Fixing device

A fixing device and mounting hole technology, applied in the direction of thin plate connection, connecting member, rivet, etc., can solve the problems of looseness, reduced operability, and heavy burden on the operator, and achieve the effect of reducing burden, good operability, and achieving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

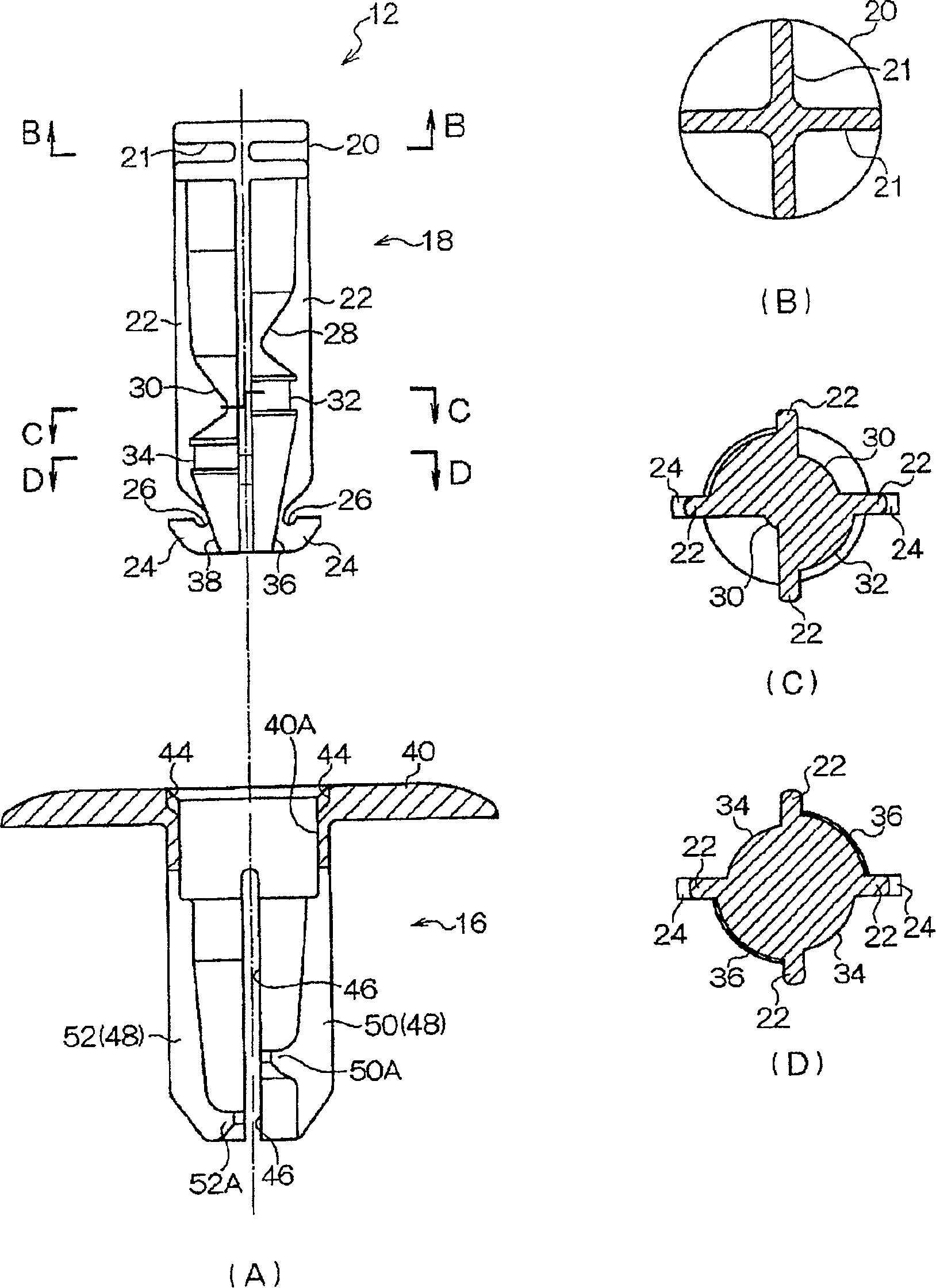

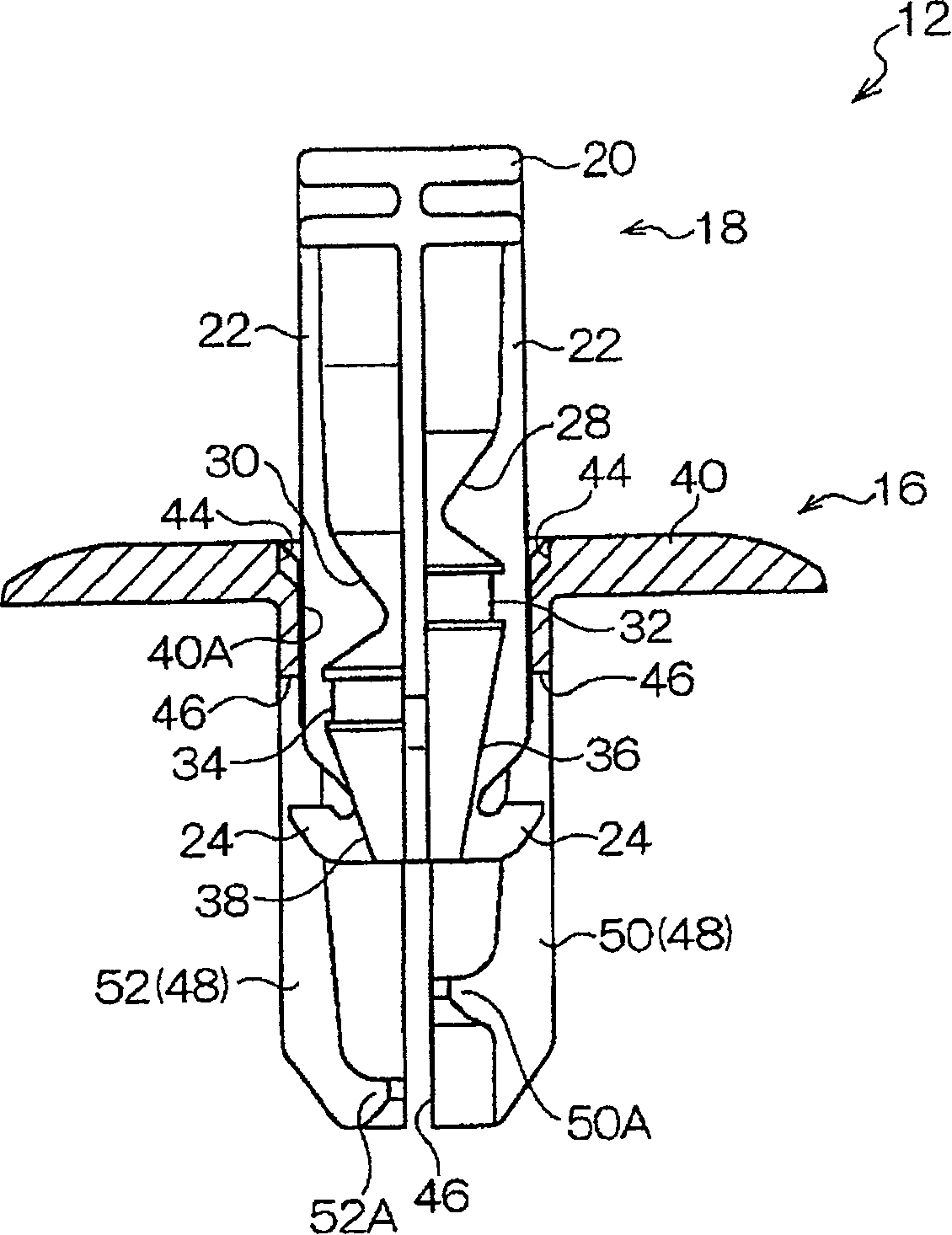

[0035]Hereinafter, a fixing device according to an embodiment of the present invention will be described with reference to the accompanying drawings.

