SMW construction method for arranging elliptic-cone-shaped pile head at end of H-shaped steel

A technology of elliptical cone and H-shaped steel, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high insertion resistance, affecting mechanical performance, and poor pile quality, so as to increase and reduce the sinking speed Insertion resistance, effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

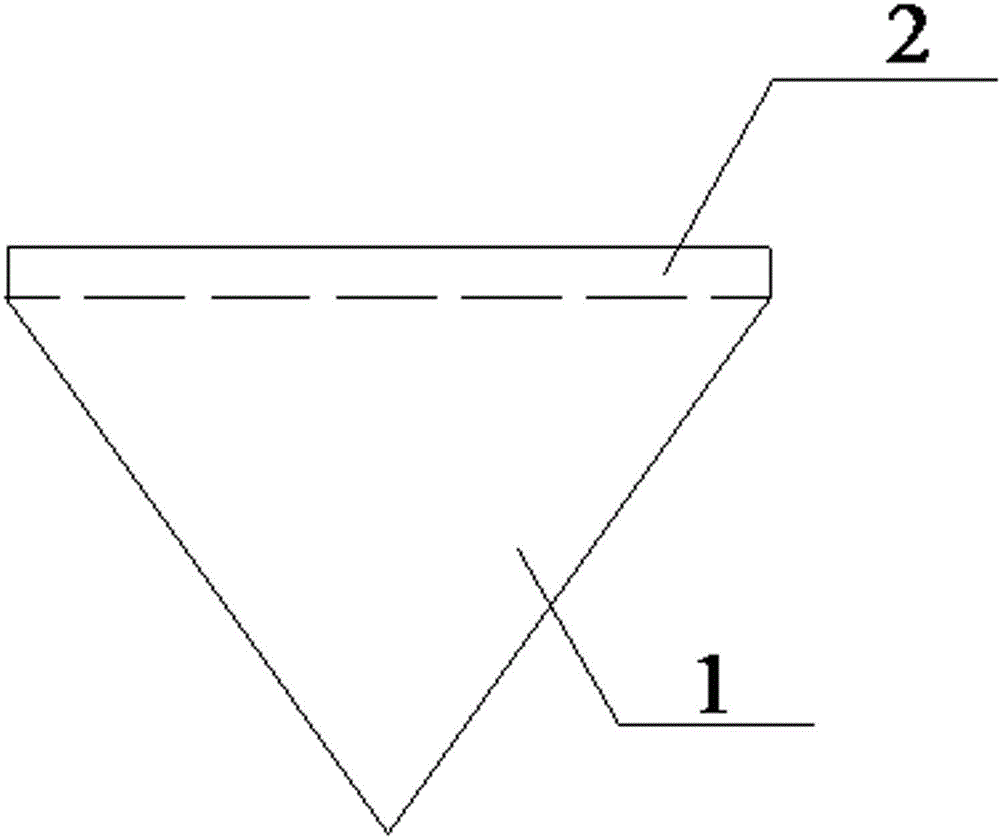

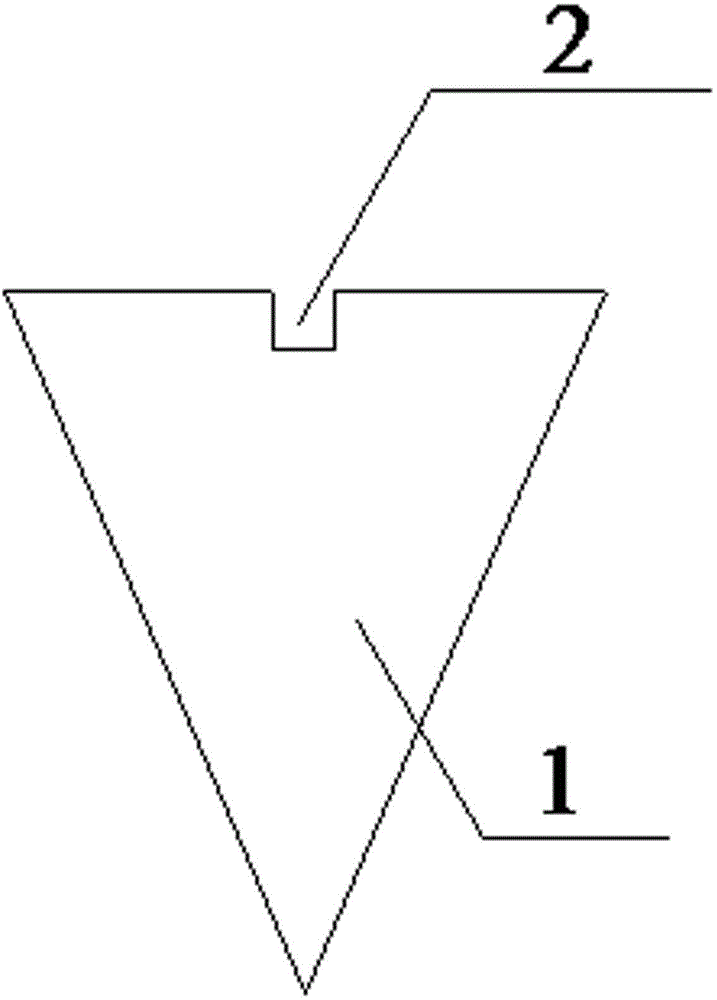

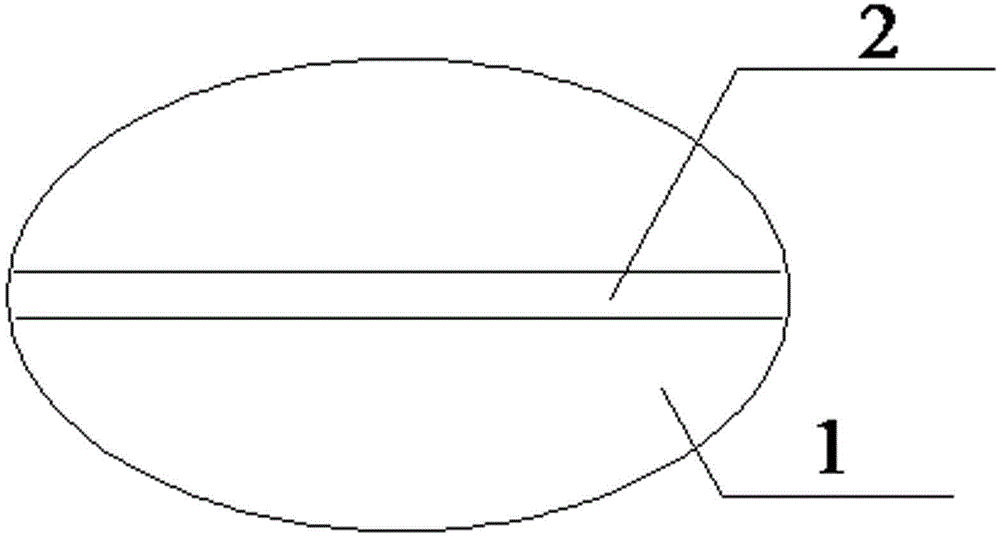

[0029] Example 1 : The present invention is provided with the SMW construction method of ellipse cone-shaped pile head at the end of H-shaped steel, comprising ellipse-shaped cone-shaped pile head 1, H-shaped steel 3 through cutting and cement-soil consolidation body 6 to form, and ellipse-shaped cone-shaped pile head 1 adopts plastic The top is provided with a reserved gap 2 that matches the thickness of the H-shaped steel web, and the H-shaped steel web can be inserted into it; the lower end flange of the H-shaped steel is cut into a "V"-shaped boundary 5 with a cutting tool to reduce the Insertion resistance during construction. Apply anti-friction agent to the surface of H-shaped steel before sinking and inserting. On this basis, we cut the end of H-shaped steel into a "V" shape and insert it into the gap of the elliptical cone-shaped pile head to form a streamlined structure; The elliptical conical pile head 1 can displace the cement and soil, which can effectively redu...

Embodiment 2

[0030] Example 2: In the present invention, the SMW construction method is provided with an elliptical conical pile head at the end of the H-shaped steel, which consists of an elliptical conical pile head 1, a cut H-shaped steel 3 and a cement-soil consolidation body 6, and the elliptical conical pile head 1 is made of reinforced concrete. material, the top of which is provided with a reserved gap 2 that matches the thickness of the H-shaped steel web, and the H-shaped steel web can be inserted into it; Insertion resistance during small construction. Apply anti-friction agent on the surface of H-shaped steel before sinking and inserting it. On this basis, we cut the end of H-shaped steel into a "V" shape and insert it into the gap 2 of the elliptical conical pile head to form a streamlined structure. ; The elliptical cone-shaped pile head 1 can displace cement and soil, which can effectively reduce the insertion resistance of section steel, increase the insertion speed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com