Distillation process of metal organic source

A metal-organic source and rectification technology, applied in the fields of organic chemistry, fractionation, distillation and separation, etc., can solve the problems of long time consumption and low single yield, and achieve the goal of reducing workload, reducing required amount and reducing enterprise cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

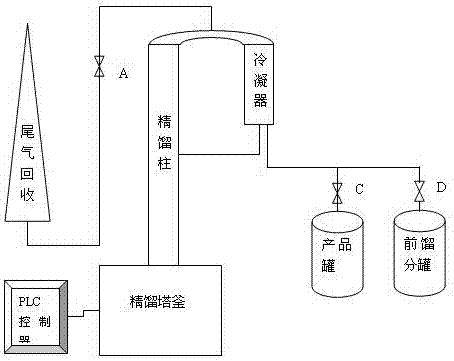

[0020] Such as figure 1 As shown, this embodiment provides a rectification process of metal-organic sources. PLC controls the rectification of trimethylgallium in intermittent heat-tracing pulse exhaust exhaust gas. The specific steps are as follows:

[0021] Gradient heating: After the start-up inspection is completed, 125kg of crude trimethylgallium is fed, and heating is started under the protection of high-purity nitrogen. , at 5°C / h, the temperature was raised to 70°C, and then at a temperature gradient of 2°C / h until the system achieved reflux.

[0022] Intermittent heat tracing total reflux removal of impurities: the first time the pressure difference between the top and bottom of the rectification column reaches 0.04bar as the total reflux mark, start to calculate the starting point of total reflux; the setting of PLC intermittent heat tracing is: the pressure difference between the top and bottom of the rectification column reaches 0.04bar, Stop the heat conduction o...

Embodiment 2

[0027] Such as figure 1 As shown, this embodiment provides a rectification process for metal-organic sources. PLC controls the rectification of triethylgallium in intermittent heat-tracing pulse discharge tail gas. The specific steps are as follows:

[0028] Gradient heating: After the start-up inspection is completed, 80kg of crude triethylgallium is fed, and the system pressure is controlled to 250torr under the condition of high-purity nitrogen protection, and heating is started. After reaching the set temperature, raise the temperature to 95°C at 5°C / h, and then use a temperature gradient of 2°C / h until the system achieves reflux (105-110°C).

[0029] Intermittent heat tracing total reflux removal of impurities: the first time the pressure difference between the top and bottom of the rectification column reaches 14Torr as the total reflux mark, start to calculate the starting point of total reflux; Heat conduction oil; when the differential pressure drops to 10bar, PLC co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com