Carbon-based liquid fertilizer, and system and method for production of the same

A liquid fertilizer and production system technology, applied in the field of agricultural resource utilization, to achieve high pyrolysis efficiency, increase yield, and reduce the amount of chemical fertilizer required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

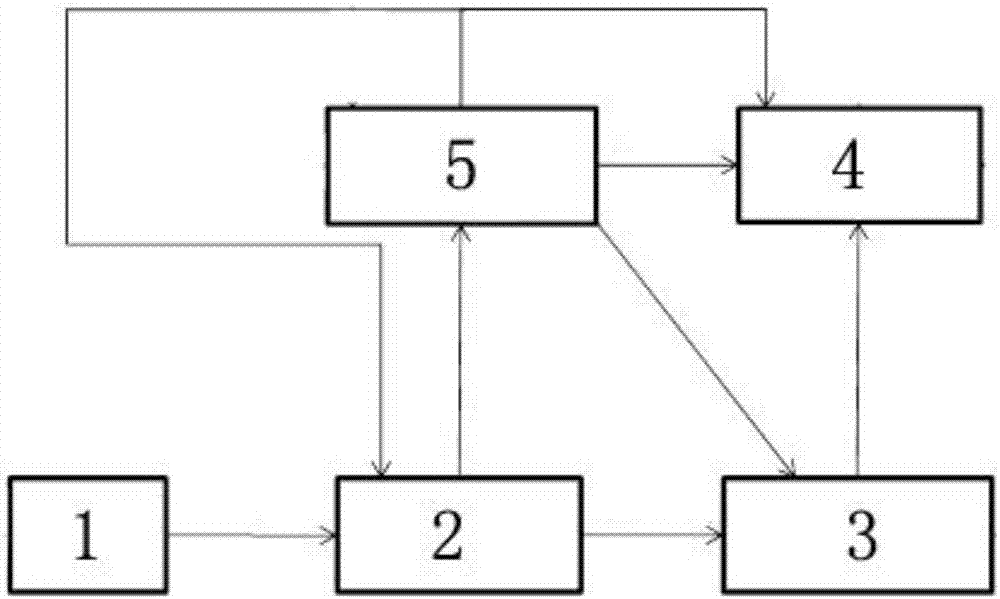

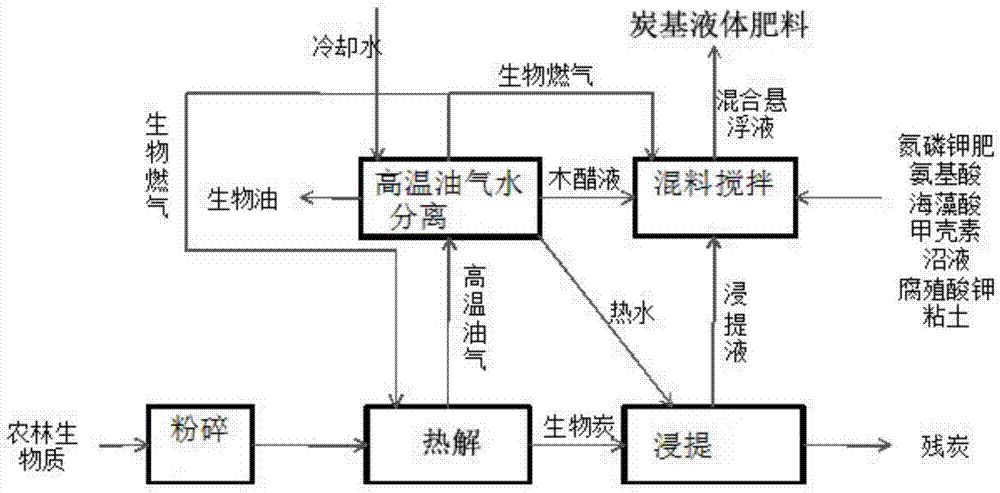

Method used

Image

Examples

Embodiment 1

[0061] The agricultural and forestry biomass raw materials in this example are rice straw and corn straw, the mass ratio is 3:7, the moisture content is 17.5%, and the total is 100kg.

[0062] Production methods for carbon-based liquid fertilizers include:

[0063] (1) Pretreatment: crush the straw to a length of 10-20cm.

[0064] (2) Carbonization: send the crushed straw in step (1) into a regenerative rotary bed carbonization furnace, wherein the carbonization temperature is 600° C., and the carbonization time is 40 minutes. The high-temperature oil and gas produced by carbonization are transported to the high-temperature oil-gas separation system through the pipeline. The biochar produced by carbonization is 28.5kg, which enters the leaching system after being discharged by the double helix.

[0065] (3) High-temperature oil-gas separation: Pass the high-temperature oil-gas generated in step (2) into the oil-gas separation system, cool it with water, and separate out 41.8...

Embodiment 2

[0072] The agricultural and forestry biomass raw materials in this embodiment are rice husk and reed, the mass ratio is 7:3, and the average moisture content is 8.7%, totaling 100kg.

[0073] Production methods for carbon-based liquid fertilizers include:

[0074] (1) Pretreatment: crush the reed stalks to a length of 10-20 cm.

[0075] (2) Carbonization: Send the reed straw and rice husk crushed in step (1) into a regenerative rotary bed carbonization furnace, where the carbonization temperature is 450°C and the carbonization time is 45 minutes. The high-temperature oil and gas produced by carbonization are transported to the high-temperature oil-gas separation system through the pipeline. The biochar produced by carbonization is 22.5kg, which enters the leaching system after being discharged by the double screw.

[0076] (3) High-temperature oil-gas separation: Pass the high-temperature oil-gas generated in step (2) into the oil-gas separation system, cool it with water, a...

Embodiment 3

[0083] The agricultural and forestry biomass raw material of this embodiment is bagasse, with a moisture content of 17.2%, and a total of 100kg.

[0084] Production methods for carbon-based liquid fertilizers include:

[0085] (1) Carbonization: Bagasse is sent into a regenerative rotary bed carbonization furnace, where the carbonization temperature is 700°C and the carbonization time is 30 minutes. The high-temperature oil and gas produced by carbonization are transported to the high-temperature oil-gas separation system through the pipeline. The biochar produced by carbonization is 25.5kg, which enters the extraction system after being discharged by the double screw.

[0086] (2) High-temperature oil-gas separation: Pass the high-temperature oil and gas generated in step (1) into the oil-gas separation system, cool it with water, and separate out 42.9kg of pyrolysis gas, 4.4kg of pyrolysis oil and 27.2 kg of wood vinegar kg. Among them, a part (24.9kg) of the generated py...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com