Temperature measurement cable component of grain condition measurement and control system

A temperature measurement cable and measurement and control system technology, applied in thermometers, measuring devices, heat measurement, etc., can solve the problems of wasting insulating materials, metal collars with large and small tensile forces, and reduce maintenance costs, save insulating materials, Effect of reducing insertion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

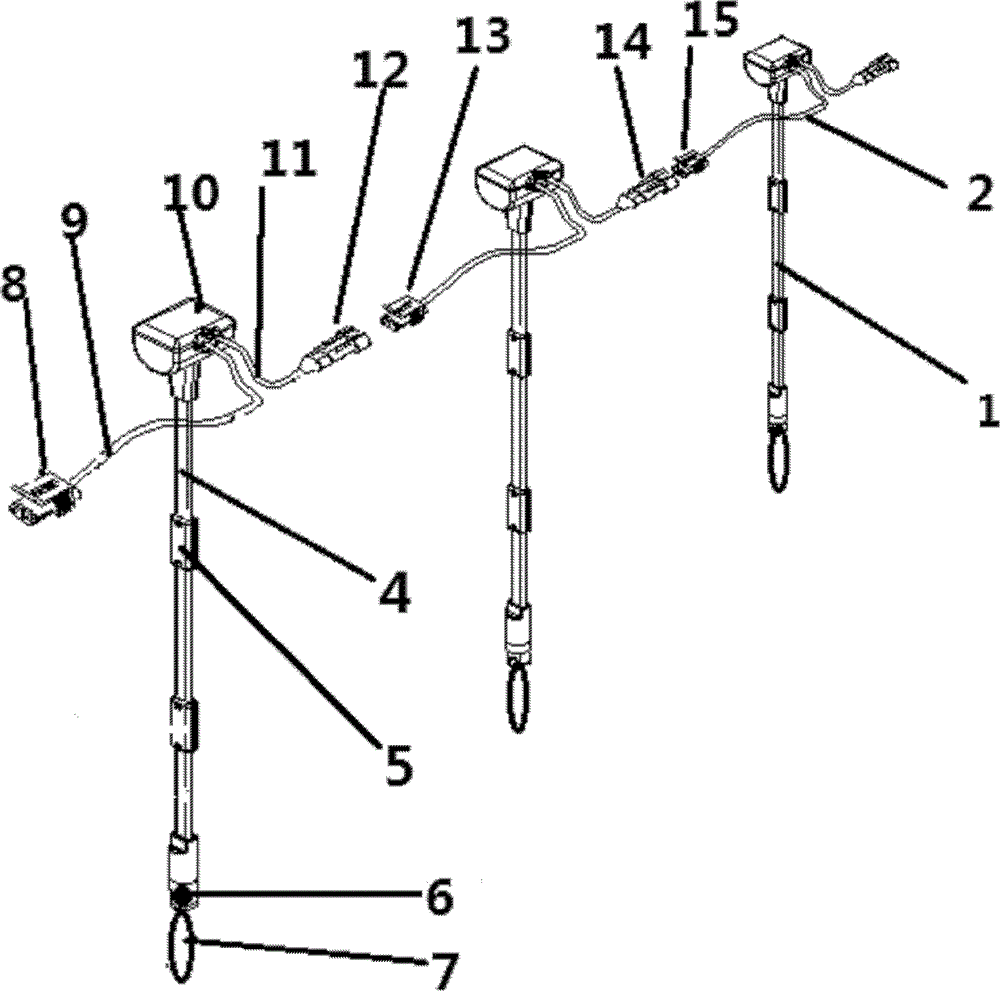

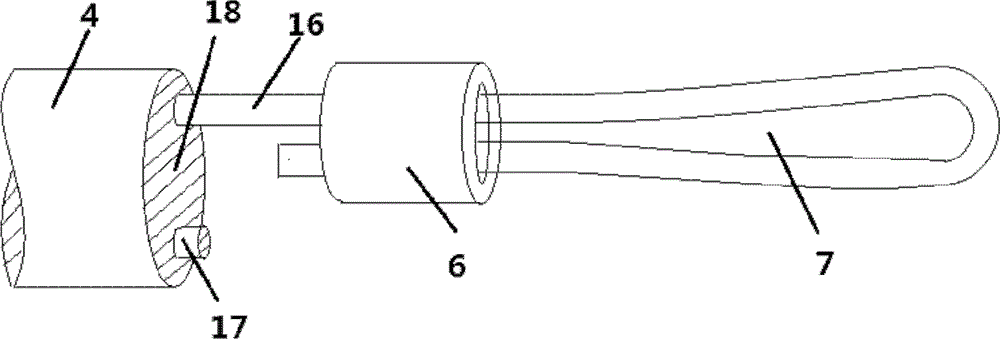

[0056] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0057] This patent improves the overall mechanical and electrical properties of the temperature-measuring cable assembly by improving the components and structures of the