Novel active sand filter

A technology of filter and active sand, which is applied in the direction of gravity filter, loose filter material filter, filter separation, etc. It can solve the problems of affecting the quality of filtered water, slowness, and untimely sewage discharge, and achieves low operation and maintenance costs. High efficiency and low head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

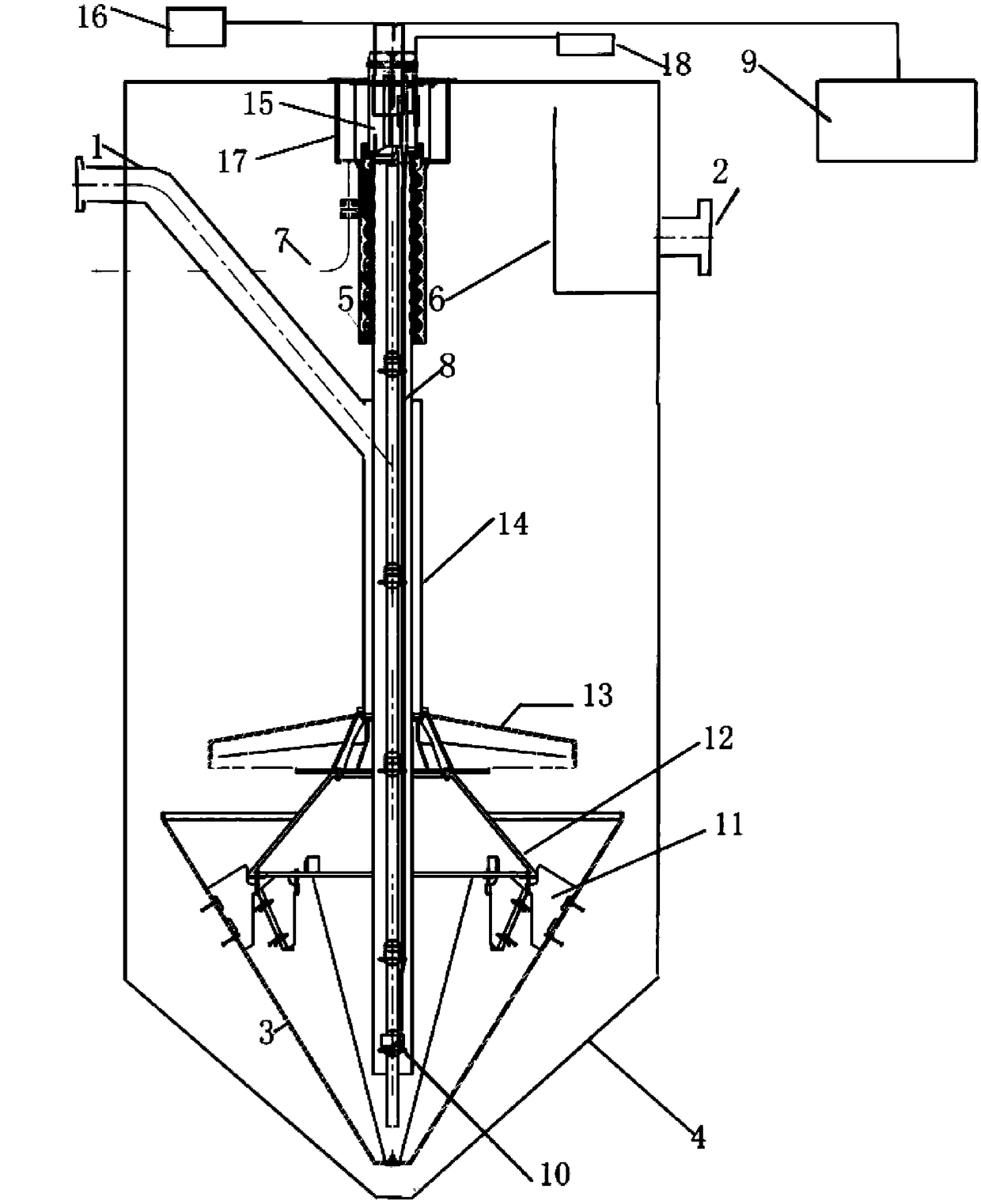

[0034] Such as figure 1 As shown, a new type of active sand filter includes a filter tank body 4, a raw water inlet pipe 1 connected to the side wall of the filter tank body 4, and also includes a water distributor assembly, a dirty sand collection assembly, and a dirty sand cleaning components, sewage discharge components and filtrate output components. The filter tank body 4 can be a carbon steel structure or a concrete structure, and can be flexibly designed according to water volume and site conditions. There is a filter bed formed by gravel in the filter tank body 4 .

[0035] The water distributor assembly includes a water inlet casing connected to the raw water inlet pipe 1 , and a water distributor 13 connected to the lower end of the water inlet casing. Raw water enters the water inlet casing through the raw water inlet pipe 1, and then enters the water distributor 13. The water distributor 13 includes a plurality of water distribution branch pipes, and the water dist...

Embodiment 2

[0045] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, one end of the connecting piece 11 is connected to the bottom of the side wall of the upper sand guiding bucket 12 , and the other end of the connecting piece 11 is connected to a position near the top of the inner side wall of the lower sand guiding bucket 3 . Ensuring that there is enough entrance space for the dirty sand to enter the lower sand guide bucket 3 from the outer sidewall of the upper sand guide bucket 12 .

Embodiment 3

[0047] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the inner side wall of the lower sand guide bucket 3 and the outer wall of the upper sand guide bucket 12 are provided with several guide channels. The diversion channel provides a channel for the sinking of the dirty sand, and due to the gathering effect of the diversion channel, the speed at which the dirty sand enters the lower sand guide bucket 3 is accelerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com