Hydraulic Sliding Insertion Panel and Its Using Method

a technology of sliding insertion and sliding panel, which is applied in the direction of shaft equipment, shaft lining, soil conditioning composition, etc., can solve the problems of slow and difficult bypassing and elimination of sinking, the expected tightness of the connection portion cannot be achieved, and it is difficult to form an integrated structure in the connection portion that has high strength and tightness, so as to increase the bearing capacity of each board and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

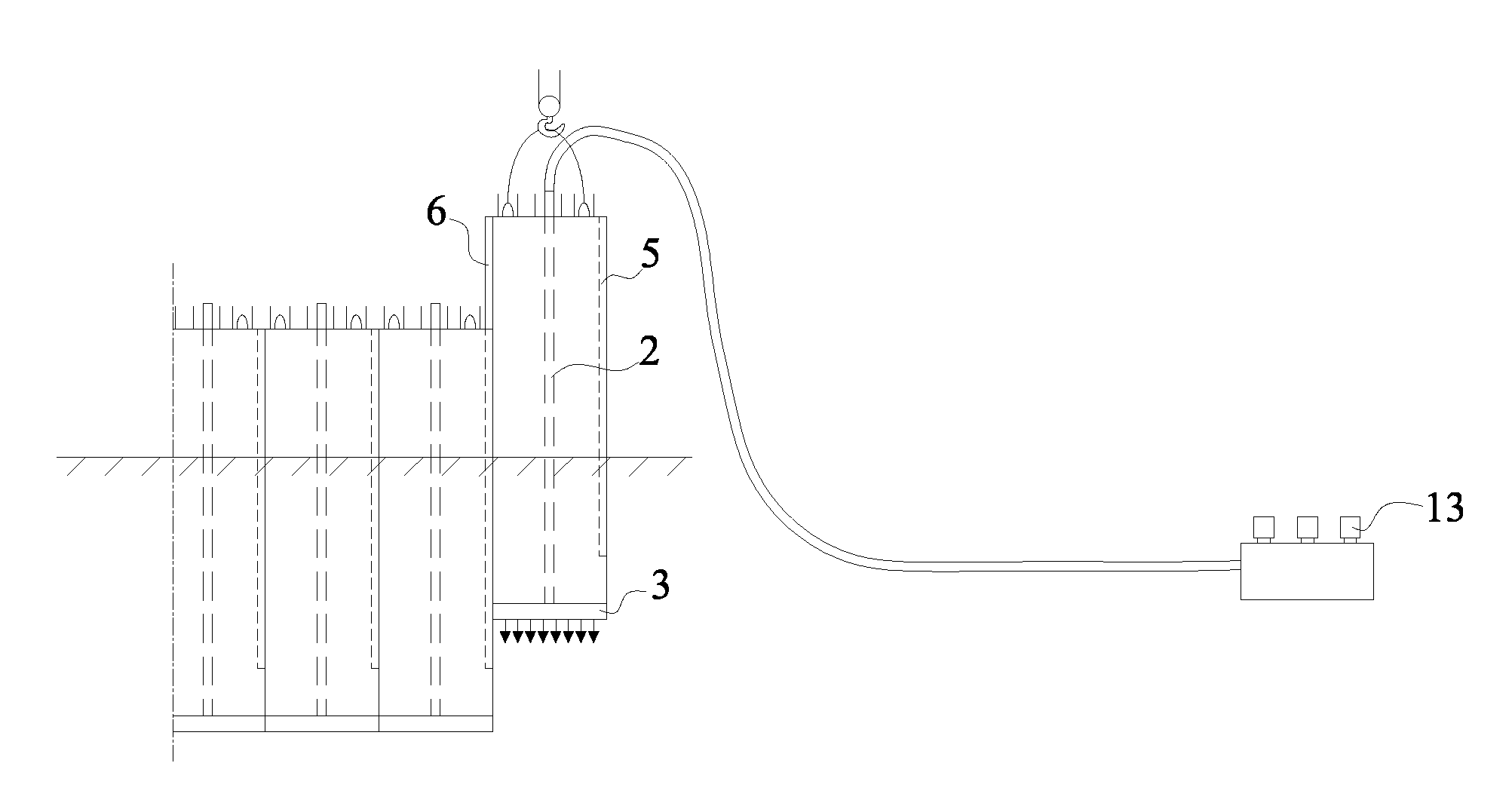

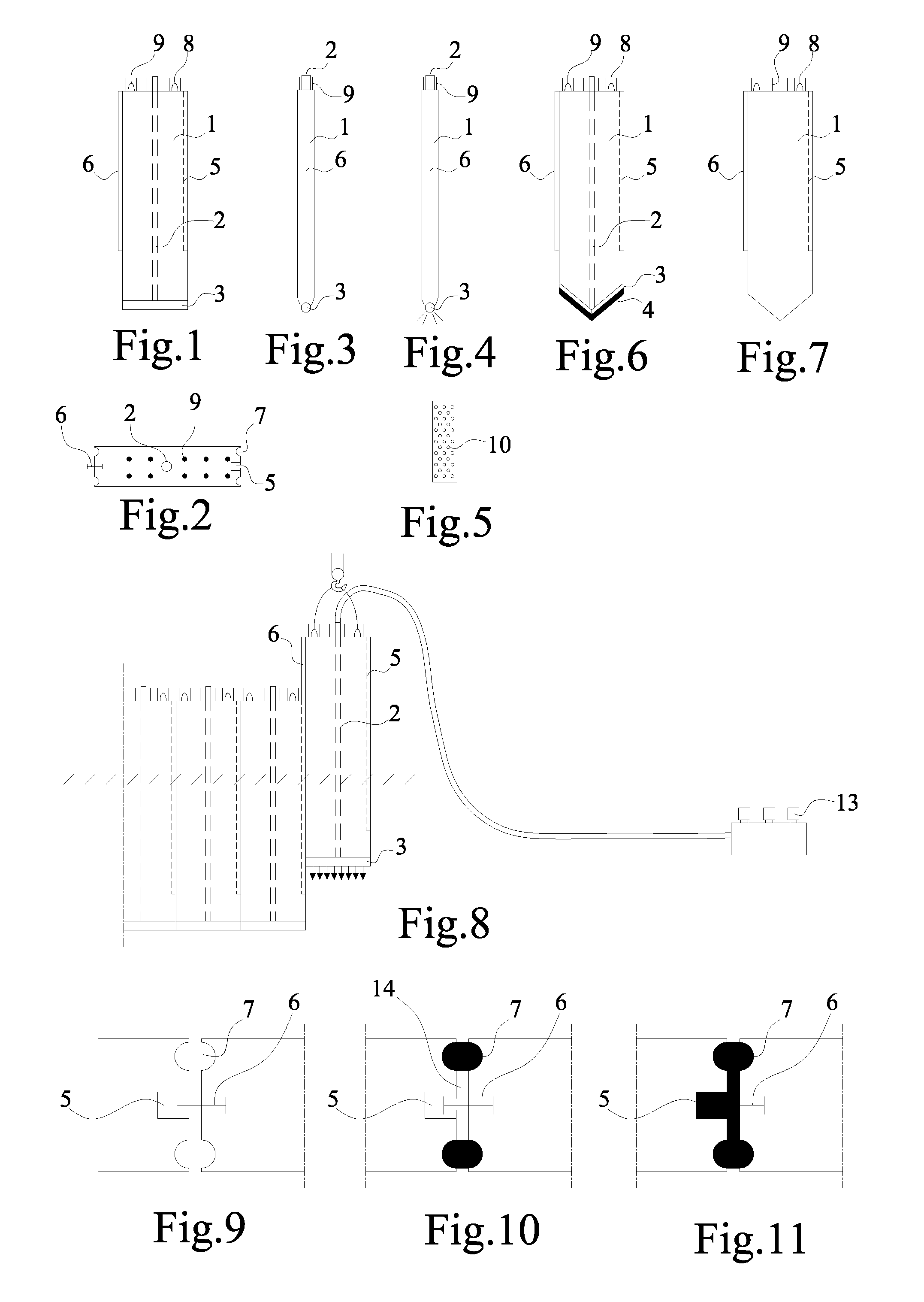

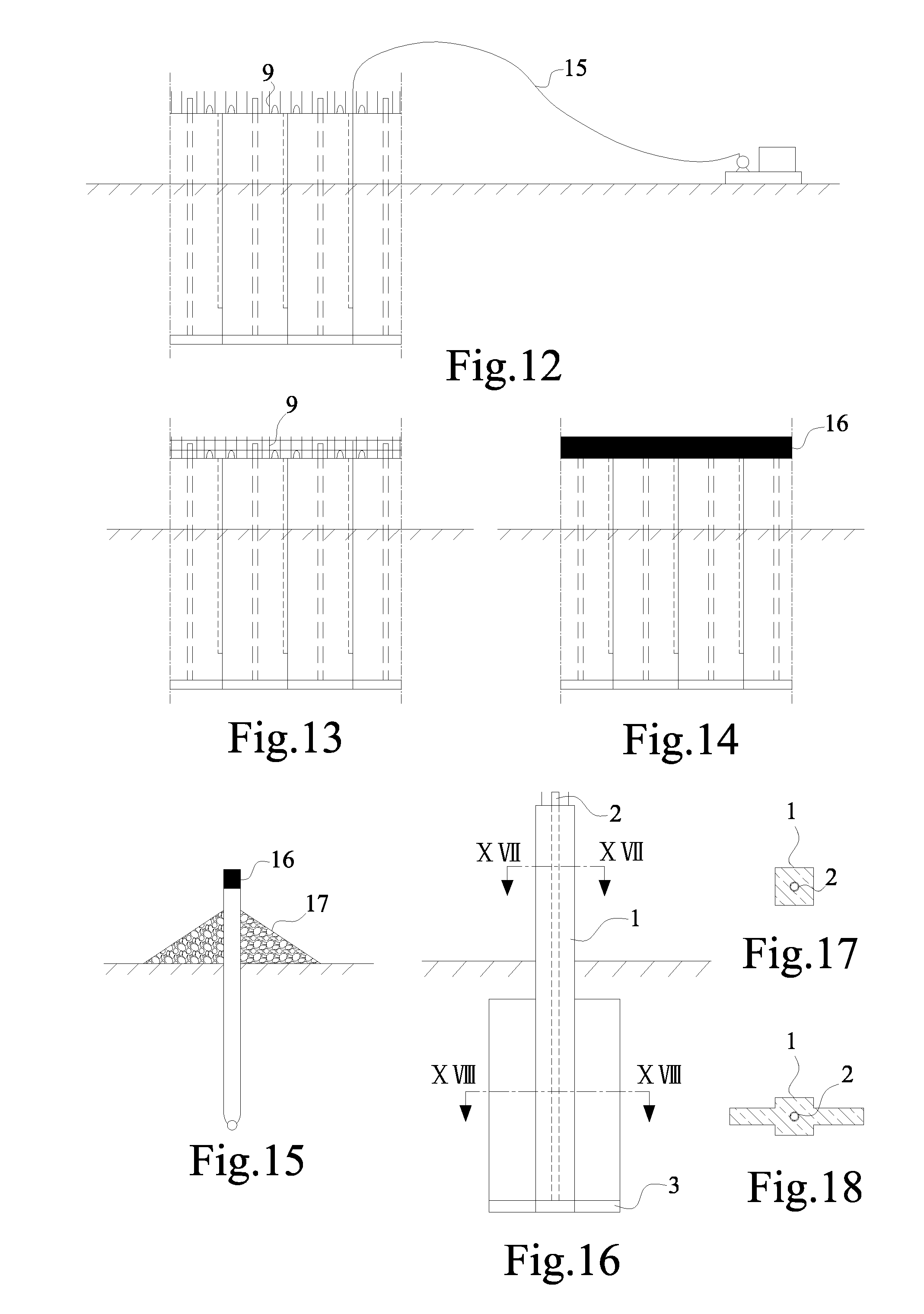

[0035]With reference to FIGS. 1 to 18, a hydraulic sliding insertion panel comprises a reinforced concrete poling board 1, a flow guide tube 2 vertically set in the poling board, a water distributing pipe 3 communicating with the flow guide tube horizontally set in the bottom of the poling board, a slideway 5 provided on the one side and a slide plate 6 provided on the other side of the poling board respectively, and erection loops 8 and inbuilt preset steel bars 9 on the top of the poling board 1. The hydraulic sliding insertion panel further comprises vertical water isolation paths 7 set in the reinforced concrete poling board on the two sides of the slide way and the slide plate.

[0036]The lower end of the reinforced concrete poling board 1 has a level, tapered or unilaterally tapered shape. The water distributing pipe 3 has an upper half embedded in the reinforced concrete poling board and a lower half provided with a plurality of sprinkler holes 10 arrayed in an uniformly spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com