Loading machine visbreaking guiding type scraper pan

It is a technology of sticky guide type and loader, which is applied in the direction of earth mover/excavator, mechanically driven excavator/dredger, construction, etc., and can solve the problems of reducing operation efficiency, high economic cost, and large working resistance , to achieve the effects of fuel saving, good material flow performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

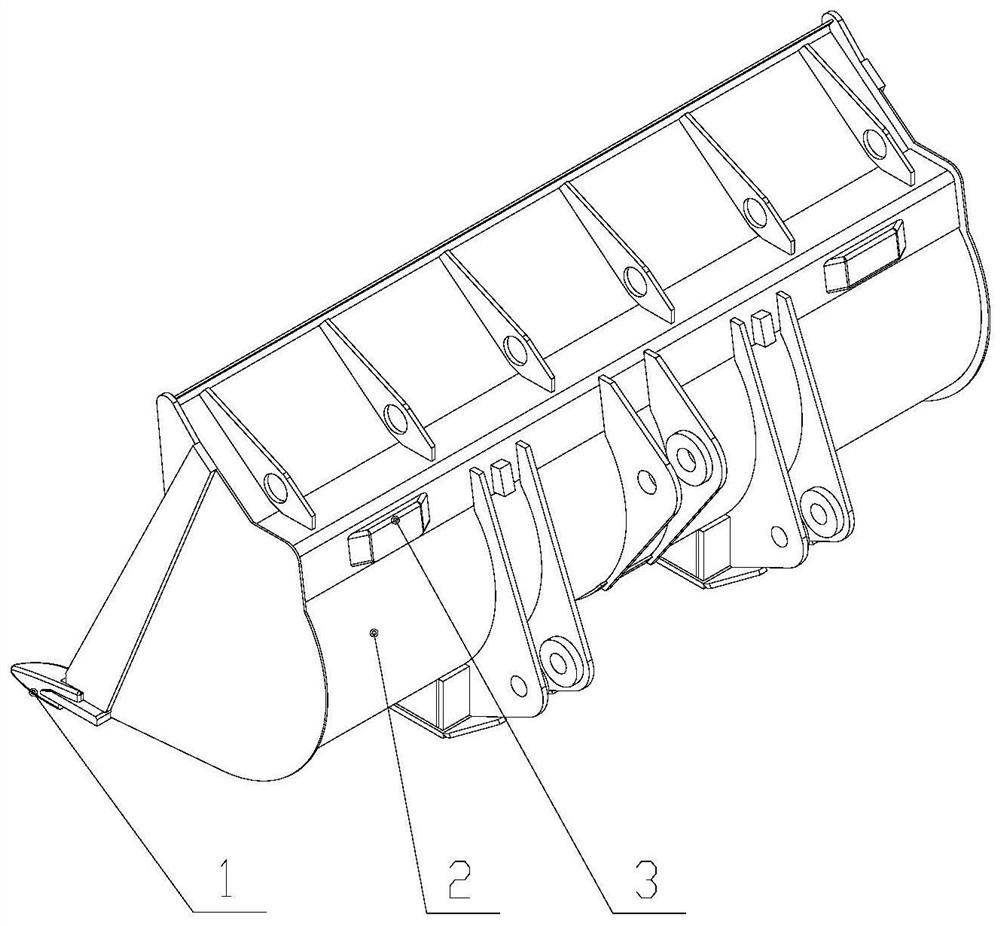

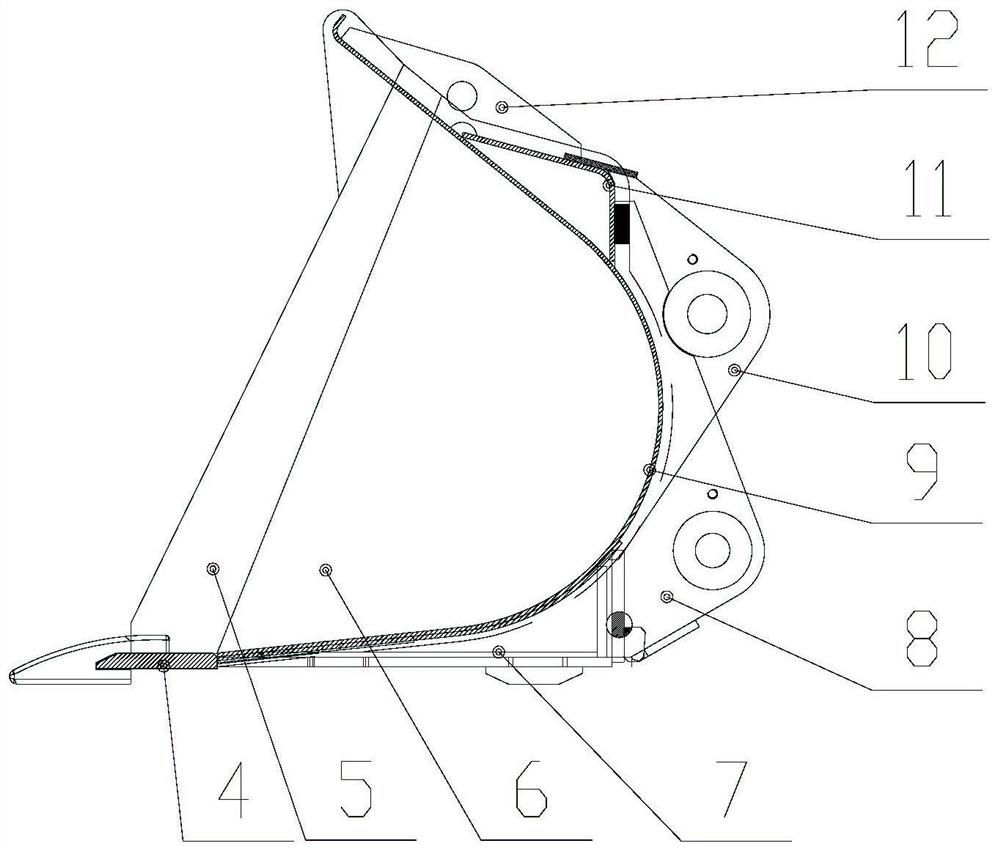

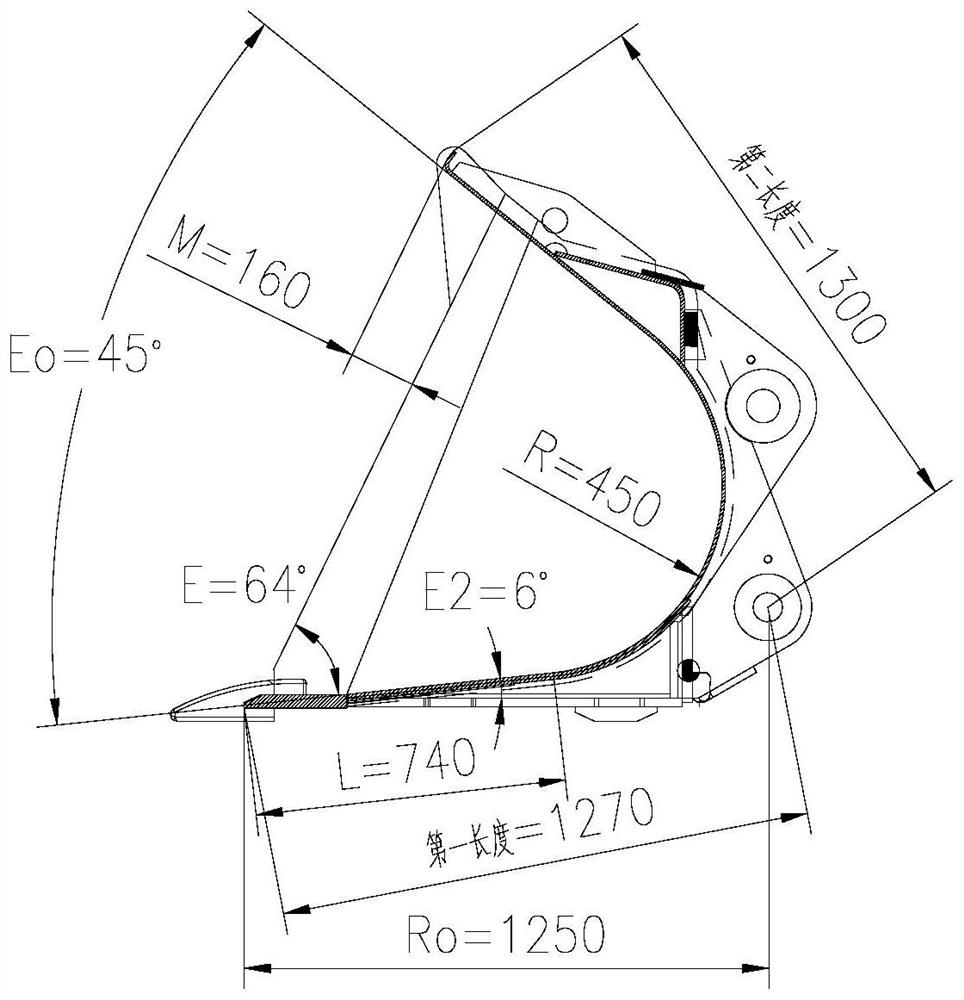

[0023] The invention provides a viscous-reducing and guiding-type bucket of a loader, such as Figure 1-Figure 3 As shown, it includes a bucket body 2 on which 8 sets of bucket teeth 1 and 2 sets of anti-corrosion anode assemblies 3 are installed; the bucket capacity of the bucket body 2 is 3m 3 , the bucket body 2 is composed of the main knife plate 4, the side knife plate 5, the side plate 6, the bucket bottom reinforcement plate assembly 7, the boom support plate 8, the bucket wall 9, the tie rod support plate 10, the reinforced angle steel 11, and the upper stop support plate 12 welded synthesis. The overall welding adopts robot automatic welding, and the quality is reliable. 8 sets of bucket teeth 1 are assembled on the lower end port of the main knife plate 4 by fasteners to reduce the insertion resistance of the bucket. Two sets of anti-corrosion anode components 3 are welded on the plane of the reinforced angle steel 11, and the outer welding protection box. The boo...

Embodiment 2

[0043] In this embodiment, the bucket wall angle E0=46°; bucket bottom angle E2=4°; side edge angle E=62°; baffle height M=180mm; bucket bottom arc R=455mm; bucket bottom length L= 746mm; first length=1290mm; second length=1290mm; radius of gyration R0=1260mm. First length / second length=1.

[0044] Others are the same as in Example 1.

Embodiment 3

[0046] In this embodiment, the angle E0 of the nine bucket walls is 44°.

[0047] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Radius of gyration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com