Patents

Literature

65results about How to "Speed up the sinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

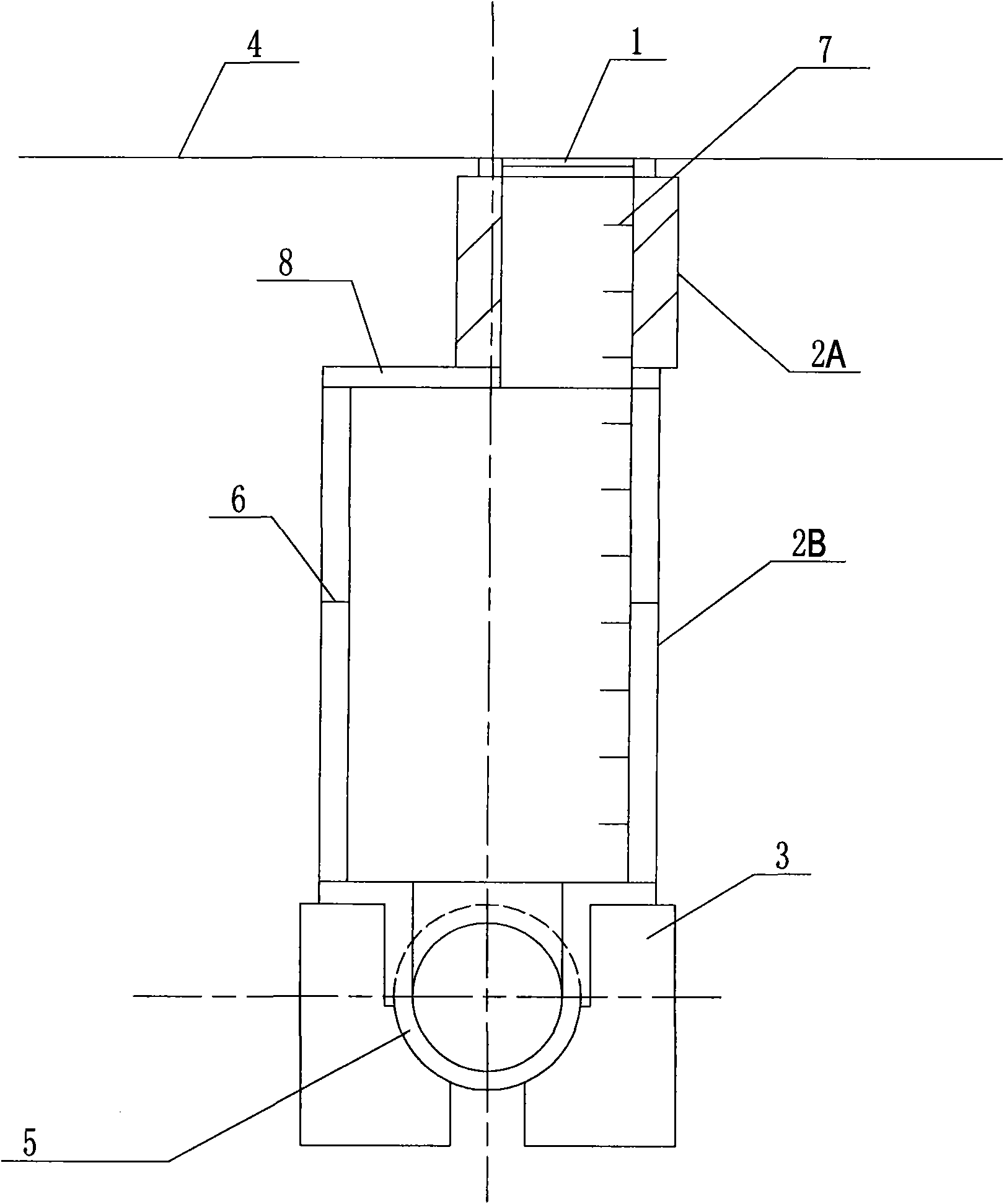

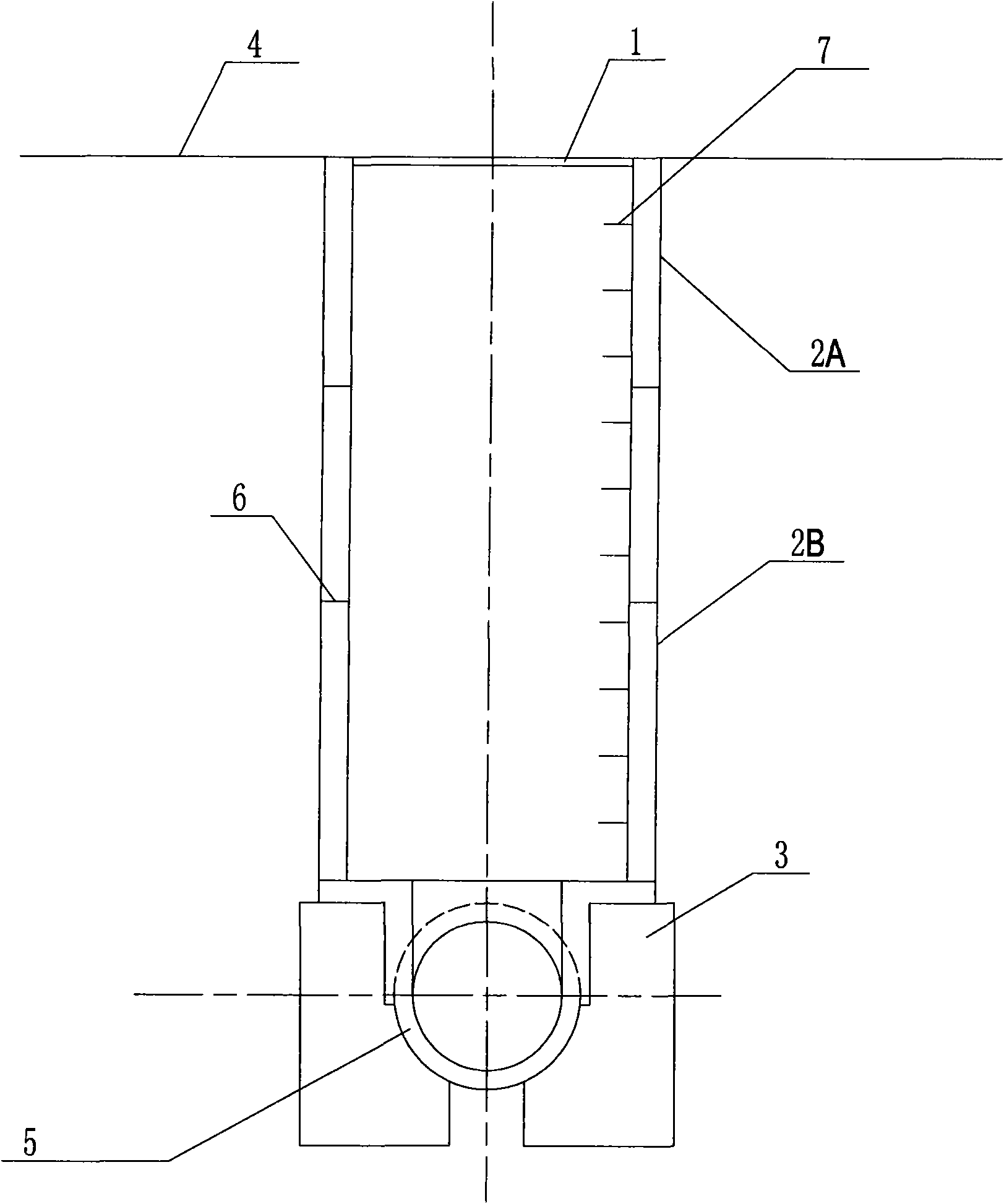

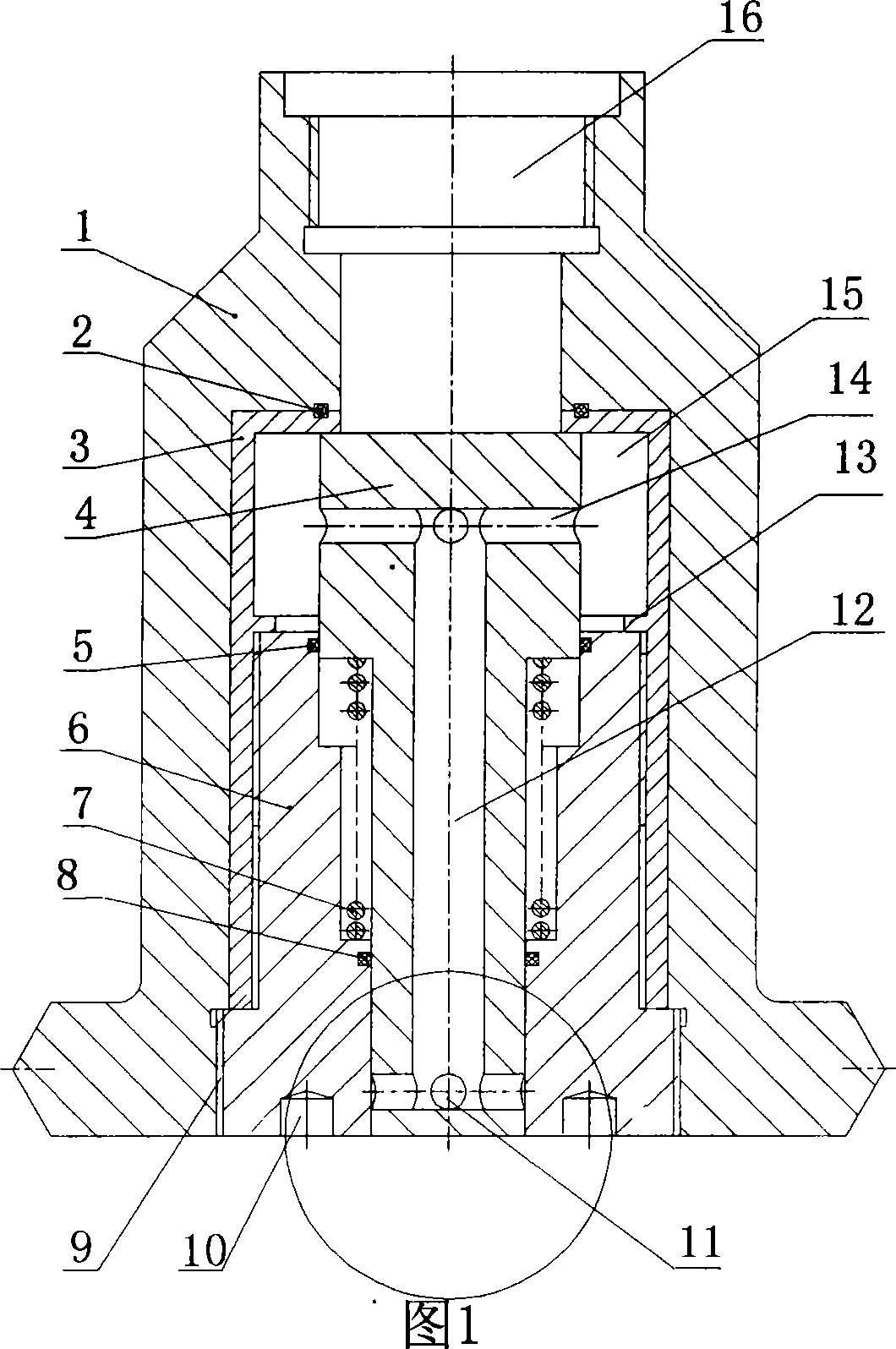

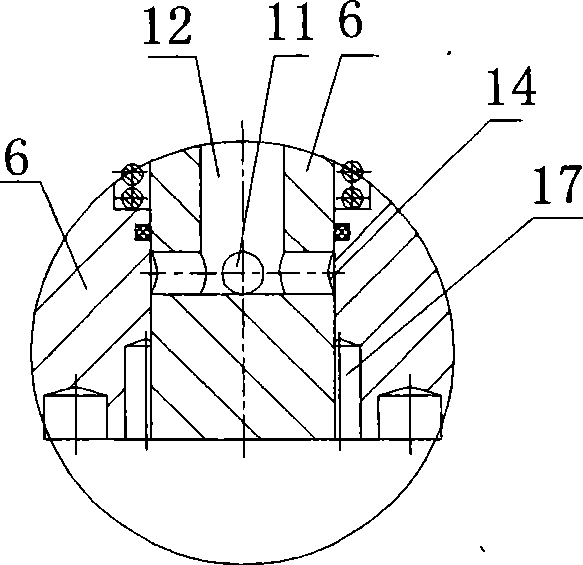

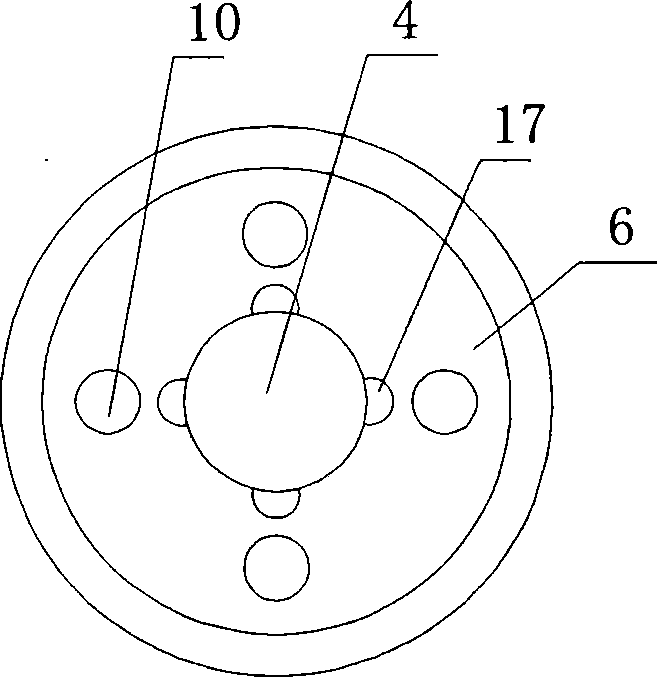

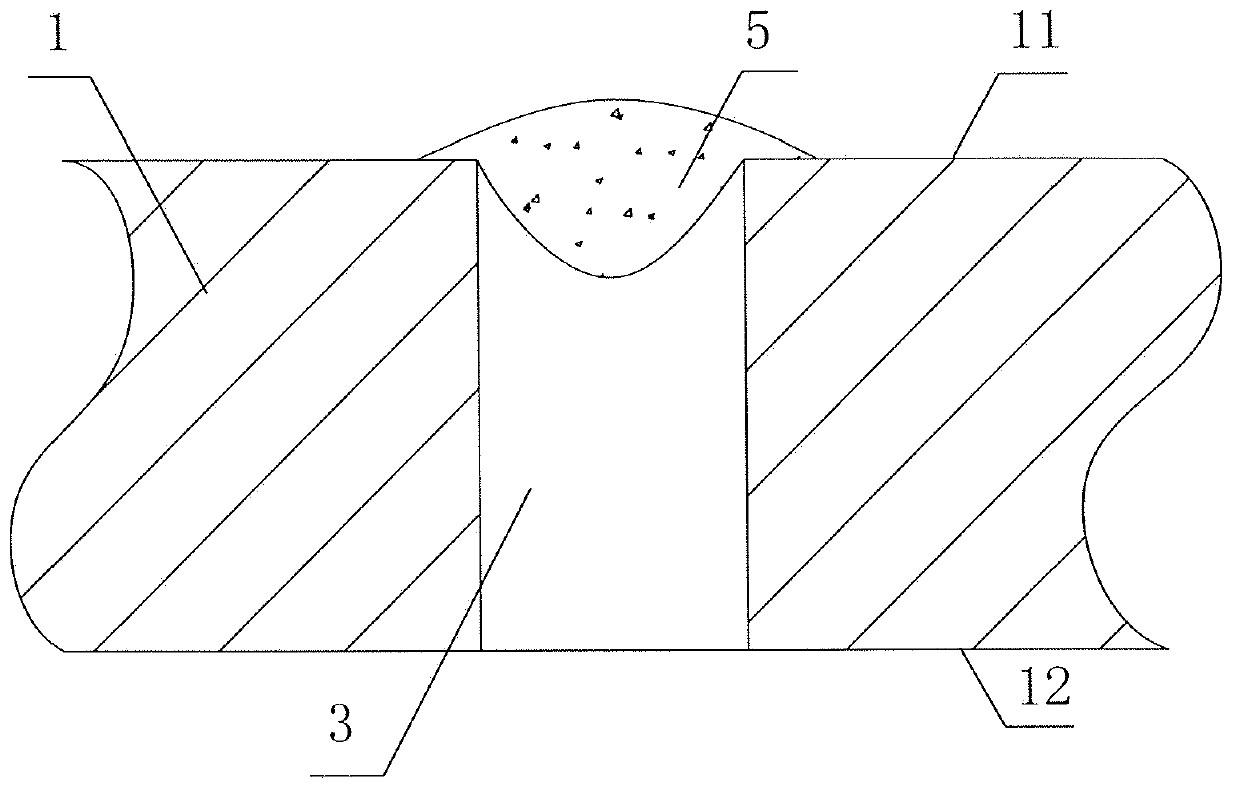

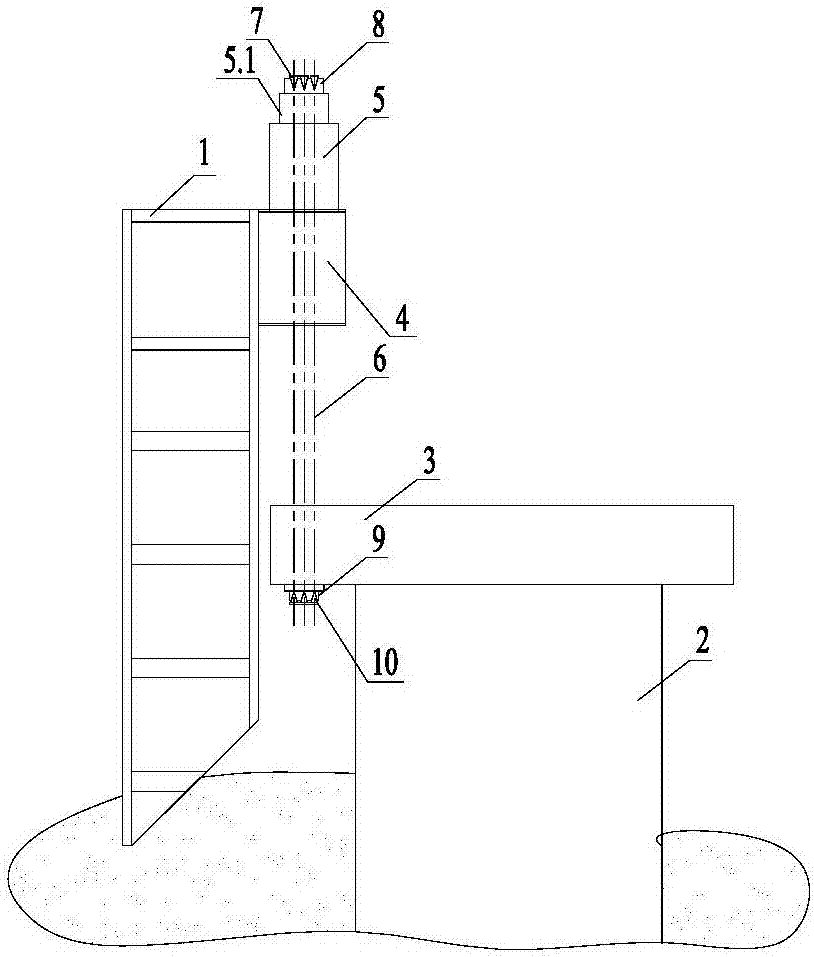

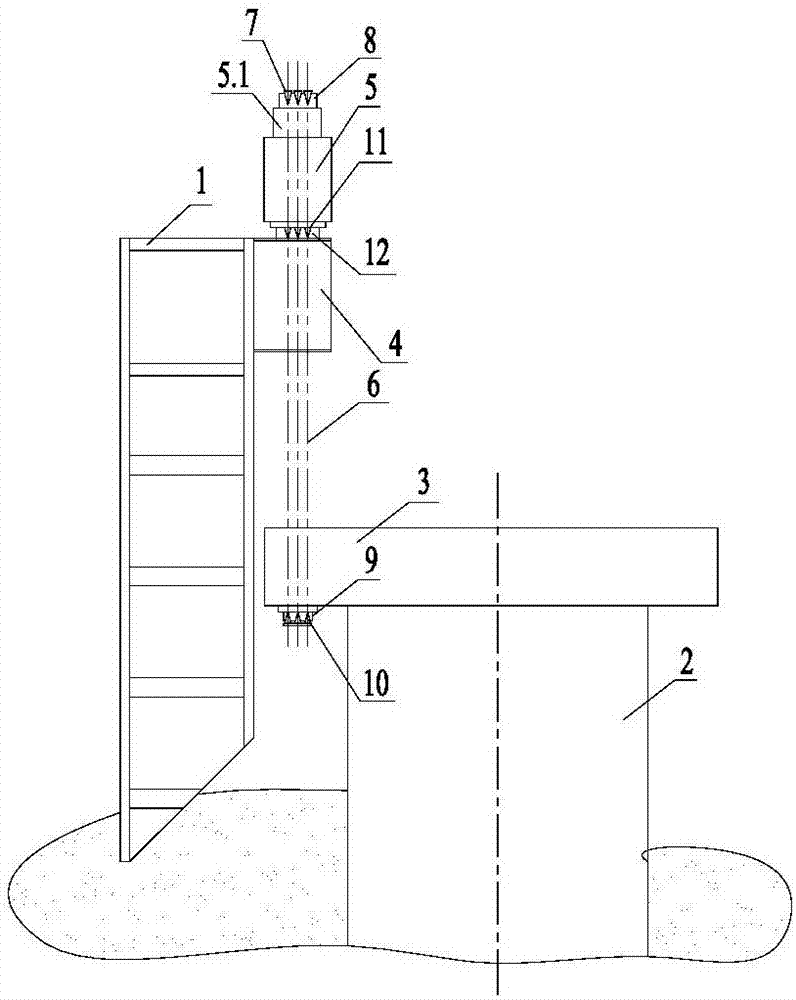

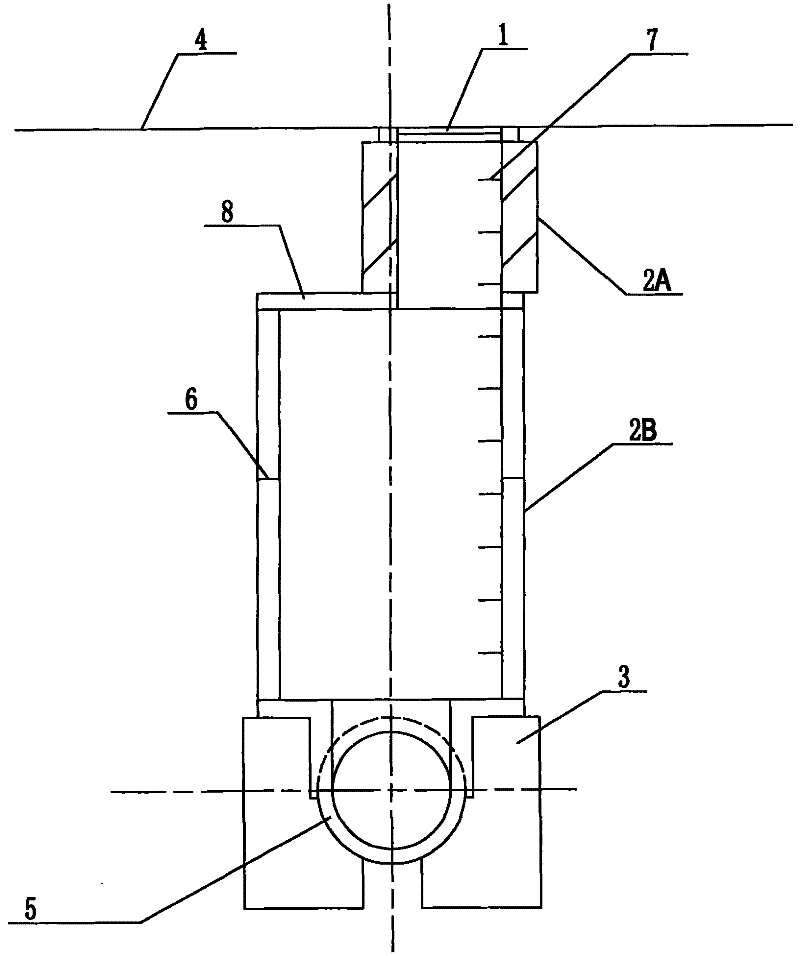

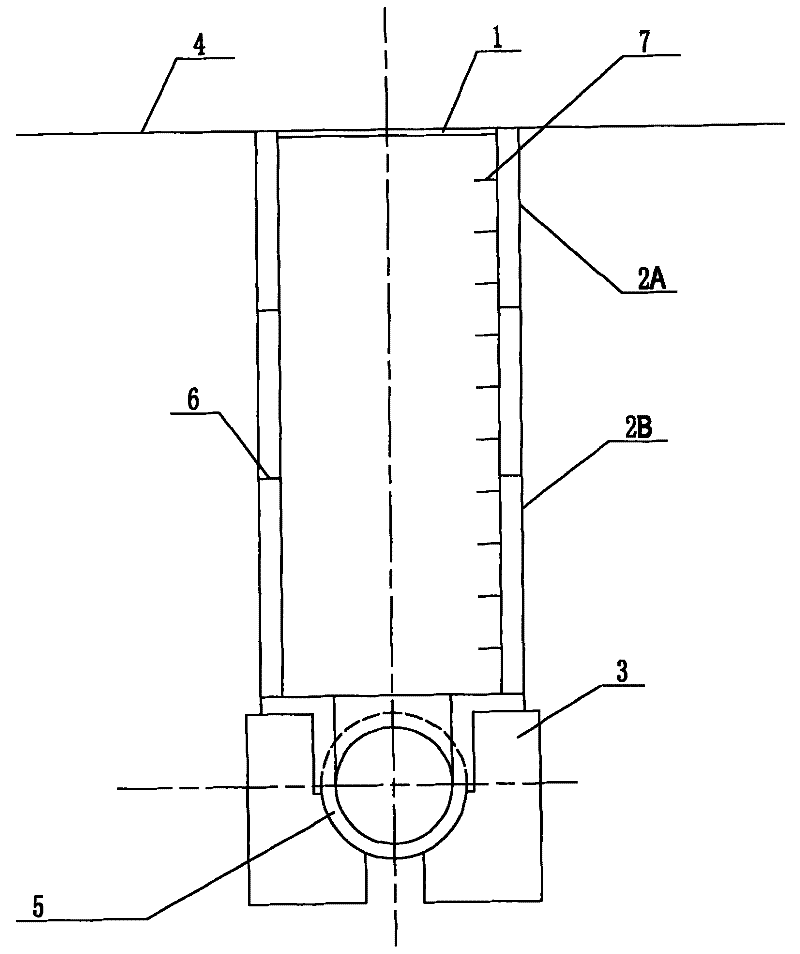

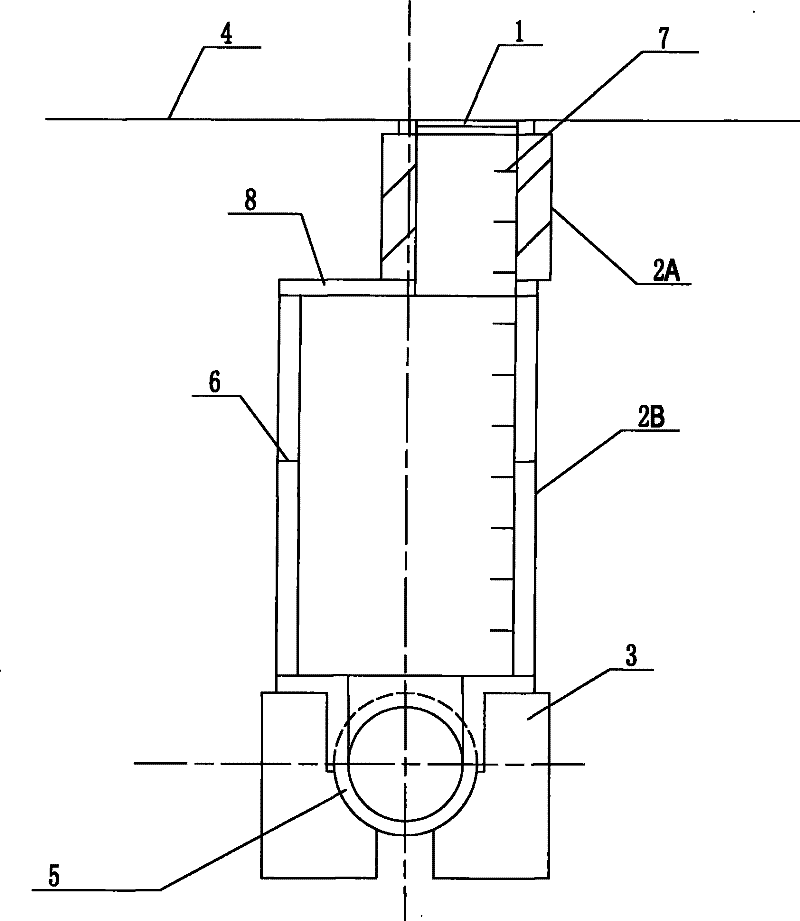

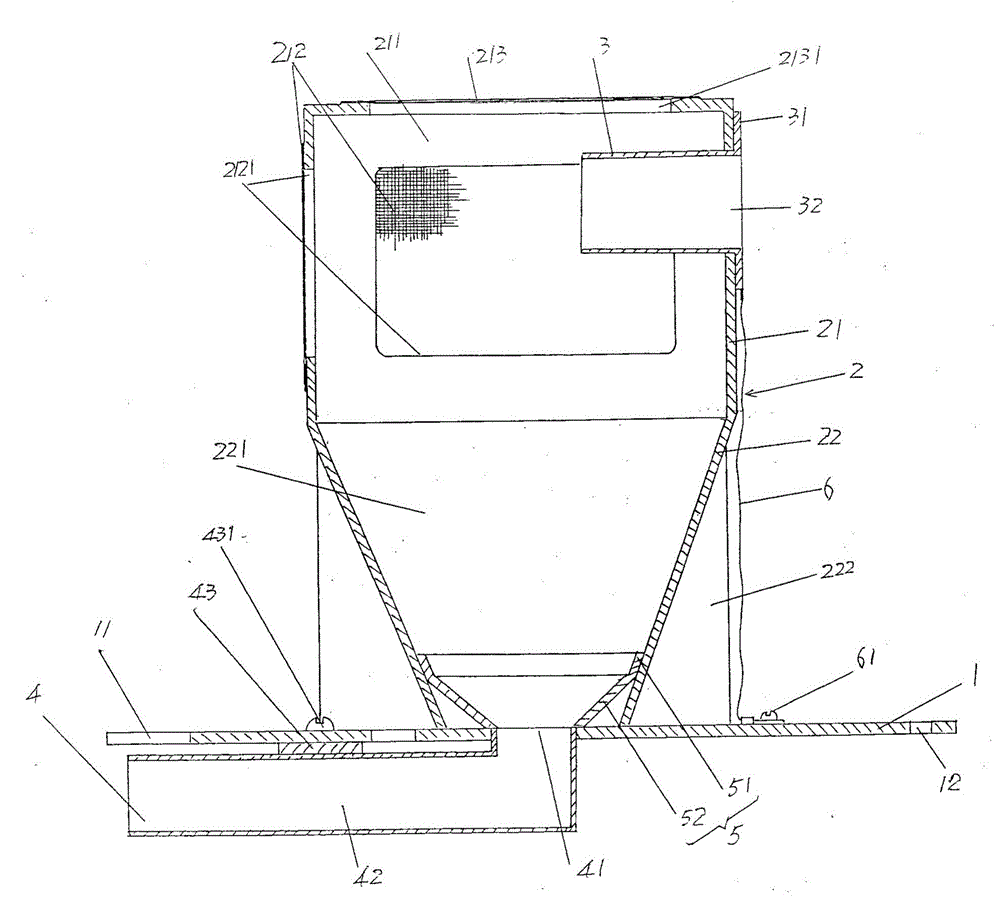

Submersed type inspection well and construction method thereof

InactiveCN101684669ASolve the contradiction that the retention interval is too shortEasy constructionSewerage structuresDowntown areaWellbore

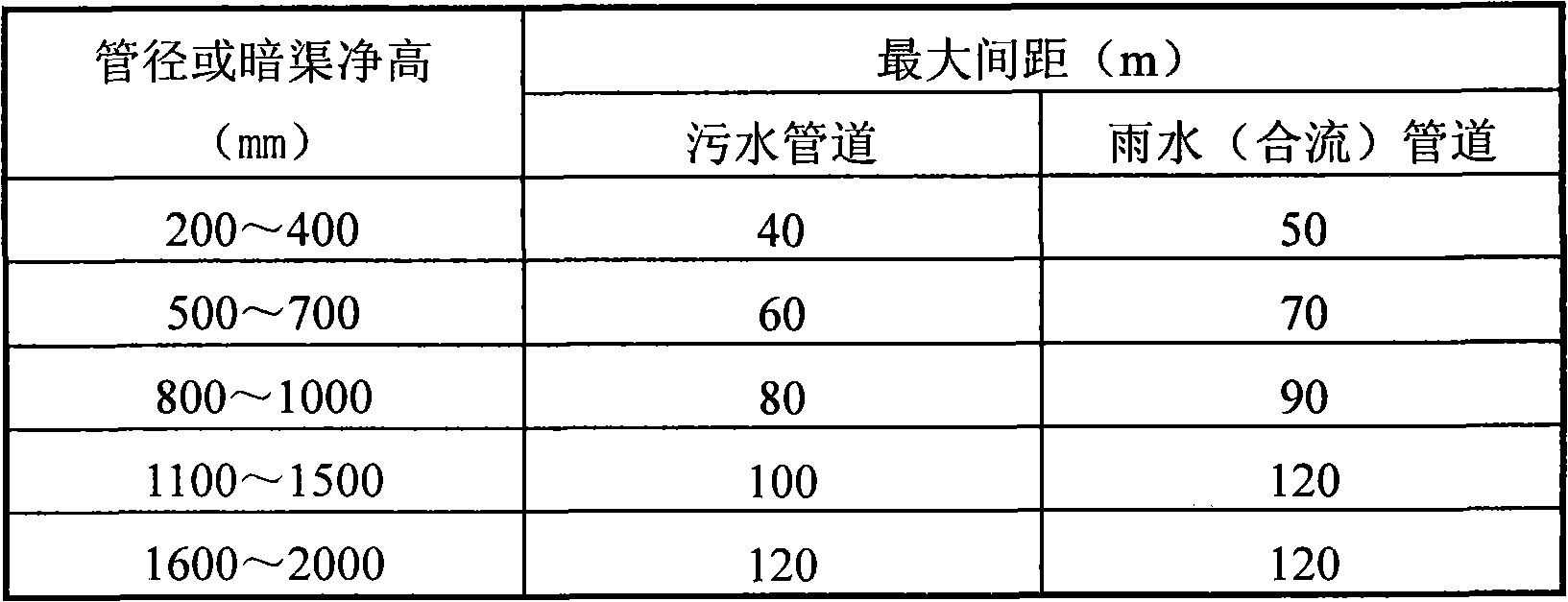

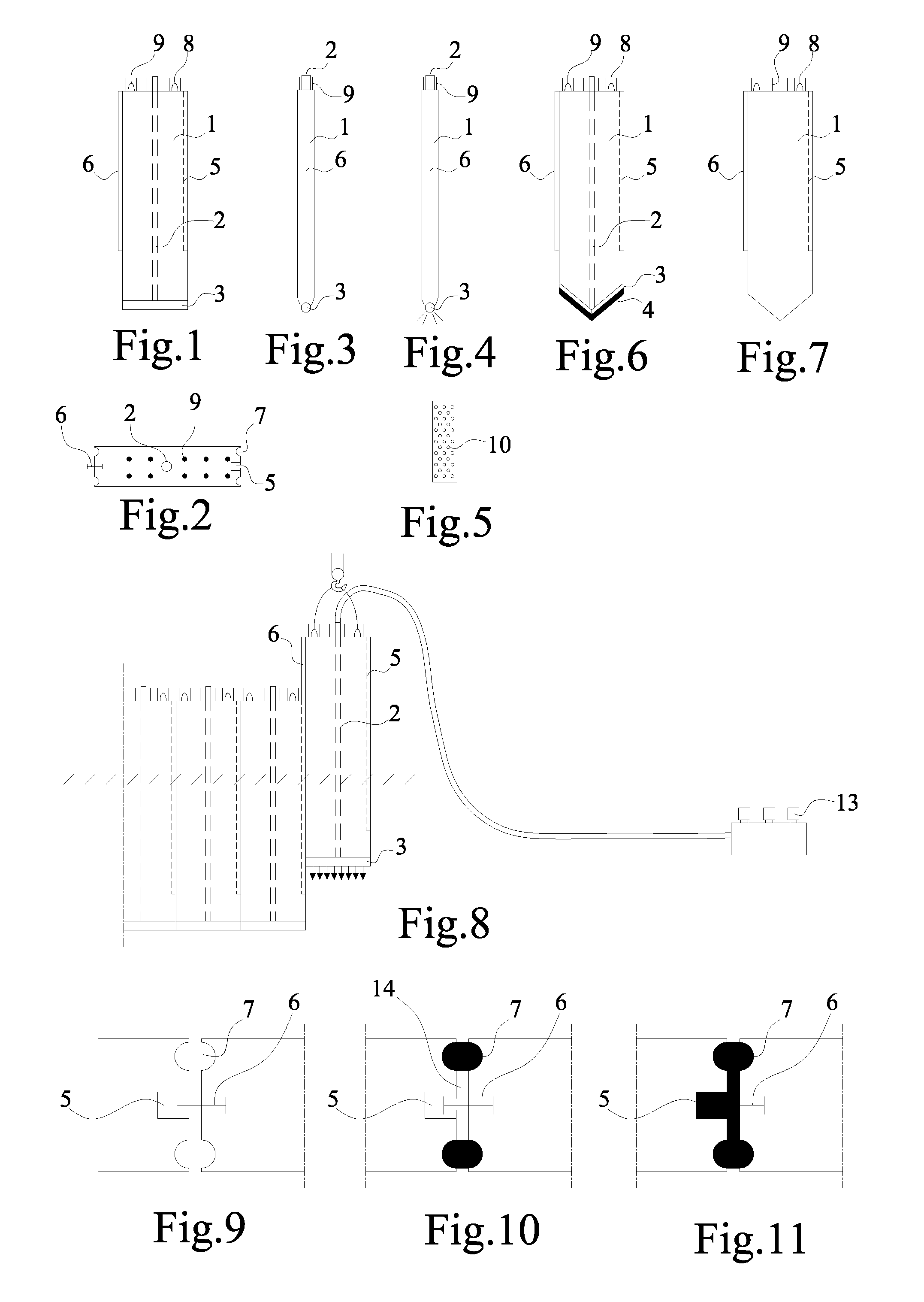

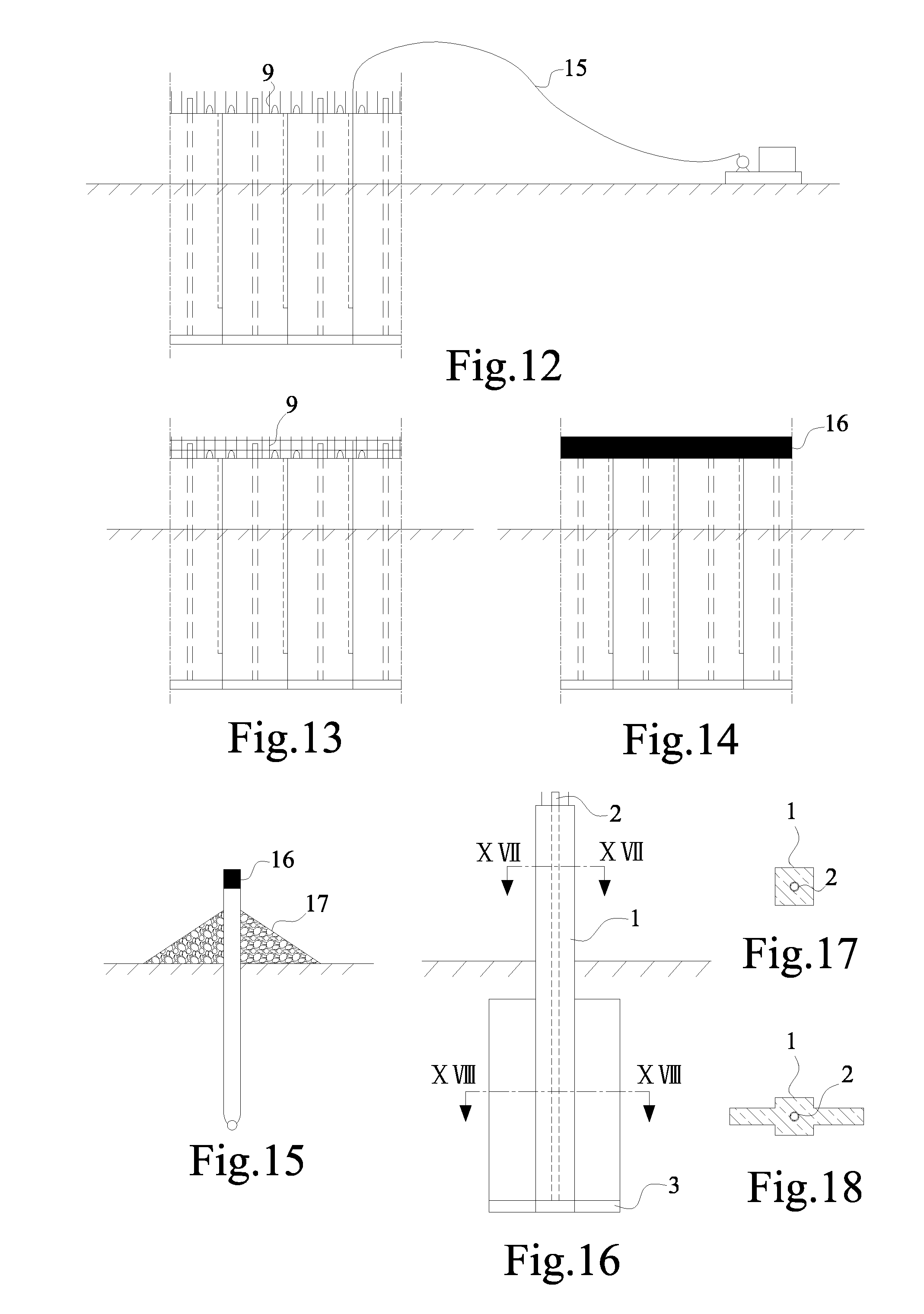

The invention discloses a submersed type inspection well which comprises a well cover above the ground as well as a shaft and a well body structure below the well cover, wherein the traditional drainage pipe is arranged below the shaft, a foundation is arranged between the lower end of the shaft and the drainage pipe, and the lower end of the shaft, the upper end of the foundation and the pipe arepoured into a whole; the diameter of the foundation is larger than the outer diameter of the shaft, and the bottom end of the foundation is located below the sheath of the traditional drainage pipe;and the bottom end of the foundation is inwards extended below the traditional drainage pipe. The invention also discloses a construction method for realizing the inspection well, which comprises thefollowing construction stages: (1) placing the inspection well; (2) submersing, joining and measuring the shaft; (3) manufacturing the foundation of the inspection well and communicating the shaft with the traditional drainage pipe; and (4) mounting a shaft cover plate and a ladder. By adopting the structure and the method of the invention, the inspection well is conveniently manufactured by adopting a submersed type construction method so as to be beneficial to carrying out long-distance jacking pipe construction and developing novel prefabricated inspection well structures and convenient for carrying out pipe engineering construction in downtown areas without excavating.