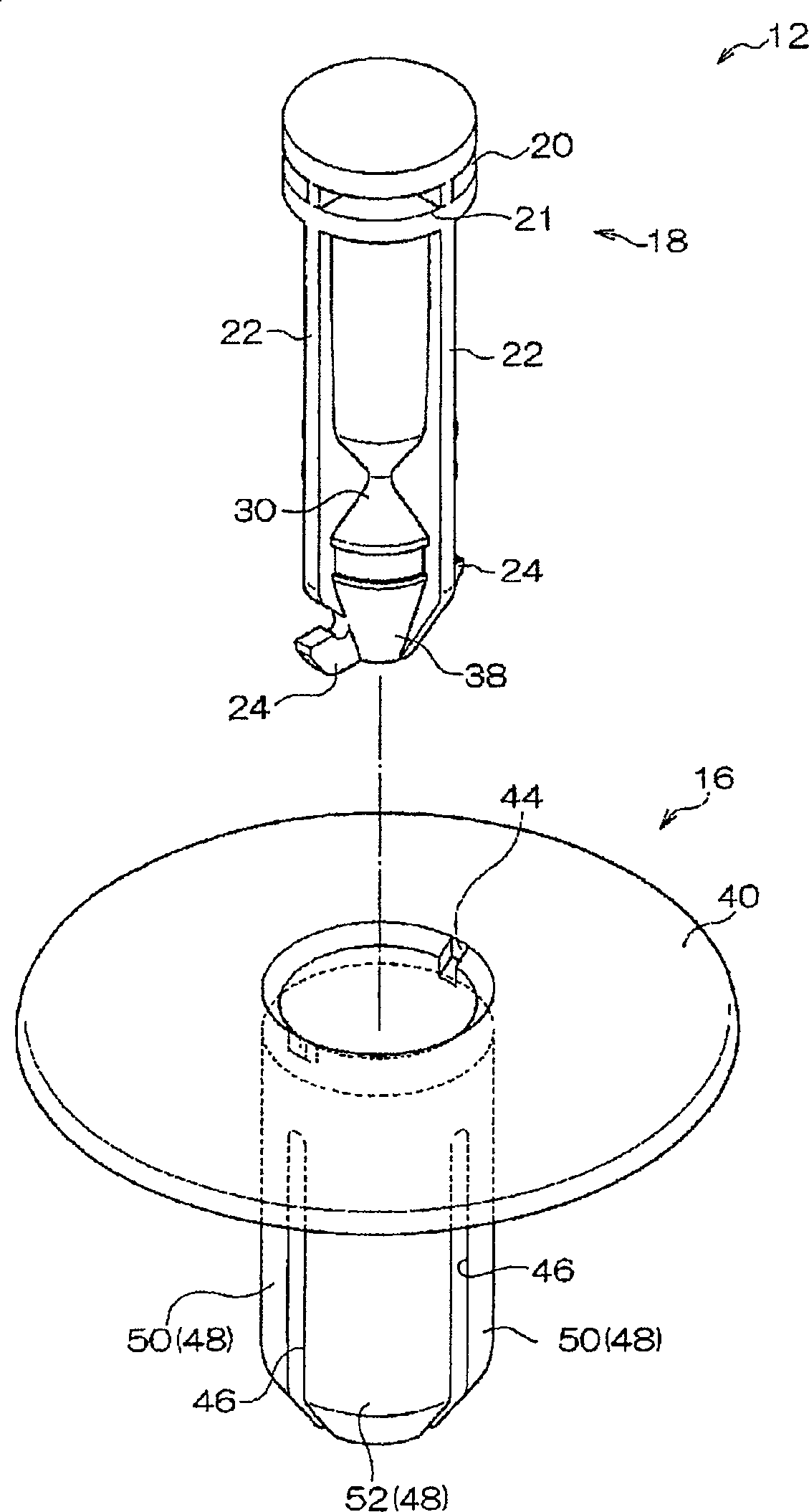

[0036] Such as Figure 4 (A), Figure 4 As shown in (B), the roof panel 14 is installed on the roof panel 10 by the fixing device 12 (in addition, in Figure 4 (A) shows the case where there is a formed ceiling 54 as a cushioning member between the roof panel 10 and the ceiling panel 14. Figure 4 (B) shows the case without the shaped ceiling 54). The case where the roof panel 10 and the roof panel 14 have the formed roof 54 will be described below.

[0037] The fixing device 12 is composed of a cylindrical grommet 16 that can be inserted through the mounting holes 10A, 54A, and 14A respectively formed on the roof panel 10, the formed ceiling 54, and the ceiling panel 14, and a pin that can be inserted into the grommet 16. 18 poses.

[0038] Such as figure 1 and figure 2 As shown in (A), the pin 18 has a substantially c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com