Treatment method and treatment device of discharge water of cooling water

A treatment device and treatment method technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve problems such as difficult cleaning and blockage, and achieve the purpose of suppressing flux reduction, long-term continuous stability and effective Effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] Hereinafter, the present invention will be described more specifically by giving examples, reference examples, and comparative examples.

[0115] [evaluation sample]

[0116] In the following examples, reference examples, and comparative examples, the following evaluation sample waters 1 and 2 were used as raw water to be treated.

[0117]

[0118] As evaluation sample water 1, the discharge water of the cooling water of A petrochemical complex plant was collected.

[0119] The cooling water treatment of this factory is treated with non-phosphorus polymer-based dispersant and the concentration factor is 4 times. The water quality of the collected cooling water discharge water is shown in Table 1.

[0120]

[0121] As evaluation sample water 2, the discharge water of the cooling water of Plant B of the Petroleum Complex was collected.

[0122] The cooling water treatment of this factory is treated with non-phosphorus polymer-based dispersant and the concentration f...

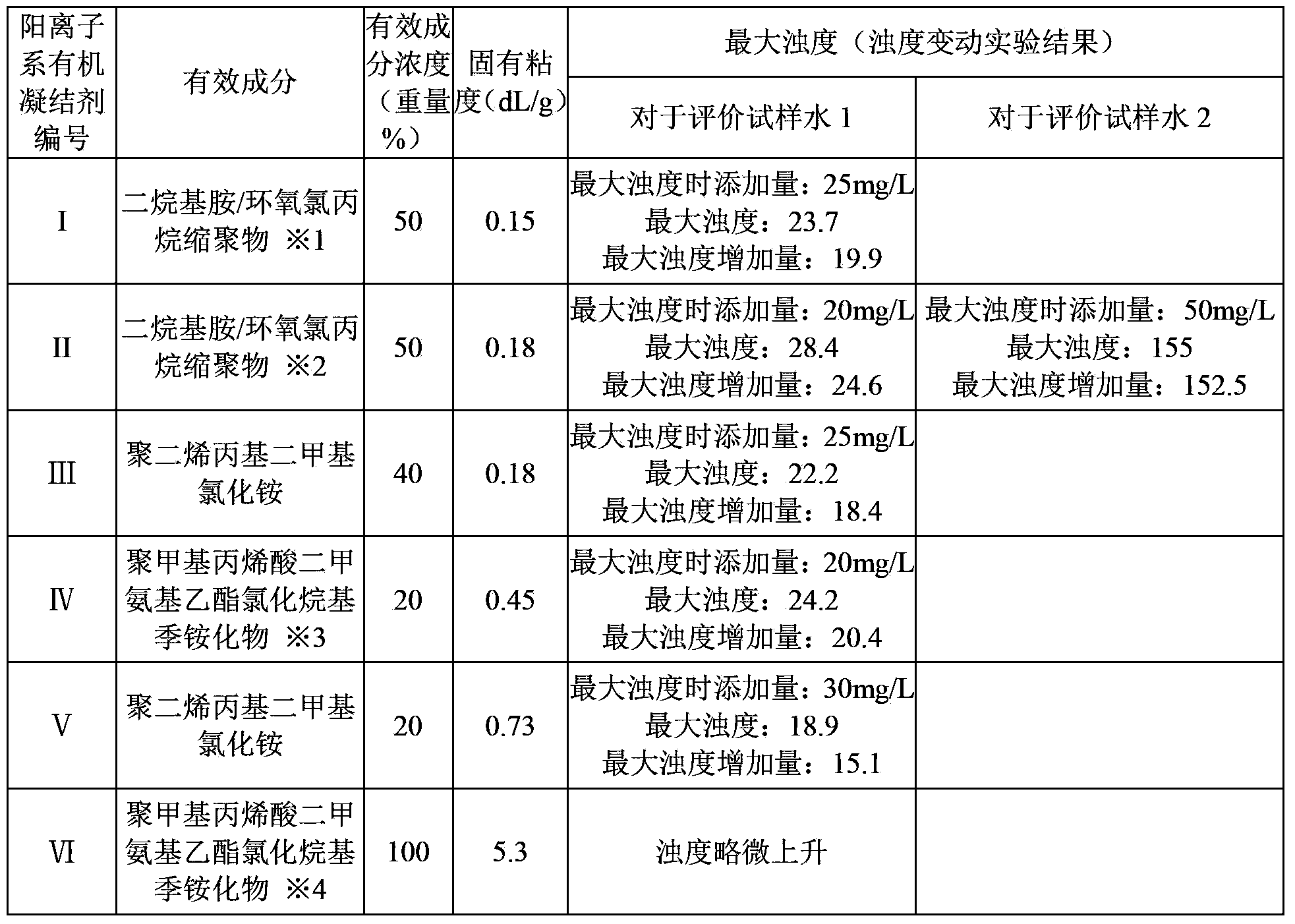

Embodiment 10、12~14

[0180] Set the maximum turbidity increase of the cationic organic coagulant to 100%, and set the addition amount of the cationic organic coagulant with an intrinsic viscosity of 0.5dL / g or less so that the turbidity increase rate becomes 50-90%. When 10 to 30 ppm, preferably 20 ppm of PAC is added, the SDI conversion value of filtered water is 3.50 to 4.76, which is judged to be substantially good.

[0181] When the turbidity increase rate is about 70%, the addition amount of the cationic organic coagulant shows the best results, and the effect decreases when the turbidity increase rate is close to 50% and close to 90%.

[0182] The cationic organic coagulant having a larger turbidity increase tends to have a larger absolute effect.

[0183] (4) Comparative examples 1-3, 5-9

[0184] Based on the addition of cationic organic coagulants whose turbidity increase rate is less than 50% and more than 90%, the fouling of the reverse osmosis membrane will be increased. When the tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com