Owner:吴纪东 +1

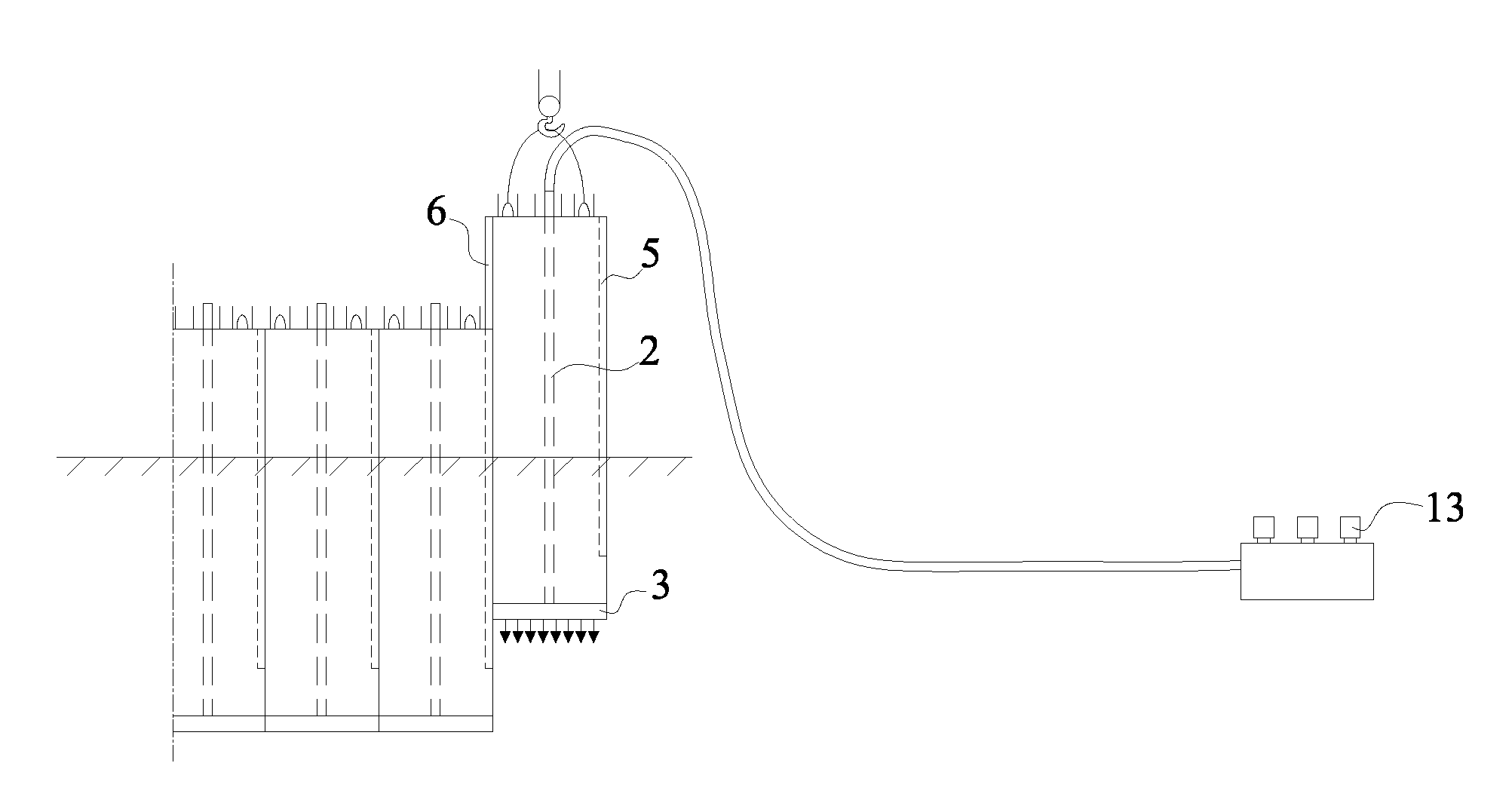

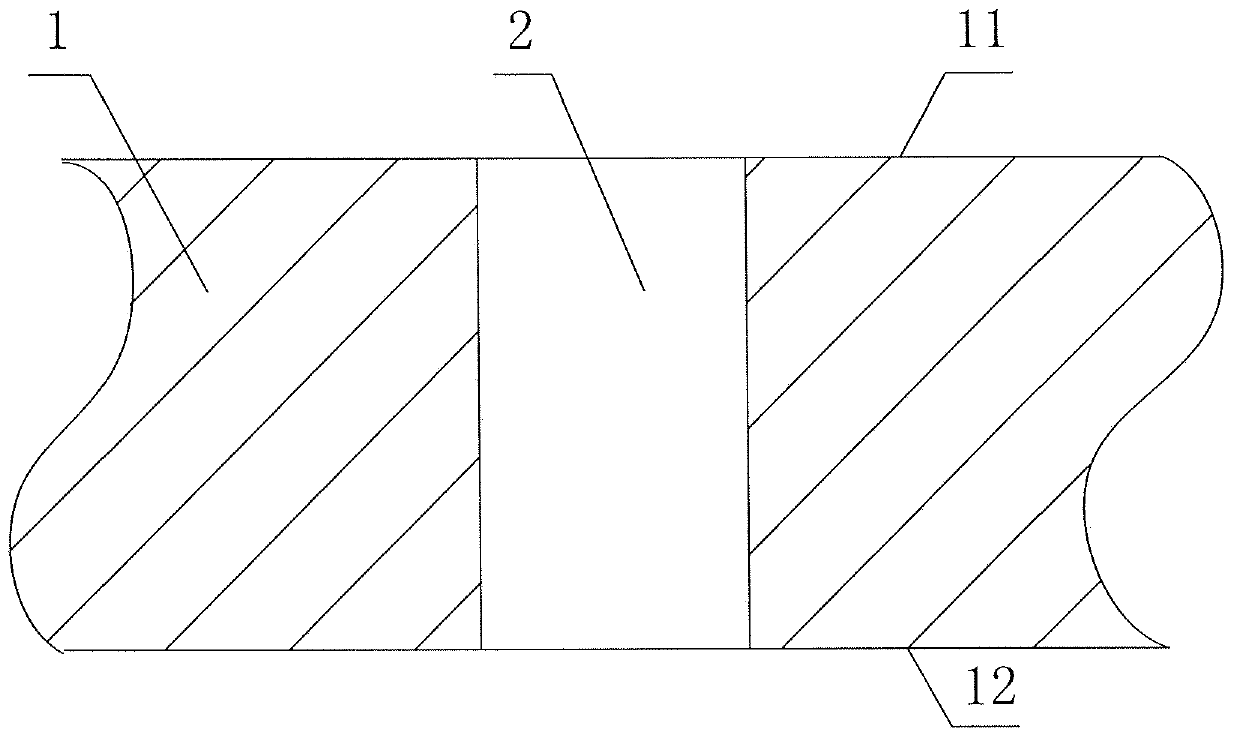

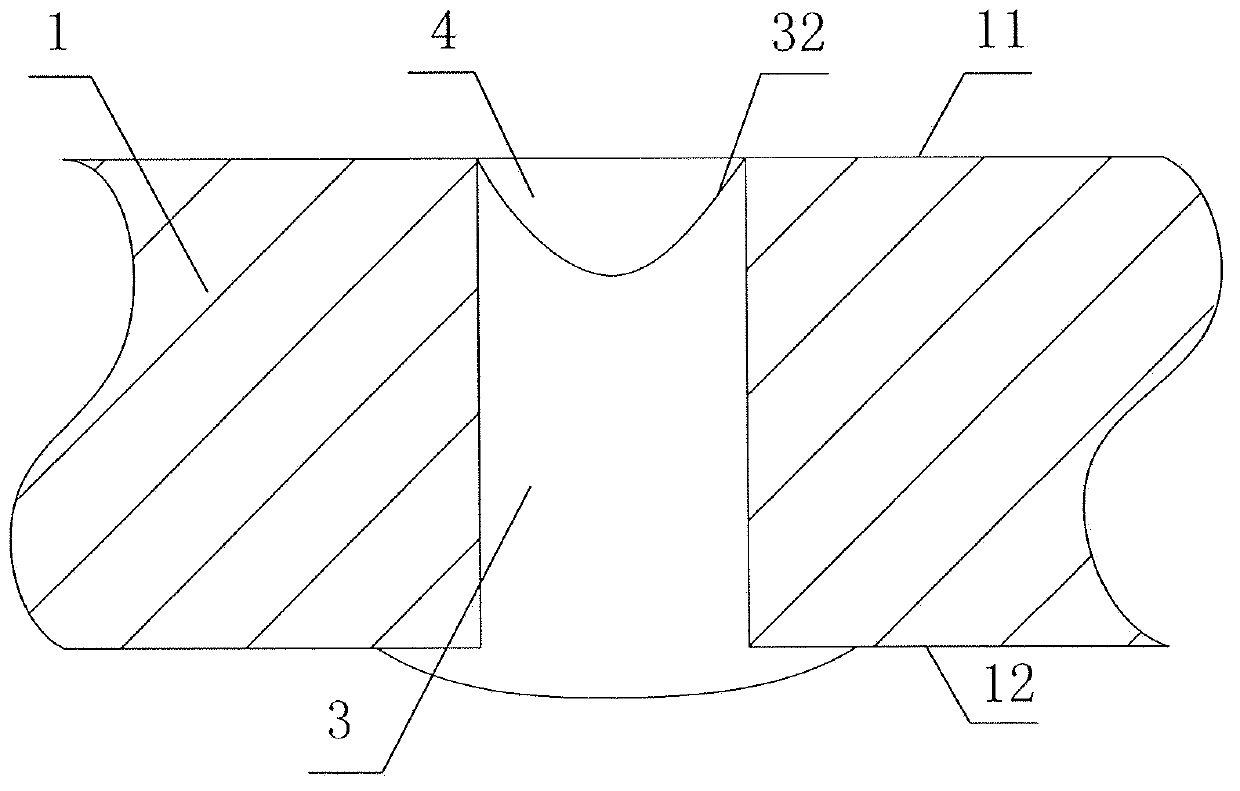

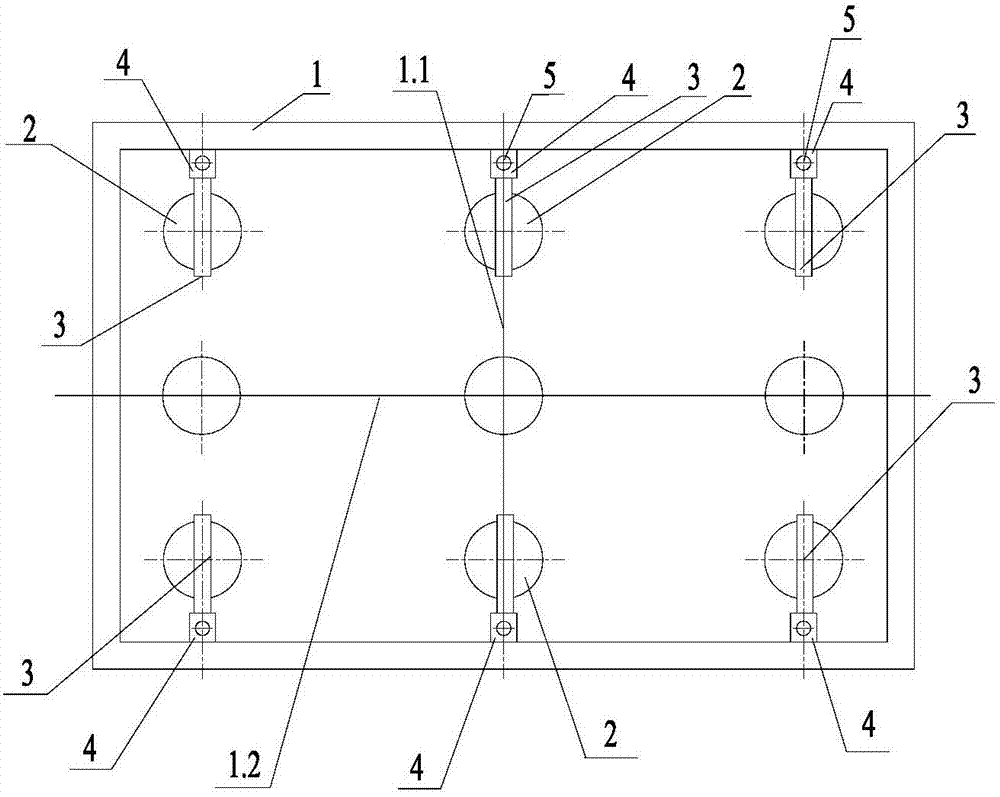

Hydraulic Sliding Insertion Panel and Its Using Method

InactiveUS20100054859A1Improve carrying capacityLow costSoil drainageIrrigation ditchesReinforced concreteSlide plate

A hydraulic sliding insertion panel comprises a reinforced concrete poling board (1), a flow guide tube (2) is set in the poling board (1) and a water distributing pipe (3) communicated with the flow guide tube (2) is set in the bottom of the poling board; moreover, a slideway (5) and a slide plate (6) are set on the two sides of the poling board (1) respectively, and an erection loop (8) is set on the top of the poling board. The using method comprises steps as follows: (A) firstly, hoisting the reinforced concrete poling board by a lifting appliance and sinking it into the stratum by hydraulic jet via the flow guide tube and the distributing pipe, then inserting the slide plate of the other reinforced concrete poling board into the stratum in the hollow square steel slideway with a gap of the poling board sunk in the stratum; (B) flushing the isolated watercourse firstly, then setting down the strip bag and infusing the grout, so forming an inner cavity isolated from the exterior between the boards; (C) putting a grout pipe into the hollow square steel in the inner cavity, and filling the grout subsequently; (D) casting the top crossbeam in position after seizing the preset steel bars and the added cross steel bars. In addition, step (D) can be omitted according to the requirements of the engineering.

