Method for improving primary salty mud washing ability

A salt mud and capacity technology, which is applied in the field of improving the washing capacity of the first salt mud, can solve the problems of poor washing effect and low processing capacity of the first salt mud washing mud tank, so as to increase the sinking speed, reduce the salt content of the waste mud, and reduce the salt content. Enhanced effect of mud treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

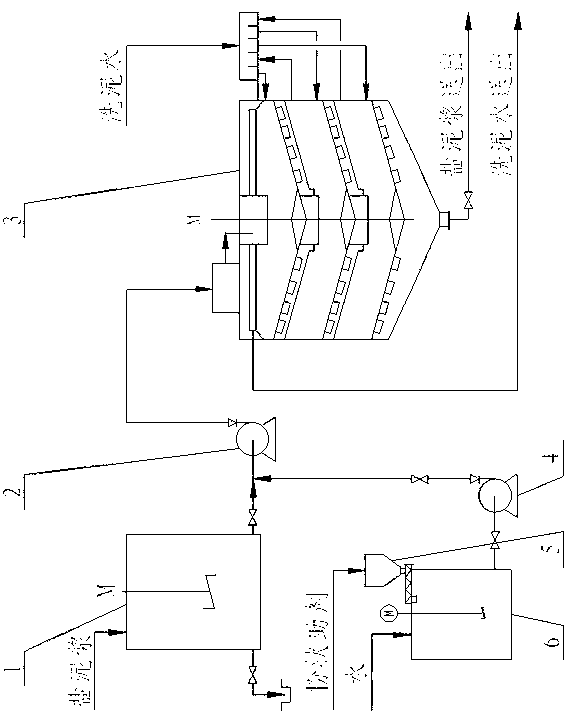

[0022] A method for improving the washing capacity of one-time salt mud is carried out as follows: (see figure 1 , in the figure: salt mud storage tank 1, salt mud delivery pump 2, mud washing tank 3, additive pump 4, sedimentation aid dry powder feeding device 5, sedimentation aid preparation tank 6)

[0023] A sedimentation aid preparation tank 6 with stirring is installed, and a sedimentation aid dry powder feeding device 5 and a water inlet pipeline are installed on the sedimentation aid preparation tank 6 . According to the actual production situation, adjust the ratio of the dry powder and water for the preparation of the sedimentation aid. During production, add the sedimentation aid dry powder to the water in the ratio of 0.5‰:1 (mass ratio) to the sedimentation aid preparation tank 6 and water, and through the agitation in the sedimentation aid preparation tank 6, the dry powder sedimentation aid is evenly dissolved.

[0024] The sedimentation aid used in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com