Flocculating agent for ecological remediation of black smelly surface water and production process thereof

A technology of ecological restoration and production process, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water pollutants, energy wastewater treatment, etc. It can solve the problems of weak flocculation and slow sedimentation speed of inorganic flocculants, so as to improve self-purification ability, Strong pH buffering ability, effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

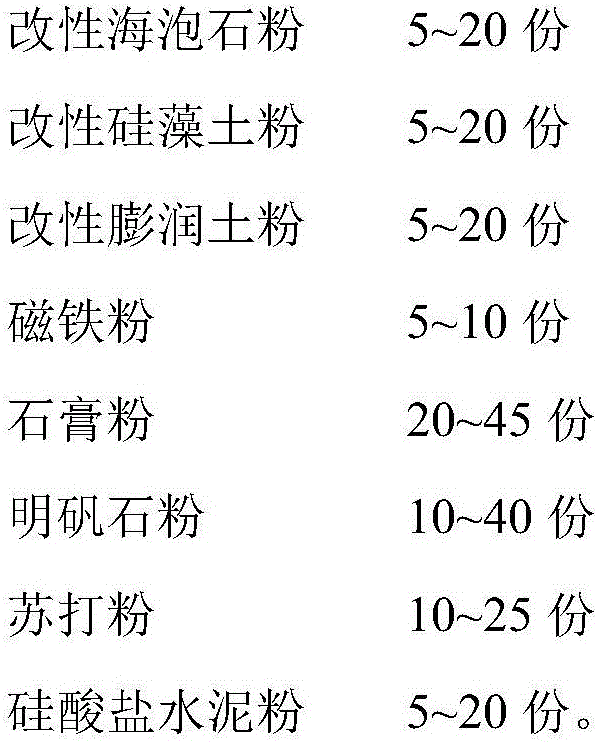

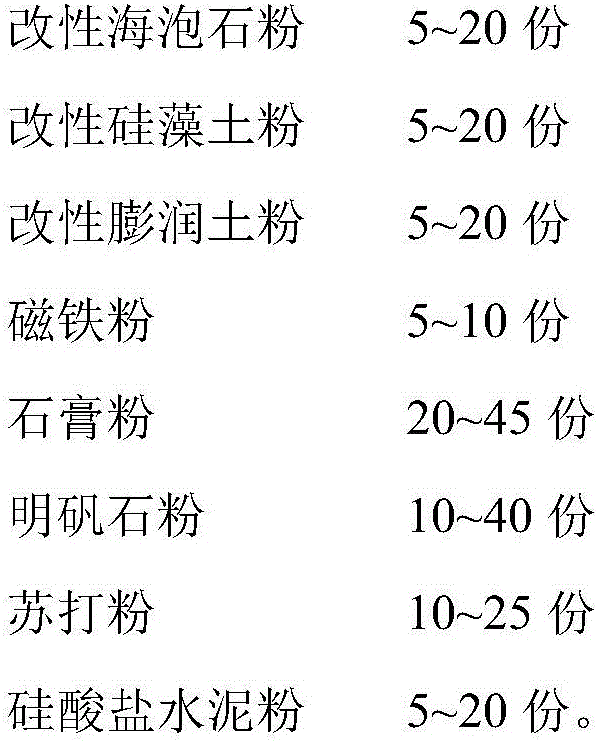

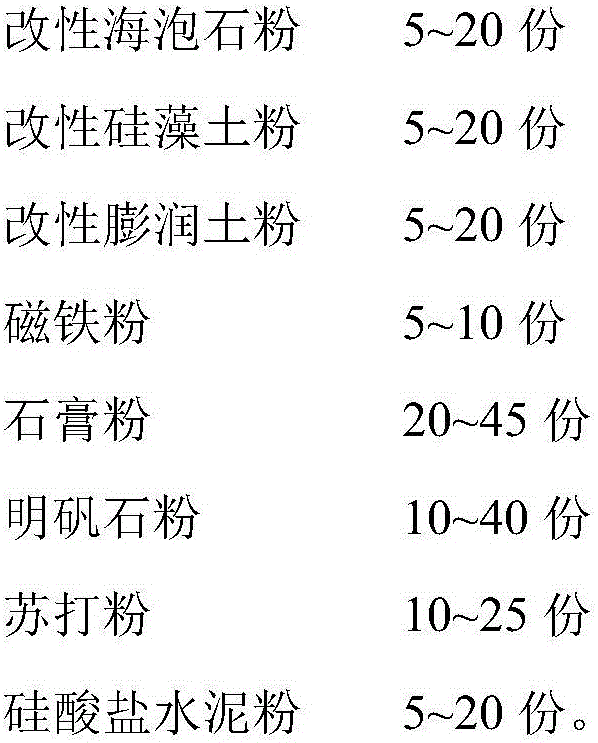

[0018] The invention provides a flocculant for ecological restoration of black and odorous surface water, which comprises the following components and the parts by weight of each component are:

[0019]

[0020] A kind of production technology of flocculant as described in above-mentioned technical scheme, comprises the following steps:

[0021] Step 1, separately grinding sepiolite, diatomite and bentonite into particles with a particle size less than 0.1 mm;

[0022] Step 2: Mix the sepiolite, diatomite and bentonite treated in step 1 with 1.8-2.4mol / L HCl solution at a ratio of 1kg to 1.25L, and soak at room temperature for at least 2 hours;

[0023] In step 3, the sepiolite, diatomite and bentonite treated in step 2 are washed with deionized water to neutrality respectively, and the surface moisture is removed in an oven respectively;

[0024] Step 4: mix the sepiolite, diatomite and bentonite treated in step 3 with alumina at a mass ratio of 10:3, and then burn at 550...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com