Owner:HE FU RONG +2

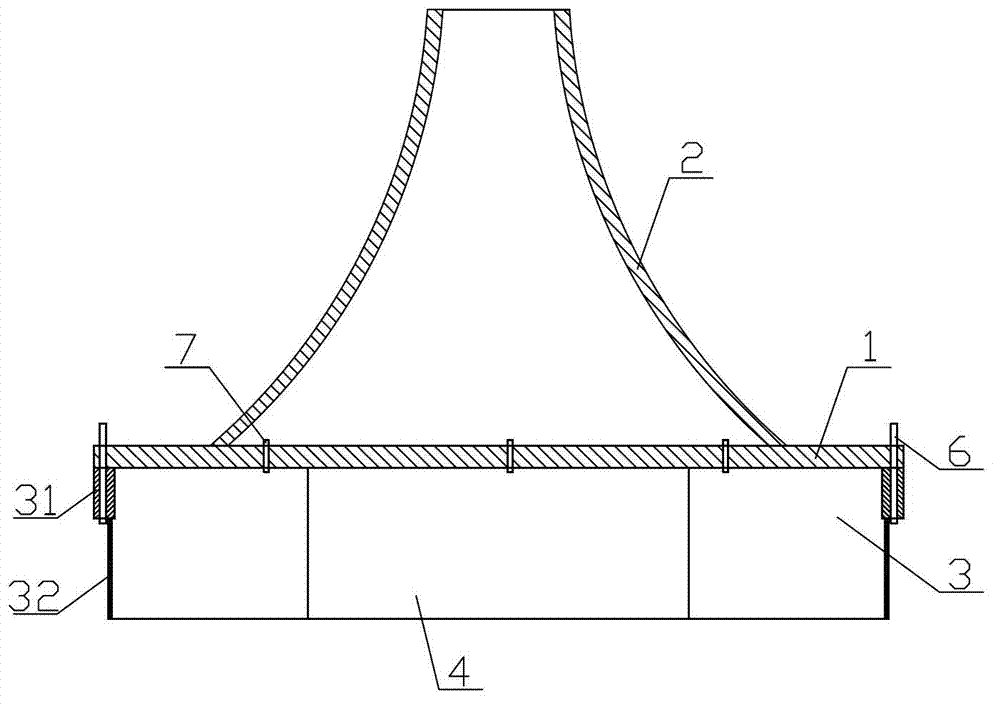

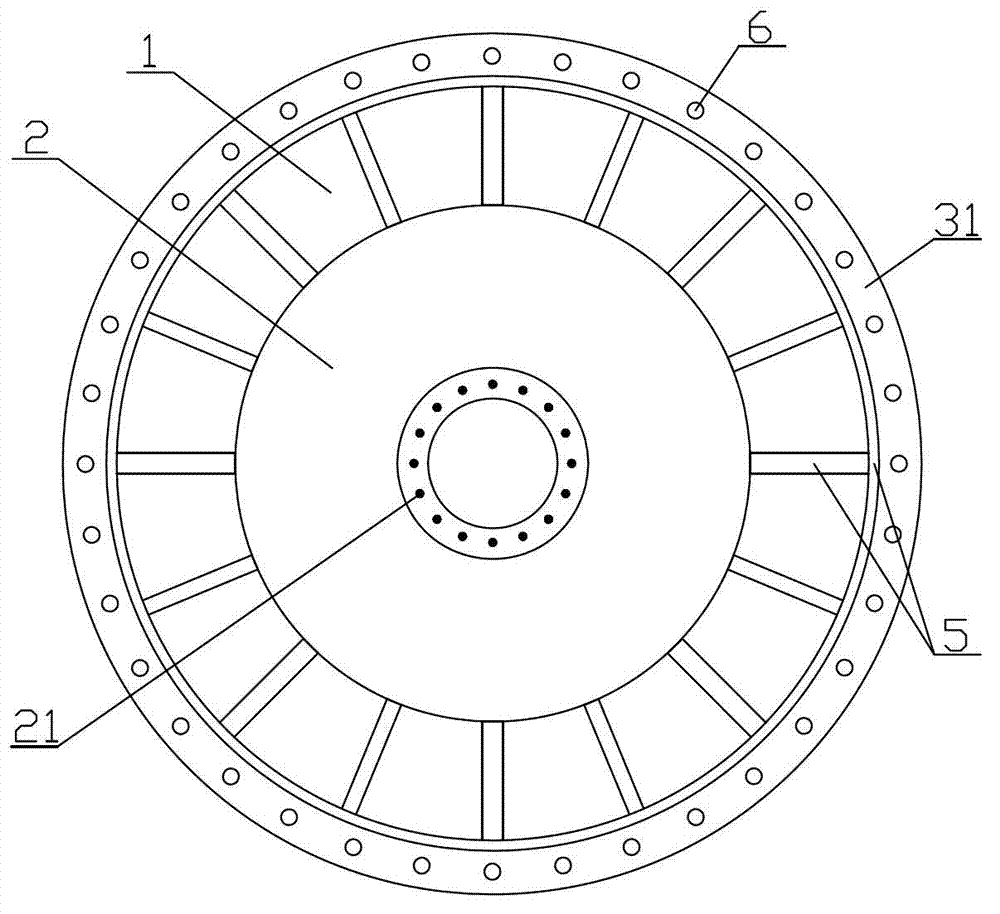

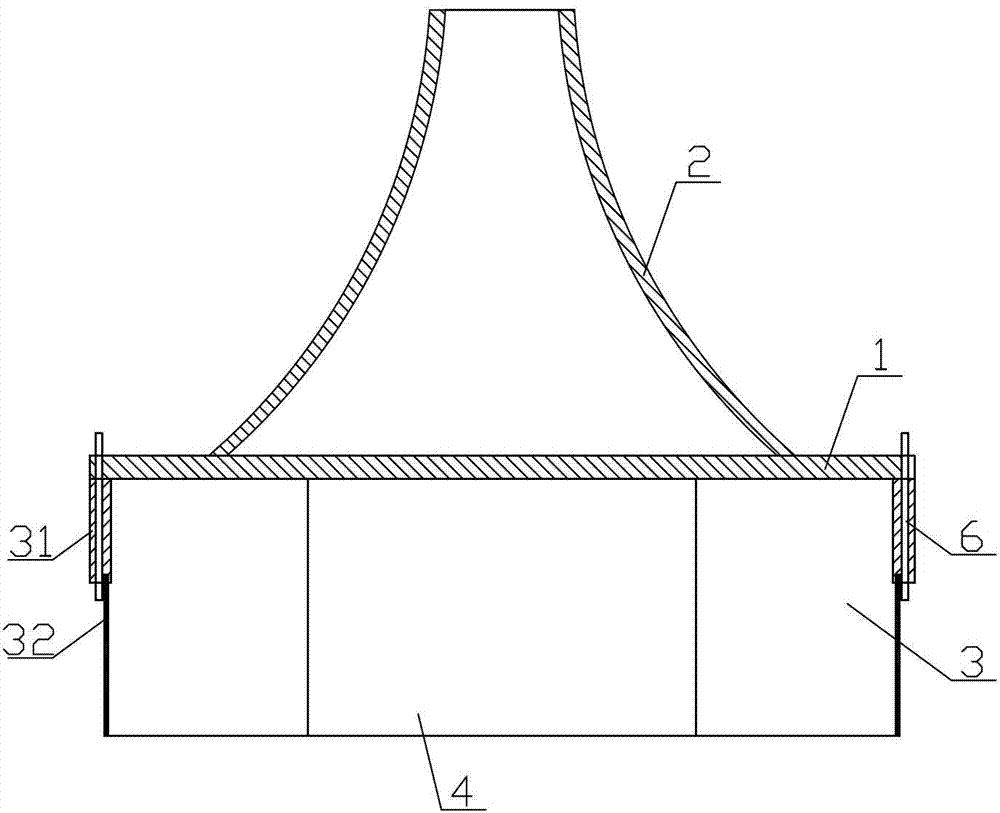

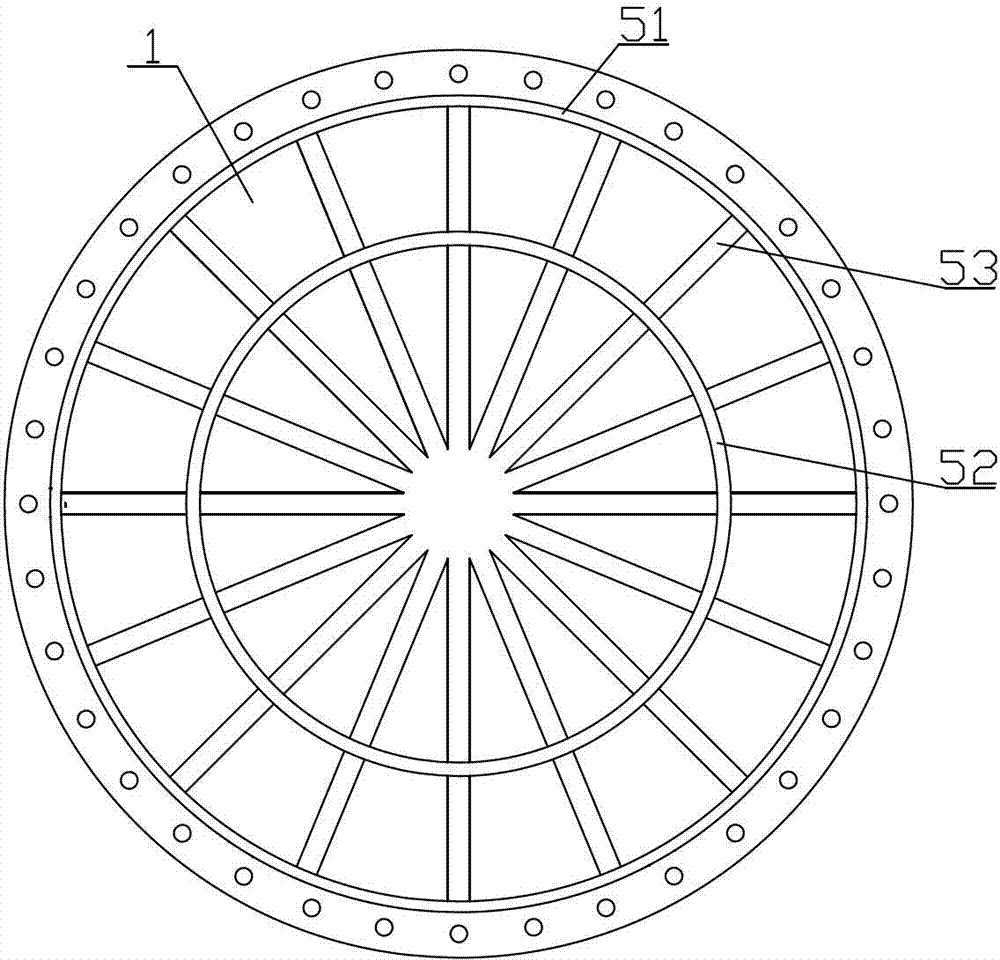

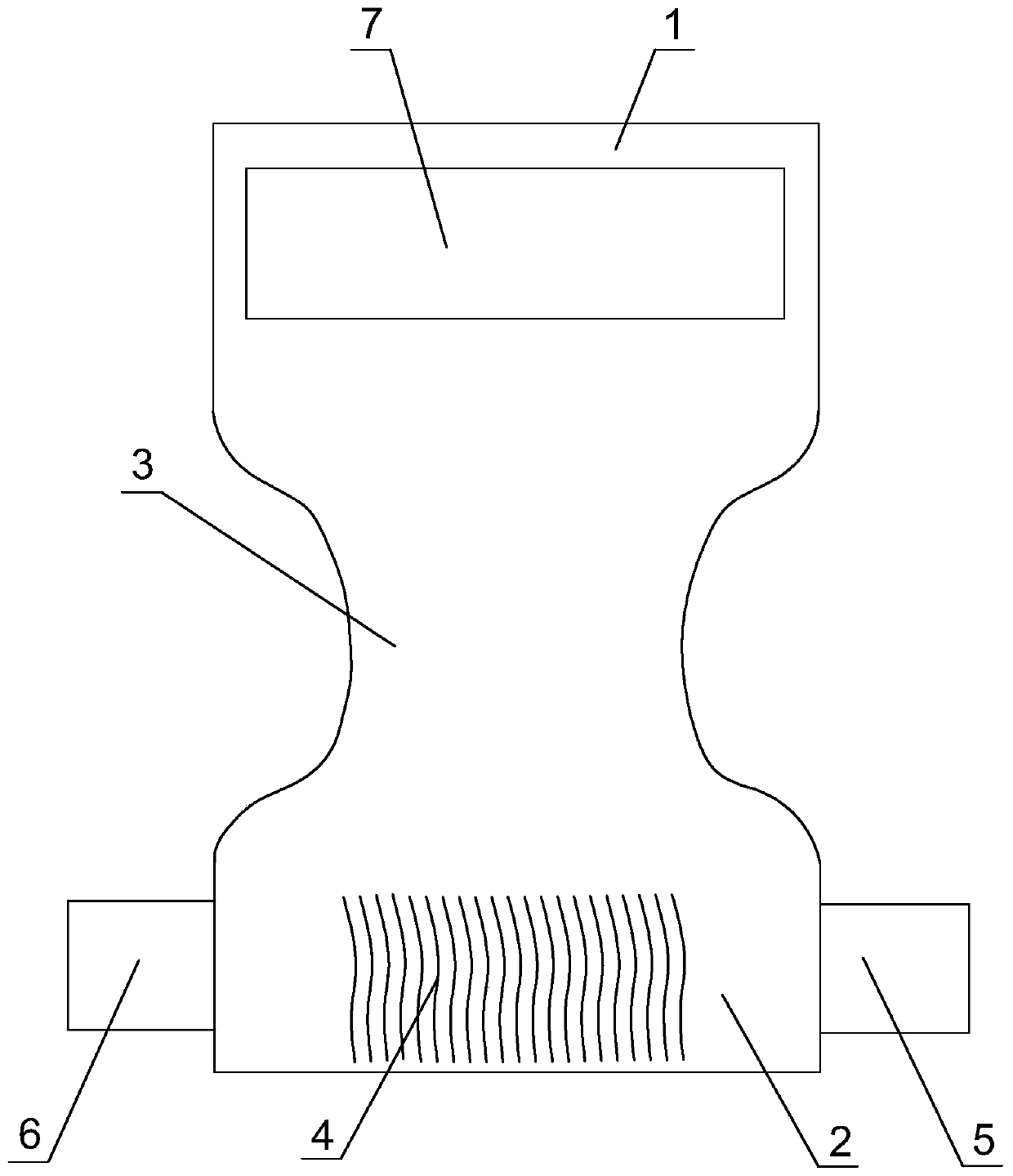

Gravity type foundation structure and construction method thereof

InactiveCN102877482ASpeed up the sinkingImprove stabilityFoundation engineeringGravitationSteel cylinder

The invention discloses a gravity type foundation structure and a construction method thereof. A concrete cylinder-type pressure loading cabin is arranged on a concrete top cover; a cylinder structure formed by a concrete cylinder wall and a steel cylinder wall is arranged on the lower side of the concrete top cover; first pipelines are uniformly arranged in the concrete cylinder wall along the radial direction; and a steel subdivision plate is arranged in the internal space of the steel cylinder wall. The construction method comprises the following steps of: prefabricating the gravity type foundation structure on the land; transporting the whole foundation to a construction site in a floating mode, and performing self-weight sinking construction and negative pressure sinking construction; after the negative pressure sinking construction is stopped, performing groundbreaking sinking construction through the first pipelines; performing grouting operation through the first pipelines and second pipelines on sub-cabins; and filling heavy objects in the concrete cylinder-type pressure loading cabin, performing ballasting operation, and simultaneously performing riprap ballasting operation above the concrete top cover and at the periphery of the concrete cylinder-type pressure loading cabin. By the structure and the method, transportation and construction difficulties can be reduced, transportation and installation speeds can be increased, and the applicability to a soil body can be enhanced, so that a construction period is shortened, and engineering cost is substantially reduced.

Owner:TIANJIN UNIV

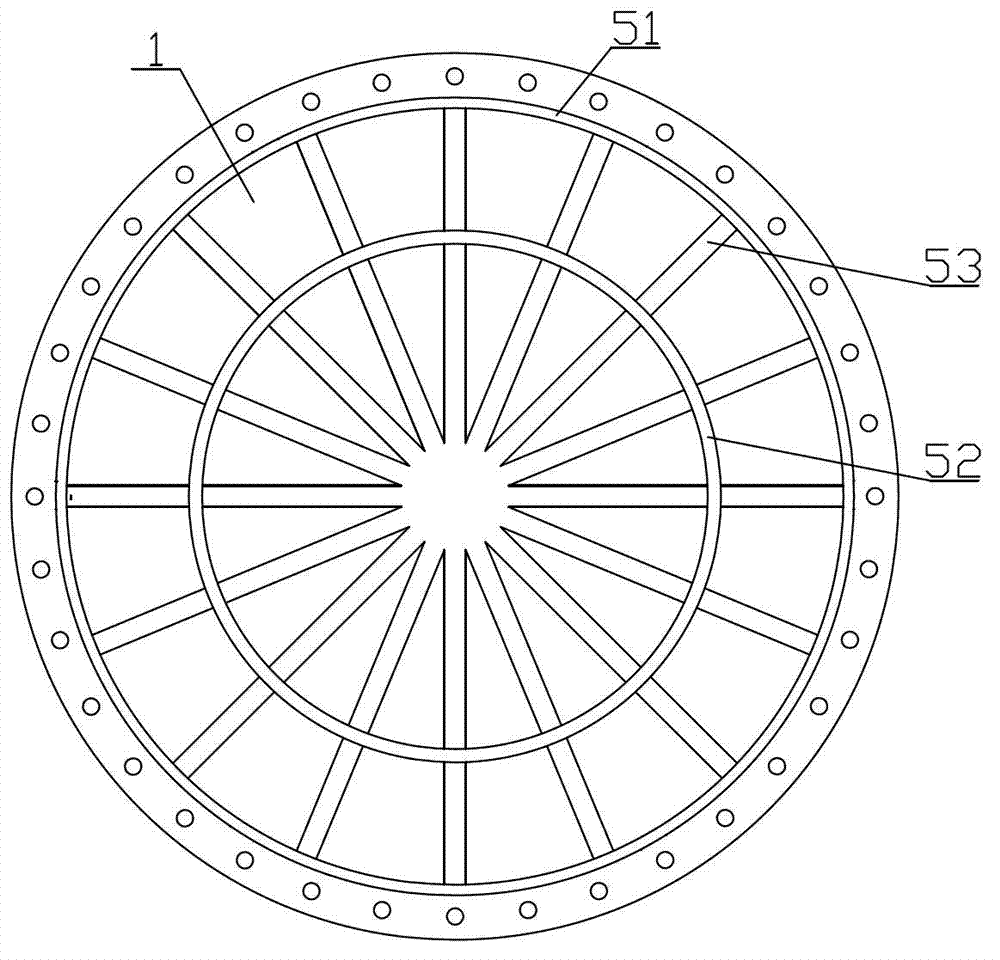

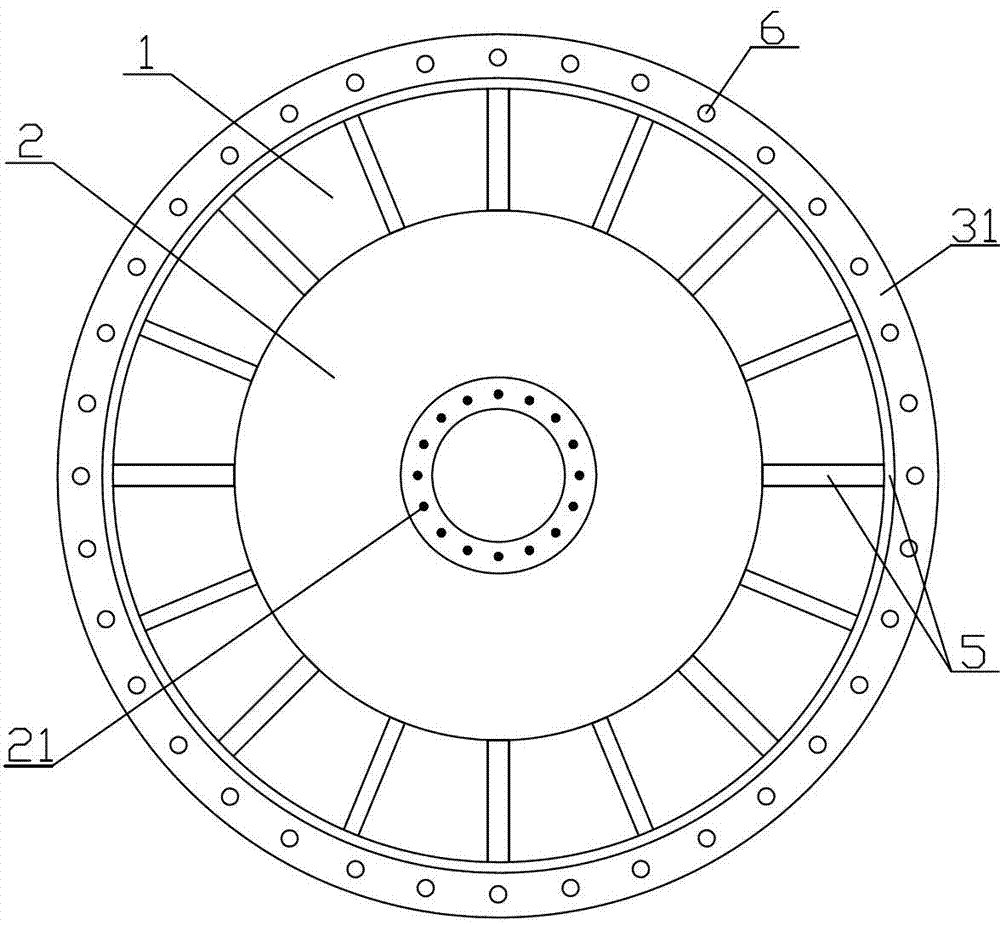

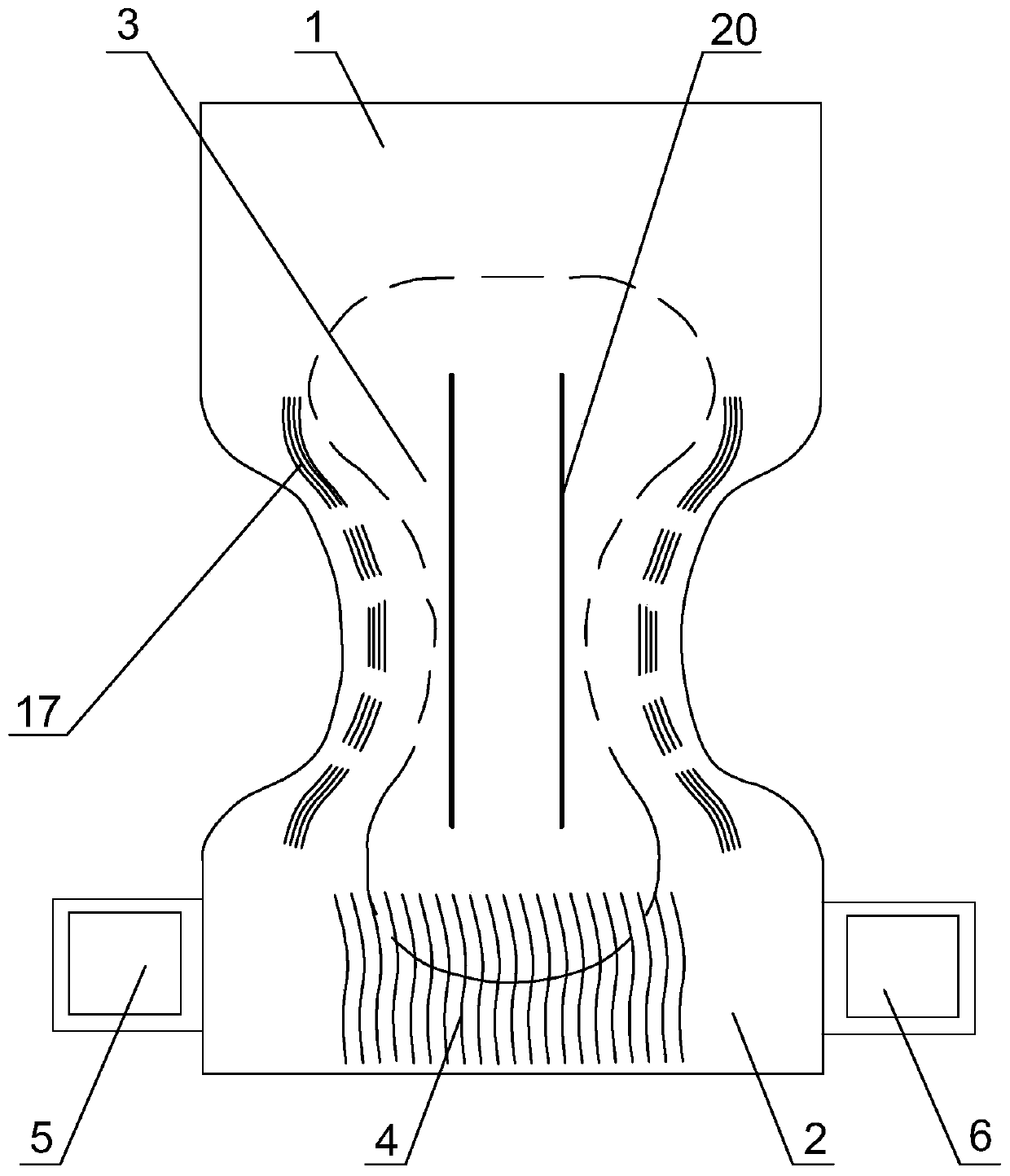

Steel-concrete composite cylinder-type foundation structure and construction method thereof

ActiveCN102877484ASpeed up the sinkingImprove sinking rateFoundation engineeringPositive pressureStructure system

The invention discloses a steel-concrete composite cylinder-type foundation structure and a construction method thereof. A concrete cylinder-type transition section with a cambered wall surface is arranged on a concrete top cover; a cylinder structure which is formed by a concrete cylinder wall and a steel cylinder wall is arranged on the lower side of the concrete top cover; air blow / water pipes are uniformly arranged in the concrete cylinder wall along the radial direction; and a steel subdivision plate is arranged in the internal space of the steel cylinder wall. The construction method comprises the following steps of: prefabricating the steel-concrete composite cylinder-type foundation structure on the land; transporting the whole foundation structure to a construction site in a floating mode, and performing self-weight sinking construction and negative pressure sinking construction; after the negative pressure sinking construction is stopped, performing groundbreaking sinking construction through the air blow / water pipes; and leveling by applying different in-cabin positive pressure onto all sub-cabins through a pump system when the foundation structure is inclined in the sinking process. The foundation structure can be extremely easily sunk into a soil body to reach a designed sinking depth by overcoming the resistance of the soil body, and the sinking speed and the sinking arrival rate of a cylinder-type foundation can be substantially improved, so that the construction period of a foundation structure system is shortened, and engineering cost is greatly reduced.

Owner:TIANJIN UNIV

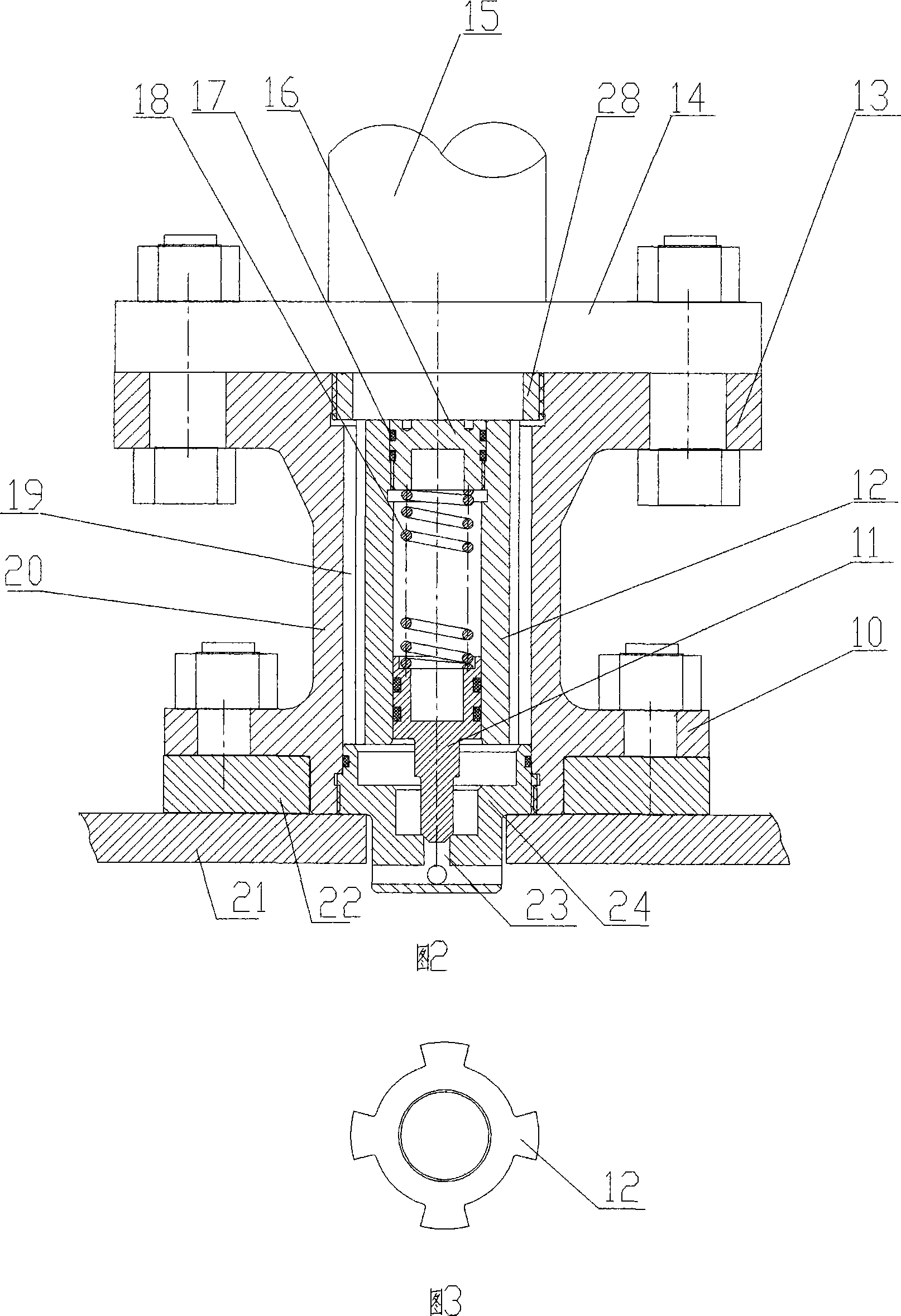

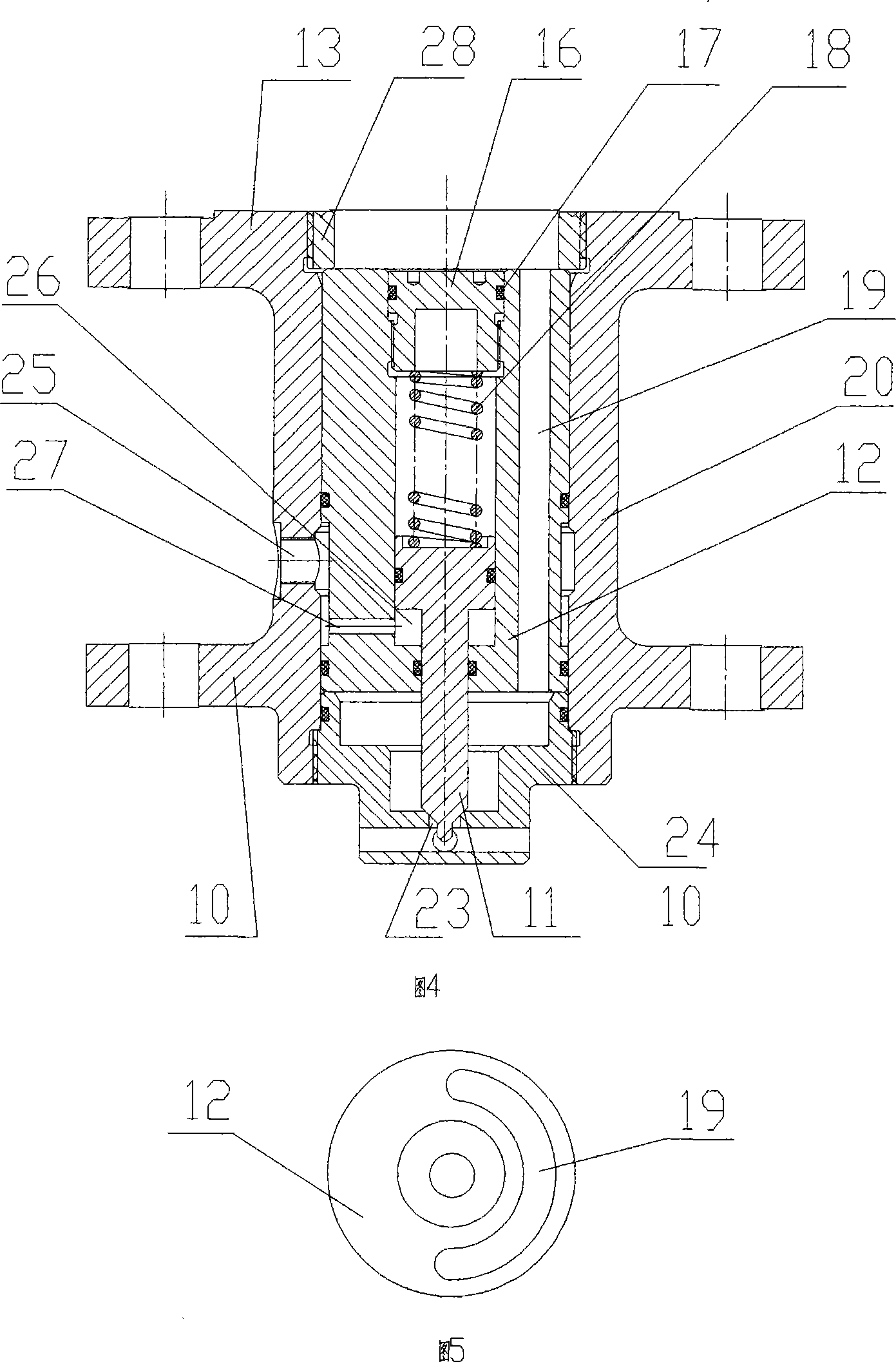

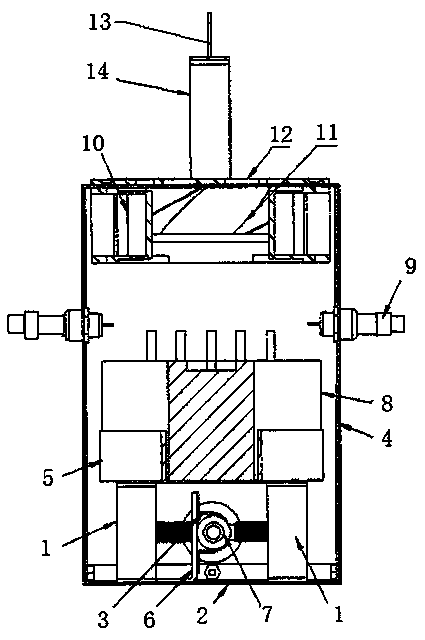

Block-resistant spraying device

ActiveCN101429769AImprove the efficiency of migration constructionImprove stabilityArtificial islandsUnderwater structuresEngineeringHigh pressure water

The invention provides an anti-clogging jetting machine, which consists of a shell, a piston sleeve, a composite piston and an anticorrosive inner sleeve, wherein the shell is provided with a cavity, and the top of the shell is provided with a high-pressure water pipe joint; the high-pressure water pipe joint and a lower cavity are arranged downwards; the bottom of the piston sleeve is provided with a threaded convex ring, and the threaded convex ring at the bottom of the piston sleeve is rotatably connected with the bottom of the shell; the middle of the piston sleeve is provided with a trapezoidal hole with large upper part and small lower part; the lower end of the composite piston is provided with a small piston which is glidingly connected with a small hole at the bottom of the trapezoidal hole in the middle of the piston sleeve, and the upper end of the composite piston is provided with a large piston which is glidingly connected with the upper part of the trapezoidal hole; a spring is sleeved on an excircle of the small piston; the lower end of the spring is connected with the middle of the trapezoidal hole; the upper part of the composite piston is provided with a water inlet hole, and the lower part of the composite piston is provided with a blowhole; and the water inlet hole and the blowhole are connected with each other through a channel in the center of the composite piston. Compared with the prior art, the jetting machine has the characteristics of reasonable design, simple structure, safety and reliability, convenient use, easy maintenance and so on, and has good popularization value and use value.