temperature-measuring cable assembly; therefore, it reduces the variety and consumption of raw materials for the grain monitoring and control system, and improves the The maintenance method of the grain condition measurement and control system is improved; the production cost, maintenance cost and use cost of the grain condition measurement and control system are reduced; the reliability of the grain condition measurement and control system is improved; the service life of the grain condition measurement and control system is prolonged.

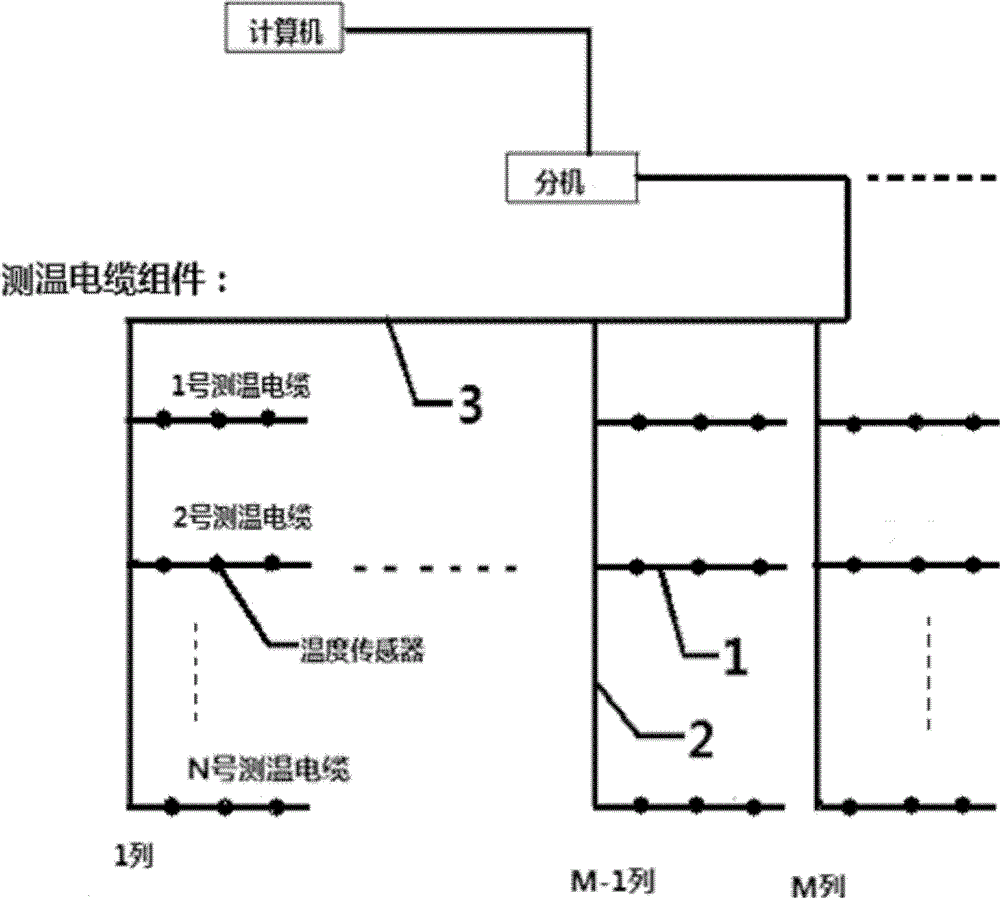

[0058] see figure 1 and figure 2 , Grain situation measurement and control system includes three major components: computer, extension, temperature measurement cable asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com