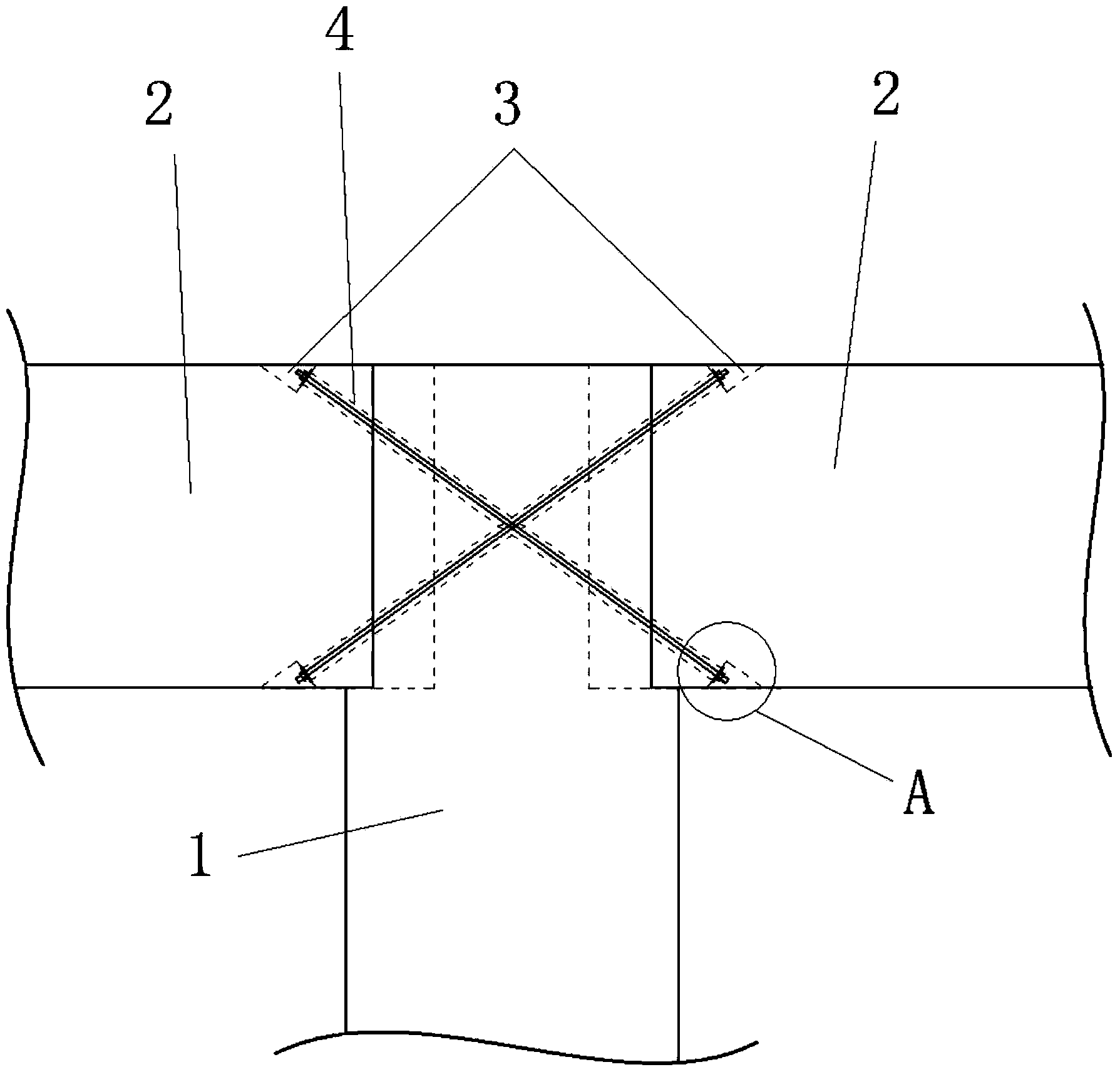

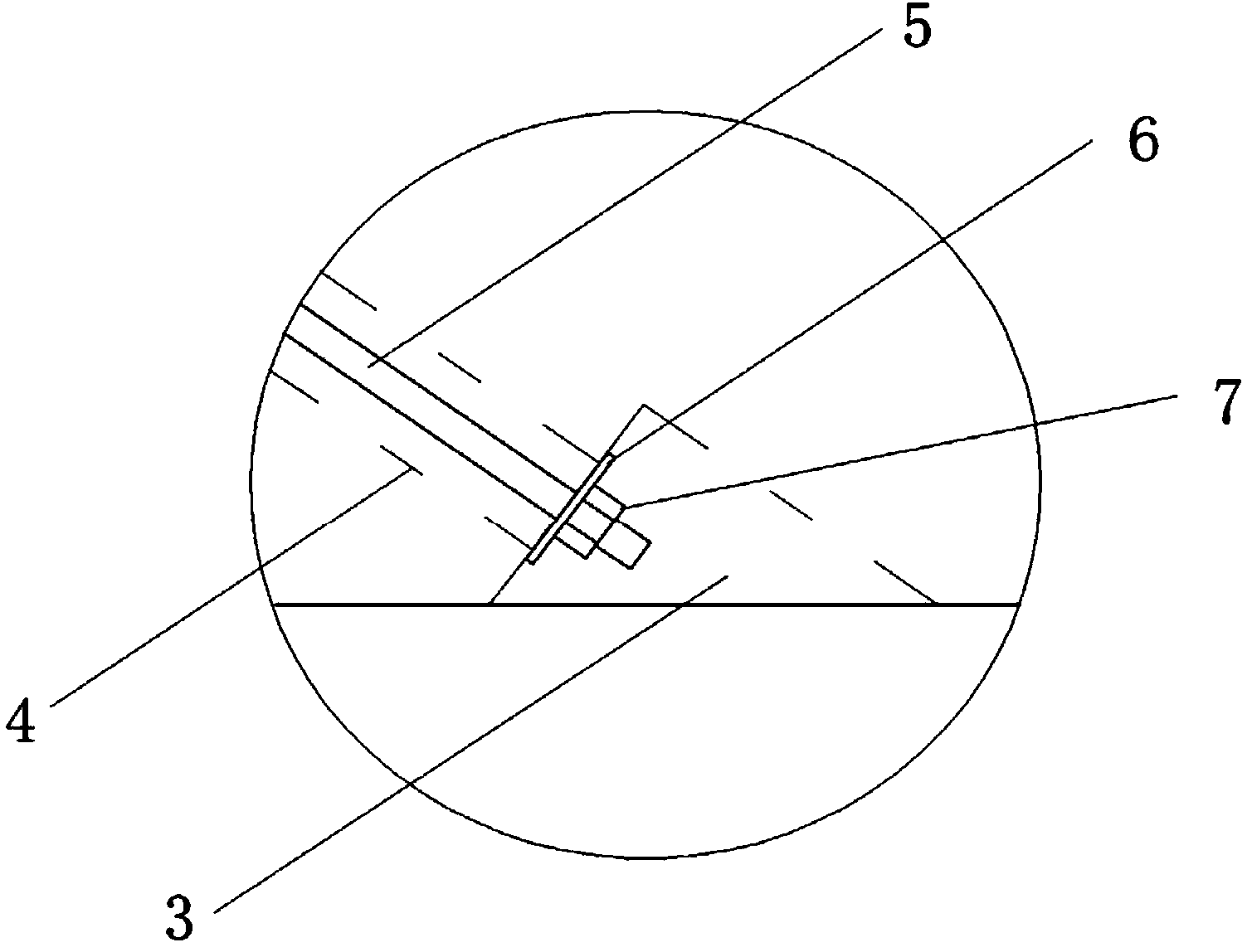

[0031] see figure 1 , The concealed reinforcement structure of middle-span mortise and tenon joints in the middle of the traditional building of middle wood structure in the present invention includes log column 1, log beam 2, concealed groove 3, connecting tie rod perforation 4, connecting tie rod 5, rigid backing plate 6 and fixing nut 7.

[0032] see figure 1 , figure 2 with image 3 According to the method provided by the present invention, the reinforcement is carried out. At first, on the mid-span node formed by the log column 1 and the log beam 2, two connecting tie rod perforations 4 are drilled, and the connecting tie rod perforations 4 are formed on the upper surface of the wooden beam 1 on one side of the node respectively. Staggered through to the lower surface of the wooden beam 1 on the other side. At the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com