Owner:ZHEJIANG BETHEL TECH CO LTD

Petroleum platform pile shoe lifting auxiliary system

ActiveCN101126235AImprove the efficiency of migration constructionImprove stabilityArtificial islandsUnderwater structuresEconomic benefitsWater flow

The invention provides a system to assist to lift the pile shoe of the petroleum platform, which is to arrange a high pressure pump on the petroleum platform, a feed water pipe of the high pressure pump passes through the central tubular cavity of the pile and is connected with an anti-blockage injector arranged in the pile shoe at the lower end of the pile, the anti-blockage injector is arranged in the upper side, the lower side and the periphery of the inner wall of the pile shoe, the high-pressure water flow injected from the anti-blockage injector is utilized to cut the silt adhered on the outer surface of the pile shoe; a pulsator is additionally arranged in the pile shoe, the silt adhered on the outer surface of the pile shoe is made loose and flow like the porridge through the vibration of the pulsator and thus, the resistance is reduced and the lifting speed of the pile shoe is improved. The invention has the advantages that the invention needs less investment, is easy to be operated and the lifting speed of the pile is high, which can improve the operating efficiency in the transfer of the petroleum platform and shorten the construction period. In addition, when the pile of the petroleum platform is lowered in a new site, the pulsator arranged in the pile shoe can be utilized to expedite the sinking speed of the pile shoe to improve the stability of the pile shoe and thus, the invention has huge economic benefit.

Owner:ZHEJIANG BETHEL TECH CO LTD

Printed circuit board and manufacturing method thereof

ActiveCN103391681AImprove yieldAvoid breakingPrinted circuit detailsPrinted circuit manufactureFill ratePrinted circuit board

The invention discloses a printed circuit board which is characterized by comprising at least one hole, wherein the hole is provided with at least one opening, and the hole is filled with at least one filler. The invention further discloses a manufacturing method of the printed circuit board, which is characterized by comprising the steps that the hole is filled with the first filler, and then filled with the second filler, so that the second filler and the first filler are coagulated into a whole to fully fill the hole. According to the printed circuit board, the hole is filled with at least one filler, so that a filling rate in the hole is as high as 95-100%, the product quality of the printed circuit board is improved, the manufacturing method of the printed circuit board can be compatible with the traditional equipment, and the production cost is lowered.

Owner:SHANGHAI MEADVILLE ELECTRONICS

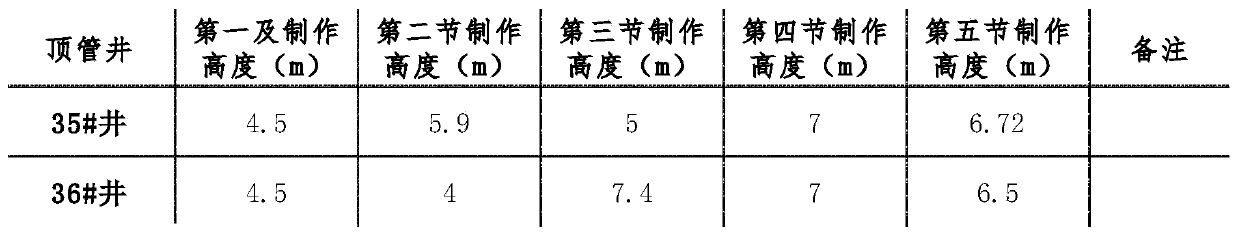

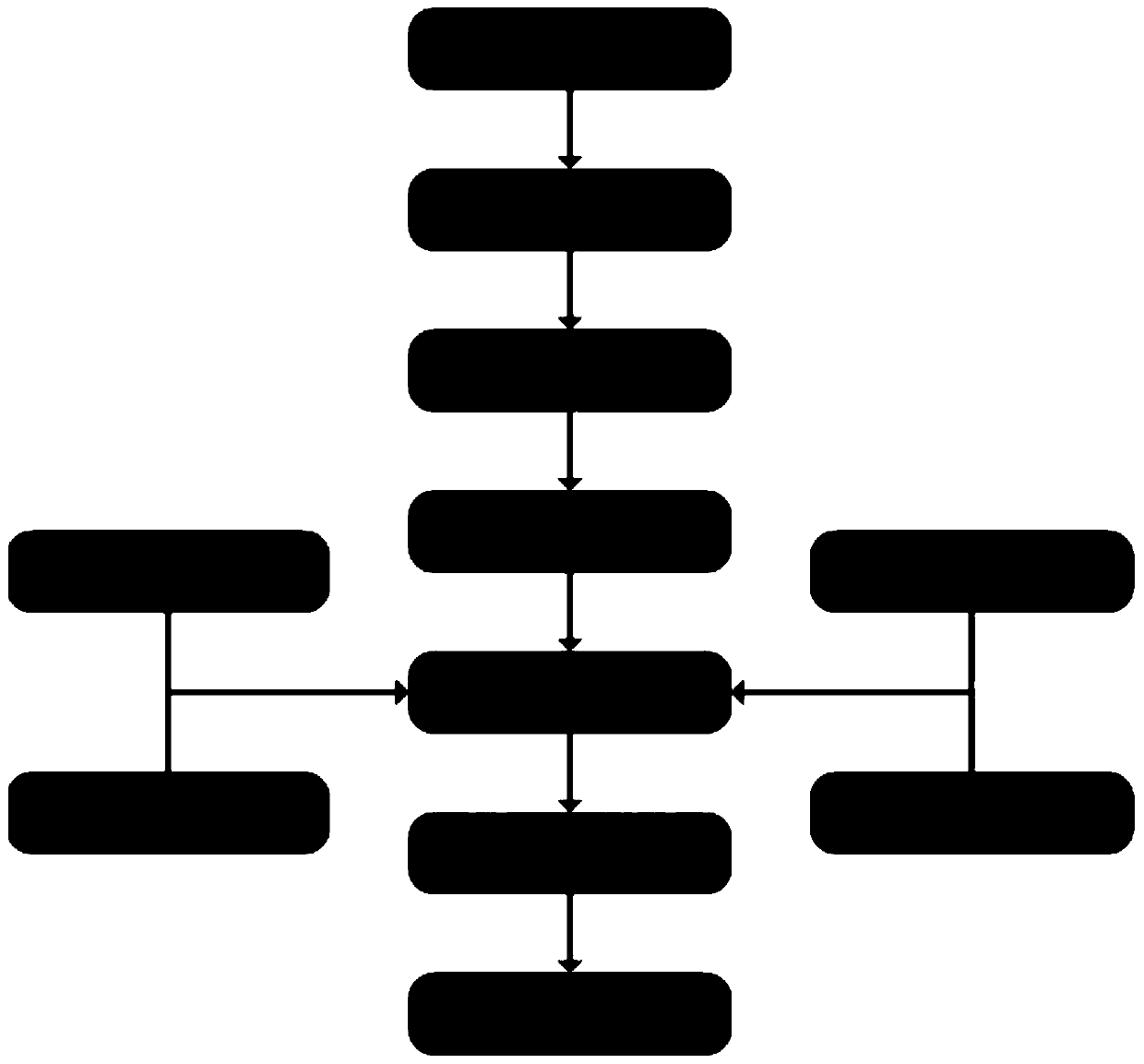

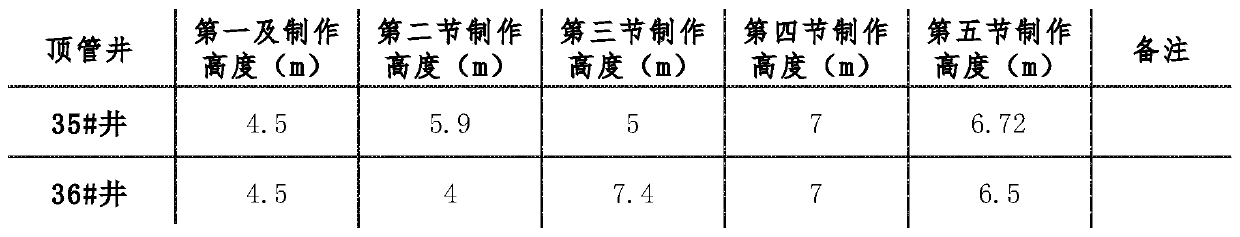

Construction method of open caisson

The invention discloses a construction method of an open caisson. The construction method comprises the steps of construction preparation work; foundation pit excavation as well as sand cushion layerand plain concrete cushion layer manufacturing; open caisson first-section, open caisson second-section and open caisson third-section manufacturing; open caisson first-time sinking; open caisson fourth-section and open caisson fifth-section manufacturing; open caisson second-time sinking; open caisson underwater plain concrete bottom sealing; open caisson bottom plate manufacturing; and pipelinebuttress, mud discharging well and tail work construction. The open caisson sinks by adopting an undrained process, the soil sampling mode is matched with an air mud suction diver, and the sinking assisting mode is sinking by a pressure sinking method and resistance reduction and sinking assisting by thixotropic mud. According to the method, the sinking method is adopted, the posture of the open caisson is convenient to control, the sinking precision of the open caisson is high, the depth of open caisson blade feet penetrating into a soil layer is larger through a counter-force system, the sufficient sinking coefficient is achieved, the sinking speed of the open caisson can be greatly increased, disturbance to external soil is small, the phenomenon that a structure is prone to differentialsettlement, deformation, cracking and the like are effectively prevented, and a soil bin in a well lattice cannot be raised in the sinking process.

Owner:广东省建筑工程监理有限公司

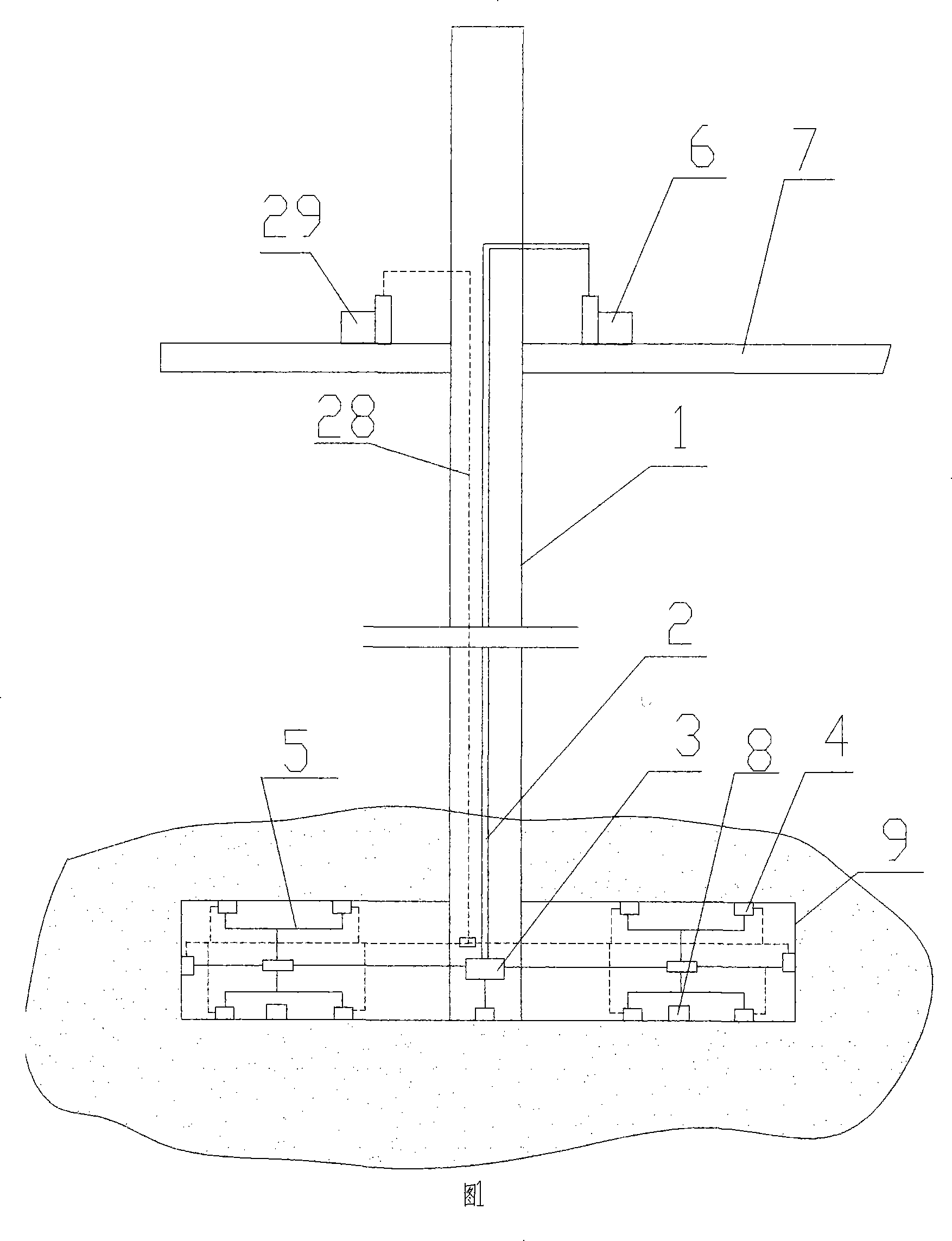

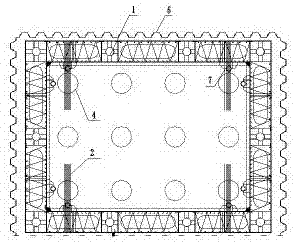

Soft soil area mud-water balance open caisson station counterforce and locking system

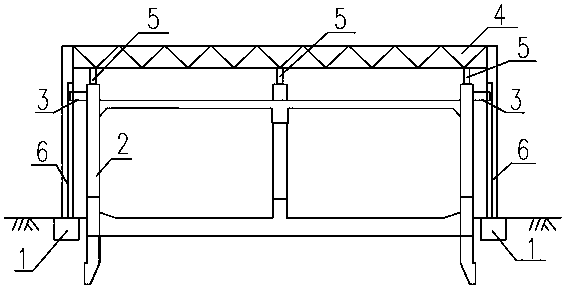

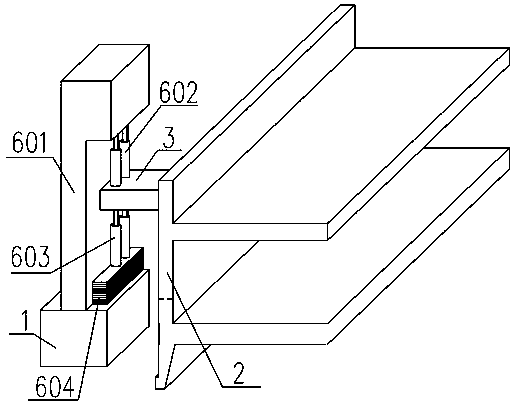

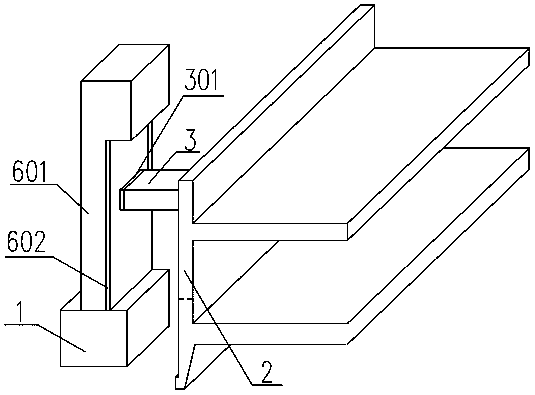

PendingCN110761328AEasy to assembleEasy to pourArtificial islandsUnderwater structuresButtressEngineering

The invention belongs to the technical field of underground engineering construction, and particularly relates to a soft soil area mud-water balance open caisson station counterforce and locking system. The soft soil area mud-water balance open caisson station counterforce and locking system comprises a counterforce truss, jacks and locking devices; the counterforce truss comprises a crossbeam andvertical columns, and the two ends of the crossbeam are fixed to the two vertical columns correspondingly; and the bottoms of the two vertical columns are fixed to the ground, and the opposite sidesof the two vertical columns are provided with the locking devices used for being matched with locking buttresses on an open caisson section side wall to lock an open caisson section. According to thesoft soil area mud-water balance open caisson station counterforce and locking system, the jacks are arranged on the lower part of the counterforce truss to apply sinking power to an open caisson structure and adjust the attitude of an open caisson; and the locking devices are arranged on the two sides of the open caisson section, and the locking devices are matched with the locking buttresses onthe open caisson section side wall to lock the open caisson section, so that the next section of open caisson structure is spliced and poured or the current open caisson section is monitored, the construction speed of the open caisson is increased, and safety is ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

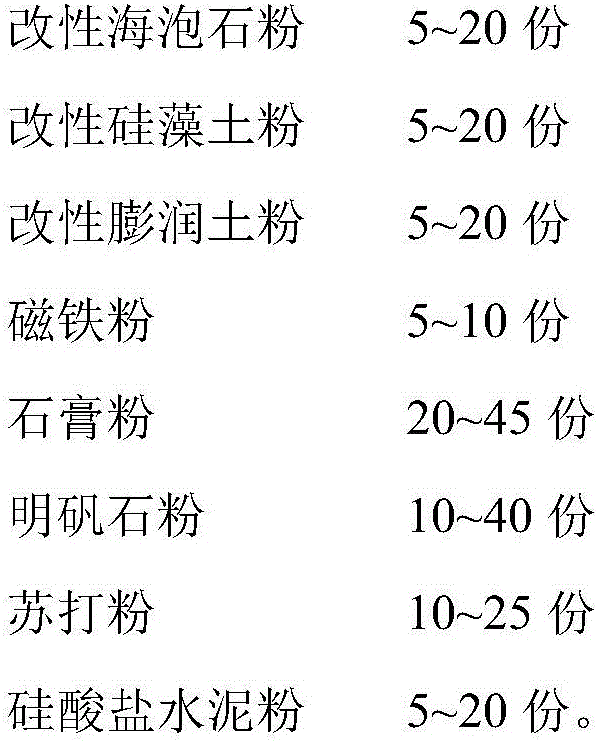

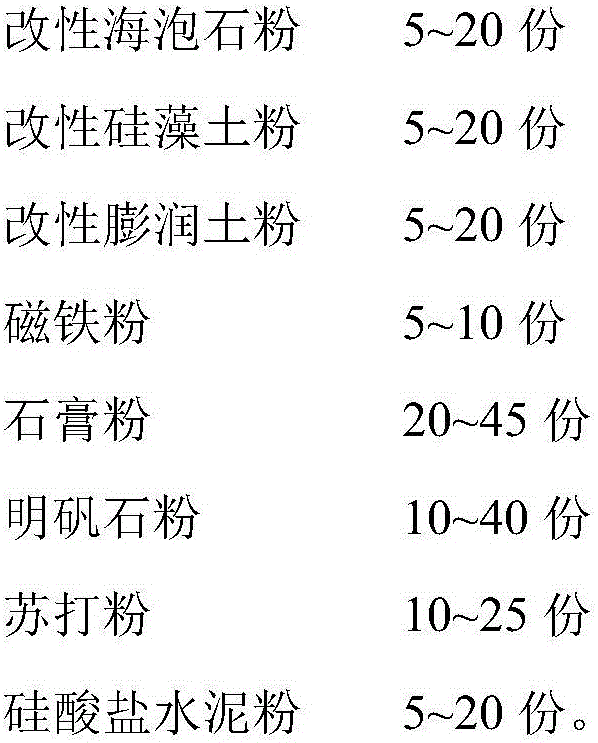

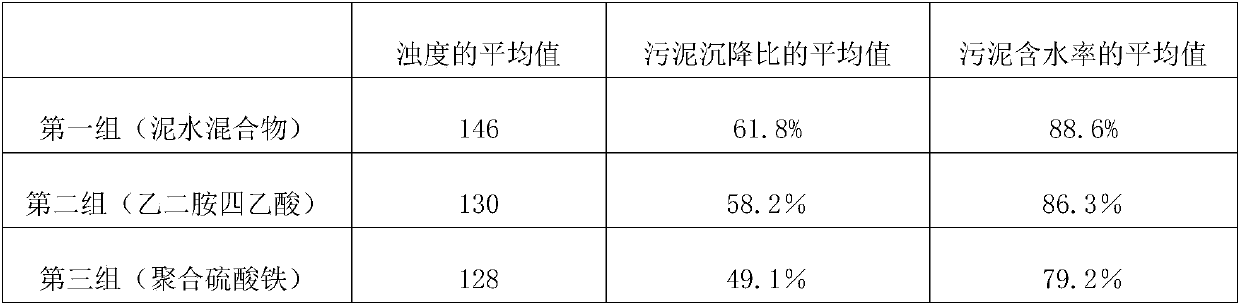

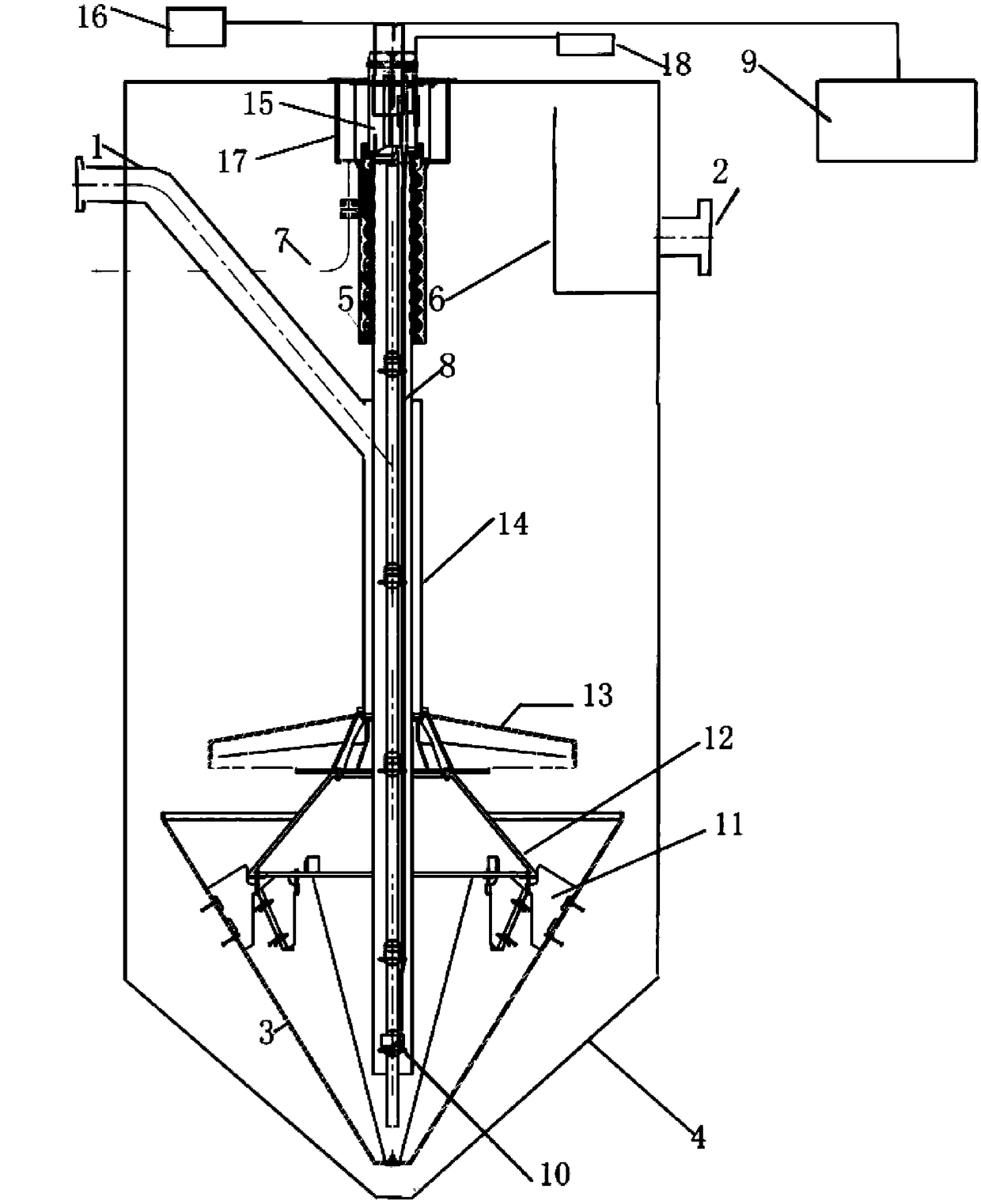

Flocculating agent for ecological remediation of black smelly surface water and production process thereof

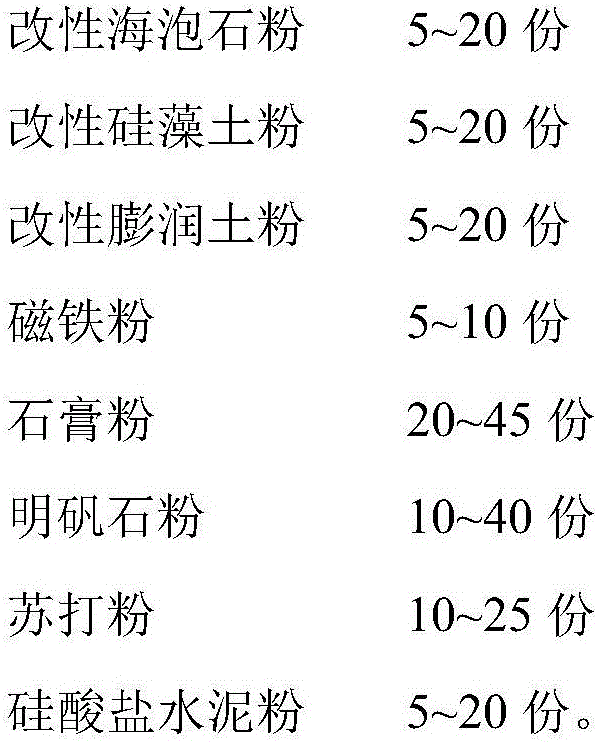

InactiveCN105967291ASpeed up the sinkingStrong pH buffering capacitySpecific water treatment objectivesWater contaminantsFlocculationSewage treatment

The invention discloses a flocculating agent for ecological remediation of black smelly surface water, belongs to the field of sewage treatment, and solves the technical problems that the existing inorganic flocculating agent is weak in flocculation force and low in precipitation speed. The flocculating agent for the ecological remediation of the black smelly surface water is prepared from the following components in parts by weight: 5 to 20 parts of modified sepiolite powder, 5 to 20 parts of modified diatomite powder, 5 to 20 parts of modified bentonite powder, 5 to 10 parts of magnet powder, 20 to 45 parts of gypsum powder, 10 to 40 parts of alunite powder, 10 to 25 parts of soda ash, and 5 to 20 parts of silicate cement powder. The invention also discloses a production process of the flocculating agent.

Owner:湖州国盛环保工程有限公司

Sewage air flotation scum defoaming machine

InactiveCN104118919AAchieve releaseSpeed up bubble breakingWater/sewage treatment by degassingWater/sewage treatment by flotationReducerSewage

The invention relates to a sewage air flotation scum defoaming machine which comprises a motor, wherein the motor is connected with a rotating rod through a speed reducer and a coupler; the rotating rod is reversely T-shaped; a plurality of fixed vertical shafts are distributed on a transverse rod of the rotating rod; blades capable of rotating around the fixed vertical shafts are arranged on the fixed vertical shafts. The sewage air flotation scum defoaming machine can release air bubbles in scum in a horizontal direction and a vertical direction, so that the bubble breakage speed and the sinking speed of the scum are greatly increased, and the solid and liquid separation time is shortened; under the general condition, bubbles can be broken within 2-10 seconds according to the difference of the thicknesses of scum layers. Furthermore, full coverage for the scum layers is realized, and the scum in a large amount of water can be defoamed.

Owner:山东华特达因健康股份有限公司

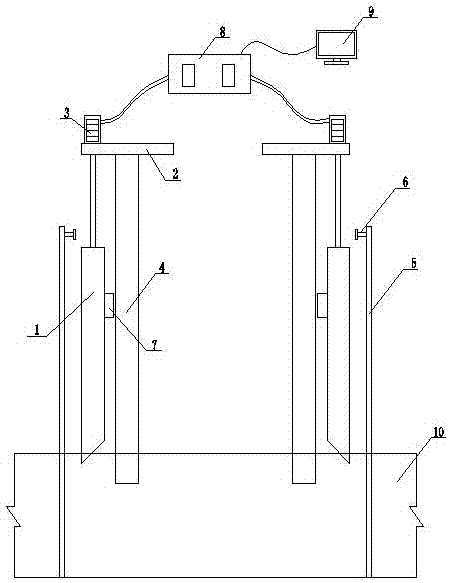

Construction method of rapid sinking of double-wall steel sleeve box cofferdam in sandy cobble stratum

The invention discloses a construction method of rapid sinking of a double-wall steel sleeve box cofferdam in a sandy cobble stratum. According to the method, the double-wall steel sleeve box cofferdam, a structural steel distribution beam, a jack, a pile foundation steel casing, a Larsen steel sheet pile, a steel ring beam, a guide device, a hydraulic pump station, a control computer and the sandy cobble stratum are included; according to the construction method, soil below the double-wall steel sleeve box cofferdam is closed, the cobble square mount in the cofferdam is fixed, the mud suction sinking time is effectively shortened, and the cofferdam sinking speed is obviously quickened. Stability of the double-wall steel sleeve box cofferdam can be improved, the effect of separating soil on the inner side and the outer side of the double-wall steel sleeve box cofferdam is achieved, a steel ring beam on the top of a Larsen steel sheet is arranged, and the aim of stabilizing a steel plate pile cofferdam hole opening is achieved; the Larsen steel sheet pile is arranged on the outer side of the double-wall steel sleeve box cofferdam, and is closed to a ring, the double-wall steel sleeve box cofferdam can smoothly sink in the closed space formed by the steel plate pile, and operation space can be provided for splicing of the next segment after the double-wall steel sleeve box cofferdam is implanted.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD +2

Steel cofferdam initiative sinking deviation correcting construction device and method

The invention discloses a steel cofferdam initiative sinking deviation correcting construction device. The steel cofferdam initiative sinking deviation correcting construction device comprises steel protection cylinder counter-force brackets, steel cofferdam counter-force brackets, centre hole jacks and pull rods, wherein the number of the pull rods is equal to the number of the steel protection cylinder counter-force brackets, the number of the steel cofferdam counter-force brackets is equal to the number of the steel protection cylinder counter-force brackets, the steel cofferdam counter-force brackets correspond to the steel protection cylinder counter-force brackets in a one-to-one manner, and each pull rod sequentially penetrates the corresponding jack, the corresponding steel cofferdam counter-force bracket and the corresponding steel protection cylinder counter-force bracket from top to bottom. According to a construction method for conducting steel cofferdam initiative sinking deviation correcting through the construction device, pistons of the jacks stretch out for tightening of the pull rods, the pull force exerted on the pull rods is converted into downward press force for a steel cofferdam, and accordingly, the steel cofferdam is subjected to initiative downward press force to sink. Due to application of the initiative downward press force, the balance weight is increased equivalently, and therefore the sinking speed of the steel cofferdam can be increased, and the mud sucking and soil excavating workload is reduced; and compared with existing deviation correcting purely through mud sucking, pressurized deviation correcting is rapid and accurate.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +2

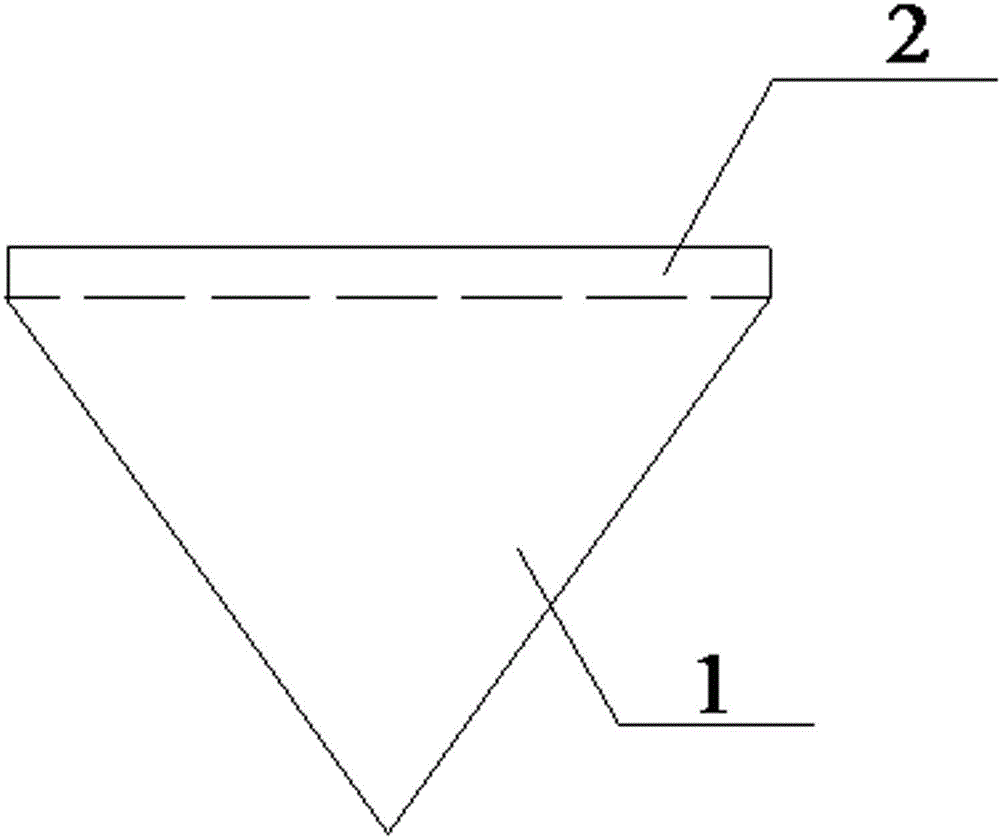

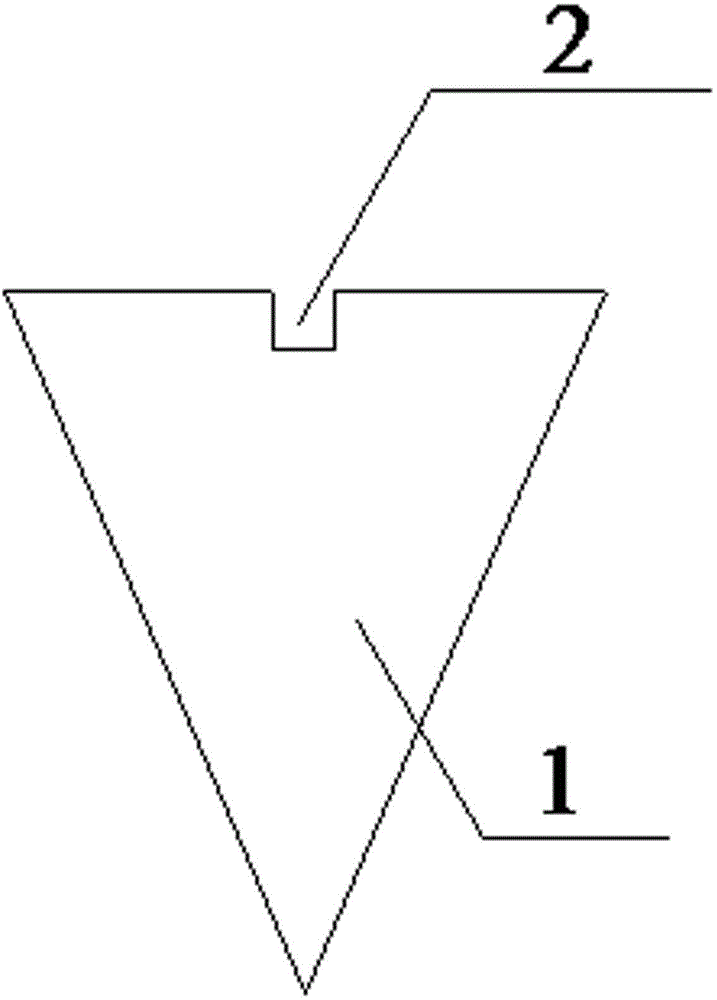

SMW construction method for arranging elliptic-cone-shaped pile head at end of H-shaped steel

ActiveCN104631445AReduced insertion resistanceSpeed up the sinkingBulkheads/pilesStructural engineeringSoil cement

The invention discloses an SMW construction method for arranging an elliptic-cone-shaped pile head at the end of H-shaped steel. According to method, the elliptic-cone-shaped pile head, the cut H-shaped steel and a cemented soil solidification body are included, wherein the top of the elliptic-cone-shaped pile head is provided with a reserved gap matched with a web of the H-shaped steel in thickness, and the web of the H-shaped steel can be inserted in the reserved gap; a V-shaped boundary is cut in a wing plate at the lower end of the H-shaped steel through a cutting tool to reduce insertion resistance during construction. In the construction process through an existing SMW construction method, in order to reduce the insertion resistance to the H-shaped steel, an anti-friction agent is smeared on the surface of the H-shaped steel before the H-shaped steel is inserted; on this basis, the end of the H-shaped steel is cut into the V shape, and the H-shaped steel is inserted in the gap of the elliptic-cone-shaped pile head to form a streamline structure; the elliptic-cone-shaped pile head can separate cemented soil, so the insertion resistance to the H-shaped steel can be effectively lowered, the insertion speed can be increased, and the construction period can be shortened; due to the design of the elliptic-cone-shaped pile head, a guiding effect can also be achieved in the inserting process of the H-shaped steel, and the H-shaped steel is prevented from deflecting in the sinking process during construction.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

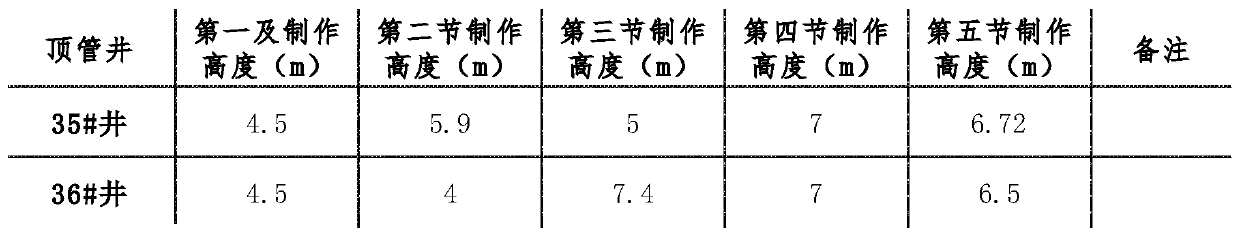

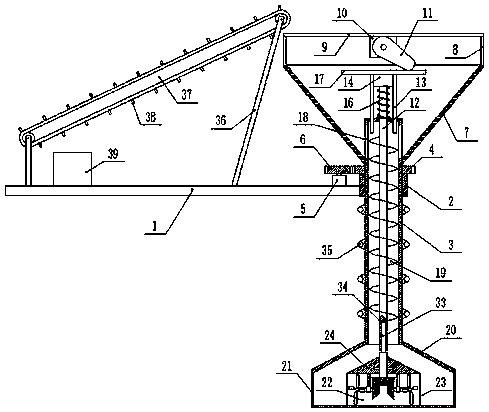

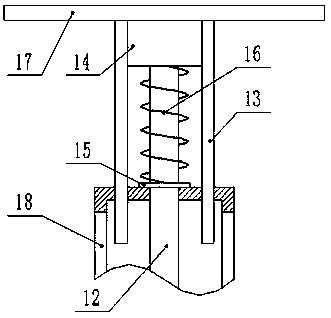

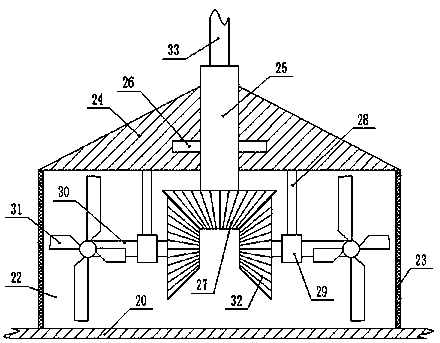

Submersed type inspection well construction method

InactiveCN101684669BAchieve preparationSpeed up the sinkingArtificial islandsSewerage structuresDowntown areaWellbore

The invention discloses a submersed type inspection well which comprises a well cover above the ground as well as a shaft and a well body structure below the well cover, wherein the traditional drainage pipe is arranged below the shaft, a foundation is arranged between the lower end of the shaft and the drainage pipe, and the lower end of the shaft, the upper end of the foundation and the pipe are poured into a whole; the diameter of the foundation is larger than the outer diameter of the shaft, and the bottom end of the foundation is located below the sheath of the traditional drainage pipe;and the bottom end of the foundation is inwards extended below the traditional drainage pipe. The invention also discloses a construction method for realizing the inspection well, which comprises thefollowing construction stages: (1) placing the inspection well; (2) submersing, joining and measuring the shaft; (3) manufacturing the foundation of the inspection well and communicating the shaft with the traditional drainage pipe; and (4) mounting a shaft cover plate and a ladder. By adopting the structure and the method of the invention, the inspection well is conveniently manufactured by adopting a submersed type construction method so as to be beneficial to carrying out long-distance jacking pipe construction and developing novel prefabricated inspection well structures and convenient for carrying out pipe engineering construction in downtown areas without excavating.

Owner:吴纪东 +1

Open caisson construction method based on thixotropic mud resistance reduction

The invention discloses an open caisson construction method based on thixotropic mud resistance reduction. The open caisson construction method comprises construction preparing work, foundation pit excavating, sand cushion layer and plain concrete cushion layer manufacturing, foundation pit excavating, sand cushion layer and plain concrete cushion layer manufacturing, open caisson first joint, second joint and third joint manufacturing, open caisson first-time sinking, open caisson fourth joint and fifth joint manufacturing and open caisson second-time sinking. The water-discharge-free sinkingtechnology is adopted in the open caisson, the soil sampling manner is cooperation of air mud suction and divers, and pressing sinking method sinking and thixotropic mud resistance reduction sinkingassisting are adopted in the sinking assisting manner. Open caisson underwater plain concrete bottom sealing, open caisson bottom plate manufacturing and pipeline buttress, mud discharging well and tail work construction are conducted. The thixotropic mud sinking assisting method is adopted for lowering disturbance influences on a surrounding soil body from the open caisson to a great degree, thestatic force action on the soil body from thixotropic mud is distributed according to the triangle, and in the thixotropic mud gel state, molecules of the thixotropic mud are arranged to form a certain net-shaped structure framework, and the thixotropic mud has the functions of reducing friction force and maintaining soil wall stability in open caisson sinking.

Owner:广东省建筑工程监理有限公司

Decolouring deodorizing sewage treatment agent

InactiveCN105253925AImprove removal efficiencyEasy to prepareWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSodium BentoniteSodium phosphates

The invention discloses a decolouring deodorizing sewage treatment agent. The decolouring deodorizing sewage treatment agent is prepared from, by mass, 1.5 to 2.5 parts of polyacrylamide, 1 to 2 parts of a coagulant aid, 3 to 8 parts of potassium peroxodisulfate, 3 to 5 parts of bentonite, 10 to 20 parts of starch, 5 to 10 parts of solvent lignin, 5 to 10 parts of a sodium phosphate-sodium dihydrogen phosphate buffer system, 10 to 15 parts of nekal, 8 to 10 parts of polyepoxysuccinic acid, and 2 to 3 parts of aluminium polychlorid. The decolouring deodorizing sewage treatment agent is used for solving technical problems of the prior art that conventional flocculating agents are poor in effects, and secondary pollution is caused by reagent ingredients; the decolouring deodorizing sewage treatment agent is wide in pollutant treatment range, excellent in effect, and wide in raw material resource, is friendly to the environment, and is non-toxic; the structural design of the coagulant aid is special, and obvious effects on the aspects of algae killing, decolouring, deodorizing, and organic matter degradation are achieved.

Owner:ANQING FENGYUAN CHEM

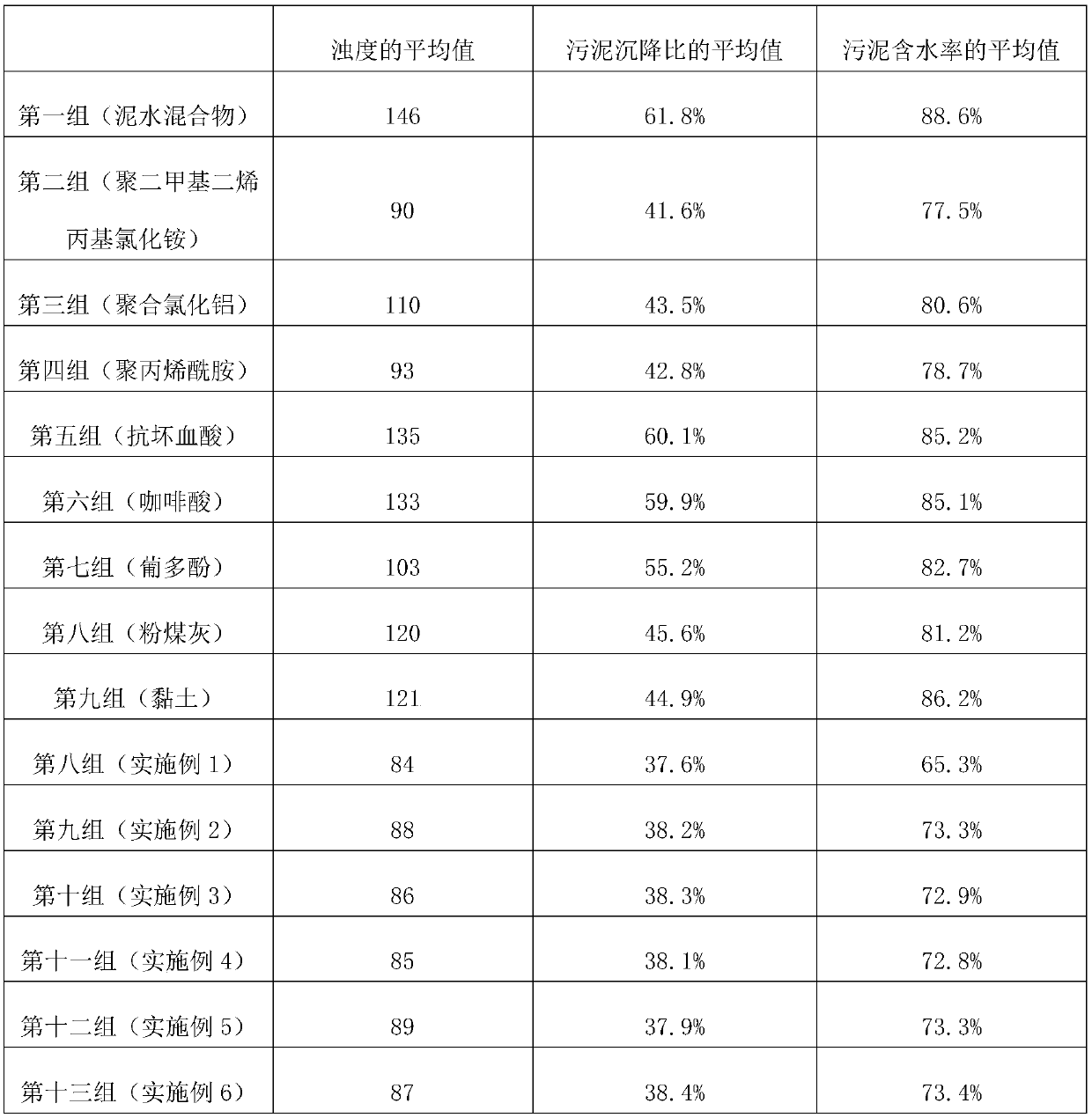

Mixed flocculating agent for sludge treatment and preparation method thereof

InactiveCN109574461AAccelerate sinkingEnhanced couplingSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSludgeCaffeic acid

The invention belongs to a technical field, and particularly relates to a mixed flocculating agent for sludge treatment. The mixed flocculating agent is prepared from the following components in partsby weight: 2 to 4 parts of polydimethyl diallyl ammonium chloride, 1 to 2 parts of polyaluminum chloride, 1 to 2 parts of polyacrylamide, 1 to 2 parts of ascorbic acid, 1 to 2 parts of caffeic acid,1 to 3 parts of grape polyphenol, 10 to 20 parts of pulverized fuel ash and 10 to 40 parts of clay. The mixed flocculating agent has the beneficial effects that, when the sewage treatment is carried out by using the mixed flocculating agent prepared by the preparation method, the water content of sludge finished in flocculation is as low as 65.3%; the size of the sludge is greatly decreased; and the treatment cost of a subsequent working procedure is decreased.

Owner:ANHUI ZHONGHUAN ENVIRONMENTAL PROTECTION TECH CO LTD +1

Air purification device for livestock breeding

InactiveCN103940001AWeight increaseEliminate the route of infectionCombination devicesLighting and heating apparatusLivestock breedingEngineering

The invention provides an air purification device for livestock breeding. The air purification device is simple in structure and reasonable in design. Air can be purified, and harmful bacteria can be killed and purified out. The air purification device for livestock breeding comprises a shell body, negative-ion generators, a fan and a probiotics liquid spray head, the shell body is of an hollow structure with the two open ends, the fan composed of a fan body and fan blades is arranged at an upper opening of the shell body, a cover plate is arranged at the lower end of the shell body, supports are arranged at the bottom of the shell body, the negative-ion generators are arranged above the supports, the probiotics liquid spray head is arranged below the negative-ion generators, and wire holders are arranged on the side face of the shell body.

Owner:山东省动物疫病预防与控制中心

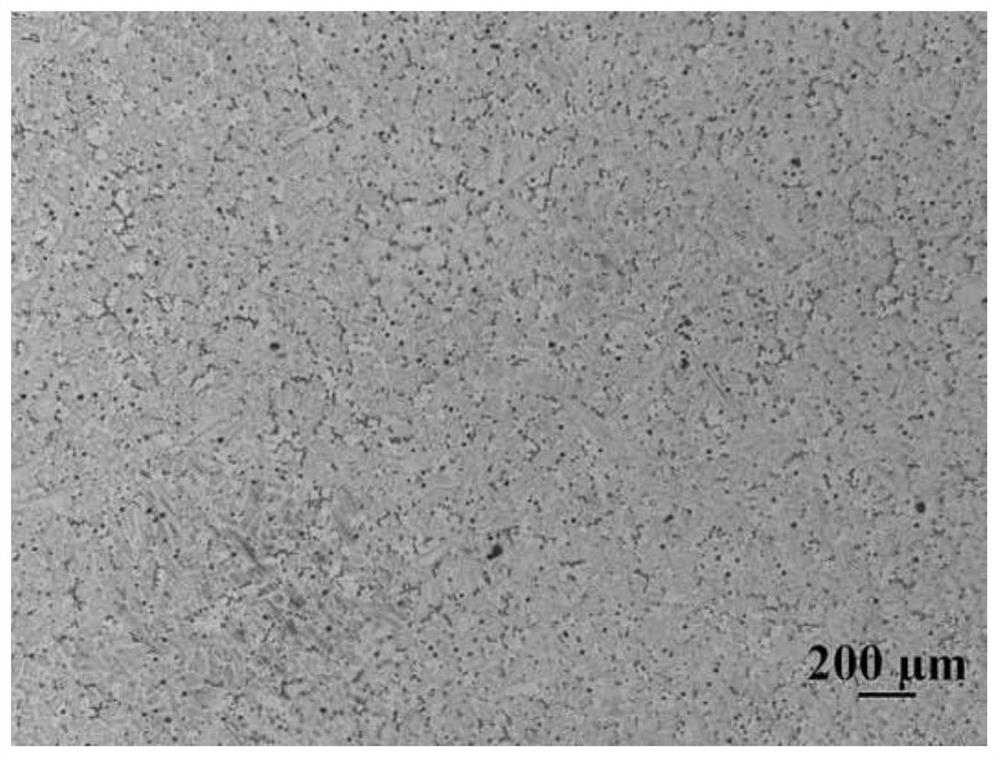

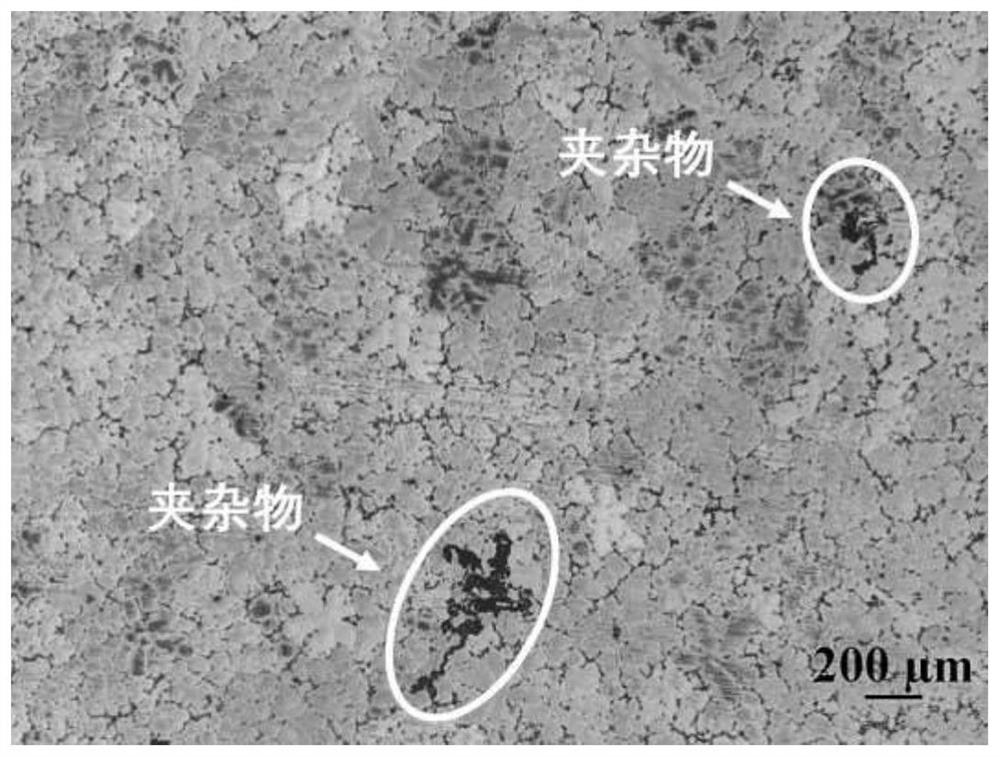

Magnesium-rare earth alloy melt purification and refinement composite treatment flux and application thereof

ActiveCN113278839AIncrease the speed of wetting to capture inclusionsSpeed up the sinkingBarium dichlorideSulfate

The invention discloses a magnesium-rare earth alloy melt purification and refinement composite treatment flux. The mass percentage range of the components is as follows: 30-40% of magnesium chloride, 8-15% of potassium chloride, 8-15% of sodium chloride, 15-20% of barium chloride, 5-8% of barium sulfate, 10-15% of zirconium diboride and 10-15% of zirconium sulfate. A preparation method comprises the following steps of: melting and mixing magnesium chloride, potassium chloride, sodium chloride, barium chloride and barium sulfate, performing cooling and solidifying to obtain a refining agent composite salt block, and then mixing and sieving the refining agent composite salt block, zirconium diboride and zirconium sulfate to prepare the purification and refinement composite treatment flux. By adopting the composite flux disclosed by the invention, the melt purification efficiency can be improved; the Zr refining action time can be prolonged; the refining and purification treatment of the alloy melt can be realized in one step; and the preparation process of the magnesium-rare earth alloy melt can be greatly shortened.

Owner:SHANGHAI JIAO TONG UNIV

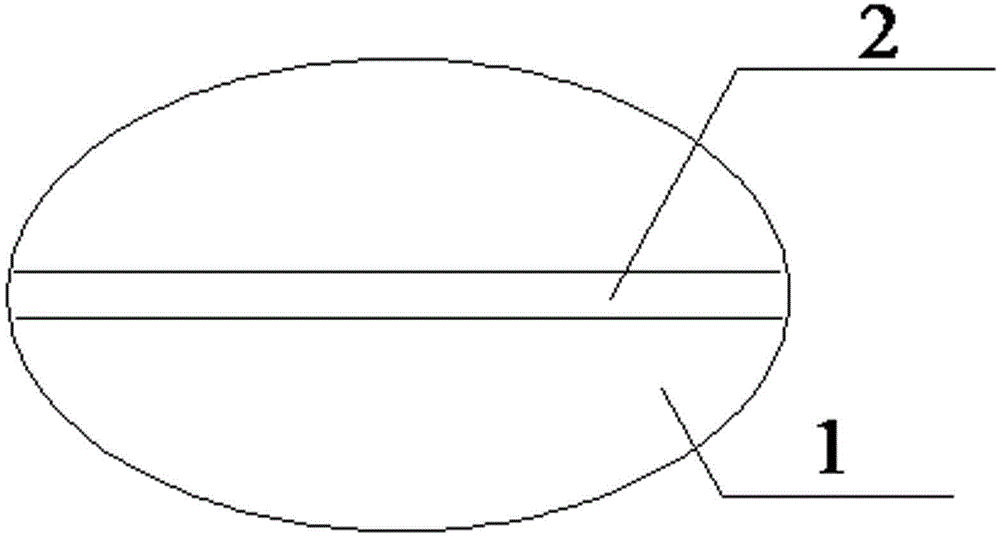

Super-large planar area partially prestressed concrete open caisson foundation and construction method thereof

The invention discloses a super-large planar area partially prestressed concrete open caisson foundation and a construction method thereof. The super-large planar area partially prestressed concrete open caisson foundation comprises a lower initial partially prestressed concrete open caisson section and a jointing partially prestressed concrete or common reinforced concrete open caisson section above the initial partially prestressed concrete open caisson section, wherein the initial partially prestressed concrete open caisson section (1) is in a partially prestressed concrete structure, a partially prestressed 'crossed' beam is formed on longitudinal and transverse internal partition walls with prestressed steel wire bundles, and the partially prestressed 'crossed' beam and an identicallyprestressed caisson wall can form a partially prestressed concrete 'beam lattice' capable of effectively resisting complex stress conditions; the initial partially prestressed concrete open caisson section is sunk down to a designated position, and then every subsequent standard section is sequentially jointed and sunk down to the designated position until final sinking is completed. The super-large planar area partially prestressed concrete open caisson foundation and the construction method thereof can improve the structural safety and the anti-cracking performance of an open caisson sunk through pot-like excavating and sinking, thereby being particularly applicable to large rectangular, round, elliptical and end-circular open caisson foundations of 4000-10000 m2.

Owner:SOUTHWEST JIAOTONG UNIV +1

Composite flocculant for sludge treatment and preparation method thereof

InactiveCN109608020APromote hydrolysis reactionReduce moisture contentSludge treatment by de-watering/drying/thickeningCaffeic acidWater content

The invention belongs to the technical field of flocculants, and particularly relates to a composite flocculant for sludge treatment. The composite flocculant consists of the following components in parts by weight: 1-25 parts of ethylenediamine tetraacetic acid, 1-20 parts of polymeric ferric sulfate, 1-10 parts of caffeic acid, 1-20 parts of polymeric ferric chloride, 10-30 parts of sodium carboxymethylcellulose, 5-15 parts of bentonite and 1-5 parts of sodium carbonate. The composite flocculant has the beneficial effects: 1, when the composite flocculant prepared provided by the invention is used for sewage treatment, the water content of sludge subjected to flocculation is low to 69.1%, the volume of sewage is greatly reduced, and processing cost of subsequent processes is reduced; and2. after flocculation by using the composite flocculant provided by the invention is completed, the composite flocculant can be recycled through simple drying and grinding treatment.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Coagulant for cleaning polluted water or contaminated water

ActiveCN100361904CWon't breakAchieve protectionWater/sewage treatment by flocculation/precipitationAdditive ingredientSludge

To provide a coagulant for cleaning polluted water or contaminated water which is capable of enhancing a cohesive force, removing heavy metals and continuously treating polluted water or contaminated water in a short time and permits simply and efficiently the dehydration without exerting any effect to the natural environment. The coagulant for cleaning polluted water or contaminated water is prepared by uniformly dispersing a pH regulator, a density increasing agent and a chelate effect accelerator to a principal ingredient consisting of aluminum sulfate, calcium sulfate and sodium carbonate and mixing them. Cement can be used as the pH regulator and the cement or magnetic material can be used as the density increasing agent. Therein, ferrite can be used as the magnetic material. Further, the chelate effect accelerator comprising powders of iron, thio sodium oxide, chitosan and citric acid can be used.

Owner:长彰德 +3

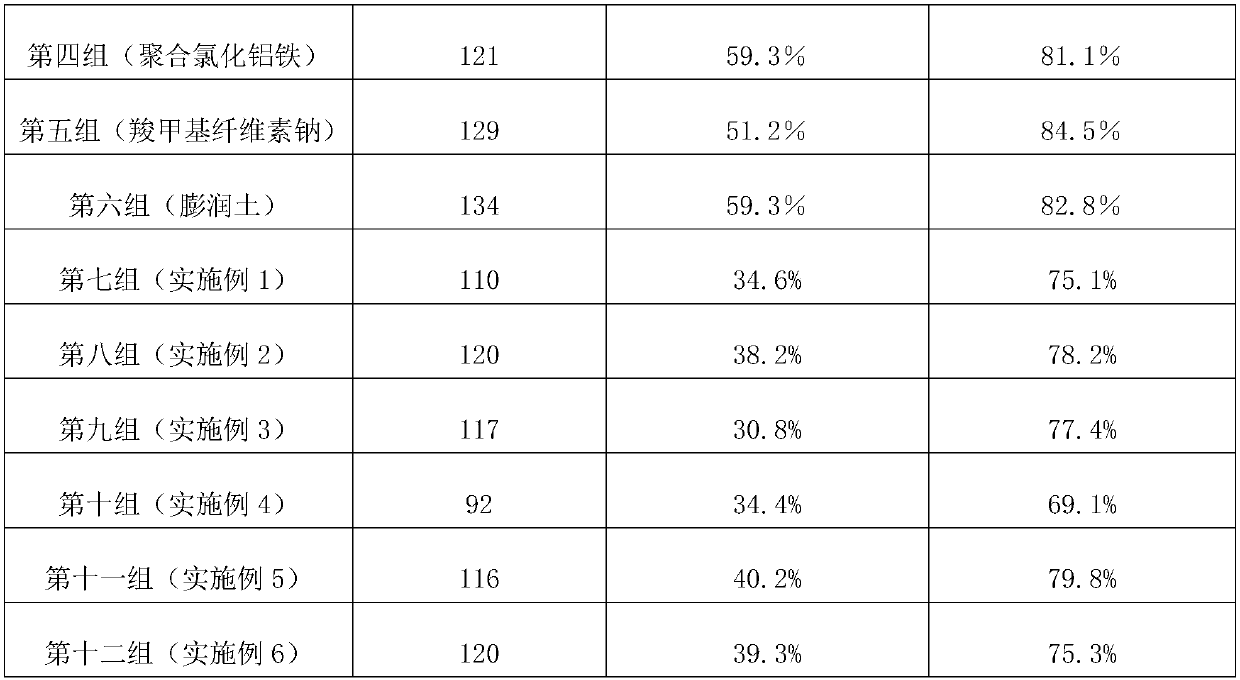

Anti-static down feather weighing box

InactiveCN104677473AAvoid deformationNegative pressure reductionWeighing apparatus for materials with special property/formMetallic materialsStructural engineering

The invention discloses an anti-static down feather weighing box, and belongs to auxiliary facilities of a down filling machine. The anti-static down feather weighing box comprises a base plate, a weighing box body composed of an upper box body and a lower box body, a down feather inlet tube, a down feather outlet tube and an air filter screen arranged on the side wall of the upper box body, wherein the down feather outlet tube is fixed to the base plate and is communicated with the lower box body; a top air filter screen is arranged at the top of the upper box body; a down feather collection and extraction hopper is arranged in a cavity of the lower box body; the down feather inlet tube or the down feather outlet tube is connected with one end of an anti-static lead wire; the other end of the anti-static lead wire is a ground terminal; when one end of the anti-static lead wire is connected with the down feather inlet tube, the down feather inlet tube is made of metallic materials, the down feather outlet tube is made of metallic or nonmetallic materials; when the anti-static lead wire is connected with the down feather outlet tube, the down feather outlet tube is made of metallic materials, and the down feather inlet tube is made of metallic or nonmetallic materials. The anti-static down feather weighing box can prevent the down feather from getting out, and has the advantages that the box body is protected; velvet accumulation is avoided; energy consumption is reduced; the weighing accuracy and security are guaranteed.

Owner:苏州比阳特服装设备有限公司

Open caisson pressing sinking method construction method

The invention discloses an open caisson pressing sinking method construction method. The open caisson pressing sinking method construction method comprises construction preparing work, foundation pitexcavating, sand cushion layer and plain concrete cushion layer manufacturing, foundation pit excavating, sand cushion layer and plain concrete cushion layer manufacturing, open caisson first joint, second joint and third joint manufacturing, open caisson first-time sinking, open caisson fourth joint and fifth joint manufacturing and open caisson second-time sinking. The water-discharge-free sinking technology is adopted in an open caisson, the soil sampling manner is cooperation of air mud suction and divers, and pressing sinking method sinking and thixotropic mud resistance reduction sinkingassisting are adopted in the sinking assisting manner. Open caisson underwater plain concrete bottom sealing, open caisson bottom plate manufacturing and pipeline buttress, mud discharging well and tail work construction are conducted. The pressing sinking method is adopted in the open caisson pressing sinking method construction method so that the open caisson posture can be conveniently controlled, the open caisson sinking precision is high, the depth of penetration into a soil layer through an open caisson blade foot is larger through a counter force system, the enough sinking coefficientis achieved, the open caisson sinking speed can be greatly increased, disturbance on an outer soil body is little, differential settlement, deformation, cracking and other phenomena are not likely tohappen to structures, and in the sinking process, the phenomenon of humping cannot happen to a soil bin in a well grid.

Owner:广东省建筑工程监理有限公司

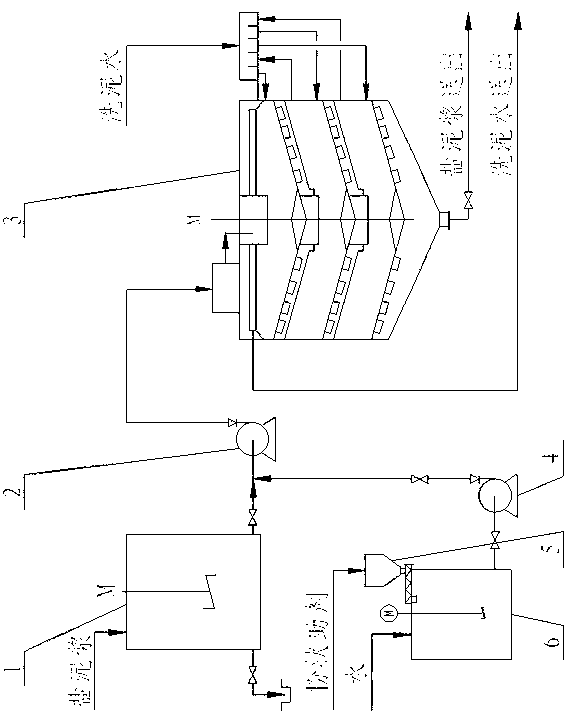

Method for improving primary salty mud washing ability

InactiveCN103232147ASpeed up the sinkingIncrease settlement rateSludge treatmentSulfateEnvironmental engineering

The invention relates to a salty mud washing process, and in particular relates to a method for improving the primary salty mud washing ability. The method comprises the following steps of adding settling agent dry powder and water into a settling agent preparation tank according to a mass ratio (0.025%-0.05%):1, and stirring the settling agent dry powder to be uniformly dissolved in the settling agent preparation tank; adding the well-dissolved settling agent and the primary salty mud into an assistant pump according to the volume ratio of 1: 10 to 20, conveying the mixture into a mud washing barrel pipeline through the assistant pump, and realizing the uniform mixing of the settling agent and the salty mud by utilizing the turbulence characteristic of the liquid inside the conveying pipeline; placing the mixture of settling agent and the salty mud into a mud washing barrel; continuing to mix the salty mud and the settling agent in the mud washing barrel, washing the mixture through the washing water, driving the magnesium hydrate (Mg(OH)2) and calcium sulfate (CaSO4) in the salty mud to be settled through the organic large molecules in the settling agent composition in the washing process, thereby realizing the settlement of the salty mud within a half hour.

Owner:TANGSHAN SANYOU CHEM IND

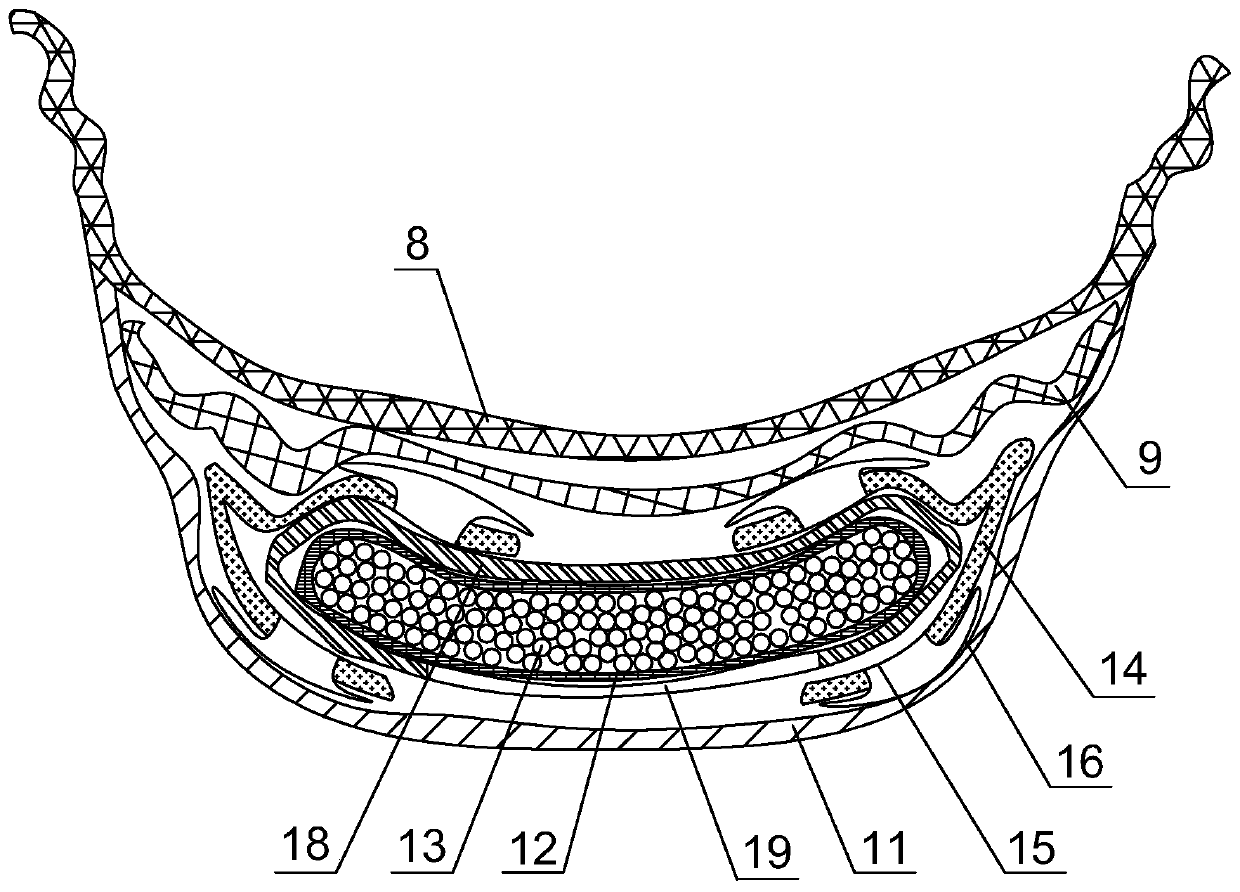

Anti-leakage baby diaper containing water absorption beads

The invention discloses an anti-leakage baby diaper containing water absorption beads, relates to the technical field of baby sanitation supplies and solves the problem that urine reverse osmosis is easily caused when the movement amplitude of a baby is excessive and a diaper absorption piece is squeezed. The baby diaper comprises a front protecting wing, a rear protecting wing and a middle core, an elastic waist is arranged at the center of the rear protecting wing, a left stud and a right stud are fixed to two sides of the rear protecting wing, hook and loop fasteners are fixed to the outer side of the front protecting wing, and the middle core comprises an inner surface layer, a flow guide layer, an absorption layer and an outer surface layer which are sequentially arranged. The absorption layer comprises two layers of wrapping cloth and a plurality of water absorption bead bodies, the wrapping cloth and the water absorption bead bodies extend to two ends of the front protecting wing and the rear protecting wing, and the edges of the wrapping cloth are fixedly sewn and connected. The water absorption bead bodies are tightly wrapped with the wrapping cloth, leakage of the water absorption bead bodies is effectively reduced, a baby is safer and more comfortable in the use process, and irritation to baby skins is reduced.

Owner:来此购(湖北)供应链有限公司

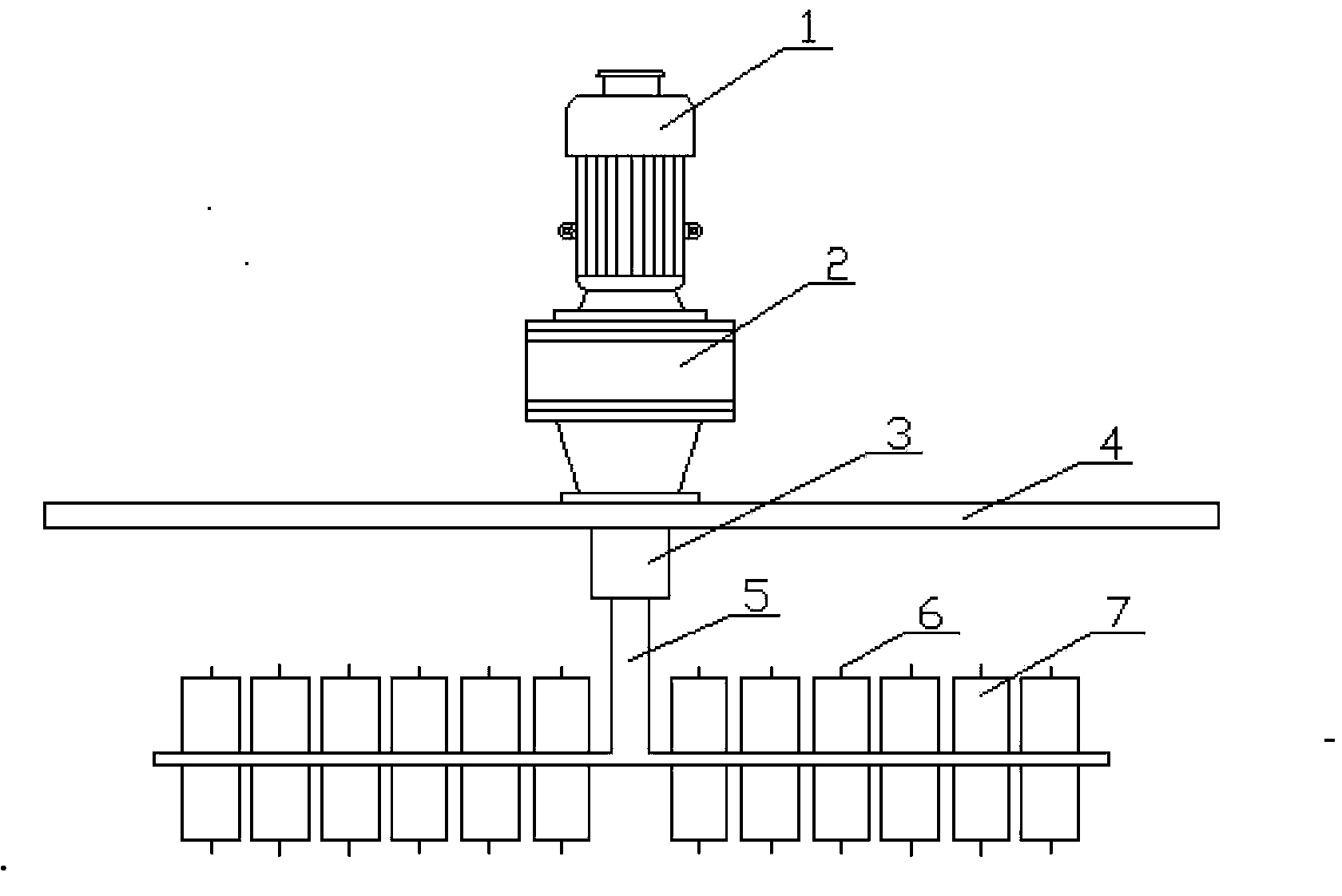

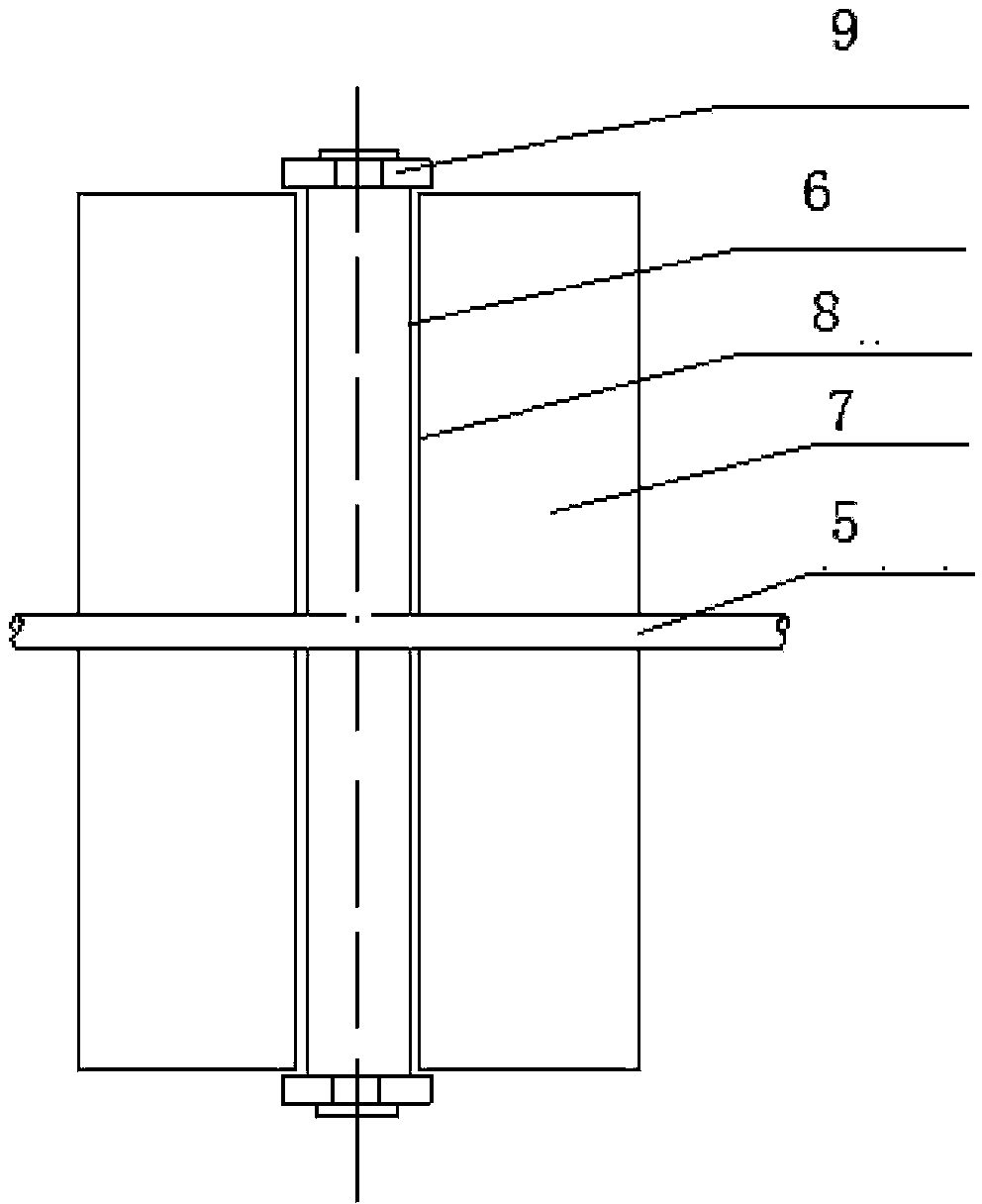

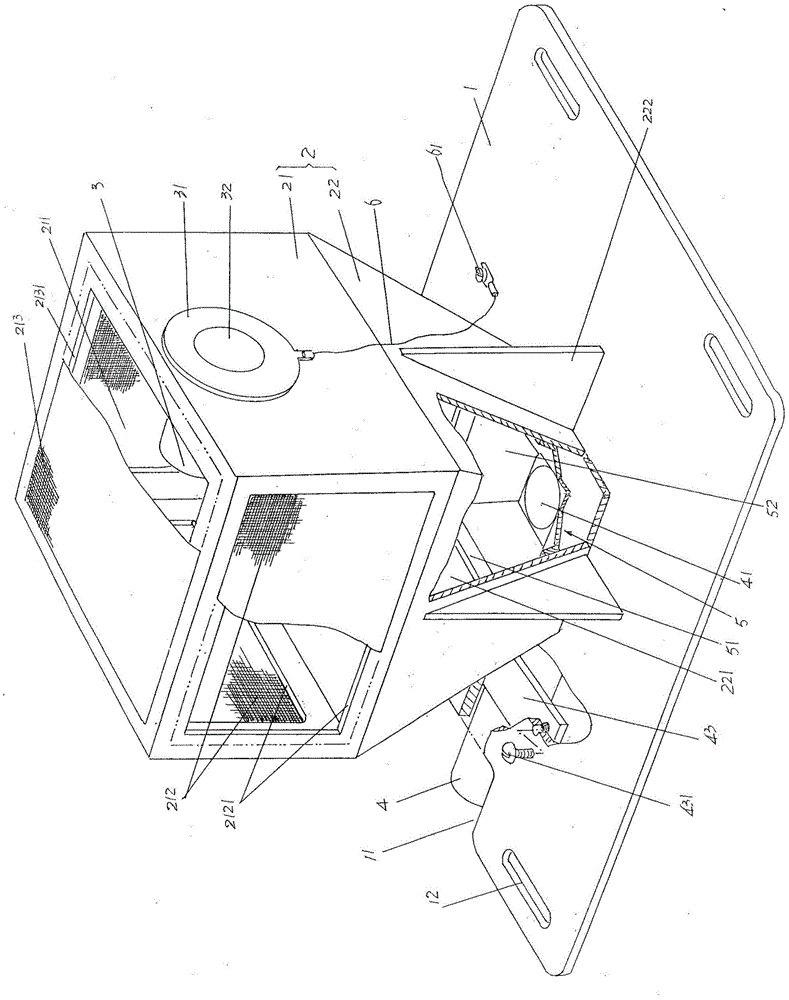

A grouper feed feeding device

ActiveCN107897092BSpeed up the sinkingIncrease profitClimate change adaptationPisciculture and aquariaAnimal scienceElectric machine

Owner:宿州速果信息科技有限公司

Novel active sand filter

PendingCN108905320ABeneficial technical effectHigh removal rateLoose filtering material filtersGravity filtersEngineeringAir compressor

The invention discloses a novel active sand filter. The novel active sand filter comprises a filter tank body, a raw water inlet pipe connected to the side wall of the filter tank body, a water distributor assembly, a polluted sand collecting assembly, a polluted sand cleaning assembly, a sewage discharge assembly and a filtrate output assembly. The water distributor assembly comprises a water inlet casing pipe connected to the raw water inlet pipe and a water distributor connected to the lower end of the water inlet casing pipe. The polluted sand collecting assembly comprises an upper sand guide bucket, a lower sand guide bucket center tube and a sand transfer pipe. The sewage discharge assembly comprises a backwash sewage pipe and a backwash sewage collection cabin. The polluted sand cleaning assembly comprises a sand washer, a multi-stage air lifting pump and an air compressor. The filtrate output assembly comprises a filtered water collection bin and a filtered water output pipe. The novel active sand filter can improve the efficiency of backwashing of the polluted sand and accelerate the discharge of impurities in the filter during the process of filtering the raw water.

Owner:广东普施德泽环保股份有限公司

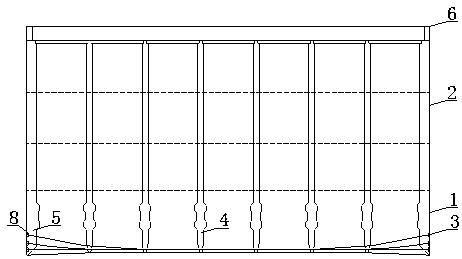

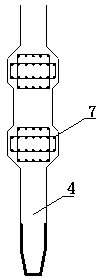

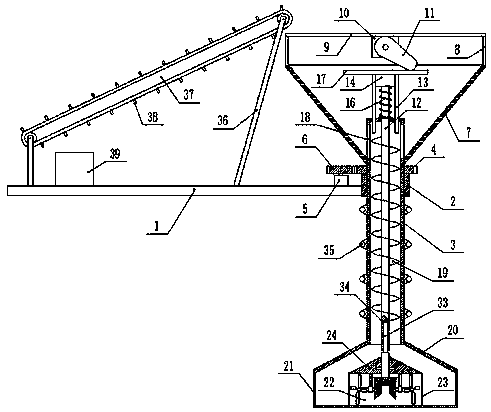

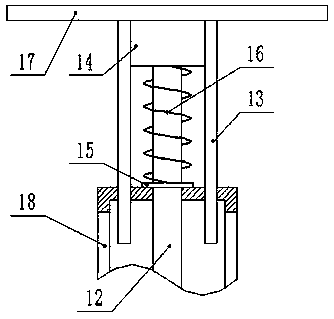

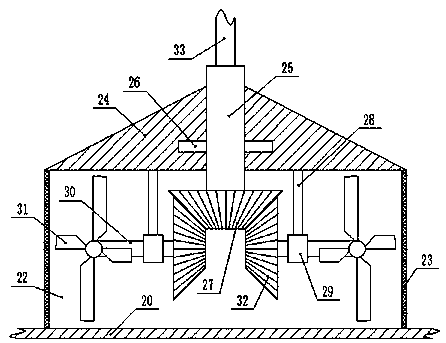

Grouper feed feeding device

ActiveCN107897092ASpeed up the sinkingIncrease profitClimate change adaptationPisciculture and aquariaGear wheelEngineering

The invention discloses a grouper feed feeding device. The grouper feed feeding device comprises a fixing plate. One end of the fixing plate is fixed to the bank, and the other end of the fixing plateis vertically fixed to a sleeve A. A barrel body rotatably connected with the sleeve body A is vertically inserted into the sleeve body A, a ring gear is fixed to the upper end of the barrel body, the lower end of the ring gear is attached to the upper end of the sleeve A, a deceleration motor is fixed to the fixing plate, and a gear meshed with the ring gear is fixed to an output shaft of the deceleration motor. A tapered box body is wrapped on and fixed to the upper end of the barrel body, supporting rods are vertically and symmetrically fixed to the upper end of the tapered box body, and across bar is fixed between the supporting bars. A motor A is fixed to the lower end of the cross bar, a cam is fixed to an output shaft of the motor A, a rotary shaft A rotatably connected to the barrel body is vertically inserted into the middle of the barrel body, and positioning rods vertically inserted into the upper end of the barrel body are arranged at both ends of the rotary shaft A. Thisdevice directly pushes feed into a deeper position in water to cater for the inactive living habits of groupers and to facilitate feeding of the groupers. The feeding effect is better, and the feed utilization is also higher.

Owner:宿州速果信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com